A startup once approached us after their previous supplier delayed a CNC prototype by three weeks, which meant they missed their product launch window.

You could feel the frustration in the room.

They didn’t need fancy. They needed fast, precise, and repeatable.

We’ve been in CNC manufacturing for years, turning ideas into tangible results for growing and established businesses alike.

Prototype work isn’t side work for us — it’s part of our core service.

This article lays out what you really need to know before diving in: the process, materials, timelines, and how to avoid common pitfalls.

If your team is planning a prototype run, this is the clarity you need.

Let’s start!

1. What Is CNC Machining Prototyping?

Let’s say you’ve got a design.

Maybe you’ve stress-tested it in CAD, run it through internal reviews, and everyone’s finally signed off. But here’s the thing. Until you have it in your hands, it’s still just an idea.

That’s where CNC machining prototyping comes in.

This is the step where your concept takes shape in the real world.

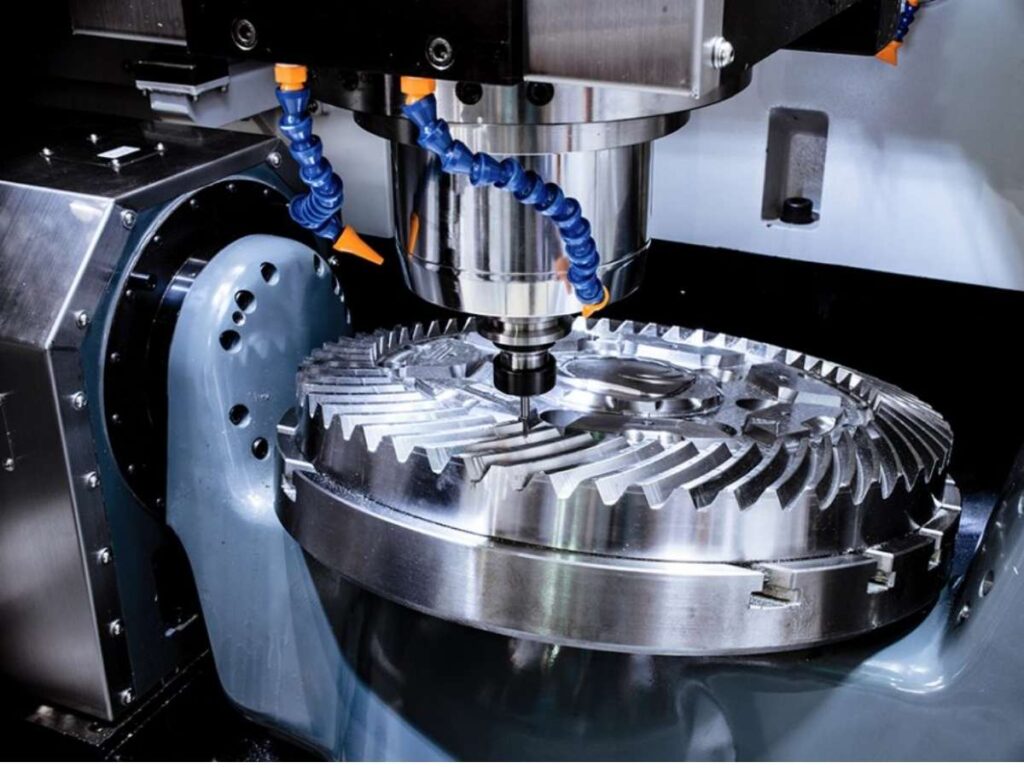

CNC (Computer Numerical Control) prototyping uses automated machines — like mills, lathes, or routers — to carve your part out of solid material. You send in a digital CAD file, and the machine gets to work with pinpoint accuracy.

It’s not about scaling up. It’s about getting things right before you do.

Here’s why this process matters:

- Fast Turnaround: You can go from file to part in a matter of hours or days, depending on complexity.

- High Precision: CNC machines deliver exact tolerances, which is critical for mechanical or assembly testing.

- Material Flexibility: From plastics to aluminum to stainless steel — you can test the real-world behavior of your design.

- Low Commitment: No need to invest in molds or dies until you’ve got a version you trust.

Most of the time, teams use CNC prototyping to test things like form, fit, and function. It’s ideal for catching flaws early, gathering user feedback, or fine-tuning geometry before locking in a final spec.

And if that prototype passes every test?

You’re one step closer to full production — and way ahead of the guessing game.

2. Key Advantages of CNC Prototyping

If you’ve ever waited weeks for a 3D printed part or suffered through the long lead time of custom molds, CNC prototyping feels like a breath of fresh air.

The ability to make real, test-ready parts quickly can help you hit milestones with confidence.

