The first time a fabricator botched our order due to poor forming tolerances, we lost a full week on a tight timeline.

That’s when we started looking into CNC sheet metal forming, and realized we should’ve made the switch sooner.

It wasn’t just about precision. It was about trust.

Since then, I’ve worked with CNC processes across multiple metal projects, collaborating with shops that prioritize quality and repeatability. This guide reflects those lessons, both the failures and the wins.

You’ll learn what CNC sheet metal forming really involves, what machines do the heavy lifting, and how to evaluate partners or equipment before you commit.

If you’re in business to build things right the first time, this is for you.

So let’s dive in!

1. What is CNC Sheet Metal Forming?

If you’ve ever walked through a production floor where metal parts were being formed, you know there’s a unique rhythm to it. The whir of machinery, the press of a brake, the slide of a metal sheet, all orchestrated into something precise. CNC sheet metal forming is where that rhythm meets automation and tight tolerances.

CNC (Computer Numerical Control) sheet metal forming is a manufacturing process where computers control machines that bend, punch, stamp, and shape metal sheets. It involves a range of forming techniques, from bending and punching to rolling and stretching, all controlled by a programmed set of instructions.

CNC forming takes traditional metalwork and supercharges it with speed and repeatability. For businesses, that means higher production volumes, fewer errors, and more consistent part quality. Whether you’re making enclosures, frames, brackets, or custom parts, CNC forming allows you to scale without compromising precision.

So, why does this matter to you? Because if you’re in the business of making things—especially things that need to last or fit perfectly, understanding CNC sheet metal forming isn’t optional. It’s essential.

2. Advantages of Using CNC for Sheet Metal Forming

When we made the jump from manual forming to CNC, the difference was almost immediate. Parts came out cleaner, jobs moved faster, and we stopped second-guessing whether our dimensions would line up. It wasn’t just about speed, it was about control. CNC forming gave us the kind of consistency that manual setups just couldn’t touch.

Precision That Holds Across Every Batch

CNC machines are programmed to follow exact paths, which means every bend, punch, or cut happens where it should. This is a game changer when you’re working with tight tolerances or complex assemblies. You’re no longer relying on the skill of one operator to get things right over and over again. That level of repeatability gives your production a serious edge.

Faster Turnaround with Less Manual Oversight

Once the program is set, a CNC forming machine can run through hundreds of parts with minimal supervision. You’re not stopping to re-measure, re-adjust, or re-check after every few pieces. This lets your team focus on quality control or prep for the next batch instead of hovering over the machine. In the long run, it saves hours that really add up.

Easy Integration With Design Software

CNC forming works hand in hand with CAD and CAM programs. You can design a part, simulate the bends, and send the file straight to the machine with very little guesswork. That seamless connection cuts down on translation errors and speeds up revisions. If a client changes specs, you’re just a few clicks away from updating the process.

Lower Waste and Better Material Usage

Manual setups often come with trial and error, which means wasted sheets and misaligned cuts. CNC forming minimizes those mistakes right out of the gate. With tight control over where and how the metal is formed, you get more usable parts from each sheet. That efficiency isn’t just good for the environment, it’s good for your bottom line.

3. Key CNC Sheet Metal Forming Techniques

I used to think sheet metal forming was just about bending metal into shape. But once we started working with CNC equipment, I realized there’s a whole toolbox of techniques that each serve a different purpose. If you’re producing at scale or working with detailed specs, knowing these techniques is a must.

CNC Bending

CNC bending uses press brakes to create sharp or curved bends along a defined axis. The machine applies pressure through a punch and die to form the sheet with exact angles. With CNC control, you can repeat bends with high accuracy and very little variation between parts. This technique is ideal for parts like boxes, flanges, and structural frames.

CNC Punching

This method uses a turret punch to quickly create holes, cutouts, or patterns in sheet metal. The turret holds multiple tools, allowing the machine to switch punches mid-process without manual changeover. It’s perfect for ventilation panels, electrical boxes, or anything with repeating features. CNC punching is both fast and cost-effective for thin to medium-gauge metals.

