A business owner once told me, “We thought we found a solid CNC supplier in China, until we received 500 units with the wrong hole diameters.”

It wasn’t a small mistake—it was a showstopper.

That’s when they called me for help.

I’ve worked with CNC manufacturers all over China, from the busy shops in Dongguan to specialized teams in Ningbo.

I help companies avoid mistakes like this by connecting them with the right-fit machining partners.

This article highlights 9 top-tier CNC machining services in China that I trust and recommend. Each one is different, and I’ll walk you through what they’re good at and how to work with them efficiently.

So, let’s get started!

Quick Comparison Chart

Here’s a comprehensive comparison chart summarizing the top CNC machining service providers in China. This chart highlights their core strengths, capabilities, certifications, and best-fit use cases to help you quickly identify the right manufacturing partner for your needs

| Manufacturer | Location | Year Established | Core CNC Services | Other Capabilities | Material Range | Certifications | Best For |

| MachMaster | Xiamen, Fujian | 2002 | Milling, Turning | Injection Molding, Die Casting, Surface Finishing | Metals & Plastics | ISO 9001 | Reliable all-round CNC machining |

| WayKen Rapid Manufacturing | Shenzhen, Guangdong | 2013 | Milling, Turning, 5-Axis | 3D Printing, Vacuum Casting, Sheet Metal | Metals & Plastics | ISO 9001 | Rapid prototyping & tight tolerance parts |

| 3ERP | Zhongshan, Guangdong | 2008 | Milling, Turning, EDM | Injection Molding, Die Casting, Sheet Metal | Metals & Plastics | ISO 9001 | Precision prototyping & low-volume production |

| RapidDirect | Shenzhen, Guangdong | 2009 | Milling, Turning, EDM, Routing | Injection Molding, Die Casting, 3D Printing | Metals & Plastics | ISO 9001:2015 | Digital manufacturing & scalable projects |

| HLH Prototypes | Shenzhen/Dongguan, Guangdong | 2008 | 3-, 4-, 5-Axis CNC | 3D Printing, Injection Molding, Sheet Metal, Vacuum Casting | Metals & Plastics | ISO 9001:2015, ISO 13485, ISO 14001, IATF 16949, ISO 27001 | Comprehensive prototyping & certified manufacturing |

| Machining-4U (Xometry China) | Shanghai | 2013 | Milling, Turning | 3D Printing, Sheet Metal, Injection Molding, Die Casting | Metals & Plastics | ISO 9001:2015, ISO 13485, AS9100D, IATF 16949 | Mass production with digital workflow |

| Runsom Precision | Dongguan, Guangdong | 2005 | Milling, Turning, Swiss CNC | 3D Printing, Sheet Metal, Rapid Prototyping | Metals & Plastics | ISO 9001:2015 | Complex geometries & custom parts |

| AT-Machining | Dongguan, Guangdong | 2010 | Milling, Turning, Swiss CNC, EDM | Wire EDM, Sheet Metal, Surface Finishing | Metals & Plastics | ISO 9001:2015, RoHS, Material Certifications | High-precision, small technical parts |

| DEK Manufacturing | Shenzhen, Guangdong | 2002 | 5-Axis, Milling, Turning, Swiss CNC, EDM | Precision Grinding, 3D Printing, Sheet Metal | Metals, Plastics, Superalloys | ISO 9001:2015, ISO 13485, AS9100D | Certified production for aerospace, medical |

1. MachMaster

When I first worked with MachMaster, I noticed something different right away.

They didn’t just talk about precision. They actually delivered it. Every part arrived on time and exactly as promised, with no need for rework or clarification.

What really impressed me was how they blend high-end tech with real hands-on expertise. Their team knows the tools, but they also understand the craft. Nothing felt rushed or careless.

It’s no surprise they’ve built such a solid reputation over the years. You can count on them to get it right, even with complex or time-sensitive jobs.

- Location: 202 Tianfeng Road, Xiamen, Fujian, China

- Year Established: 2002

Key Services

- CNC Milling Services: MachMaster specializes in 3-axis and 4-axis CNC milling, ideal for precision prototypes and custom production runs. Their advanced machines ensure high accuracy and consistent quality, meeting diverse project requirements efficiently.

- CNC Turning Services: Offering rapid CNC turning, MachMaster produces custom components with intricate details such as axial holes, radial slots, and grooves. Their CNC lathes ensure quick turnaround times, often completing orders in as few as three days.

- Injection Molding: They provide comprehensive plastic injection molding services, perfect for creating complex plastic parts. MachMaster also supports a variety of surface finishes, ensuring your products meet both functional and aesthetic standards.