High Precision

This is where CNC prototyping truly shines. It delivers incredibly tight tolerances that allow you to test real-world fit and function. The surface finishes are also smooth and accurate, which helps you spot potential flaws before they go to production. That level of accuracy is hard to match with other prototyping methods. If your project relies on exact alignment, movement, or sealing, precision is non-negotiable.

Material Versatility

CNC machines work with a wide range of real-world materials.

You can choose from aluminum, stainless steel, nylon, and many others to match your production-grade needs. This makes your prototype more relevant and realistic for testing.

It also helps reduce surprises later in the manufacturing process. When the prototype behaves like the final product, your test data becomes more valuable.

Speed and Turnaround

Once your CAD model is finalized, production can begin almost immediately. Most prototypes can be completed and shipped within a few business days.

That quick response is a big advantage when timelines are tight. It helps you move from design to decision without unnecessary delays.

Speed keeps your development process moving and reduces the risk of missing market windows.

Repeatability

If you need five or ten identical parts, CNC prototyping makes it easy.

Each piece will match the last with exact dimensions and consistent quality. That repeatability is critical for testing assemblies or preparing small pilot runs.

You can trust that what you get is what you asked for. This consistency also builds trust with stakeholders who expect reliable results.

Scalability

CNC prototyping is not just a one-off solution. Many of the same setups used for prototyping can be used for low-volume production runs.

This makes it easier to bridge the gap between concept and manufacturing. It also lets you scale confidently without having to start from scratch.

Whether you’re validating a single idea or preparing for batch orders, CNC can keep up.

3. Materials Commonly Used in CNC Prototypes

Material choice can make or break a prototype. Choose wrong, and it doesn’t behave like the final part. Choose right, and you get insight that’s actually useful. That’s why it’s important to match your material to the goal of your test.

Here are some of the most common materials I’ve seen used in CNC prototyping:

Metals

- Aluminum (6061, 7075): Lightweight, corrosion-resistant, and easy to machine, aluminum is one of the most popular prototyping metals. It’s perfect for enclosures, brackets, and mechanical parts where weight and strength matter.

- Stainless Steel (303, 304, 316): This material offers excellent strength, high temperature resistance, and a clean, professional finish. It’s often used for structural parts, medical components, and food-grade machinery.

- Brass: Brass is easy to machine and provides strong corrosion resistance, especially in wet or plumbing-related applications. It’s also chosen for parts that need a decorative or polished appearance.

Plastics

- ABS: ABS is affordable, strong, and has good machinability for plastic-based prototyping. It’s commonly used in consumer product housings and test-fit enclosures.

- Nylon (PA): Nylon is tough, flexible, and highly resistant to wear and abrasion. It works well for moving parts or gear components that undergo repeated stress.

- POM (Delrin): Known for low friction and high dimensional stability, POM is ideal for parts that need smooth, accurate movement. It’s often used in mechanical prototypes that involve rotation or sliding.

- Polycarbonate: Polycarbonate is clear, impact-resistant, and stronger than most plastics. It’s a go-to for protective covers, light housings, and parts that need to stay transparent under pressure.

Others

- Titanium: Titanium is expensive and harder to machine, so it’s rarely used in early prototyping. But when you need unmatched strength and low weight in aerospace or medical testing, it’s a top pick.

- Foam or Wax Blocks: These materials are used for basic form studies or trial toolpaths without the cost of real metals or plastics. They’re perfect when you just need to see the shape before investing in performance testing.

4. CNC Prototyping Process Step-by-Step

If you’re new to CNC prototyping, it might seem like a black box. CAD goes in, and parts come out.

