The first time I handled a copper-plated part, I didn’t know what I was looking at.

It was for a custom bracket on a small electronics prototype. Looked like a regular metal piece until I realized how well it conducted current. The designer leaned in and said, “That’s the copper layer. Electroplated.”

That was my lightbulb moment.

Since then, I’ve worked with manufacturers, engineers, and designers who rely on this process every day. And I’ve learned something important: if you understand copper electroplating, you can make better decisions faster.

In this guide, you’ll learn:

- What copper electroplating is

- How it works, step by step

- Which materials are involved

- And where it fits into product design and manufacturing

You’ll walk away knowing how to apply this process or when to ask for it. This article will help you decide if copper electroplating is the right fit for you.

Let’s start!

1. What is Copper Electroplating?

I used to think electroplating was just about making things look shiny. Like chrome bumpers or gold-plated jewelry, but copper electroplating is a lot more than that.

At its core, copper electroplating is the process of applying a thin layer of copper onto the surface of another material. That base material is usually metal, but it can also be plastic if it’s prepared properly. The copper coating is added using electricity and a special chemical solution.

Here’s the basic idea:

You place the part you want to plate into a liquid solution called an electrolyte. This solution contains copper ions. Then you run an electric current through it. The electricity causes the copper ions to stick to the part’s surface, forming a smooth, even layer of copper.

It sounds simple, but it’s powerful.

Now you might be wondering: how is this different from other metal plating?

Good question.

With other plating processes, like zinc or nickel, the goal might be more about corrosion protection or hardness. Copper plating stands out because it offers:

- Excellent electrical conductivity

- Strong corrosion resistance

- A smooth finish that looks clean and professional

So why is copper electroplating important?

Because it shows up everywhere especially in industries where performance matters.

Here are a few examples:

- Electronics: Printed circuit boards, connectors, semiconductors

- Automotive: Engine parts, fuel systems, wiring components

- Telecommunications: Electrical contacts and RF shielding

- Consumer goods: Handles, fasteners, decorative items

In all these applications, copper plating improves function. It helps electricity flow. It slows down rust. It creates a clean, consistent surface.

I’ve seen projects fail just because a part didn’t conduct well or corroded too fast. Copper plating fixed those issues.

So, if you’re building something that needs reliability, looks clean, or moves electricity well, copper electroplating might be what you’re missing.

Ready to see how it actually works? Let’s walk through the process step by step.

2. The Copper Electroplating Process

Once you understand what copper electroplating is, the next question is: how does the process actually work?

It’s not as complex as it sounds. But every step matters. If one thing goes wrong, the plating might peel, look uneven, or fail completely.

Let me walk you through it, step by step.

Preparation

Before anything gets plated, the surface has to be clean.

I learned this the hard way. Years ago, I tried plating a part without fully removing the oils from machining. The result looked fine at first. But within days, the copper layer started bubbling and flaking off.

Here’s what proper prep includes:

- Surface cleaning: Use solvents, alkaline cleaners, or ultrasonic baths to remove dirt, grease, and rust.

- Surface activation: Some materials need a light acid etch or abrasive blast to roughen the surface. This helps the copper stick.