- Die Casting: Specializing in aluminum and zinc alloy die casting, MachMaster creates high-quality, durable metal components. Their die-casting services meet strict dimensional tolerances and surface finish requirements.

- Sheet Metal Fabrication: MachMaster offers end-to-end sheet metal fabrication services, including laser cutting, bending, welding, and finishing. Their expert team handles each stage meticulously to produce precise and robust metal parts.

- Surface Finishing Services: To ensure parts are production-ready, MachMaster provides finishing options such as anodizing, painting, powder coating, and polishing. These finishing processes enhance durability and aesthetics to meet industry standards.

Materials They Work With

- Aluminum: Lightweight yet durable, aluminum is perfect for components needing strength without excessive weight. MachMaster expertly machines aluminum parts suited for automotive, aerospace, and industrial uses.

- Stainless Steel: Highly corrosion-resistant, stainless steel is ideal for demanding environments. MachMaster’s stainless steel machining delivers precision components for medical, marine, and food processing industries.

- Brass: Brass offers excellent machinability and electrical conductivity, making it suitable for gears, fittings, and precision components. MachMaster crafts brass parts tailored to specific application needs.

- Copper: Known for superior conductivity, copper is used widely in electrical applications. MachMaster machines copper into custom components ideal for electronics and heat-transfer solutions.

- Titanium: With exceptional strength and corrosion resistance, titanium is essential for aerospace and medical components. MachMaster provides precise machining solutions for this challenging material.

- ABS (Acrylonitrile Butadiene Styrene): ABS is tough, durable, and easily moldable, making it popular for injection-molded parts. MachMaster frequently employs ABS to create detailed, impact-resistant components.

- PC (Polycarbonate): Polycarbonate is strong, transparent, and impact-resistant, commonly used for lenses and housings. MachMaster excels at machining PC for precision applications requiring transparency and toughness.

- POM (Polyoxymethylene): Known as Delrin, POM provides low friction and high rigidity, suitable for precision gears and bearings. MachMaster ensures tight tolerances when machining this versatile plastic.

- Nylon (PA): Nylon combines strength, chemical resistance, and wear resistance, making it ideal for mechanical parts. MachMaster efficiently produces nylon components that withstand tough conditions.

- PMMA (Acrylic): Acrylic offers excellent clarity and resistance to weathering, widely used in transparent parts. MachMaster expertly handles PMMA machining for applications demanding optical clarity.

- PEEK (Polyether Ether Ketone): Known for its heat resistance and strength, PEEK is crucial in high-performance engineering applications. MachMaster reliably produces complex, high-quality PEEK components for demanding industries.

Bottom Line

MachMaster checks every box when it comes to CNC machining reliability: consistent quality, fast turnaround, and exceptional customer service.

Their ability to handle both small and large orders while maintaining tight tolerances sets them apart. There’s no downside here, they simply deliver what they promise, every time.

2. WayKen Rapid Manufacturing

WayKen Rapid really impressed me with how fast they turned around high-precision prototypes.

They didn’t just meet expectations. They hit every detail with accuracy and consistency. Even on a tight timeline, nothing slipped.

Their mix of advanced CNC tech and real-world know-how makes a big difference. You can tell their team knows what they’re doing and that they care about getting it right.

If your project depends on precision, reliability, and speed, WayKen is exactly the kind of partner you want on your side.

- Location: Penglongpan Hi-tech Park, Dafu Rd, ShenZhen, China

- Year Established: 2013

Key Services

- CNC Milling Services: WayKen provides precise CNC milling with capabilities in 3-axis, 4-axis, and 5-axis machining. They handle complex parts with intricate designs, ensuring accuracy and quick turnaround.

- 5-Axis CNC Machining: WayKen’s advanced 5-axis CNC machining allows manufacturing of highly complex components in fewer setups. This reduces production time and enhances accuracy, essential for sophisticated aerospace and automotive applications.

- Vacuum Casting: WayKen uses vacuum casting for low-volume, production-quality plastic parts. This process is cost-effective for small runs, enabling the creation of durable, functional prototypes.

- Rapid Tooling & Injection Molding: They offer rapid tooling solutions, quickly producing aluminum and steel molds for injection molding. This method is cost-effective and perfect for low-volume runs and quick production changeovers.

- Parts Finishing Services: To enhance product aesthetics and durability, WayKen provides comprehensive finishing services, including anodizing, painting, powder coating, and polishing. These services ensure your prototypes or components are ready for end-use applications.

