The first CNC shop I used gave me great pricing, but forgot to mention they didn’t handle post-processing. I ended up spending more time fixing their work than I saved.

That’s when I learned that not all “full-service” machining shops are created equal.

This guide comes from hands-on projects, production runs, and years of trial and error. The companies here were chosen because they delivered when it counted.

In this article, you’ll see 8 CNC machining services that businesses actually rely on, whether for one-off prototypes or production batches.

It’s written to help you avoid the mistakes I’ve made.

Because CNC quality issues don’t just hurt your parts, they hurt your business.

Let’s get started!

Quick Comparison Chart

Here’s a comprehensive comparison table of the top 8 CNC machining service providers to help you quickly assess their strengths. This chart covers key factors like headquarters, year founded, core services, global reach, turnaround time, and certifications, so you can pick the best fit for your business needs.

| Manufacturer | HQ Location | Established | Key Services | Global Reach | Typical Turnaround Time | Certifications |

| Protolabs | USA | 1999 | CNC Machining, 3D Printing, Injection Molding, Sheet Metal | Global (US, EU, Asia) | As fast as 1 day | ISO 9001, AS9100, ISO 13485, ITAR |

| Fictiv | USA | 2013 | CNC Machining, 3D Printing, Injection Molding, Urethane Casting, Sheet Metal | Global (US + Asia) | As fast as 2 days | ISO 9001, ISO 13485, AS9100 |

| MachMaster | China | 2002 | CNC Machining, Injection Molding, Die Casting, Sheet Metal, Surface Finishing | Global | 1–7 days | ISO 9001 |

| Xometry | USA | 2013 | CNC Machining, 3D Printing, Injection Molding, Sheet Metal, Die Casting | Global (10,000+ partners) | As fast as 1 day | ISO 9001, AS9100, ISO 13485, IATF 16949, ITAR |

| RapidDirect | China | 2009 | CNC Machining, Injection Molding, 3D Printing, Sheet Metal, Vacuum Casting | Global | 1–5 days | ISO 9001, ISO 13485, ISO 14001, IATF 16949 |

| Hubs | Netherlands | 2013 | CNC Machining, 3D Printing, Injection Molding, Sheet Metal, Urethane Casting | Global (via partner network) | 3–10 days | ISO 9001 (network supports AS9100, ISO 13485) |

| Precision CNC Machining Inc. | USA | 1997 | CNC Milling & Turning, Manual Machining, Prototyping | Mainly USA | 2–10 days | ISO 9001 |

| WayKen | China | 2011 | CNC Machining, Rapid Prototyping, Injection Molding, Vacuum Casting, 3D Printing | Global | 3–7 days | ISO 9001, ISO 14001 |

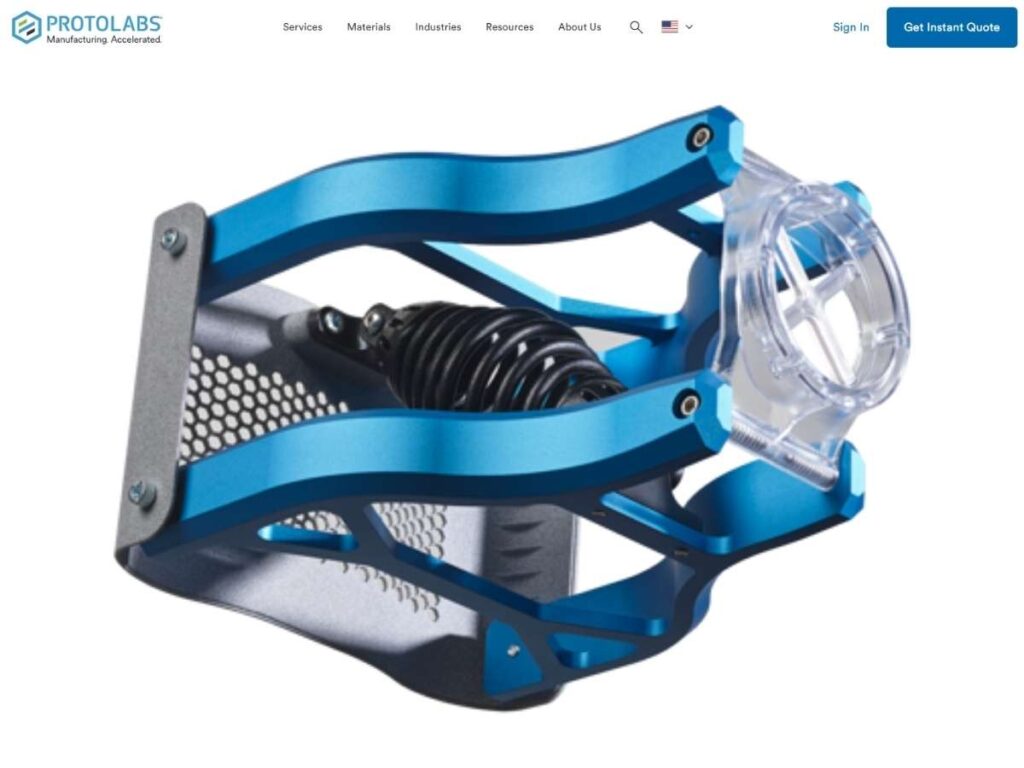

1. Protolabs

Company Background

When I first heard of Protolabs, it was during a tight-turnaround project where speed mattered more than anything else. This company has been making waves in digital manufacturing since it was founded back in 1999.