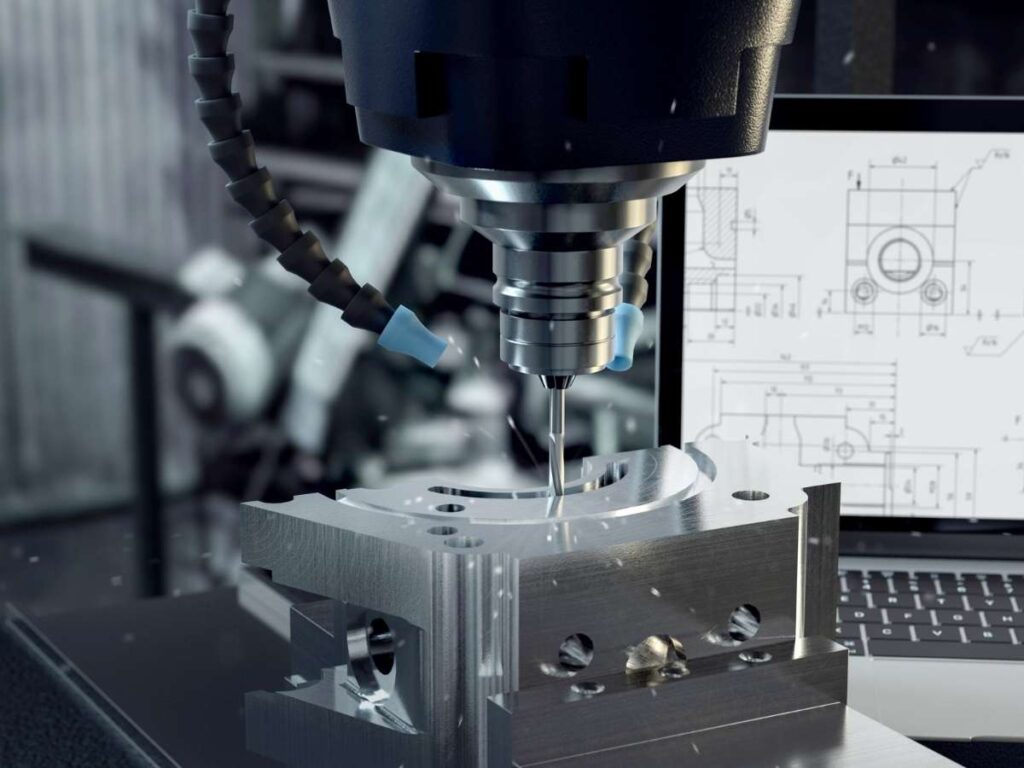

But there’s a method behind the magic. Understanding each stage can help you communicate better with your prototype partner and avoid costly errors.

Here’s a breakdown of the process:

- Step#1 Design the CAD Model: Everything starts with a solid 3D model built in CAD software. This file should include accurate dimensions, defined tolerances, and notes for features like threads, holes, or cutouts.

- Step#2 Select the Right Material: Material selection affects the strength, weight, and overall performance of your prototype. Your choice should match the part’s end-use, as well as be suitable for machining.

- Step#3 Program the Toolpaths: CAM software converts your 3D model into machine-readable instructions. These toolpaths tell the machine exactly where, how fast, and how deep to cut the material.

- Step#4 Set Up the Machine: The machinist secures the material block on the machine bed and installs the correct cutting tools. A careful setup is key to ensuring accuracy and avoiding costly mistakes.

- Step#5 Machining the Part: The CNC machine cuts the material based on the programmed toolpaths. Depending on the design, this might include milling, drilling, or turning operations.

- Step#6 Post-Machining Inspection: After machining, the part is carefully measured to ensure it matches the original specifications. Inspection tools like calipers, gauges, or CMM scanners may be used for this step.

- Step#7 Finishing (Optional): Some prototypes benefit from added surface finishing to improve appearance or durability. Options include anodizing, bead blasting, polishing, or painting, depending on the part’s use.

5. Tolerances and Surface Finishes in Prototypes

When it comes to CNC prototyping, details matter more than most people think. A part can look perfect on the surface but fail in the field because of poor tolerance or the wrong finish.

Here’s what you need to know to avoid frustrating surprises.

When it comes to CNC prototyping, details matter more than most people think. A part can look perfect on the surface but fail in the field because of poor tolerance or the wrong finish.

Here’s what you need to know to avoid frustrating surprises.

Tolerances That Actually Matter

Tolerances define how much variation is allowed in a part’s size or position. They directly affect how parts fit, function, and wear over time.

- Standard Tolerance (±0.005”): Good for most non-critical features like holes, outlines, or slot widths. It keeps machining simple and costs down for prototypes.

- Tight Tolerance (±0.002”): Used when components must align or move smoothly with others. It helps reduce friction and keeps assemblies running true.

- Precision Tolerance (±0.001” or tighter): Ideal for sealing surfaces, press fits, and high-accuracy parts. This level requires high-end machines and adds machining time.

- Geometric Tolerances (GD&T): Controls shapes and how surfaces relate to each other, like flatness or concentricity. These are critical when parts interact in 3D space.

- Fit-Based Tolerances (Clearance or Interference): Applied when two parts must either slide together or lock tight. This affects assembly feel, load transfer, and performance.

How to Pick the Right Surface Finish for the Job

Surface finishes impact how a part looks, feels, and performs. They’re just as important as size and fit, especially when parts will be touched, moved, or assembled.

- As-Machined (125 µin Ra): Straight off the CNC machine with visible tool paths. It’s a good default for prototypes where function matters more than looks.

- Bead Blasted: Produces a smooth, matte texture that hides tool marks. Great for grip surfaces or visual consistency in low-gloss parts.