Materials They Work With

- Aluminum: Lightweight yet strong, aluminum is used extensively by WayKen for automotive, aerospace, and electronics applications. It provides excellent machinability and versatility for various design requirements.

- Stainless Steel: Known for durability and corrosion resistance, stainless steel is ideal for precision parts in demanding environments. WayKen regularly machines stainless steel components for medical and industrial applications.

- Brass: With excellent machinability and conductivity, brass is preferred for gears, fittings, and decorative parts. WayKen produces high-quality brass components customized to exact specifications.

- Copper: Highly conductive and resistant to corrosion, copper is widely used in electrical components and heat exchangers. WayKen ensures precise machining of copper parts suited for electronics and energy applications.

- Titanium: Known for high strength, lightweight, and corrosion resistance, titanium is popular in aerospace and medical industries. WayKen expertly machines titanium parts to tight tolerances.

- ABS (Acrylonitrile Butadiene Styrene): ABS is tough and versatile, widely used in rapid prototyping and injection molding for parts requiring durability. WayKen frequently molds and machines ABS for functional prototypes and production parts.

- PC (Polycarbonate): Polycarbonate is known for its strength, transparency, and impact resistance, ideal for transparent enclosures or lenses. WayKen precisely machines PC components to meet tight tolerances.

Bottom Line

WayKen excels at fast prototyping and custom low-volume manufacturing, with a strong focus on finish quality and material variety. Their one-on-one engineering support adds real value for teams needing design guidance.

However, for high-volume production needs, they may not be as cost-effective as other providers.

3. 3E Rapid Prototyping (3ERP)

What really makes 3ERP stand out is how effortlessly they handle complex manufacturing.

From the first quote to final delivery, everything feels smooth and well-organized. You get the precision, speed, and clear updates you’d expect from a global supplier, but without the red tape or communication gaps.

They’re responsive, detail-oriented, and genuinely invested in getting your parts right the first time. Even when projects get technical, they don’t flinch.

If you want a CNC partner that respects your timelines and understands what’s at stake, 3ERP is one of the few I’d put at the top of the list.

- Location: GangKou, ZhongShan City, GuangDong Province, China

- Year Established: 2008

Key Services

- CNC Machining: 3ERP provides precision CNC milling, turning, and EDM machining, accommodating tolerances as tight as ±0.01 mm. Their services are ideal for producing prototypes and precision parts for various industries.

- Rapid Prototyping: Offering fast-turnaround prototyping solutions, 3ERP utilizes CNC machining, 3D printing (SLA, SLS), and vacuum casting. These services help businesses quickly validate their product designs before mass production.

- Injection Molding: 3ERP offers rapid tooling and low-volume injection molding services. They efficiently produce functional plastic components ideal for testing and small production runs at competitive costs.

- Sheet Metal Fabrication: Their sheet metal capabilities include laser cutting, bending, stamping, spinning, and welding. They deliver accurate, robust metal prototypes and small-batch production parts suited for numerous applications.

- Pressure Die Casting: Specializing in aluminum, zinc, and magnesium die casting, 3ERP can efficiently create precise, high-quality metal components. These services are suitable for automotive, industrial, and electronics applications.

- Surface Finishing: 3ERP provides comprehensive finishing services including anodizing, painting, powder coating, and polishing. These enhance part durability, aesthetics, and corrosion resistance.

Materials They Work With

- Aluminum: Widely preferred for its excellent machinability and corrosion resistance, aluminum is frequently utilized for aerospace, automotive, and consumer electronics parts. 3ERP consistently produces high-quality aluminum components to precise specifications.

- Brass: Known for excellent machinability and electrical conductivity, brass is commonly used for fittings, gears, and decorative components. 3ERP reliably fabricates brass parts with precision and consistency.

- Copper: Highly conductive and corrosion-resistant, copper is ideal for electronic components and heat-transfer applications. 3ERP provides expert machining services to create intricate copper components.

- Steel: With exceptional strength and durability, steel is suitable for parts requiring structural integrity and longevity. 3ERP efficiently processes various steel grades for both prototyping and low-volume production.

- Stainless Steel: Resistant to corrosion and staining, stainless steel is perfect for medical, food-grade, and marine components. 3ERP machines stainless parts that meet tight engineering and industry-specific standards.

- Bronze: Durable and wear-resistant, bronze is ideal for bushings, bearings, and marine applications. 3ERP offers precision bronze machining for both functional and decorative uses.