What sets them apart is how seamlessly they combine automated quoting with actual production, it’s like having an engineer on standby 24/7. Today, their global presence makes them a go-to choice for both prototypes and production parts.

Address: 5540 Pioneer Creek Dr, Maple Plain, MN 55359, USA

Established: 1999

Key Services

- CNC Machining: Offers 3-axis and 5-axis milling and turning for precision prototypes and low-volume production. Customers can choose from a wide range of materials and finishes, and even request inspection reports for quality assurance.

- Injection Molding: Rapid tooling for prototype molding as well as bridge and production molding. Great for validating plastic part designs before committing to high-volume tooling.

- 3D Printing: Provides multiple additive manufacturing processes including SLS, SLA, DMLS, PolyJet, and Multi Jet Fusion. Ideal for concept models, functional prototypes, and small-batch production.

- Sheet Metal Fabrication: Quick-turn sheet metal parts for enclosures, brackets, and other industrial components. Offers capabilities like laser cutting, bending, tapping, and welding.

- Design for Manufacturability (DFM) Analysis: Instant feedback on part geometry, wall thickness, and other manufacturing challenges. Helps you optimize designs before hitting the production floor.

- Surface Finishing: Provides bead blasting, anodizing, chromate plating, and powder coating. These finishes improve both the look and function of CNC and sheet metal parts.

Turnaround Time

Protolabs is hands-down one of the fastest manufacturers I’ve worked with. They can machine and ship parts in as little as 1 day, which is almost unheard of in the industry. Even their standard lead times are just 3 to 5 days for most CNC and 3D printing jobs. And if you’re not in a rush, they offer economy options that extend delivery but reduce cost.

Materials Supported

- Aluminum Alloys: Includes common grades like 6061-T6, 7075, and 2024. Perfect for lightweight structural parts with good machinability and corrosion resistance.

- Stainless Steel: Offers options like 304, 316, and 17-4 PH. Great for high-strength, corrosion-resistant applications including medical and aerospace parts.

- Mild and Alloy Steels: Covers materials such as 1018, 4140, and A36. Ideal for structural components that need durability and weldability.

- Titanium: Common grades include Ti-6Al-4V. Known for its excellent strength-to-weight ratio and resistance to corrosion, making it a favorite for aerospace and medical parts.

- Copper and Brass: Materials like C110 and C360 are supported. These are widely used for electrical, decorative, and low-friction components.

- Plastics: Includes ABS, polycarbonate, nylon, PEEK, and acetal. Suitable for functional prototypes, housings, and components needing chemical or electrical resistance.

- Engineering Thermoplastics: Offers advanced materials like Delrin (POM), Ultem (PEI), and PTFE. Excellent for applications requiring heat resistance, mechanical stability, or low friction.

Bottom Line

Protolabs is one of the fastest and most consistent manufacturers in the market, especially if you need instant quoting and rapid delivery. Their global infrastructure and robust quality certifications make them ideal for high-spec, low-volume parts. However, pricing can climb quickly for complex parts or premium finishes, which may not suit every budget.

2. Fictiv

Company Background

I remember running into Fictiv while researching faster ways to get aerospace parts prototyped without juggling multiple vendors. What stood out to me was how seamlessly their platform connects you to vetted manufacturers worldwide. They’ve built a name for making custom part procurement more reliable and less stressful, especially for complex jobs.

Address: 168 Welsh Street, San Francisco, CA 94107, USA

Established: 2013

Key Services

- CNC Machining: Provides high-precision 3-axis, 4-axis, and 5-axis milling as well as turning operations. Ideal for prototyping and end-use parts with tight tolerances.

- Injection Molding: Offers rapid tooling and production molding using a wide range of thermoplastics. Great for bridging the gap between prototypes and full-scale manufacturing.

- 3D Printing: Supports a variety of additive manufacturing methods including SLS, SLA, DMLS, MJF, and FDM. Perfect for complex geometries and low-volume runs.

- Urethane Casting: Delivers silicone molds and cast urethane parts with properties close to final plastics. Often used for bridge production or functional testing.

- Sheet Metal Fabrication: Includes laser cutting, bending, forming, and assembly of metal parts. Best suited for enclosures, brackets, and panels.

- Automated DFM Feedback: Instantly reviews CAD files to identify manufacturability issues. Saves time during design iterations and helps prevent costly rework.

