Are you tired of sending out your designs and just hoping the shop understands what you mean? You’re not alone.

We’ve seen too many projects go wrong because no one really took the time to explain CNC precision machining in simple terms.

I’ll be honest with you. When we first started offering CNC services, we messed up. I gave quotes that were way too tight. I missed small details like edge breaks. We learned the hard way how much clear, simple communication matters.

That’s why you can trust us. We’ve worked with business owners worried about wasted costs, designers stressing over tight tolerances, and buyers trying to keep deadlines on track.

In this article, I’ll give you a plain, honest look at CNC precision machining. You’ll see what it is, how it works, and what you really need to know to get it right.

By the end, you’ll have the clarity you need to talk to suppliers, review specs, and make better decisions.

Let’s jump in!

1. What Is CNC Precision Machining?

If you’ve ever handed off a design to a machine shop and gotten back parts that didn’t fit right, holes misaligned, edges rough, you’re not the only one. You might think it’s a tooling issue or a production delay. But sometimes, the real issue is understanding how those parts are actually made.

That’s what I learned early on. Until I understood CNC precision machining, I couldn’t communicate what I really needed and that gap caused delays and rework.

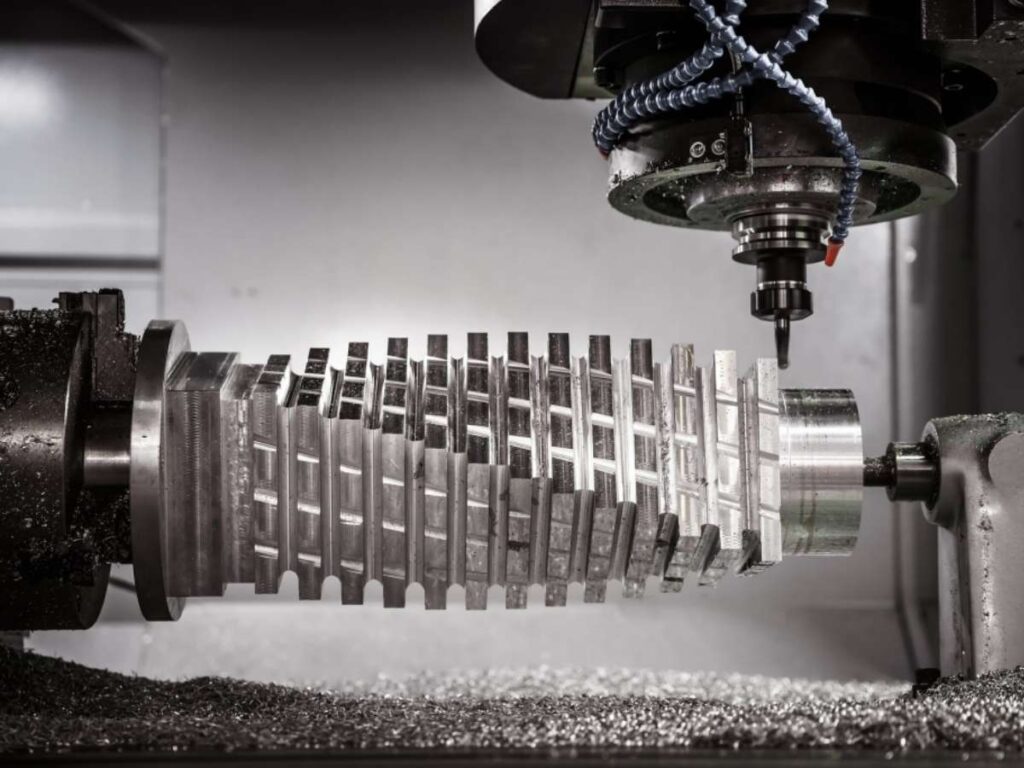

CNC stands for Computer Numerical Control. It’s a method where machines use computer code to control how they cut or shape raw material into finished parts.

And “precision machining”? That’s the part that makes CNC special. It means removing material with extreme accuracy down to tiny fractions of a millimeter.

In short:

- A digital file tells the machine what to do

- The machine follows those steps exactly

- The result is a part that matches the original design, closely, consistently, and cleanly

CNC precision machining gives you control, consistency, and accuracy, all critical when you’re working on tight timelines or sourcing complex components.