- Titanium: With a high strength-to-weight ratio and corrosion resistance, titanium is critical for aerospace and high-performance applications. 3ERP has the tooling and expertise to handle titanium with precision.

- Magnesium: Lightweight and strong, magnesium is suited for automotive and aerospace applications where weight matters. 3ERP handles magnesium with care to ensure consistent machining without distortion.

Bottom Line

3ERP blends Western-standard project management with Chinese production efficiency, making them easy to work with across time zones.

Their precision in CNC machining and versatility across services is a major asset. The only drawback is that ultra-rush jobs might require closer coordination to hit tight deadlines.

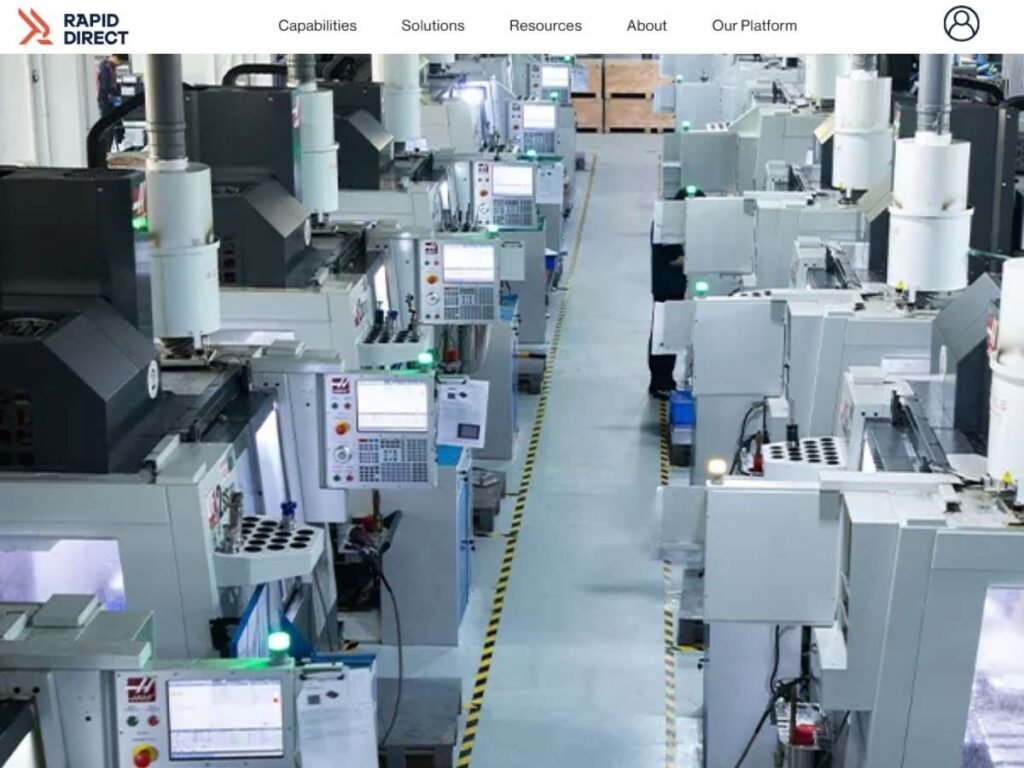

4. RapidDirect

There’s something refreshingly modern about the way RapidDirect runs its operation.

From their instant online quoting system to how quickly they respond, everything feels built for real-world production speed. It’s efficient, but never rushed.

You don’t deal with endless back-and-forth or long gaps in updates. Instead, your project moves forward with clarity, confidence, and solid quality control at every step.

If you’re juggling tight timelines and need a CNC partner that keeps up without cutting corners, RapidDirect is a smart, forward-thinking choice.

- Location: Building A12, Haosi Industrial Park, Nanpu Road, Xinqiao Street, Bao’an District, Shenzhen, China

- Year Established: 2009

Key Services

- CNC Machining: RapidDirect offers CNC milling, turning, drilling, routing, EDM, and precision grinding. With over 700 machines, they can handle everything from simple prototypes to highly complex custom parts with tight tolerances.

- Injection Molding: Their rapid tooling and injection molding services cover overmolding, insert molding, and production-grade runs. It’s a solid solution if you’re scaling from prototyping to low-volume manufacturing.

- 3D Printing: The company leverages SLA, SLS, SLM, and MJF technologies to produce detailed plastic and metal parts. This is perfect for rapid prototyping or small-batch end-use components.

- Die Casting: They offer aluminum, zinc, and magnesium die casting with precise tooling and consistent output. These are great options for durable, high-volume metal parts.