- Global Supplier Network: Connects users to vetted manufacturing partners in North America, Asia, and other key regions. Ensures flexibility in cost, lead time, and production scale.

Turnaround Time

Fictiv stands out for its ability to meet short lead times even on complicated jobs. CNC machined parts can be delivered in as fast as 2 days, depending on material and geometry. For less time-sensitive orders, the platform also offers cost-saving options with slightly longer production cycles. I found their dynamic lead time estimator helpful when balancing urgency against budget.

Materials Supported

- Aluminum Alloys: Includes grades like 6061, 7075, and 2024. Commonly used for lightweight aerospace, automotive, and structural components.

- Stainless Steel: Offers 303, 304, 316, and 17-4 PH options. Excellent for corrosion resistance and parts that require mechanical strength.

- Carbon and Alloy Steels: Includes 1018, 4140, and 1045 steel. Ideal for high-strength parts in automotive and industrial settings.

- Titanium: Commonly supports Ti-6Al-4V. Great for weight-sensitive components that also need excellent corrosion resistance.

- Brass and Copper: Includes C360 and C110. Well-suited for electrical parts, connectors, and decorative elements due to conductivity and machinability.

- Engineering Plastics: Supports ABS, nylon, polycarbonate, PEEK, acetal, and Ultem. Suitable for prototypes, housings, fixtures, and functional testing.

- High-Performance Resins (3D Printing): Includes flexible, heat-resistant, and medical-grade options. Used in prototyping for specialized applications.

Bottom Line

Fictiv shines when it comes to combining speed, digital transparency, and a vetted global network—all with enterprise-level quality. Their DFM tools and responsive customer support make the sourcing process feel streamlined and collaborative. That said, smaller orders may come with higher price points compared to regional vendors.

3. MachMaster

Company Background

I stumbled across MachMaster while sourcing CNC parts under a tight deadline, and they didn’t just deliver quickly, they nailed the tolerances too. MachMaster has been steadily building a global client base ever since. They offer that rare blend of high precision and responsive service, even across time zones. For me, they’ve become a reliable option when quality and cost both matter.

Address: 1199 Huli Avenue, Huli District, Xiamen, Fujian 361006, China

Established: 2002

Key Services

- CNC Machining: Offers 3-, 4-, and 5-axis milling and CNC turning with tight tolerances and high repeatability. Supports both rapid prototyping and production runs.

- EDM and Wire Cutting: Electrical discharge machining capabilities enable the creation of intricate, high-precision components. Perfect for hardened steels and tight spaces.

- Plastic Injection Molding: Provides in-house tooling and molding for low- to mid-volume plastic part production. Also offers mold design and modification services.

- Sheet Metal Fabrication: Includes laser cutting, bending, stamping, and welding. Useful for fabricating enclosures, frames, and brackets.

- Rapid Prototyping: Fast-track manufacturing for design validation and functional testing. Combines speed with functional accuracy across materials.

- Die Casting: Supports both aluminum and zinc alloy die casting. Ideal for medium- to high-volume production of complex metal parts.

- Surface Finishing: In-house anodizing, electroplating, powder coating, polishing, and silk-screening. Ensures both function and visual appeal of final parts.

- Quality Control and Inspection: Includes CMM, high-precision gauges, and optional third-party inspections. All parts undergo strict tolerance verification before shipping.

Turnaround Time

What really impressed me about MachMaster was how quickly they got back with quotes—and how fast they shipped after that. They can deliver parts in as little as 1–2 days for urgent prototypes, and standard lead times hover around 5–7 days depending on complexity.

Their internal scheduling system is designed to be 30% faster than industry averages. For large-scale production, timelines remain competitive without compromising on precision.

Materials Supported

- Aluminum Alloys: Offers 6061, 7075, and other high-strength variants. Widely used for aerospace, electronics, and automotive parts requiring both strength and light weight.

- Stainless Steel: Supports 304, 316, and 17-4 PH. Ideal for high-durability parts in medical, marine, and industrial environments.

- Carbon and Alloy Steels: Includes 1018, 4140, and tool steels like D2. Commonly chosen for mechanical assemblies, gears, and structural frames.

- Brass and Copper: Offers C360, C110, and similar grades. Great for components needing conductivity, corrosion resistance, or aesthetic polish.

- Titanium: Includes Ti-6Al-4V and other aerospace-grade alloys. Preferred for medical and high-performance aerospace applications.

- Engineering Plastics: Supports ABS, POM (Delrin), polycarbonate, PMMA, PEEK, and nylon. Suitable for wear-resistant, functional, and cosmetic parts.

- Zinc and Magnesium Alloys: Available for die casting and lightweight structural parts. Useful for enclosures, housings, and high-volume metal production.

Bottom Line

MachMaster offers full-spectrum manufacturing from CNC and injection molding to anodizing and die casting—all under one roof. Their turnaround times are impressive, and they consistently deliver high-precision parts at globally competitive prices. The team is also highly responsive, and their quoting process is smooth, making them a dependable partner for international projects.

