I remember the first time a supplier told me a part couldn’t be made fast enough using standard processes. That delay cost us a client.

That moment pushed me to explore CNC machining more seriously.

Since then, I’ve helped businesses figure out where custom CNC parts make a real difference, whether it’s for speed, precision, or flexibility.

In this article, you’ll see the 8 best use cases where CNC custom parts bring the most value. It’s designed to help you decide where it fits in your workflow.

You’re not here for theory. You’re here to get real, usable answers.

Let’s dive into it!

1. Automotive Industry Applications

I’ve seen firsthand how demanding automotive timelines can be. Whether you’re supplying components to a Tier 1 manufacturer or prototyping for a next-gen EV, custom CNC machining is often the secret weapon that keeps everything running on schedule and on spec.

When production demands precision, speed, and repeatability, CNC parts deliver.

They fill in the gaps where mass production can’t keep up or doesn’t offer enough flexibility.

- Rapid Prototyping for Vehicle Parts: Before a single part hits mass production, it needs to be tested. CNC lets you turn CAD models into functional prototypes in days, not weeks. This helps design teams iterate fast and reduce development cycles.

- Precision Engine Components: Think cylinder heads, pistons, and turbo housings. These parts need tight tolerances to handle heat and stress. Custom CNC machining delivers the repeatable accuracy that engine builders rely on.

- Transmission and Drivetrain Assemblies: CNC is often used to create complex gears, shafts, and couplings that aren’t available off the shelf. With 5-axis capabilities, even intricate geometries are fair game.

- Brackets, Mounts, and Custom Fixtures: Sometimes it’s not the high-profile parts that cause delays. It’s the little things. CNC makes it easy to whip up strong, lightweight fixtures that solve mounting or alignment problems on the production floor.

- Motorsports and Racing Upgrades: For performance applications, there’s no room for error. Racing teams often turn to CNC to make one-off or low-volume parts that optimize performance and reduce weight.

- Electric Vehicle Specific Parts: EVs come with their own challenges like battery trays, motor housings, and cooling plates. These often require custom designs that CNC machining is perfect for. You can experiment without committing to expensive tooling.

2. Medical and Dental Devices

Medical parts leave no room for guesswork. I’ve worked with clients in the health sector who need parts that are not just precise but also biocompatible, safe, and ready to meet strict regulatory standards.

In this field, custom CNC machining is more than helpful. It’s essential.

The parts might be small, but the expectations are high. Whether it’s a surgical tool or a dental implant component, everything must perform exactly as intended, every time.

- Custom Surgical Instruments: Surgeons often require tools tailored to specific procedures. CNC machines can produce one-off or limited-run tools quickly, using stainless steel, titanium, or other medical-grade materials.

- Orthopedic Implants and Bone Plates: These parts must fit the patient’s anatomy with incredible accuracy. CNC machining helps manufacturers create customized bone plates, spinal rods, and joint implants that meet those needs.

- Dental Abutments and Crowns: Precision is especially critical in dental applications. CNC machining ensures a perfect fit, allowing dental labs to craft crowns, bridges, and abutments with consistent, repeatable results.

- Enclosures for Medical Equipment: It’s not just internal parts that matter. CNC machining is ideal for crafting clean, polished enclosures that protect sensitive components inside imaging or diagnostic machines.

- Rapid Prototyping for Device Design: Medical device innovation happens fast. CNC machining allows design engineers to prototype and test components quickly before scaling up for production.

3. Electronics and Semiconductor Equipment

In electronics, every millimeter matters. I’ve seen companies lose weeks of progress because of poor tolerances or generic parts that didn’t quite fit the layout.

That’s where custom CNC machining comes in to save the day.