2. How CNC Precision Machining Works

Precision machining is all about getting the details right. With CNC, that means using computer-guided machines to cut parts exactly to your specs down to tiny measurements you might barely see.

It starts the same way as regular CNC. Your CAD file (the detailed drawing) goes into CAM software, which writes G-code , step-by-step moves for the machine.

But with precision machining, everything is tighter. The machine follows the G-code in tiny, careful steps. It takes off just the right amount of material, often measured in thousandths of an inch. I’ve stood by plenty of these jobs, holding my breath while the tool cuts because even a small slip can throw off the whole piece.

Why this matters to you:

- Makes tight tolerances possible so your parts fit and work without extra tweaks.

- Handles complex surfaces and fine details, like pockets, grooves, or sharp edges.

- Keeps every piece the same, even in big batches, so you’re not stuck sorting out bad parts later.

Once the cutting’s done, I always check with precise tools like micrometers or gauges. That’s how you get parts that meet strict size needs, the kind used in medical, aerospace, or high-performance gear.

It’s still one of the best ways to take your design and turn it into a part that fits exactly where you want it, right on the first try.

3. Advantages of CNC Precision Machining

Once you understand the full process, the value of CNC precision machining becomes clear. If you’re developing a new product, whether it’s a one-off prototype or a production run, you know that speed and accuracy aren’t optional. They’re what keep your timeline and your budget on track.

Across many projects from basic fixtures to complex assemblies, CNC precision machining consistently solves common manufacturing challenges. Here’s why it matters:

High Accuracy

CNC machines can hold incredibly tight tolerances. Parts come out with clean cuts, sharp edges, and exact dimensions that match the design file. We’re talking tolerances as tight as ±0.005 mm in many cases (source: Protolabs).

But what really impressed people especially purchasing teams and engineers was how repeatable the process is. The first part looks like the 10th. The 10th looks like the 100th. Once the machine is dialed in, it stays locked in.

This is a big deal in industries like aerospace or medical, where even a small variation can lead to failure or rework.

Fast Turnaround

Prototypes that used to take weeks can now be turned around in days. In some cases, same-day machining is possible with the right setup and part complexity.

That kind of speed makes it easier to test a design, make changes, and keep the project moving. It keeps teams agile especially when working with tight product development timelines.

More than once, a supplier came through with short lead times thanks to CNC. It wasn’t magic, it was the ability to take a clean file, load the machine, and start cutting within hours.

Works with Many Materials

CNC precision machining supports a wide range of materials. Metals like aluminum, steel, and titanium. Plastics like ABS, nylon, and Delrin. Even composites or exotic alloys, depending on the shop’s capabilities.

This flexibility helps you test different material options without needing to change your production method. Whether you’re switching from plastic to metal or comparing surface finishes, CNC gives you room to explore.

Ideal for Complex Shapes

Because CNC machines operate on multiple axes, you can create intricate features, angled holes, undercuts, or tight internal pockets that would be too slow or impossible by hand.

This allows for more compact and functional designs without adding manual steps.

I worked with a designer who needed a part with three angled holes intersecting at the center. CNC handled the entire cut in one setup with perfect alignment. That wouldn’t have been feasible manually.

4. Machine Types Used in CNC Precision Machining

When a part comes out perfectly shaped clean edges, tight holes, smooth cuts, it’s not just luck. The machine you choose plays a big role.

Here’s a quick breakdown of the main CNC machine types and what you should use them for:

CNC Milling Machines

If you need flat surfaces, pockets, slots, or angled features, start with a CNC mill. These machines use a rotating cutting tool to remove material while your workpiece stays mostly in place.

Whether you’re working in 3, 4, or 5 axes, mills are a solid choice for shaping complex parts with tight tolerances. If your job involves a lot of holes and sharp edges, this is likely where you’ll begin.

CNC Lathes (Turning Machines)

When your parts are round like shafts, rods, or bushings, you’ll want to use a lathe. This machine spins the material while a stationary cutting tool shapes it.

Turning is ideal when your project needs threading, boring, tapering, or grooving. It’s the go-to choice for consistent, concentric features. If you’re running production work in aerospace or automotive, this is probably one of your main machines.