4. Xometry

Company Background

The first time I used Xometry, I was blown away by how fast their quote engine spit out a real price, and it was accurate. What makes them different is how their AI-powered system connects you to thousands of vetted suppliers worldwide. If you’re trying to juggle cost, speed, and quality in one place, Xometry tends to check all three boxes.

Address: 7529 Standish Place, Suite 200, North Bethesda, MD 20855, USA

Established: 2013

Key Services

- CNC Machining: Provides 3-, 4-, and 5-axis milling and turning with tolerances down to ±0.001″. Offers prototyping and production machining with optional inspection reports.

- 3D Printing: Includes SLS, SLA, MJF, DMLS, FDM, and PolyJet technologies. Useful for functional prototypes, end-use parts, and rapid design iterations.

- Injection Molding: Offers rapid tooling and full production runs with a wide range of thermoplastics and elastomers. Also includes mold flow analysis and T1 samples.

- Sheet Metal Fabrication: Provides laser cutting, bending, stamping, and welding. Used for chassis, housings, brackets, and custom enclosures.

- Urethane Casting: Ideal for bridge production and functional prototypes that mimic injection-molded plastic performance. Supports a range of polyurethane materials.

- Die Casting and Metal Extrusion: Available through its global partner network. Helps reduce cost and complexity for medium- to high-volume production parts.

- Finishing Services: Includes anodizing, powder coating, painting, plating, and heat treatment. Helps bring cosmetic and functional characteristics to end-use components.

- DFM and Real-Time Quoting Engine: Instant, AI-driven pricing and manufacturability feedback when you upload a CAD file. Optimizes design choices before production.

Turnaround Time

Xometry is known for speed, especially when you’re in a bind. They can ship CNC parts in as little as 1 business day if you select expedited options. For most standard orders, lead times are around 3–7 days, depending on the material, geometry, and finish. Their platform also offers economy options if you want to trade time for cost savings, and it’s easy to compare those options during quoting.

Materials Supported

- Aluminum Alloys: Offers 6061, 7075, 2024, and others. Lightweight, strong, and highly machinable—ideal for aerospace, automotive, and consumer products.

- Stainless Steel: Includes grades like 304, 316, 17-4 PH, and 303. Excellent for corrosion resistance and applications requiring durability under harsh conditions.

- Carbon and Alloy Steels: Includes 1018, 4140, A36, and D2 tool steel. Common in structural parts, tooling, and mechanical assemblies.

- Titanium: Supports Ti-6Al-4V and other aerospace-grade options. Combines high strength, low weight, and excellent corrosion resistance.

- Brass and Copper: Offers C360, C260, and C110 grades. Perfect for thermal or electrical conductivity, often used in electronics and plumbing parts.

- Engineering Plastics: Includes ABS, polycarbonate, PEEK, nylon, PTFE, acetal, and more. Suitable for housings, insulators, gears, and functional test parts.

- Composites and Exotic Materials: Offers Inconel, carbon fiber composites, magnesium, and more. Great for high-temperature, high-stress, or specialty use cases.

Bottom Line

Xometry is excellent for anyone looking for a one-stop digital solution that covers nearly every manufacturing process imaginable. Their instant quoting engine and ability to scale from prototype to production make them a favorite among engineers. However, the vast partner network can sometimes result in variability in finish or communication depending on the selected supplier.

