“Should I use turning or milling?”

It’s a question I hear a lot—and for good reason.

These two processes might sound similar, but they do very different things. Choosing the wrong one can lead to higher costs, longer lead times, or parts that just don’t work right.

I’ve spent years working with machinists, engineers, and buyers—helping them choose the right process for every kind of project.

I’ve worked on shop floors, reviewed countless drawings, and seen firsthand how small decisions can make a big impact.

In this article, I’ll explain the real difference between CNC turning and milling in plain language. You’ll see how each process works, what parts they’re best for, and how to choose the right one.

By the end, you’ll feel confident picking between turning and milling for your project needs—no guesswork needed.

So let’s get started!

Quick Comparison Chart

Before we go deeper into each topic, here’s a quick side-by-side look at how CNC turning and milling compare.

| Feature | CNC Turning | CNC Milling |

| Part Movement | The part spins | The tool moves |

| Best For | Round, cylindrical parts | Flat, square, or complex parts |

| Machine Type | Lathe | Milling machine |

| Tool Path | 1-2 axes (mainly Z and X) | Multi-axis (X, Y, Z) |

| Speed | Fast for round shapes | Slower for detailed or multi-face cuts |

| Accuracy | Excellent for round tolerances | Great for flatness, edges, and holes |

| Material Fit | Soft metals, plastics, bar stock | Hard metals, flat stock, odd shapes |

| Setup Time | Often shorter and simpler | Usually longer and more involved |

| Best Volume Use | High-volume production | Small batches or complex one-offs |

| Design Flexibility | Limited to symmetrical shapes | Can handle diverse, custom designs |

Next, we’ll explore what makes each method work best for different jobs.

1. What is CNC Turning?

CNC stands for Computer Numerical Control. That just means a computer controls the machine to shape your part with high precision.

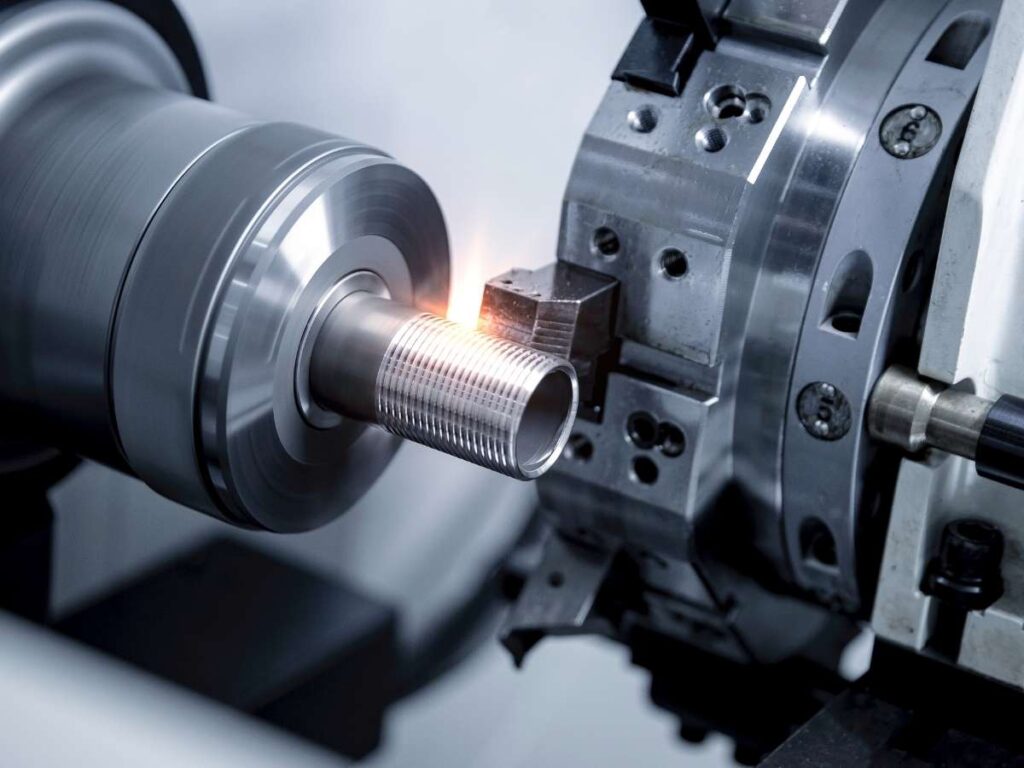

In turning, the part spins while a tool stays still and removes material. Picture a piece of metal spinning like a top. Then a sharp tool cuts into it while it turns.