- Brushed Finish: Adds fine, linear texture in one direction using abrasive tools. It’s common for panels, enclosures, or visible flat surfaces.

- Anodized (Type II or III): Adds color and corrosion resistance, especially on aluminum. Type III gives a harder layer, good for wear-prone parts.

- Polished or Buffed (16 µin Ra or smoother): Delivers a glossy, mirror-like finish that feels smooth to the touch. Often used for sealing surfaces or high-end cosmetic parts.

- Powder Coated or Painted: Applies a tough outer coating for protection and aesthetics. It also hides surface flaws and comes in many colors or textures.

6. CNC Prototype vs. Production Parts

It’s easy to assume that a CNC prototype will match the production version exactly, but that’s rarely the case.

Both serve different purposes, and understanding those differences will help you manage expectations, costs, and timelines more effectively.

| Aspect | CNC Prototypes | Production Parts |

| Purpose | Built for design validation, testing, or presentation. | Built for consistent performance at scale and ready for customer use. |

| Volume | Typically one-off or small batch (1–10 units). | High-volume production, often hundreds to thousands of parts. |

| Speed | Faster turnaround, often within a few days. | Longer lead time due to tooling, setup, or batch scheduling. |

| Cost per Part | Higher per part due to setup costs spread over fewer units. | Lower per part due to economies of scale. |

| Material Flexibility | Can match production materials, but substitutions are common for cost or speed. | Must match final design specs exactly, especially for certifications. |

| Tolerances | Can be tight, but may be slightly looser if full precision isn’t needed. | Consistently tight tolerances as defined in production drawings. |

| Surface Finishes | Optional and often basic unless the prototype is for demo or investor use. | Finished according to full spec including coating, painting, or branding. |

| Testing Value | Ideal for form, fit, and function evaluation. | Used for long-term performance, safety, and regulatory compliance testing. |

| Design Flexibility | Easy to change or iterate without major cost. | Changes are expensive once tooling and processes are finalized. |

| Manufacturing Method | Often CNC machined directly from CAD with minimal setup. | Could involve CNC, injection molding, casting, or other scalable methods. |

7. 4 Factors to Consider When Choosing the Right CNC Prototype Partner

Not all machine shops are built the same. When you’re developing a CNC prototype that needs to reflect real-world performance, the partner you choose can make or break your timeline, your budget, and your design.

Below are four technical areas you should evaluate before handing over your CAD files.

#1 Multi-Axis Machining Capabilities

One of the first things to check is whether your prototype partner has advanced CNC equipment, especially 4-axis or 5-axis machines. These allow for complex geometries and multi-sided machining in fewer setups, which means tighter tolerances and better alignment.

If your design includes undercuts, compound angles, or intricate features, a basic 3-axis machine may not cut it.

The more advanced the machine, the more flexibility you’ll have in prototyping high-performance parts. Always ask what axis capabilities they offer and whether they’ve handled similar part complexity.

#2 Material Machinability and Stock Inventory

The right shop should not only have access to a wide range of materials but also know how to machine them well. From aerospace-grade aluminum to medical-grade stainless steel and high-performance plastics, each material behaves differently under the cutter.

A partner who understands speeds, feeds, and tool wear for your chosen material will save you time and money.

Bonus points if they stock raw material in-house, as that shortens lead times significantly. You don’t want to wait a week just for a block of 7075 aluminum to arrive.

#3 In-House Quality Control and Tolerance Verification

Precision without verification is just guesswork. Look for a CNC partner with a dedicated quality control department that uses tools like calipers, micrometers, and CMM (Coordinate Measuring Machines).

MachMaster is equipped with advanced inspection systems and provides dimensional reports when required, making quality a measurable part of the process. Whether your spec calls for ±0.005 inches or tighter, you need a team that inspects every part and delivers a dimensional inspection report if needed.

Shops that take quality seriously will proactively flag issues before parts reach your hands.

It’s not just about hitting tolerances, it’s about proving it every time.

#4 CAD/CAM Engineering Support and DFM Feedback

Sometimes what looks good in CAD doesn’t machine well in real life. A high-quality prototype partner will have engineers who can review your design for manufacturability (DFM) before it hits the machine.

They should flag thin walls, deep pockets, or tool clearance issues that might cause problems during machining.

If your shop just cuts without questions, you risk wasting material and budget.

A proactive review process ensures your part can be made efficiently and correctly the first time.

Conclusion

That client who came to us after their prototype delay?

They didn’t just recover — they launched on time with our help and never looked back.

Now you’ve got the full picture of CNC prototyping: how it works, what to watch out for, and how to make it work for your business. You’re not flying blind anymore.

If precision and speed matter to you, now’s the time to move.

Contact MachMaster today. Your one-stop CNC production partner.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.