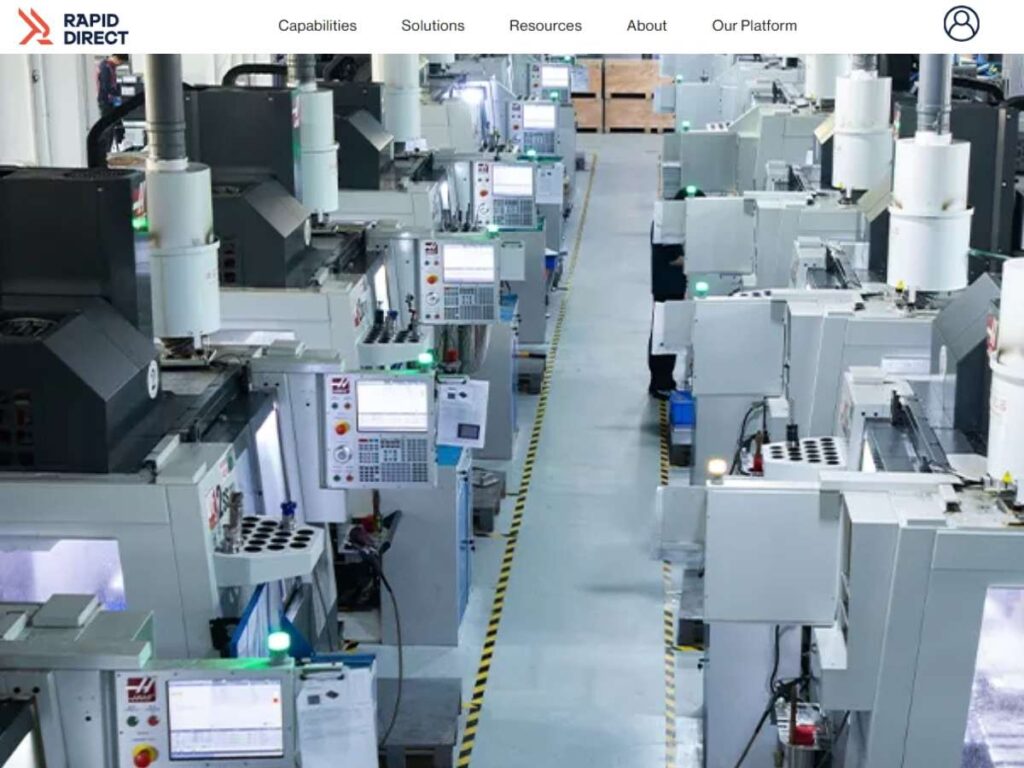

5. RapidDirect

Company Background

I came across RapidDirect while looking for CNC suppliers that could hit tight tolerances without breaking the bank, and they didn’t disappoint. The company has grown into a full-stack custom parts manufacturer with a global footprint. What I really appreciated was their ability to pair local production speed with international-grade quality systems.

Address: 3rd Floor, Building B, Mingjun Industrial Park, Liuxian 2nd Road, Bao’an District, Shenzhen, Guangdong, China

Established: 2009

Key Services

- CNC Machining: Offers 3-, 4-, and 5-axis CNC milling and turning with tight tolerances and consistent quality. Suitable for both prototypes and small-to-mid-size production runs.

- Injection Molding: Provides rapid tooling and production injection molding using a wide range of thermoplastics and elastomers. Great for functional testing and low-volume batches.

- 3D Printing: Covers SLA, SLS, FDM, and MJF printing. Best used for complex geometries and quick-turn prototyping needs.

- Sheet Metal Fabrication: Includes cutting, bending, stamping, and welding. Used for fabricating precision metal enclosures, brackets, and structural components.

- Vacuum Casting: Produces polyurethane parts from silicone molds. Ideal for bridge production and testing before investing in full tooling.

- Die Casting: Offers aluminum, magnesium, and zinc alloy die casting. Perfect for high-volume production requiring detailed, durable metal parts.

- Surface Finishing: Provides anodizing, bead blasting, powder coating, plating, and painting. Enhances both appearance and corrosion resistance.

- Online Quoting Platform: Upload your CAD files to receive instant pricing and design-for-manufacturing feedback. Streamlines project setup and cuts back-and-forth delays.

Turnaround Time

RapidDirect lives up to its name with genuinely fast production cycles. CNC parts can be manufactured and shipped in as little as 1 to 3 days, depending on geometry and material. Standard lead times are around 5 to 7 days, with additional days for finishing processes. Their online system speeds up quoting and order processing, making it easy to launch a job quickly, even across time zones.

Materials Supported

- Aluminum Alloys: Offers 6061, 7075, 2024, and more. Excellent for aerospace, robotics, and general-purpose lightweight structures.

- Stainless Steel: Supports 304, 316, 17-4 PH, and other corrosion-resistant grades. Common in medical, food-grade, and marine applications.

- Carbon and Alloy Steels: Includes 1018, 4130, 4140, and tool steels. Great for durable, high-stress mechanical parts.

- Titanium: Primarily Ti-6Al-4V. Used for aerospace and medical applications where strength and corrosion resistance are crucial.

- Brass and Copper: Offers grades like C360 and C110. Preferred for electronic components, thermal systems, and aesthetic parts.

- Engineering Plastics: Includes ABS, nylon (PA6/PA66), PC, POM (Delrin), PMMA, PEI, PEEK, and PTFE. Great for housings, mechanical parts, and high-performance prototypes.

- Magnesium and Zinc Alloys: Commonly used for die casting. Useful for lightweight casings and high-volume production with tight tolerances.

Bottom Line

RapidDirect is a solid pick if you’re after fast lead times, a broad material selection, and competitive pricing from a China-based supplier. Their online platform is smooth, and they back up production with proper certifications and quality controls. Still, for highly regulated industries, additional QA verification might be necessary to meet stricter standards.

6. Hubs

Company Background

When I needed parts produced outside the U.S. but still wanted reliable quality, Hubs quickly became my go-to. Hubs originally started as a peer-to-peer 3D printing platform before evolving into a global manufacturing network. Since being acquired by Protolabs, they’ve expanded their reach and now offer access to hundreds of vetted manufacturers worldwide.

Address: John M. Keynesplein 12-46, 1066 EP Amsterdam, Netherlands

Established: 2013

Key Services

- CNC Machining: Provides 3-axis, 4-axis, and 5-axis CNC milling and turning services. Supports both prototypes and end-use parts with tolerances down to ±0.001″.