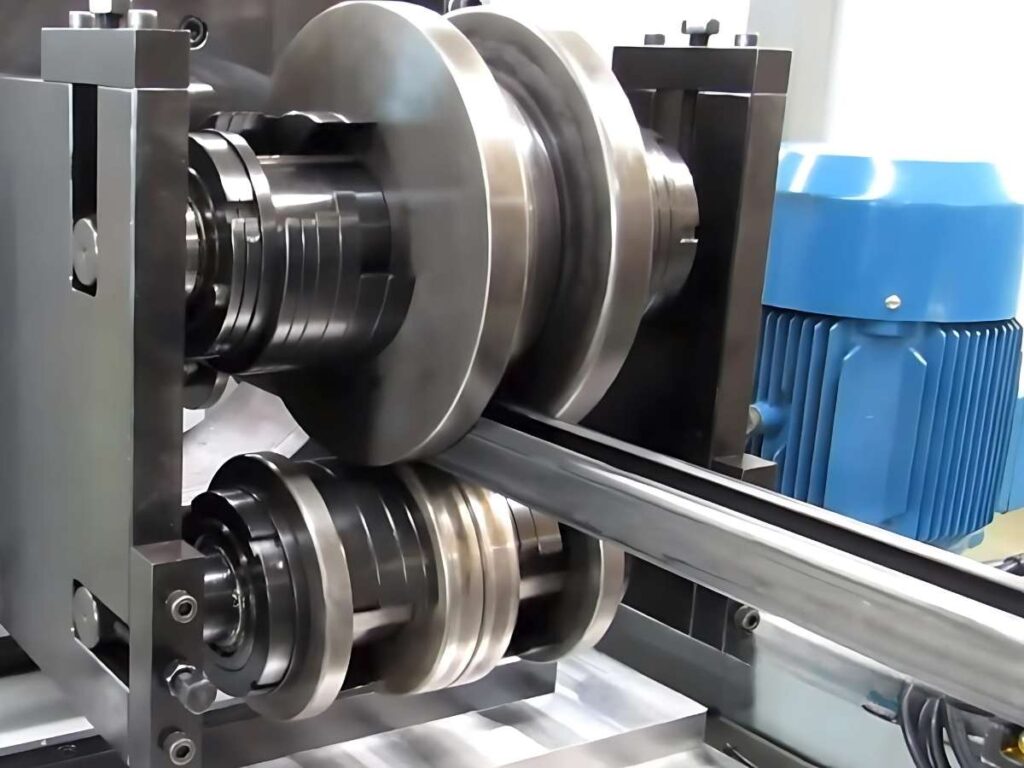

CNC Roll Forming

Roll forming involves feeding a metal sheet through a series of rollers that gradually shape it into a desired profile. It’s great for long, continuous parts like rails, channels, or roofing panels. Once set up, roll forming produces parts at high speed with excellent consistency. It’s especially useful for projects that need high volume and tight control over dimensions.

CNC Stamping

CNC stamping combines a die and press system to form or emboss features into the sheet. It’s often used for creating complex forms, stiffeners, or textured surfaces. Stamping works best when high volume and speed are priorities. With CNC integration, the process is repeatable and adaptable for various shapes.