CNC turning works best for:

- Cylindrical parts

- Shafts

- Bushings

- Round fittings

We use CNC lathes for this. A lathe is the machine that spins the workpiece.

If your part is round or has a lot of curves along its length, turning may be the better choice.

Still not sure? Ask yourself:

- Is the part mostly symmetrical around a center point?

- Do you care more about outside diameter than flat surfaces?

If you answered yes, you’re probably looking at turning.

I’ve run turning jobs for everything from bike axles to valve stems. It’s quick, reliable, and ideal for smooth, round finishes.

And if you’re still on the fence—that’s okay. You’re not alone.

If precision-machined parts are what you need, talk to MachMaster. They can help you deliver reliable CNC machining services with competitive pricing, fast turnaround, and a strong focus on quality from start to finish.

2. What is CNC Milling?

CNC milling is very different from turning. In milling, the part stays still while the cutting tool spins and moves across the surface.

It’s the opposite of turning.

Instead of spinning the part, you spin the tool.

Milling is great for:

- Flat surfaces

- Complex shapes

- Slots and pockets

- Holes and threads in different directions

I use CNC mills to cut materials from different angles. The machine can move the tool left, right, up, down—even tilt if needed.

This makes milling more flexible for custom shapes.

Ask yourself:

- Does your part have flat faces or corners?

- Does it need holes drilled in different spots?

If yes, you’re likely looking at milling.

I’ve milled parts like brackets, plates, housings—even molds.

It’s great for detailed cuts and 3D contours.

Don’t worry if you’re not sure yet.

That’s exactly why we’re walking through this step by step.

3. Process Movement

If you’re trying to decide between CNC turning and CNC milling, you need to start with one key difference: what moves and what stays still. That single detail changes everything about how the part is made.

Here’s how each process works:

CNC Turning: The Part Spins

Picture a rod spinning fast while a tool gently cuts away its surface. That’s CNC turning.

In this process, the workpiece (your part) spins on a machine called a lathe. The cutting tool stays mostly still but moves in and out to shape the outside of the part.

This setup works best when your part is:

- Round

- Cylindrical

- Symmetrical along its length

Think about shafts, bushings, tubes, or anything that looks like it could roll.

I remember working with a buyer who needed 1,000 aluminum pins. They asked if we could mill them. I said, “We could, but turning will be quicker, cleaner, and cheaper.” Once they saw the results, they came back for a second order.

So ask yourself: Is your part shaped like a tube or a rod?

If yes, turning is likely the better choice.

CNC Milling: The Tool Moves

Milling works the opposite way. Your part stays still while the cutting tool spins and moves around it. This tool cuts from above, from the side, and sometimes even from an angle.

A milling machine can move in:

- X-axis (side to side)

- Y-axis (forward and backward)

- Z-axis (up and down)

That flexibility lets you cut flat faces, slots, grooves, holes, and other features.

I worked with an industrial designer who needed a flat bracket with a few angled holes. No way that would work with turning. Milling gave us clean edges and exact hole placement.

Use milling when your part has:

- Square or rectangular shapes

- Features on multiple sides

- Complex designs

Does your part need lots of detail or angles?

That’s a sign milling is the right call.

Which One Should You Use?

Still not sure? Here’s a quick way to decide:

Use turning if your part is:

- Round or tube-shaped

- Symmetrical from end to end

- Needing outside diameters shaped

Use milling if your part is:

- Flat or block-shaped

- Has features on more than one side

- Includes pockets, slots, or odd angles

Sometimes, it’s not either-or. Some parts use both.Once you get that down, choosing the right process becomes a lot easier.