- 3D Printing: Offers SLA, SLS, MJF, FDM, DMLS, and PolyJet technologies. Ideal for complex geometries, concept models, and low-volume production.

- Injection Molding: Delivers rapid tooling and production-grade molding using a wide range of plastic and elastomer materials. Great for bridge production and functional prototypes.

- Sheet Metal Fabrication: Includes laser cutting, punching, bending, welding, and hardware insertion. Used to create metal enclosures, brackets, and custom panels.

- Urethane Casting: Produces cast urethane parts from silicone molds. Useful for low-quantity production and material testing.

- Surface Finishing: Offers anodizing, powder coating, bead blasting, painting, and electroplating. Helps improve part appearance, durability, and corrosion resistance.

- Automated Quoting and DFM Feedback: Instant online quotes with built-in design-for-manufacturability checks. Helps refine your design before production begins.

- Global Manufacturing Network: Access to a broad network of partners across Europe, Asia, and the Americas. Gives you the choice between fast local production or lower-cost overseas options.

Turnaround Time

Hubs is designed for speed and flexibility. CNC parts are typically delivered in 5–10 business days, while 3D printed parts can ship in as fast as 1–3 days depending on the technology and region. The platform allows you to compare lead times across different materials and suppliers in real time. For international orders, Hubs handles logistics and duties, so even global shipping stays efficient.

Materials Supported

- Aluminum Alloys: Includes 6061, 7075, 6082, and more. Lightweight, corrosion-resistant, and widely used across industries like aerospace, automotive, and electronics.

- Stainless Steel: Offers 304, 316, 17-4 PH, and other industrial grades. Common in medical, food-safe, and marine environments due to its corrosion resistance.

- Carbon and Alloy Steels: Covers 1018, 4140, A36, and tool steels like D2 and A2. Used in structural, industrial, and high-wear applications.

- Titanium: Features aerospace-grade Ti-6Al-4V and similar alloys. Perfect for weight-sensitive, high-strength parts in aerospace and healthcare.

- Brass and Copper: Provides options like C360 and C110. Good for electrical applications, fittings, and aesthetic components.

- Plastics: Includes ABS, polycarbonate, POM, PEEK, PTFE, nylon, acrylic, and more. Suitable for both prototyping and functional components.

- High-Performance Resins (3D Printing): Offers flexible, transparent, and heat-resistant resins for specialized prototype needs.

- Composites and Exotic Materials: Includes Inconel, carbon fiber-infused polymers, and magnesium alloys. Best for advanced or extreme-use applications.

Bottom Line

Hubs gives you access to a wide array of manufacturing capabilities across a global supplier network, backed by Protolabs’ quality standards. Their platform makes it easy to compare cost, lead time, and options across multiple suppliers instantly. The only trade-off is that production isn’t done in-house, so direct control over the process is limited.