Electrolyte Solution

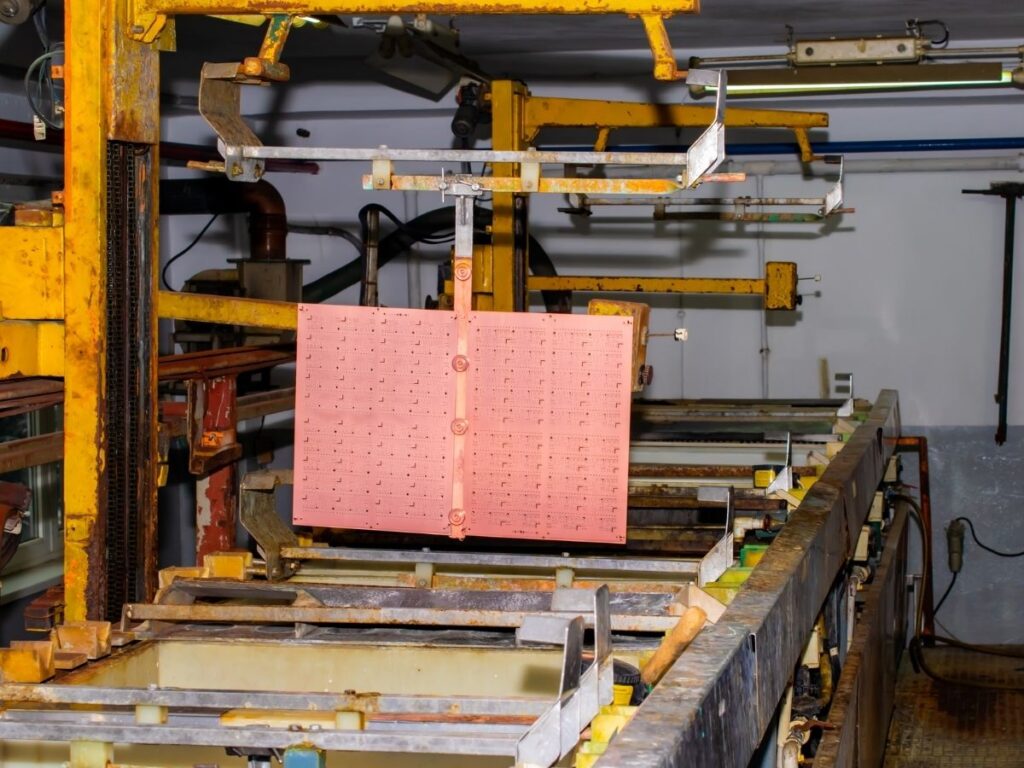

Once the part is clean, it goes into the copper bath.

The electrolyte solution contains copper salts—usually copper sulfate—and sulfuric acid.

Together, they create a chemical environment that lets copper ions move freely. These ions are what eventually bond to the part.

Plating Process

Now comes the electricity.

An electric current runs through the solution. One terminal connects to a copper anode (the source of copper), and the other to your part (the cathode).

Copper ions in the solution are attracted to your part’s surface and begin to stick.

Things like voltage, current density, and bath temperature all affect how smooth and even the coating is.

Post-Plating Process

Once the part is plated, it’s not done yet.

You need to:

- Rinse it to remove leftover chemicals

- Dry it completely

- Polish or buff it if needed

Some parts might also get a heat treatment or protective coating for added durability.

Getting this process right takes care. But once you’ve seen how much better a copper-plated part performs, it’s worth every step.

Next, let’s look at where copper electroplating is used and why it matters.

3. Key Benefits of Copper Electroplating

Now that you know how the copper electroplating process works, you might be asking: why use it?

The answer comes down to performance, protection, and value. Copper electroplating doesn’t just make things look better. It makes them work better, too.

Let’s break down the key benefits.

Improved Durability and Corrosion Resistance

Copper forms a protective layer on the part’s surface. This layer acts as a barrier between the metal underneath and the surrounding environment.

Why does that matter?

Because without that protection, things like moisture, air, and chemicals can eat away at the base metal. That leads to rust, pitting, or even total failure.

I’ve seen untreated metal parts fail in just a few weeks. A thin layer of copper could’ve added months—or years—to their life.

Enhanced Electrical Conductivity

Copper is one of the best conductors of electricity. That’s why you see it everywhere in electronics.

When you plate a part with copper, you’re improving how easily electricity flows across its surface.

This is especially useful for:

- Circuit boards

- Battery contacts

- Connectors and switch parts

Even small improvements in conductivity can make a big difference in performance. And when the product depends on fast, stable current? Copper plating makes it happen.

Aesthetic Improvements

Some people choose copper plating just for how it looks.

It gives parts a smooth, warm shine that stands out. That’s why copper is often used for:

- Jewelry

- Hardware

- Decorative finishes

When appearance matters, copper delivers a clean and professional look.

Cost-Effectiveness and Efficiency

Compared to gold or silver plating, copper is far more affordable.

It’s also faster to apply and easier to work with. That means lower production costs and shorter lead times—without sacrificing quality.

You get:

- Strong performance

- Protective properties

- Visual appeal

All at a reasonable cost.

Copper electroplating isn’t just a technical step. It’s a smart choice for durability, function, and finish.