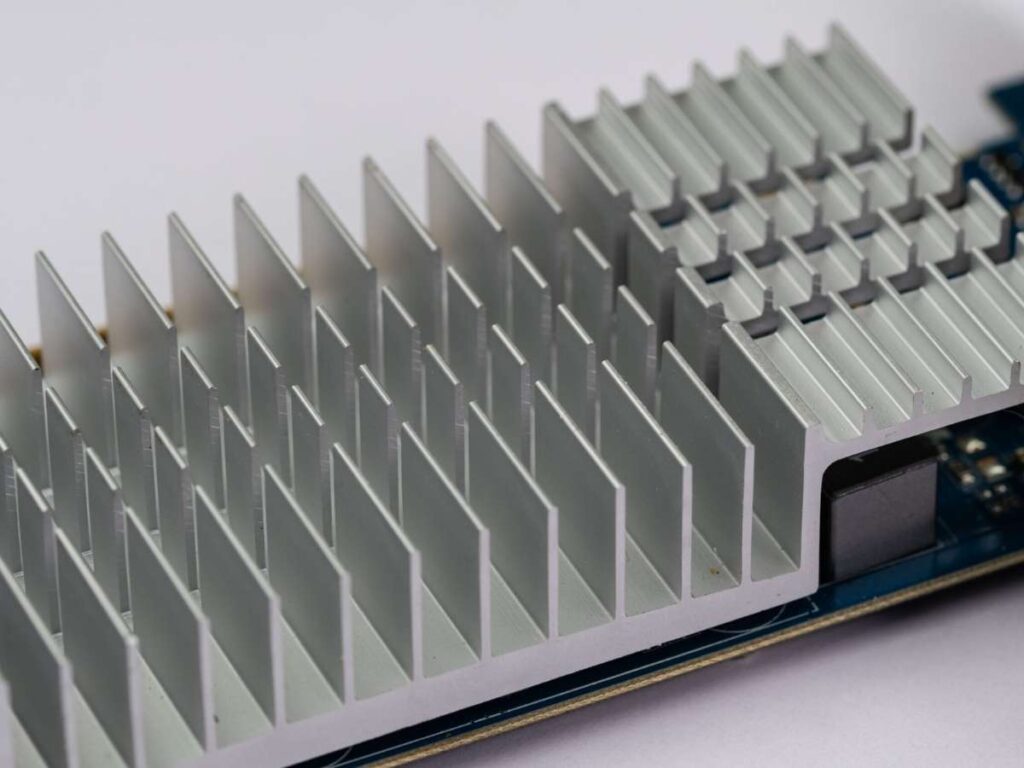

From precise heat sinks to component housings, CNC lets you build smarter, tighter, and cleaner designs for even the most space-constrained systems.

- Precision Housings for Circuit Boards: These parts need to be tight-fitting and durable without interfering with sensitive signals. CNC machining allows for exact measurements, helping engineers keep everything aligned and protected.

- Heat Sinks and Thermal Management: Custom aluminum heat sinks need both function and form. CNC allows you to control size, surface finish, and geometry to improve cooling without wasting space.

- Tooling for Semiconductor Manufacturing: Chip fabrication equipment relies on custom tooling that can hold up to extreme cleanliness and process stability. CNC machining produces these fixtures with a high degree of accuracy and surface quality.

- Enclosures for Sensitive Equipment: EMI shielding and structural integrity are vital for lab and test equipment. CNC machining provides the tight seals and clean finishes that keep things protected.

4. Robotics and Automation Systems

I’ve worked with automation teams where a single missing bracket could delay an entire project. In robotics, everything has to fit just right.

There’s no room for guesswork when you’re dealing with moving parts, sensors, and real-time systems.

That’s where CNC machining steps in. It gives you the freedom to build exactly what your design calls for, instead of forcing you to adjust around what’s available.

- Joint Parts and Connection Mounts: Every robotic arm I’ve seen has custom joints that aren’t something you find on a shelf. CNC machining makes it easy to get those odd-shaped components that need to pivot or lock precisely into place.

- Lightweight but Strong Frames: I’ve seen teams struggle to balance strength and weight, especially on mobile robots. Machining aluminum frames has been a go-to solution to keep structures rigid without adding extra load.

- End Effectors That Actually Fit the Task: From suction cups to grippers to welding nozzles, I’ve helped companies design end effectors that weren’t one-size-fits-all. CNC helps get that exact shape and size to make their automation smarter.

- Custom Housings for Sensors: Robots rely on eyes and ears like LIDARs, cameras, and touch sensors. CNC lets you design protective housings that fit around those parts snugly without getting in the way of data flow.

- Alignment and Calibration Fixtures: Every time I visit a robotics lab, I see someone checking alignment. CNC-machined fixtures help make those tests fast and consistent, especially when a robot is doing repetitive, critical tasks.

5. Oil, Gas, and Energy Sectors

I remember talking with a plant manager who told me, “If this valve fails, we lose $50,000 an hour.” That kind of pressure makes you rethink what quality really means.

In energy, even the smallest part carries a heavy responsibility.

Custom CNC machining has become a quiet hero in this space. It helps teams build parts that hold up under heat, corrosion, and high loads without slowing down operations or waiting for weeks.

- Pump and Valve Components: These parts see nonstop wear, especially with aggressive fluids or pressure changes. CNC machining helps create replacements in stainless or specialty alloys that stay sealed and hold up longer.

- Downhole Drilling Tools: For oil and gas wells, space is tight and tolerances are tighter. CNC makes it possible to machine long tools with deep features that still line up perfectly in rugged environments.

- Sensor and Electronics Housings: Whether it’s monitoring a pipeline or a wind turbine, electronics need serious protection. CNC lets you build custom enclosures that are strong, sealed, and don’t interfere with data signals.