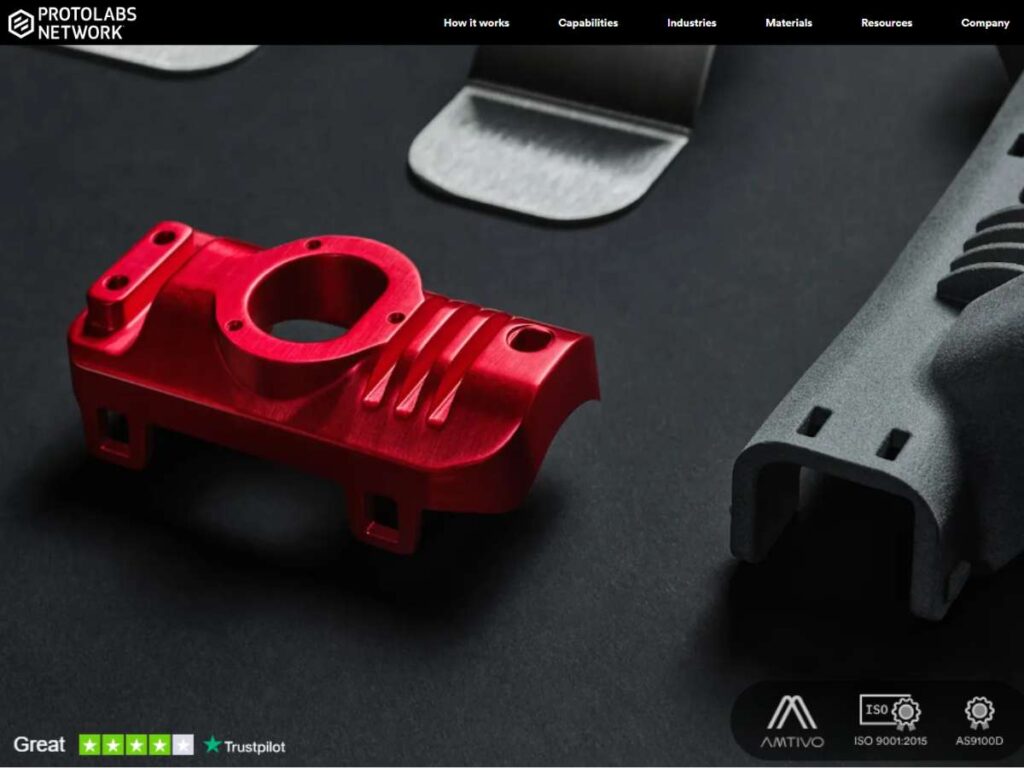

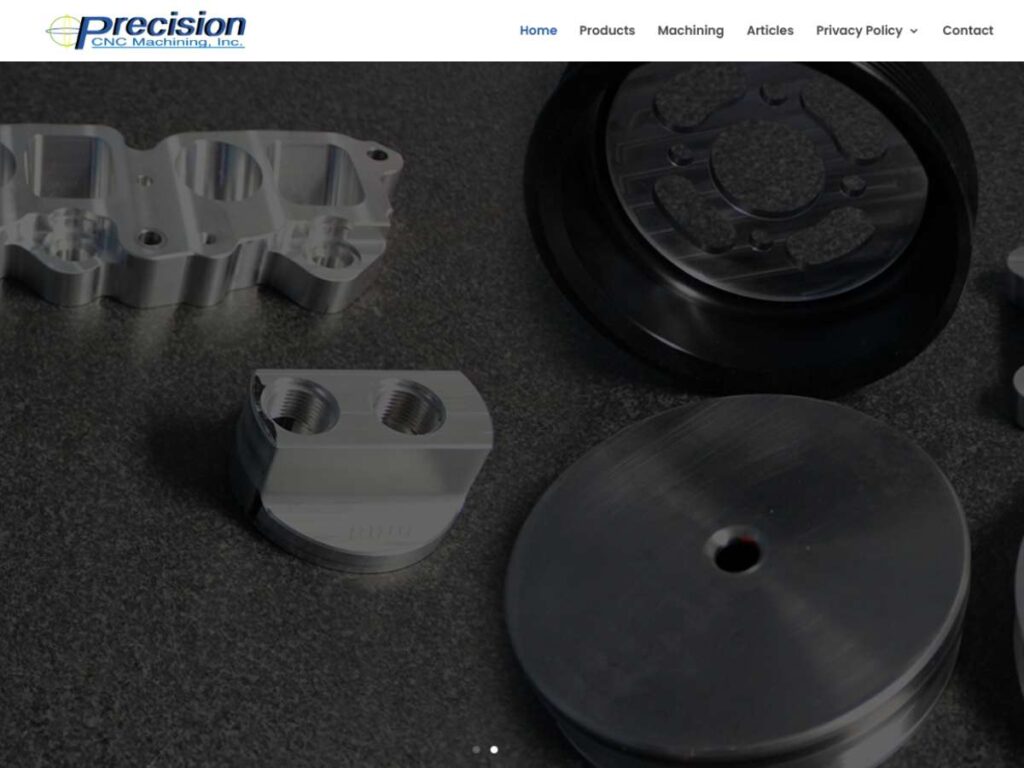

7. Precision CNC Machining Inc.

Company Background

I first heard about Precision CNC Machining Inc. from a colleague who needed medical-grade components machined with zero tolerance for error. This company has built a reputation for producing high-precision parts for critical industries. What stood out to me was their balance of personalized service and industrial-grade capabilities. For U.S.-based businesses that value responsive communication, they’re a dependable partner.

Address: 1659 Walter Street, Suite C, Oxnard, CA 93036, USA

Established: 1997

Key Services

- CNC Milling: Provides 3-axis and 4-axis milling using HAAS machines with precision fixturing. Ideal for complex prismatic parts and multi-face machining.

- CNC Turning: Offers high-accuracy lathe work for cylindrical components. Suited for aerospace pins, shafts, and defense connectors.

- Manual Machining: Equipped with manual mills and lathes for secondary ops or low-volume custom work. Great for one-offs or simple parts that don’t need CNC precision.

- Prototype Machining: Supports low-quantity runs with fast turnarounds. Helps engineers test and refine designs before scaling up.

- Production Machining: Handles mid- to high-volume machining jobs with consistent quality. Useful for repeat orders and long-term part programs.

- Inspection and Quality Control: All parts undergo in-process and final inspections with calibrated instruments. Ensures every part meets spec before shipment.

- Material Sourcing and Certification: Procures certified raw materials and includes full traceability upon request. Supports defense, medical, and regulated industry needs.

Turnaround Time

What I like most about Precision CNC is their ability to pivot based on urgency. For small prototype orders, they can deliver parts in as little as 2–3 business days, depending on shop load. Standard lead times for production runs fall within 1–2 weeks, with rush jobs accommodated when capacity allows. Their flexibility and clear communication make timing much easier to manage on the customer side.

Materials Supported

- Aluminum Alloys: Includes 6061, 7075, and 2024. Used for lightweight aerospace components, brackets, and electronic housings.