4. Applications of Copper Electroplating

So now you understand the benefits. But where is copper electroplating actually used?

The short answer is almost everywhere.

From the tiny circuits in your phone to the trim on a vintage car, copper plating plays a big role in how things perform and last. Let’s look at how it’s used in different industries.

Electronics Industry

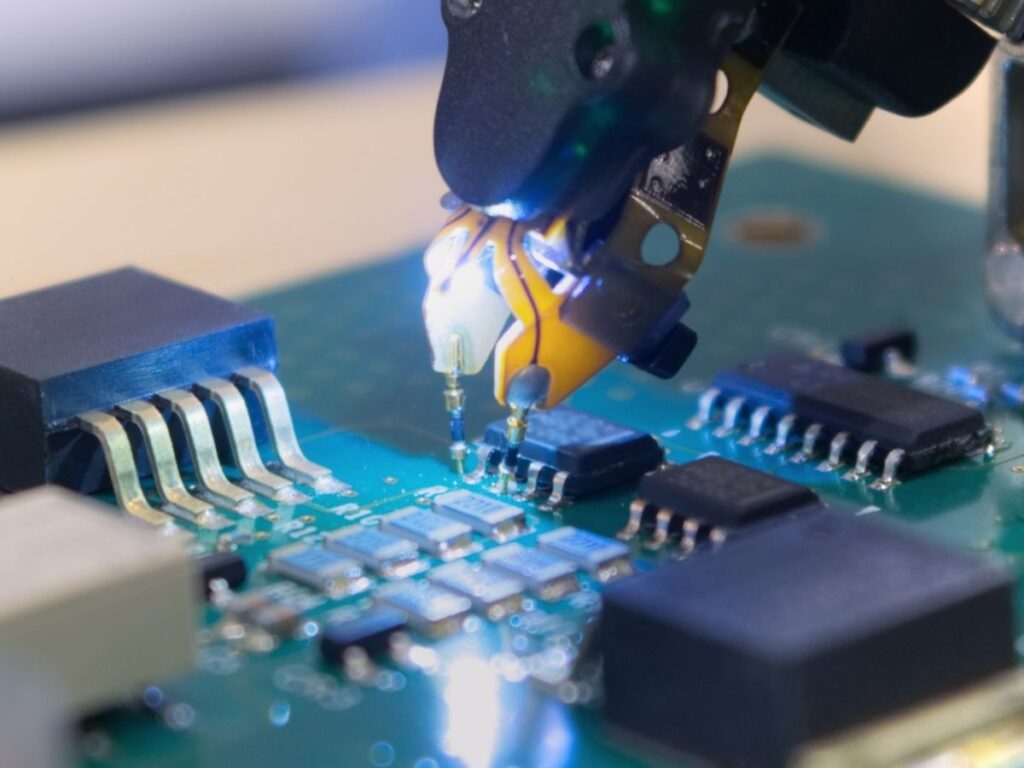

This is one of the biggest users of copper electroplating.

Why? Because electronics need strong conductivity and precise surfaces.

Copper is used in:

- Circuit boards

- Microchips

- Electrical connectors

On a circuit board, copper pathways carry electricity from one component to another. Without that copper layer, nothing works.

As devices get smaller and faster, copper becomes even more important. It helps support miniaturization, the ability to fit more power into less space.

When I visited a PCB factory years ago, I watched rows of tiny boards dipped into copper baths. Each step had to be perfect. One bubble or impurity could ruin the whole part.

Automotive Industry

Cars depend on reliable electrical systems. From headlights to fuel sensors, copper is everywhere.

You’ll find copper electroplating used in:

- Battery connectors

- Wire terminals

- Engine components

Copper helps parts resist corrosion, especially under the hood where heat and moisture are constant. That added protection keeps things running longer.