- Vacuum Casting: Ideal for short-run production or functional testing, their vacuum casting process replicates high-detail parts in polyurethane resins. The result mimics injection-molded quality without the tooling cost.

- Surface Finishing: RapidDirect offers over 30 finishing options including anodizing, bead blasting, powder coating, and polishing. These services help improve the performance, appearance, and longevity of your parts.

Materials They Work With

- Aluminum: A favorite for lightweight strength and corrosion resistance, aluminum is used widely across aerospace, automotive, and consumer products. RapidDirect machines and finishes aluminum with tight precision.

- Copper: Known for its thermal and electrical conductivity, copper is essential for power systems and electronics. Their machining process maintains tight tolerances while preserving conductivity.

- Stainless Steel: Strong and corrosion-resistant, stainless steel is ideal for harsh environments and structural parts. RapidDirect works with several grades for everything from medical to marine use.

- Brass: Brass provides excellent machinability and a bright finish, making it ideal for gears, valves, and aesthetic parts. Their team produces detailed components with smooth finishes and precise dimensions.

- Titanium: High strength, low weight, and top-tier corrosion resistance make titanium a premium material. RapidDirect machines it for industries like aerospace and medical with advanced tools and know-how.

- PA (Nylon): Nylon’s wear resistance and chemical stability make it great for structural parts. They mold and machine nylon to create bushings, spacers, and load-bearing components.

- PMMA (Acrylic): Acrylic is great for clear parts that need rigidity and UV resistance. RapidDirect machines it to optical standards for displays, panels, and enclosures.

- PEEK (Polyether Ether Ketone): PEEK excels in high-heat and chemically aggressive environments. It’s commonly used in aerospace and medical applications, and they machine it with extreme precision.

Bottom Line

RapidDirect offers a very polished and user-friendly digital experience, backed by a vast manufacturing network. Their real-time quoting and wide range of finishing options make them especially convenient for scaling projects.

The tradeoff is that consistency can vary slightly depending on which partner facility fulfills your order.

5. HLH Prototypes

HLH Prototypes has always stood out to me for how well they blend Western-style service with Eastern efficiency.

Their team is sharp, responsive, and easy to work with. You never feel like you’re chasing updates or clarifying instructions.

They also offer a wide range of in-house services, which means fewer handoffs and fewer delays. Everything moves faster, with better control over quality.

If you’re looking for a CNC partner who gets both the technical details and the business side right, HLH is one of the best I’ve worked with.

- Location: 1801 Xing Ji Building, Xin Sha Road Shajing, Baoan, Shenzhen, China

- Year Established: 2008

Key Services

- CNC Machining: HLH offers 3-, 4-, and 5-axis CNC milling and turning services, capable of producing parts with tight tolerances and complex geometries.

- Vacuum Casting: Their vacuum casting services are perfect for producing small batches of plastic parts that mimic the properties of injection-molded components.

- Sheet Metal Fabrication: HLH provides sheet metal services, including laser cutting, bending, welding, and forming, catering to various industries.

- Die Casting: They offer die casting services for aluminum, zinc, and magnesium alloys, suitable for producing high-strength metal parts.

- Surface Finishing: HLH provides a range of finishing options, such as anodizing, painting, powder coating, and polishing, to enhance the appearance and durability of parts.

Materials They Work With

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for aerospace, automotive, and consumer electronics applications.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is used in medical devices, food processing, and marine applications.

- Titanium: Known for its high strength-to-weight ratio and corrosion resistance, titanium is used in aerospace, medical, and high-performance applications.

- ABS (Acrylonitrile Butadiene Styrene): A thermoplastic polymer known for its strength and durability, ABS is commonly used in injection molding applications.

- PC (Polycarbonate): Polycarbonate offers high impact resistance and transparency, making it suitable for lenses, enclosures, and other applications requiring clarity and strength.

- POM (Polyoxymethylene): Also known as Delrin, POM provides low friction and high stiffness, ideal for precision parts like gears and bearings.

- PA (Nylon): Nylon offers high chemical and heat resistance, along with excellent abrasion and wear resistance, suitable for mechanical components.

- PEEK (Polyether Ether Ketone): PEEK is a high-performance thermoplastic with very high strength, thermal, and chemical resistance, used in demanding engineering applications.

Bottom Line

HLH brings strong capability across both plastic and metal prototyping with a wide variety of services under one roof. Their ISO and industry-specific certifications (like medical and automotive) give extra peace of mind.

On the downside, lead times may stretch a bit longer for complex multi-process projects.