I once ran a steel spindle job on a lathe, hundreds of parts, and not one slipped out of spec.

CNC Routers

If you’re cutting wood, plastic, or thin aluminum sheets, a router will save you time. Routers work like mills but are better for lighter, softer materials.

They’re fast, accurate enough for general work, and ideal for signage, enclosures, and flat panels. You won’t use them for tight-tolerance parts in steel, but for speed and efficiency on flat stock, they’re hard to beat.

CNC EDM (Electrical Discharge Machines)

EDM stands for Electrical Discharge Machining. It removes material using sparks literally. This method doesn’t involve physical contact between the tool and the part.

EDM is used when working with very hard materials or tiny internal features that traditional tools can’t reach. For example, if you need a deep, narrow slot inside a hardened steel block, EDM gets the job done without stress on the material.

It’s slower than other methods but highly precise.

5. Applications Across Industries

After learning how CNC precision machining works and what machines are used, the next question is simple: Where does this matter most?

The answer? Almost everywhere.

Let’s look at a few industries where CNC machining shows up in powerful ways:

Aerospace

This is one of the strictest industries when it comes to tolerances, quality checks, and material performance. Aircraft parts no matter how small must meet exact standards. A tiny error in a turbine blade, landing gear shaft, or structural bracket could cause failure.

CNC machining is trusted here because it can hold extremely tight tolerances and work with aerospace-grade materials like titanium, Inconel, and aluminum alloys. Shops that support aerospace are often certified under AS9100 or ISO 9001, adding an extra layer of process control.

Medical Devices

In medical manufacturing, the stakes are even higher. Parts must be clean, biocompatible, and made with absolute accuracy. CNC machining is used to create surgical instruments, implants, dental components, and lab tools.

One case involved producing a batch of stainless-steel bone plates for a research hospital. The tolerances were tight, and the finish had to be smooth enough to go inside the human body. Manual methods wouldn’t cut it literally. CNC machining made it possible to get every piece exactly right.

Automotive

Whether you’re building engines, brake housings, or custom suspension parts, you need repeatability and speed. CNC machines let you move fast from design to part, which is huge when you’re iterating through revisions or chasing deadlines.

We’ve supported customers who needed prototype parts by Monday and full production ready the next week. CNC helped make that happen with clean threads, smooth bores, and exact fits.

Even if you’re running a small aftermarket shop, CNC is your friend. It helps you get that perfect fit for performance parts, restorations, or racing upgrades without wasting time on trial and error.

At MachMaster, they’ve worked closely with automotive clients of all sizes. Whether it’s a small batch or a long-term production run, they deliver accurate, reliable parts on time and to spec.

6. CNC Precision Machining vs. Other Methods

If you’re running a fab shop or sourcing parts for clients, you’ve likely defaulted to CNC because it sounds like the “pro” route. I’ve done the same. Early on, I picked CNC by default thinking it was always the smartest choice. But after working across projects with different budgets, timelines, and material needs, it became clear: the right process depends on your part.

So before you commit to a CNC job, here’s how it stacks up against other manufacturing methods and where it shines or falls short:

| Consideration | CNC Machining | 3D Printing | Injection Molding | Laser Cutting | Manual Machining |

| Best For | Functional metal and plastic parts (low to mid volume) | Prototyping, complex geometries | High-volume plastic production | Flat sheet metal parts | Simple one-offs or quick repairs |

| Precision | Very high; tight tolerances possible | Moderate; varies by material and printer type | High once molds are made | High for 2D profiles | Depends on operator skill |

| Material Options | Wide range: metals and plastics | Mostly plastics and resins | Mostly thermoplastics | Mainly metals (aluminum, steel, etc.) | Metals and plastics |

| Setup Time | Medium (needs programming and setup) | Low | High (requires mold fabrication) | Low | Low |

| Cost (Low-Volume) | Moderate to high | Low | Very high | Low | Low to moderate |

| Scalability | Flexible for prototypes and small to mid batches | Not ideal for high volume | Excellent for mass production | Limited to flat parts | Poor for high-volume jobs |

| Surface Finish | Smooth, machine-quality surface | Often rough without post-processing | Smooth (with right mold and process) | Clean edges, flat cuts | Varies by operator and tooling |

| Complex Shapes | Supports complex 3D forms with multi-axis setups | Very strong for internal complexity | Limited to mold design | Only 2D shapes | Limited without advanced tools |

Looking at it this way, CNC precision machining offers a strong middle ground. It’s accurate, flexible, and works with many materials. It’s often the best choice when quality and repeatability are important even for small batches.