- Stainless Steel: Supports grades like 303, 304, 316, and 17-4 PH. Excellent for parts requiring corrosion resistance and medical or food-grade compliance.

- Carbon and Alloy Steels: Offers 1018, 1045, 4130, and 4140. Commonly used in structural components and industrial machinery.

- Tool Steels: Machine materials like D2, A2, and O1. Great for jigs, fixtures, and wear-resistant applications in aerospace and defense.

- Titanium: Works with Ti-6Al-4V and other grades. Perfect for medical implants, aerospace fasteners, and ultra-strong structural parts.

- Brass and Copper: Provides machining for C360 and C110 grades. Frequently used in electrical hardware, fittings, and decorative parts.

- Engineering Plastics: Includes Delrin (POM), polycarbonate, acrylic, Ultem (PEI), and PEEK. Suitable for insulators, test fixtures, and precision medical or lab equipment.

Bottom Line

Precision CNC is a dependable U.S.-based partner for high-tolerance, small-batch parts in regulated industries like aerospace and defense. Their hands-on service and ISO-certified processes provide peace of mind for sensitive or complex orders. However, their capacity and reach may not be suited for very high-volume or international needs.

8. WayKen

Company Background

I discovered WayKen when I was on a tight timeline and needed a supplier that could handle both prototype machining and cosmetic finishes. What I liked most was their ability to support everything from concept models to short-run production without the need to switch vendors. They’re especially good when aesthetics and function both matter.

Address: Building B, No. 2, Tangtou 1st Industrial Zone, Shiyan, Bao’an, Shenzhen, Guangdong 518108, China

Established: 2011

Key Services

- CNC Machining: Offers 3-axis, 4-axis, and 5-axis milling and turning. Great for everything from simple brackets to highly detailed, multi-surface parts.

- Rapid Prototyping: Specializes in fast-turn prototypes for visual presentation, functional testing, and pre-production. Combines speed with tight tolerances.

- Plastic Injection Molding: Provides rapid tooling and low-volume production molding. Ideal for bridge tooling and initial production runs.

- Vacuum Casting: Produces urethane parts from silicone molds, simulating injection-molded materials. Useful for short-run plastic parts with production-like appearance.

- 3D Printing: Includes SLA and SLS printing services for detailed plastic parts. Supports early-stage prototyping and concept modeling.

- Sheet Metal Fabrication: Offers laser cutting, bending, and welding for simple or complex sheet metal parts. Common for enclosures and support structures.

- Surface Finishing: Performs polishing, anodizing, painting, plating, tinting, and chrome-like finishes. Delivers high-end cosmetic surfaces for appearance models.

- Optical Prototyping: Specializes in transparent plastic parts like automotive lenses and light guides. Provides polishing and coating for optical clarity.

Turnaround Time

WayKen is known for its fast and flexible delivery options. CNC and 3D printed parts can often be produced in as little as 3–7 business days, depending on geometry and finish. For vacuum casting and rapid tooling, expect 2–3 weeks, which is still quick compared to traditional methods. Their engineers typically reply to quote requests within 24 hours, and their production team runs multiple shifts to meet urgent needs.

Materials Supported

- Aluminum Alloys: Includes 6061, 7075, and 2024. Used for enclosures, brackets, automotive housings, and prototype tooling.

- Stainless Steel: Offers 304, 316, and 17-4 PH. Perfect for corrosion-resistant parts in medical, marine, and consumer applications.

- Carbon and Tool Steels: Supports 1018, 4140, and D2, among others. Best for mechanical parts and test fixtures requiring strength and durability.

- Titanium: Works with Ti-6Al-4V and similar aerospace-grade alloys. Ideal for high-performance components in medical and aerospace fields.

- Brass and Copper: Offers machining for C360 and C110. Excellent for electrical, heat transfer, and aesthetic applications.

- Engineering Plastics: Supports ABS, POM, PC, PMMA, PEEK, PEI, and PTFE. Used for functional prototypes, gears, housings, and insulative components.

- Urethane Resins: Offers a wide range of PU materials via vacuum casting. Mimics the look, feel, and mechanical properties of production plastics.

- Clear Plastics: Specializes in transparent materials like PMMA and PC for optical applications. Ideal for light covers, display parts, and lenses.

Bottom Line

WayKen combines technical versatility with polished presentation, making them a top choice for detailed prototypes and cosmetic models. Their ability to handle everything from CNC to transparent plastic polishing is genuinely impressive. Just be aware that while they excel in low-volume work, scaling to high production may require switching to another supplier.

Conclusion

Choosing the right CNC partner isn’t easy. I’ve made the wrong call before, and it stung.

But you? You’ve now got a shortcut.

This guide walks you through eight top-tier machining services. What they do, where they shine, and how they help.

Still hesitating?

MachMaster offers everything under one roof: machining, molding, sheet metal, and finishing.

Contact us today and let’s build something that lasts.