4. Tolerances and Accuracy

Tolerances define how much variation is allowed in the final dimensions of a part. I know that even a small difference can affect how parts fit and function, especially in mechanical assemblies.

Here’s how CNC turning and milling compare when precision matters:

CNC Turning: High Accuracy for Round Parts

Turning is great for tight tolerances—especially on round shapes.

Because the part spins smoothly, the cutting is more stable. That means less vibration and better precision on:

- Outer diameters

- Inner holes

- Threads

- Long, round parts

I worked on a stainless steel shaft project last year. The parts needed to fit inside bearings with no slop. Turning nailed it. Every piece came out within 0.01 mm of spec.

So if you need exact roundness or smooth finishes, turning is often the better option.

CNC Milling: Great for Flat Surfaces and Details

Milling handles tight tolerances too—just in a different way.

Instead of working on round surfaces, milling shines when you need:

- Flat faces

- Square corners

- Holes with tight positions

- Complex 3D shapes

Just know that complex shapes sometimes need more setup, which can affect accuracy if not done carefully.

What Should You Pick?

Ask yourself:

- Does your part have round features that must be smooth and exact? → Go with turning.

- Is it flat, square, or has lots of detail and hole positions? → Choose milling.

Both can deliver accurate results. The trick is knowing which one matches your part’s shape and function.

5. Speed and Lead Time

Speed always matters—especially when you’re racing against a deadline or trying to hit a tight production window.

CNC turning and milling can both move fast.

But how fast? That depends on the shape, size, and how complex your part is.

Here’s how turning and milling compare when speed and lead time are on the line:

CNC Turning: Fast for Simple, Round Parts

Turning is usually faster when you’re making:

- Cylindrical shapes

- Straight features

- Repeated parts in high volume

The machine spins the part and cuts with less tool movement. That means shorter cycle times and less chance of setup errors.

I remember one job where we had to deliver 2,000 brass spacers in three days. Thanks to turning, we finished ahead of schedule and with no rework needed.

So if your part is simple and round, turning can save hours—or even days.

CNC Milling: Slower But More Flexible

Milling often takes more time. That’s because:

- The tool moves in more directions

- The machine needs multiple setups for complex parts

- You might need more cutting passes for different surfaces

But that extra time gives you more detail and flexibility. For example, if you need holes on multiple sides or a mix of pockets and flat faces, milling can do all of that—just not as fast.

Still, for small batches or low-volume parts with tricky shapes, milling might be worth the wait.

Which One is Faster for You?

Here’s what to ask yourself:

- Is the part round and repeated in high quantity? → Turning is likely faster.

- Does it have multiple faces or features that need careful setup? → Milling might take longer, but it gives better control.

Sometimes, speed isn’t just about the machine—it’s about matching the process to the job. One shop manager told me, “You don’t bring a lathe to a pocketing fight.” I laughed at the time, but he was right.

6. Cost Comparison

Cost is often the deciding factor, especially in long-term production planning. Both CNC turning and milling have setup, tooling, and operation costs—but each adds up differently depending on complexity, volume, and part design.

Here are all the cost factors to consider:

CNC Turning: Lower Cost for Simple Shapes

Turning is usually more affordable when the part:

- Has a round or cylindrical shape

- Doesn’t need a lot of tool changes

- Can be made in large quantities

It’s quicker to set up and runs faster for certain parts. Less time on the machine means lower cost per part.

One customer once sent me a drawing for a round connector. It had no side holes or flats. They asked for milling. I told them, “We can, but turning will cost half as much.” They were surprised—and grateful.

Turning works best when speed and simplicity are on your side.

CNC Milling: Higher Cost, More Flexibility

Milling often costs more, and here’s why:

- The machine moves in more directions

- It may need more setup and tool changes

- Some shapes take longer to cut

But the trade-off? You can do much more.