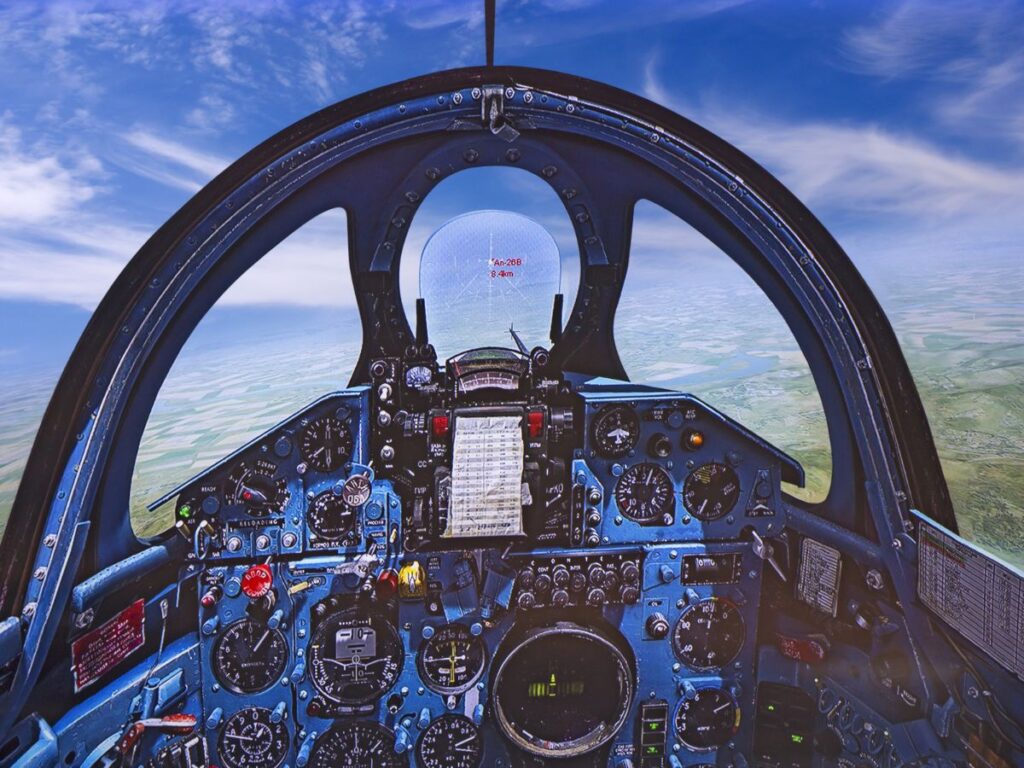

Aerospace and Defense

This is a high-stakes industry. Every part must work under stress, pressure, and time.

Copper electroplating is used in aerospace to:

- Improve conductivity

- Protect critical components

- Extend lifespan under extreme conditions

There’s no room for shortcuts here. A single failure can have serious consequences.

Jewelry and Decorative Items

Not every use is technical. Copper plating also brings warmth and shine to decorative items.

Common products include:

- Jewelry

- Medals

- Art pieces

- Coins

It gives a polished look without the high cost of solid copper. I’ve seen small artisans use it to bring their work to life adding detail, depth, and durability.

From tech to art, copper electroplating quietly supports products we use every day.

5. Challenges and Considerations in Copper Electroplating

Copper electroplating has a lot of benefits. But like most manufacturing processes, it comes with its own set of challenges.

If you’re using this method or thinking about it, you’ll want to understand what can go wrong, and how to handle it.

Quality Control and Consistency

Let’s start with quality.

Getting a smooth, even layer of copper sounds simple, but it takes practice. I remember one of my early projects ended with patchy plating. Some areas were shiny. Others were dull or peeling.

What happened?

The thickness wasn’t consistent. The surface wasn’t fully cleaned. Small mistakes made a big difference.

Here are a few common problems:

- Uneven coating

- Rough texture

- Weak adhesion

Each of these can affect performance or appearance. That’s why it’s so important to stick to a careful process every time.

Environmental and Safety Concerns

Next comes safety.

Electroplating involves chemicals like copper sulfate and acids. If handled the wrong way, they can be harmful—to people and to the environment.

That’s why shops follow strict safety rules:

- Proper chemical storage

- Protective gear for workers

- Wastewater treatment before disposal

You might also need to follow local or national environmental regulations. If you’re doing this in-house, be sure you’re set up for it.

Equipment and Technology Requirements

Thinking of setting up your own electroplating line?