6. Xometry

Xometry makes sourcing feel less like a task and more like a system that actually works.

Their Instant Quoting Engine is fast, clear, and surprisingly accurate. You upload your file, and within minutes, you’ve got real pricing and lead times to plan around.

Behind the tech is a massive global network of trusted manufacturing partners. No matter the material or complexity, they’ve got someone who can handle it.

If you need flexibility, scale, and a streamlined process that keeps up with real production demands, Xometry is built for that.

- Location: No. 735 Liyang Rd, Hongkou Dist., Shanghai, P. R. China

- Year Established: 2013

Key Services

- CNC Machining: Xometry China provides CNC milling, turning, and drilling services, utilizing 3-, 4-, and 5-axis machines to produce parts with tight tolerances and complex geometries.

- Sheet Metal Fabrication: Their sheet metal services include laser cutting, bending, welding, and forming, delivering precise and durable metal components for various applications.

- 3D Printing: Xometry China offers a range of 3D printing technologies, including SLA, SLS, FDM, and DMLS, suitable for rapid prototyping and functional parts.

- Injection Molding: They provide rapid tooling and injection molding services, ideal for low to mid-volume production runs with a variety of materials.

- Die Casting: Xometry China’s die casting services are suitable for producing high-strength metal parts with excellent mechanical properties and surface finishes.

- Surface Finishing: They offer a wide range of finishing options, such as anodizing, painting, powder coating, and polishing, to enhance the appearance and durability of parts.

Materials They Work With

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for aerospace, automotive, and consumer electronics applications.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is used in medical devices, food processing, and marine applications.

- Brass: With good machinability and electrical conductivity, brass is suitable for components like gears, bushings, and fittings.

- Copper: Copper’s excellent electrical conductivity makes it ideal for electrical components and heat exchangers.

- PC (Polycarbonate): Polycarbonate offers high impact resistance and transparency, making it suitable for lenses, enclosures, and other applications requiring clarity and strength.

- POM (Polyoxymethylene): Also known as Delrin, POM provides low friction and high stiffness, ideal for precision parts like gears and bearings.

- PA (Nylon): Nylon offers high chemical and heat resistance, along with excellent abrasion and wear resistance, suitable for mechanical components.

- PEEK (Polyether Ether Ketone): PEEK is a high-performance thermoplastic with very high strength, thermal, and chemical resistance, used in demanding engineering applications.

Bottom Line

Xometry China offers unmatched scale and convenience with its global manufacturing network and AI-powered quoting engine.

They support nearly every service you might need, from 3D printing to die casting. Still, if you’re looking for a more personalized or dedicated point of contact, their system can feel a bit automated.