Flat parts with holes, angled faces, or fine details? Milling makes those possible. So even if it’s a bit more expensive, you get design freedom.

Also, for one-off parts or small batches, milling may be the only option.

What’s Right for Your Budget?

Ask yourself:

- Is the part round and easy to repeat? → Turning will usually save you money.

- Does the part have features on different sides or complex cuts? → Milling may cost more, but it’s worth it for the results.

I guess, the lowest quote doesn’t always win. If you’re looking for high-quality service without breaking the bank, MachMaster is a smart choice. They offer competitive pricing without cutting corners—each part is carefully crafted, quality-checked, and built to meet real production demands.

7. Material Application

Choosing the right CNC process isn’t just about shape or speed—it’s also about what material you’re working with.

Some materials are better suited to turning. Others behave better during milling.

Here’s how turning and milling compare when it comes to materials:

CNC Turning: Great for Softer or Round-Friendly Materials

Turning works best on materials that cut clean and stay stable while spinning.

Common turning materials include:

- Aluminum

- Brass

- Mild steel

- Nylon or other plastics

- Stainless steel (for certain shapes)

Since the part spins fast, you want something that holds up under rotation. If it’s too brittle or out of balance, it can chip, crack, or throw off the cut.

I once had a client try to turn a large, flat Delrin disc. The size made it wobble. We switched to milling for better control. Sometimes, shape and material need to match the motion.

CNC Milling: Handles Harder or More Complex Materials

Milling handles a wider range of materials, especially when you need cuts from multiple sides.

Materials often used in milling:

- Tool steel

- Titanium

- Copper

- Hardened plastics

- Composites

- Cast aluminum

Milling gives more control for tough cuts or tricky surfaces. You can slow things down, change tools, and adjust depth easily.

It’s a better choice when you’re working with something dense, fragile, or oddly shaped.

How to Choose Based on Material

Ask yourself:

- Is the material soft, round, and easy to spin? → Turning is likely better.

- Is the material harder, or does it need side features? → Milling might be the safer bet.

Material choice isn’t just about looks. It affects how well the machine performs—and how your part turns out.

8. Tips When Choosing Between CNC Turning and Milling

You won’t always find a clear answer when deciding between CNC turning and milling. Both processes have strengths, and your best choice depends on the part’s geometry, timeline, and tolerance needs in your production. In many cases, using both methods gives you the best results.

Here are four practical tips to help you choose the right path for your next project:

Tip#1 Consider Quantity

If you’re planning a large batch, turning usually gets the job done faster. Once you’ve dialed in the setup, it runs part after part with little downtime.

But if you’re in prototyping or expect design tweaks, milling gives you more flexibility. You can make multiple features in one setup, which saves time and cuts down on fixture changes.

Tip#2 Look at Feature Complexity

For simple features—like clean bores, chamfers, or round profiles—turning is often the most efficient route. But if your part has slots, angled holes, or irregular cutouts, you’ll want to go with milling.

One job I handled started with turning the round base, then moved to milling to add precise holes. That combo saved time and avoided rework.

Tip#3 Think About Material Shape and Behavior

Start with the raw shape. Round bar stock works better on a lathe, while flat plates belong on a milling bed. Also, think about how your material reacts.

If you’re working with soft plastics or thin-walled metals, turning could distort the part. Milling offers a more stable approach that reduces the risk of deformation.

Tip#4 Match Finish and Surface Expectations

If the finish matters—especially for visible or customer-facing parts—milling may be your better option. It gives you cleaner surfaces without needing extra polishing.

I once machined a batch of aluminum brackets where the client wanted a brushed finish. Milling gave us a smooth, consistent surface with less post-processing.

Conclusion

This guide walked you through the essentials—what turning does best, where milling fits, and how to choose between them.

It’s not just about machine types. It’s about getting the job done right.

Mistakes cost time and money. You don’t have to make the same ones I did.

Let MachMaster help you move with confidence.

Contact us today to get expert support and real solutions!

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.