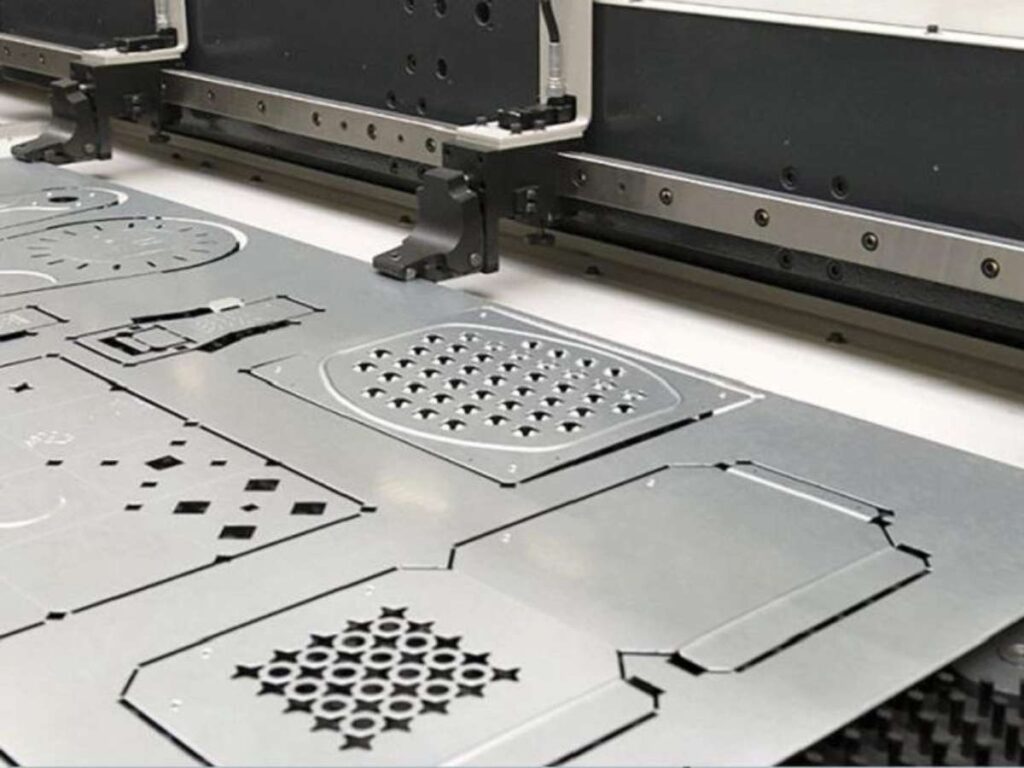

CNC Laser Cutting with Forming

While not a forming technique by itself, CNC laser cutting is often the first step before forming begins. It allows for precise cutting of flat blanks, which are then sent to a press brake or roller for shaping. This combo makes it easier to handle complex parts in fewer steps. The result is clean cuts, efficient workflows, and reduced handling time.

4. Materials Commonly Used in CNC Sheet Metal Forming

Over the years, I’ve learned that even the most advanced CNC machine can’t compensate for choosing the wrong metal. It all comes down to understanding how each metal behaves during forming. Here’s a closer look at the most common ones we work with in CNC sheet metal projects.

- Mild Steel: This is one of the most commonly used metals because it’s affordable, easy to work with, and readily available in different thicknesses. It forms cleanly without much resistance, making it perfect for everything from structural frames to general-purpose brackets.

- Stainless Steel: Known for its strength and resistance to rust, stainless steel is a favorite in industries like food processing, medical, and architecture. It can be tougher to form due to its hardness, but the long-term durability it offers is usually worth the extra effort.

- Aluminum: Lightweight and naturally corrosion-resistant, aluminum is easy on tools and forms well at low to medium thicknesses. It’s often used when weight savings matter, especially in aerospace parts, automotive panels, and consumer electronics.

- Galvanized Steel: This metal is coated with a layer of zinc to protect against corrosion, making it great for outdoor products, ductwork, and HVAC components. It bends well but requires care around edges and corners to avoid damaging the coating during forming.

- Copper: Copper is soft, highly conductive, and ideal for electrical enclosures, terminals, and plumbing systems. It forms easily under low pressure, though it scratches and dents quickly if not handled gently.

- Brass: With a bright, polished finish and good formability, brass is often chosen for decorative panels, nameplates, or electrical components. It handles well on CNC equipment and adds a professional look to customer-facing parts.

- Titanium: While not commonly used for everyday applications, titanium is valued for its strength-to-weight ratio and extreme resistance to corrosion. It’s a challenge to form and usually requires specialized setups, but it’s ideal for aerospace, defense, and high-performance industrial parts.

5. The CNC Sheet Metal Forming Workflow

The first time I watched a full CNC sheet metal job run from start to finish, I realized just how organized and intentional the process really is. It’s not just a matter of feeding metal into a machine and hoping for the best. Every step in the workflow plays a role in making sure the final part meets expectations.

- Design and Programming: Everything starts with a CAD model, which is then converted into CNC code using CAM software. This step makes sure that the machine knows exactly where to bend, punch, or cut with minimal need for manual adjustment.