- Pipe Couplings and Transition Flanges: Mixing old lines with new tech? You’ll probably need a custom flange to make it all connect. CNC gives teams the flexibility to get those connectors quickly and precisely.

- Mounts and Brackets for Renewables: Solar panels and wind systems come with custom layouts. CNC parts help teams adapt mounting solutions without waiting for a manufacturer to catch up.

- Heat Transfer and Turbine Parts: These are high-precision components where a small flaw can cause big losses. CNC machining ensures those details are just right and repeatable.

6. Industrial Machinery and Tooling

There’s something satisfying about a well-running machine. But the truth is, behind every smooth production line is a collection of custom parts that most people never notice.

I’ve seen how the right tooling can cut downtime, boost accuracy, and make life a lot easier for operators on the floor.

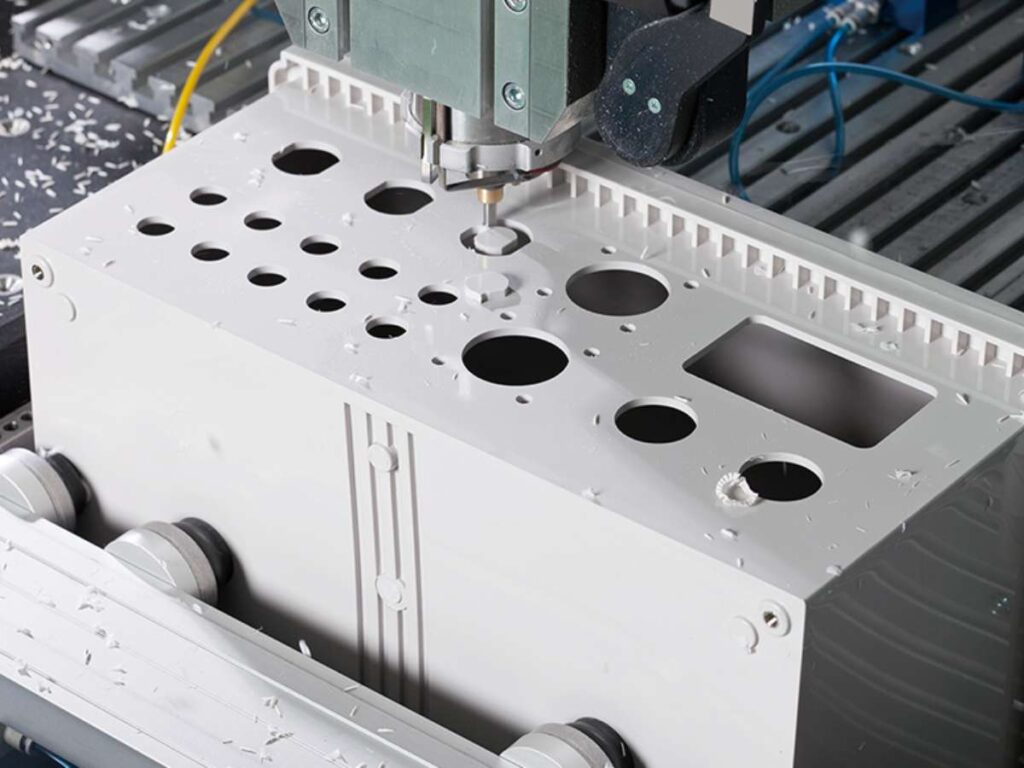

That’s where CNC machining comes in. It gives manufacturers the flexibility to design tooling and machine parts that actually match their workflow, not the other way around.

- Custom Jigs and Fixtures: I’ve watched teams waste time trying to force-fit generic fixtures. CNC machining solves that by letting you design exactly what your operators need for consistent alignment, clamping, or part support.

- Replacement Parts for Legacy Machines: Some older machines still run strong but don’t have parts in stock anymore. CNC lets you reverse engineer and produce one-off replacements without needing original documentation.

- Tool Holders and Cutting Components: When production requires non-standard tooling, CNC makes it possible to shape custom tool holders, inserts, or adaptors that extend machine capabilities without investing in new equipment.

- Precision Plates, Guides, and Rails: If something wobbles or shifts during production, accuracy suffers. CNC-machined rails and guide systems help keep everything tight, aligned, and efficient.

7. Consumer Product Prototypes

I remember walking through a product design lab where sketches were still pinned to the wall. The team had an idea, a deadline, and a prototype that needed to be real by the end of the week.

That’s the kind of pressure that makes CNC machining a lifesaver.

When you’re creating a product that customers will touch, hold, and judge, precision matters. CNC lets you move from concept to prototype without cutting corners on quality.

- Form and Fit Testing: When you need to check how parts come together before mass production, CNC gives you a fast and reliable way to create functional prototypes. No guesswork, just clean fits.