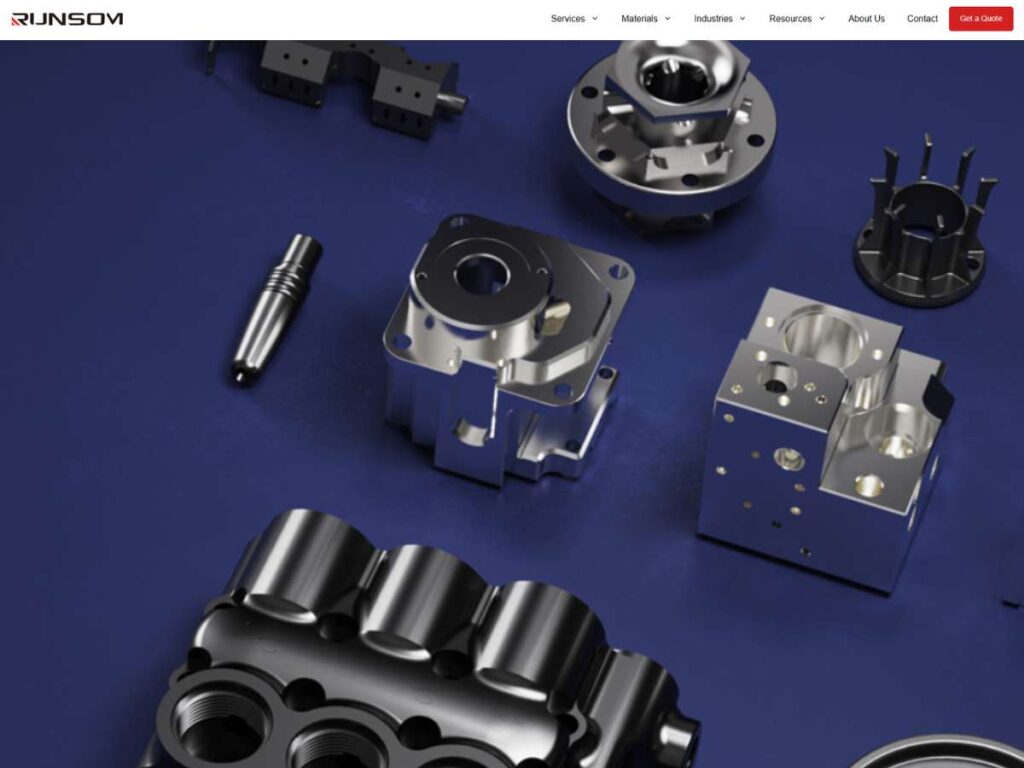

7. Runsom Precision

Runsom Precision is one of those shops that just gets it right from the start.

Their team is sharp, responsive, and pays attention to the details that others often miss. You don’t have to micromanage—they take ownership from day one.

What makes them especially easy to work with is their full range of in-house services. Everything stays under one roof, which means fewer delays and more control.

If your business depends on speed and precision without the stress, Runsom is a partner worth trusting.

- Location: Hongshi Road No.52, Yantian, Fenggang Town, Dongguan City, China

- Year Established: 2005

Key Services

- CNC Machining: Runsom Precision offers a comprehensive range of CNC machining services, including 3-, 4-, and 5-axis milling, CNC turning, Swiss CNC machining, and micromachining. Their advanced equipment ensures high precision and tight tolerances for complex parts.

- Rapid Prototyping: They provide rapid prototyping services to help clients quickly validate designs and accelerate product development cycles.

- 3D Printing Services: Runsom Precision offers 3D printing services using various technologies to produce prototypes and functional parts with intricate geometries.

- Sheet Metal Fabrication: Their sheet metal services include laser cutting, bending, welding, and forming, delivering precise and durable metal components for various applications.

- Surface Finishing: They provide a wide range of surface finishing options, such as anodizing, painting, powder coating, and polishing, to enhance the appearance and durability of parts.

Materials They Work With

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for aerospace, automotive, and consumer electronics applications.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is used in medical devices, food processing, and marine applications.

- Brass: With good machinability and electrical conductivity, brass is suitable for components like gears, bushings, and fittings.

- PC (Polycarbonate): Polycarbonate offers high impact resistance and transparency, making it suitable for lenses, enclosures, and other applications requiring clarity and strength.

- POM (Polyoxymethylene): Also known as Delrin, POM provides low friction and high stiffness, ideal for precision parts like gears and bearings.

- PA (Nylon): Nylon offers high chemical and heat resistance, along with excellent abrasion and wear resistance, suitable for mechanical components.

- PMMA (Acrylic): Acrylic provides high transparency and good chemical stability, often used in applications requiring clear and durable materials.

- PEEK (Polyether Ether Ketone): PEEK is a high-performance thermoplastic with very high strength, thermal, and chemical resistance, used in demanding engineering applications.

Bottom Line

Runsom is a reliable choice for complex CNC projects that need tight tolerances and careful attention to detail. Their in-house Swiss machining and HDPE capabilities add depth to their service list.

For urgent turnarounds, though, their timeline may not be as fast as more specialized rapid-prototyping firms.

8. AT-Machining

AT-Machining stands out for how seriously they take both precision and service.

Their team is responsive, easy to communicate with, and genuinely invested in getting the details right. You never feel like just another order in the queue.

They also handle a wide range of services in-house, which helps keep projects on track without surprises. Everything moves smoothly from quote to delivery.

If you’re looking for a CNC partner who delivers clean work and clear updates, AT-Machining is a solid choice.

- Location: Zhihuigu Creative Zone, Bantian, Longgang, Shenzhen, China

- Year Established: 2010

Key Services

- CNC Milling: AT-Machining offers 3-, 4-, and 5-axis CNC milling services, capable of producing parts with tight tolerances and complex geometries. Their advanced equipment ensures high precision for various applications.

- CNC Turning: They provide CNC turning services with live tooling, combining lathe and milling capabilities to machine parts with cylindrical features efficiently.

- Swiss CNC Machining: Specializing in small, complex parts, their Swiss CNC machining services are ideal for industries requiring high precision, such as medical and electronics.

- Wire EDM Machining: AT-Machining offers precision wire EDM services, suitable for intricate shapes and tight tolerances in hard materials.

- Sheet Metal Fabrication: Their sheet metal services include laser cutting, bending, welding, and forming, delivering precise and durable metal components for various applications.