7. Challenges and Solutions in CNC Precision Machining

Even with all its strengths, CNC precision machining isn’t problem-free. Like any other process on your floor, issues can creep in especially when drawings, material specs, or setup instructions are unclear.

In the early days, I assumed CNC machines would automatically “get it right.” But these machines only follow what they’re told. When the design isn’t practical or the wrong tool gets loaded, you don’t just lose time, you lose parts.

If you’re overseeing operations or sourcing jobs, here are common problems to watch for and how to fix them before they hit your schedule or budget:

Poor Design for Machinability

Not all designs are CNC-friendly. Features like deep internal pockets, sharp internal corners, or unsupported thin walls may look good in CAD, but they can be tough or expensive to machine.

Solution: Involve machinists early during the design stage. Ask for feedback on what’s practical to cut and what’s not. A few simple tweaks like adding corner radii or adjusting hole depths can save hours of machine time and reduce cost. This is known as Design for Manufacturing (DFM), and it often makes the difference between a smooth project and one full of rework.

Wrong Material Choice

Some materials are hard to cut, prone to warping, or create too much tool wear. Others might not match the strength, weight, or cost expectations for the project.

Solution: Choose materials based on both performance and machinability. For example, 6061 aluminum is a favorite for prototyping because it’s easy to cut and still strong enough for most parts. If unsure, ask the shop for their input. They often know what runs well and what to avoid.

Tolerance Issues

Sometimes a drawing calls for tight tolerances in areas that don’t need them. That adds cost and complexity. Other times, the wrong tolerances are used and parts don’t fit during assembly.

Solution: Only apply tight tolerances where they’re truly needed. Be clear about which dimensions are critical to function. Communicate with suppliers to make sure they understand which features require extra attention and which ones don’t.

8. Factors to Consider When Choosing CNC Precision Machining Services

After seeing different CNC shops over the years, some great, some not. I’ve learned that choosing the right service partner matters just as much as having a good design.

A supplier might have top-grade machines, but if communication is poor or lead times drag, the whole project suffers. Whether it’s for a quick prototype or a production run, there are a few core things to keep in mind when selecting a CNC precision machining service.

Turnaround Time

Time is money, especially when a delayed part holds up your assembly line or slows down your R&D cycle.

Before committing, ask how fast they quote, how soon they can start, and how long the job will take. Be upfront about your deadlines. A reliable shop will tell you right away if your schedule is doable or not.

Experience with Similar Projects

The first question to ask is: Have they worked with parts like yours before? Experience with similar materials, tolerances, and part features often means fewer mistakes and smoother results.

I suggest working with reliable suppliers like MachMaster. Their team has hands-on experience across industries handling diverse materials, tight tolerances, and complex part designs.

Machine Capabilities

CNC equipment isn’t one-size-fits-all. Some shops only have basic 3-axis mills. Others offer multi-axis setups, lathes, EDM, or even hybrid systems.

Think about what your part needs. Got angled holes or curved surfaces? You’ll want at least 4- or 5-axis capability. Don’t just assume, they might not have the right tools for the job. Ask what machines they use and how they handle multi-operation parts.

Tolerances and Quality Standards

Precision is the promise, but not every shop can consistently deliver on that. If your job has tight tolerances, confirm the shop’s capabilities. Ask if they follow in-house inspection protocols or hold certifications like ISO 9001.

Shops that take quality seriously will have documented processes, traceable results, and someone on the floor checking parts, not just trusting the machine.

Conclusion

From how CNC works to why details matter, you’ve got the picture now.

I once missed edge breaks and blew quotes.

We fixed that and helped clients stay ahead.

Still unsure what to do next?

MachMaster is ready to help bring that knowledge to life.

Contact us today for expert support and reliable CNC solutions!