- Custom Enclosures and Casings: Whether it’s for an electronic gadget or a personal care device, appearance and feel matter. CNC lets you machine smooth, sleek shells in aluminum or plastic so you can see exactly how the product will look and handle.

- Iterative Design Changes: Every round of feedback usually means tweaks. CNC machining makes it easy to update small batches or one-offs so designers can test multiple versions without starting from scratch.

- Low-Volume Market Testing: Some products need real-world feedback before going all-in on molds or injection tooling. CNC is great for short runs that look and feel like final production.

- Functional Mechanical Parts: Gears, sliders, hinges—if your product moves, CNC can create the inner mechanics quickly and accurately. You can test real-world motion without having to commit to high-volume tooling too soon.

8. Marine and Shipbuilding Components

I once toured a shipyard where they were fabricating components the size of compact cars. The scale was massive, but the attention to detail was just as tight as in any small machine shop.

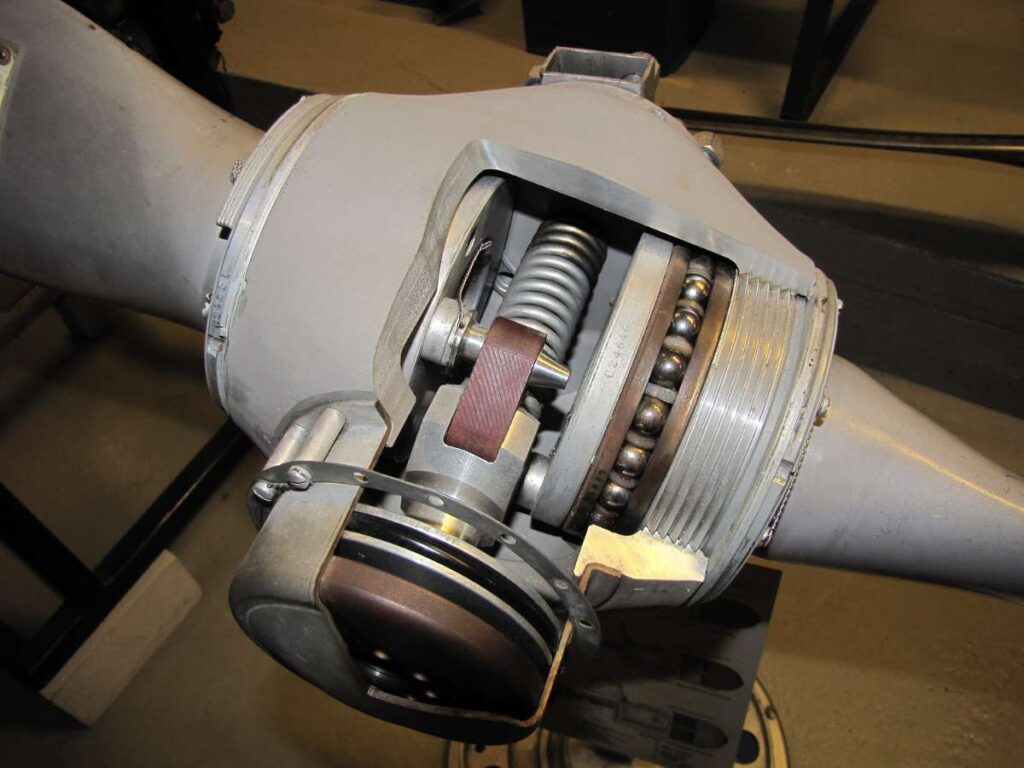

That’s the thing about marine work, it demands durability and precision at the same time.

CNC machining plays a crucial role here, especially when off-the-shelf parts don’t hold up in saltwater, heavy load, or continuous vibration environments. Custom machining lets marine engineers solve design challenges without compromising performance.

- Propeller Hubs and Shaft Components: These parts have to resist corrosion and transfer power smoothly. CNC makes it possible to machine exact tapers and press fits from marine-grade materials like bronze or stainless steel.

- Sealing Surfaces and Flanges: Leaks are not an option at sea. CNC machining delivers the flatness and surface finish needed to ensure tight seals, even on irregular or custom-designed interfaces.

- Brackets, Housings, and Structural Fittings: Boats and vessels are full of mounting challenges. CNC allows builders to fabricate parts that line up perfectly with hull shapes, engine layouts, and unique equipment.

- Navigation and Instrument Enclosures: Electronic gear must be protected from salt spray and vibration. CNC-machined aluminum housings offer both shielding and structural integrity in compact designs.

Conclusion

Remember that delay I shared at the start? CNC was the fix that kept the client and saved the project.

If you’re still making do with generic parts, this is your sign to stop. You’ve seen how CNC can work across industries, and now it’s your move.

Use this guide as your map. Keep it close.

MachMaster can help. Custom machining. Real precision. Fast turnaround.

Contact us today and get things moving.