- Material Selection and Prep: The correct sheet metal is chosen based on thickness, type, and tolerance requirements. Sheets are usually cleaned and checked for defects before being loaded into the machine to establish smooth forming.

- Tooling Setup: The right dies, punches, or forming tools are installed in the machine based on the job’s specs. This step takes careful attention since incorrect tooling can throw off bend angles or damage the material.

- Machine Operation: The CNC machine follows the programmed path and performs the required operations like bending, punching, or rolling. Operators monitor the process to make sure everything stays aligned and within tolerance.

- In-Process Quality Checks: As parts are formed, they’re often spot-checked for accuracy, angle, and overall dimensions. This helps catch any minor errors early before a whole batch needs rework.

- Post-Processing and Finishing: If needed, parts go through secondary steps like deburring, welding, or coating after forming. This final touch makes sure they’re ready for assembly, shipping, or end use.

6. Common Applications of CNC Sheet Metal Forming

I’ve seen CNC sheet metal forming used in everything from tech startups to heavy industry, and the range of applications still impresses me. If you’re in the business of building anything metal, chances are this process already supports your product line.

Electronics and Enclosures

CNC forming is widely used for creating metal housings, brackets, and internal structures for electronics. These parts need tight tolerances so components fit cleanly and wires route properly. You’ll find formed metal in everything from server racks to handheld device shells. The precision of CNC machines guarantees every cutout and bend lines up exactly where it needs to be.

Construction and Architecture

In building and architectural work, CNC forming supports both structural integrity and visual design. Think metal trims, wall panels, window frames, and even decorative elements on modern buildings. CNC techniques help maintain uniformity across large projects, especially when aesthetics matter. It also makes customization easier when adapting parts for different site conditions.

Automotive and Transportation

Vehicle manufacturing depends heavily on formed metal parts for things like chassis mounts, brackets, and underbody panels. CNC forming makes it possible to repeat these parts at scale while holding performance-critical tolerances. It’s also used for lighter aluminum components where weight savings are important. The ability to move quickly from design to production gives manufacturers more control over timelines and costs.

7. How to Choose the Right CNC Sheet Metal Forming Partner

Finding a CNC forming partner isn’t just about who has the latest machines. It’s about who knows how to use them well and can turn your designs into consistent, production-ready parts without delays or surprises. When you’re trusting someone else with your metal work, the technical details matter just as much as the price.

Expertise in Tooling Setup and Die Selection

A reliable partner should understand how to match the right tooling with your material and bend requirements. Poor tool selection can lead to springback, cracking, or inconsistent bends. Ask how they handle new project setups and what tooling inventory they maintain. Their knowledge in this area says a lot about how smoothly your jobs will run.

Bend Sequence Optimization Capabilities

CNC forming isn’t just about bending metal, it’s about choosing the smartest order of operations. A partner who uses software to simulate and optimize bend sequences will reduce rework and improve part consistency. This also minimizes handling and improves efficiency during production. Make sure they can demonstrate how they approach sequencing for complex or multi-bend parts.

In-Process Inspection and Tolerance Control

You want a shop that doesn’t wait until the end of the batch to start checking parts. Look for partners who perform in-process inspections to catch errors early and ensure tolerances are maintained. Ask what kind of measuring tools or systems they use, whether it’s digital calipers, angle checkers, or laser scanners. Consistency starts with checks at every step, not just at final delivery.

Integration with CAD/CAM and File Management Systems

A strong CNC forming partner should work seamlessly with your engineering files and design updates. Whether it’s SolidWorks, AutoCAD, or STEP files, they should be able to import, adjust, and program from your designs with minimal back-and-forth. Ask how they manage revisions and store job histories for repeat orders. Their digital workflow can either help your project move faster or slow it down with versioning issues.

Conclusion

I didn’t fully understand CNC forming until I saw the results for myself.

Now you’ve got the full picture. What CNC sheet metal forming is. How it works. Where it fits. And why it matters.

What’s the one area you know you could improve today? And what would it feel like to finally solve it?

Contact MachMaster today to partner with a precision manufacturing team that delivers flawless CNC forming, every time.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.