You’ll need some key tools:

- Plating tanks (plastic or glass)

- DC power supply

- Anodes and cathodes

- Temperature control system

Small shops can use tabletop systems. Larger factories need custom tanks and automated controls. Either way, the setup has to match your production needs.

Troubleshooting Common Problems

What if something goes wrong?

Here are issues I’ve run into:

- Copper won’t stick

- Bubbles or rough spots appear

- Plating peels after drying

Sometimes it’s the cleaning. Other times it’s the voltage or bath chemistry. The key is testing, adjusting, and documenting your process.

Mistakes will happen. That’s part of learning. But when you catch them early, you save time and money.

6. Copper Electroplating for Different Audiences

Copper electroplating isn’t one-size-fits-all.

Whether you run a factory, design products, handle procurement, or build things at home, this process can fit your goals in different ways.

Let’s break it down by audience.

| Audience | Use Case | Key Points |

| Business Owners & Entrepreneurs | Improve product performance and reliability | – Copper plating adds durability and corrosion resistance – Enhances product quality and reduces returns – Better for electronics, automotive, and consumer products |

| Choose the right plating partner | – Look for ISO 9001 certification – Ask about lead times and production capacity – Request past work or samples before placing orders | |

| Product Designers | Add copper plating to design features | – Use it to improve function and appearance – Works well for prototypes and design iterations – Supports conductivity and fine detail |

| Design around copper-plated components | – Consider plating thickness in tolerances – Think about weight, size, and finish impact – Communicate with suppliers early in the process | |

| Procurement Professionals | Source reliable electroplating services | – Prioritize suppliers with ISO 9001 certification – Ask about pricing, support, and lead time stability – Evaluate based on reliability and clear communication |

| Personal Buyers | Use copper plating for personal or student projects | – DIY kits are available with simple instructions – Great for coins, models, and small metal parts – Always follow safety steps with chemicals |

No matter what kind of work you do, copper electroplating has a place in your process.

If you’re looking for a reliable copper plating partner, MachMaster can help. We’re an ISO 9001 certified manufacturer that supports both prototyping and large-scale production handling surface treatments with precision and consistency.

7. Environmental Considerations and Sustainability in Copper Electroplating

Copper electroplating offers real benefits. But like many industrial processes, it also creates waste.

So how do you keep your work effective and responsible?

Let’s look at a few ways to do that.

Eco-Friendly Alternatives to Traditional Copper Electroplating

Traditional copper electroplating uses acids and metal salts. These chemicals work well—but they can harm the environment if not handled properly.

Over the years, I’ve seen some shops switch to greener options. It’s not always easy, but it’s worth the effort.

Here are a few alternatives:

- Electroless plating: This method doesn’t use electricity. Instead, it relies on a controlled chemical reaction to deposit copper. It reduces energy use and produces less waste.

- Low-toxicity chemicals: Some suppliers now offer plating solutions made with safer additives. These can reduce harmful byproducts and improve worker safety.

- Closed-loop systems: These setups filter and reuse the plating solution, cutting down on disposal needs.

If you’re working in a facility or even planning a small setup, it helps to ask: what chemicals am I using? Are there safer substitutes?

Recycling Copper and Waste Disposal

Recycling plays a big role in reducing the impact of electroplating.

Once the copper bath is used up, the leftover metal can often be recovered and reused. Some shops send this waste to metal recovery services. Others process it in-house using filters or evaporation tanks.

Proper disposal is just as important. Never pour spent chemicals down the drain. Instead:

- Store chemical waste in labeled containers

- Work with licensed disposal companies

- Follow local environmental rules

I’ve talked to small business owners who learned this the hard way. A single fine or cleanup order can cost more than an entire production run.

Being responsible with copper plating isn’t just about doing the right thing, it also protects your business, your team, and your long-term success.

Conclusion

We’ve walked through the process, the benefits, the problems, and even who it’s for.

Now you know:

- What copper electroplating is

- How it’s done

- Where it fits in real work

And hopefully, you’ve seen how it could fit in yours.

I didn’t get it right the first time either. But once I learned what copper plating could do, I never skipped it again.

So, what will you do differently now?

If you’ve got a product, a part, or just a rough idea, take the next step.

Contact us today. Let’s talk about how to make it real.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Machining & Molding Services:

Finishing Processes:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.