- Surface Finishing: They provide a wide range of surface finishing options, such as anodizing, electroplating, powder coating, and carburizing heat treatment, to enhance the appearance and durability of parts.

Materials They Work With

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for aerospace, automotive, and consumer electronics applications.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is used in medical devices, food processing, and marine applications.

- Brass: With good machinability and electrical conductivity, brass is suitable for components like gears, bushings, and fittings.

- Copper: Copper’s excellent electrical conductivity makes it ideal for electrical components and heat exchangers.

- Titanium: Known for its high strength-to-weight ratio and corrosion resistance, titanium is used in aerospace, medical, and high-performance applications.

- PA (Nylon): Nylon offers high chemical and heat resistance, along with excellent abrasion and wear resistance, suitable for mechanical components.

- PMMA (Acrylic): Acrylic provides high transparency and good chemical stability, often used in applications requiring clear and durable materials.

- PEEK (Polyether Ether Ketone): PEEK is a high-performance thermoplastic with very high strength, thermal, and chemical resistance, used in demanding engineering applications.

- HDPE (High-Density Polyethylene): HDPE is known for its high strength-to-density ratio, good resistance to chemicals and moisture, and is FDA-compliant for food storage.

Bottom Line

AT-Machining is a strong contender for high-precision work, especially in aerospace, medical, and electronic components. Their Swiss CNC machining and finishing range add solid value to small and medium batch orders.

That said, they are better suited to technical projects rather than bulk commodity parts.

9. DEK Manufacturing

DEK Manufacturing has earned a strong reputation for precision across a wide range of industries.

Their team combines advanced equipment with real craftsmanship. You can tell they care about getting every spec right, no matter the complexity.

What I appreciate most is how they balance speed and quality. Projects move efficiently, but never feel rushed.

If you need a CNC partner that takes quality seriously and delivers consistently, DEK is one worth keeping on your shortlist.

- Location: 7F, Tianhui Building, #4545, Songbai Road, Guangming District, Shenzhen, 518107, China

- Year Established: 2002

Key Services

- CNC Machining: DEK offers high-precision CNC machining services with tolerances as tight as ±0.005mm, suitable for both prototyping and large-scale production.

- CNC Milling and Turning: DEK provides CNC milling and turning services, producing parts with tight tolerances and excellent surface finishes.

- Swiss CNC Turning: Ideal for small, complex parts, their Swiss CNC turning services cater to industries requiring high precision.

- Precision Grinding: Their precision grinding services ensure ultra-tight tolerances and superior surface finishes for metal parts.

- 3D Printing Services: They offer 3D printing services using various technologies to produce prototypes and functional parts with intricate geometries.

- Surface Finishing: DEK provides a wide range of surface finishing options, such as anodizing, powder coating, and electropolishing, to enhance the appearance and durability of parts.

Materials They Work With

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for aerospace, automotive, and consumer electronics applications.

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is used in medical devices, food processing, and marine applications.

- Brass: With good machinability and electrical conductivity, brass is suitable for components like gears, bushings, and fittings.

- Copper: Copper’s excellent electrical conductivity makes it ideal for electrical components and heat exchangers.

- Tool Steel: Tool steel offers high hardness and resistance to abrasion, making it suitable for cutting tools and dies.

- PEEK (Polyether Ether Ketone): PEEK is a high-performance thermoplastic with excellent mechanical and chemical resistance properties, suitable for demanding engineering applications.

- Delrin (Polyoxymethylene): Delrin provides low friction and high stiffness, ideal for precision parts like gears and bearings.

- Nylon (Polyamide): Nylon offers high chemical and heat resistance, along with excellent abrasion and wear resistance, suitable for mechanical components.

- PMMA (Acrylic): Acrylic provides high transparency and good chemical stability, often used in applications requiring clear and durable materials.

- PVC (Polyvinyl Chloride): PVC is known for its durability and resistance to chemicals and moisture, commonly used in piping and medical devices.

Bottom Line

DEK stands out with its full-suite manufacturing and finishing capabilities, plus a strong certification portfolio across aerospace and medical sectors.

Their tolerances and equipment are ideal for both high-mix and high-volume runs. However, pricing can lean toward the premium side compared to smaller shops.

Conclusion

Looking for CNC machining partners used to mean hours of browsing and second-guessing.

Not anymore.

This article showed you the 9 best CNC services in China, laid out clearly.

Now the decision is yours. Are you ready to build better, faster, and smarter?

Contact MachMaster today. We make custom production simple, efficient, and accurate.

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.