I remember the first part I had machined.

It looked great. But when I tried to assemble it—it didn’t fit.

Back then, I had no clue what CNC machining precision meant. I just assumed any machine could hit the numbers in my drawing.

Turns out, it’s not that simple.

That failure pushed me to learn the truth. Over time, I saw how machine condition, tool wear, material movement—even temperature—can throw off a part.

And I saw what happens when suppliers don’t follow proper processes.

If you’re trying to understand why CNC precision matters—or what makes a machine truly accurate—this article will walk you through it.

You’ll learn how tolerance works, how machines control accuracy, and how to avoid costly mistakes on your next part.

So let’s begin!

1. What is CNC Machining Precision?

Precision in CNC machining means how close your part is to the exact size you planned in your drawing.

Let’s say you call for a 10.00 mm hole. But the finished part comes out 10.02 mm or 9.98 mm. That tiny difference is what we call the precision gap. The smaller the gap, the more precise the machine.

When I first got into machining, I didn’t think about any of that. I figured: if it looks right, it probably is. But I was wrong. My part didn’t fit. And I had no idea why.

Turns out, there’s more going on than you think. Tool wear, heat, material movement, machine setup—it all matters. Even room temperature can throw things off.

Here are just a few things that affect CNC precision:

- Worn-out or dull tools

- Machines that aren’t properly calibrated

- Material shifting or expanding under heat

- Poor part setup or loose fixtures

- Temperature changes in the workshop

At MachMaster, we focus on getting that part right—not just once, but every time. Whether it’s one prototype or a thousand parts, precision is built into everything we do. Precision means our machine can make the same part again and again, with very little difference. It’s about consistency, accuracy, and trust in every cut.

If you’re designing parts, this stuff matters. Because the closer you hit your numbers, the better everything fits—and the fewer problems you’ll deal with later.

2. Factors That Influence CNC Machining Precision

Precision doesn’t just depend on the machine. That’s something I learned the hard way.

I once worked on a project where we used a high-end CNC machine. The specs looked great. But the parts still came out slightly off. The issue? It wasn’t the machine—it was everything else around it.

CNC precision is like a chain. Every link matters. If one weakens, the whole result suffers. Let’s look at the key factors that affect it.

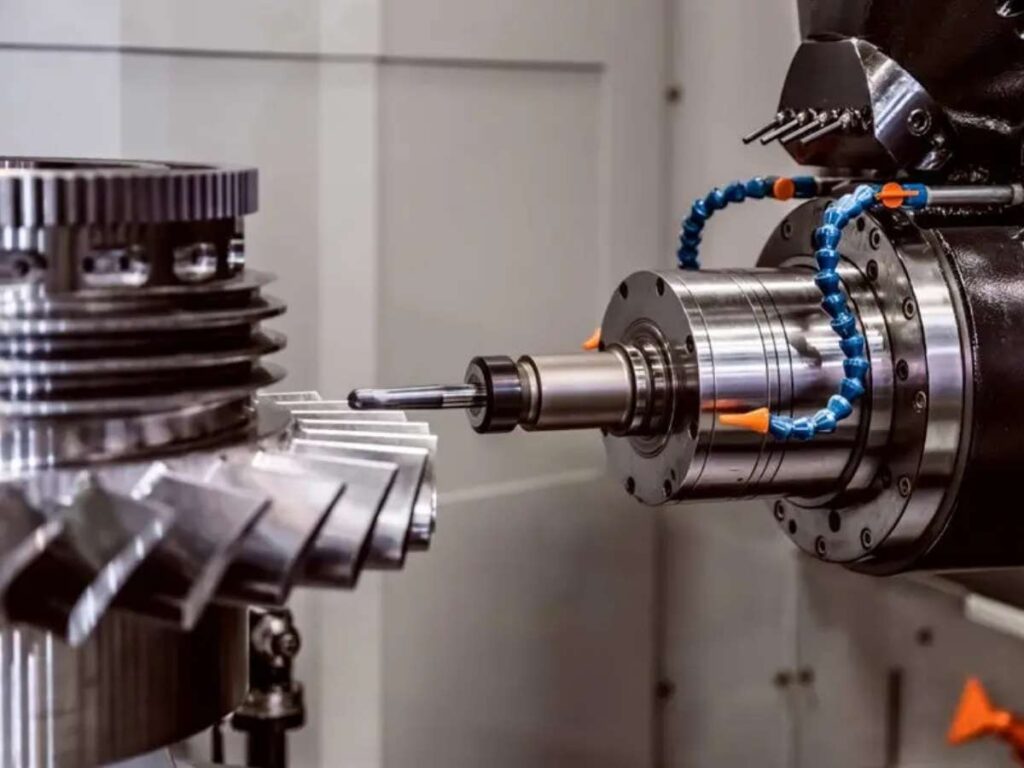

Machine Capability

The type of machine you use plays a big role in how precise your parts will be.

- Number of axes: A 5-axis machine can move in more directions than a 3-axis. That means fewer setups, smoother cuts, and less room for error

- Rigidity: A sturdy machine doesn’t vibrate as much, which keeps the tool steady during cutting

- Thermal stability: Machines heat up while working. A well-built one stays stable even as the temperature rises

- Spindle accuracy: This controls how precisely the cutting tool rotates. Wobbly spindles can ruin a part

- Tool path control: A smooth, consistent path helps maintain tight tolerances

Material Properties

Not all materials behave the same. Some cut like butter. Others fight back.

- Aluminum: Easy to machine, holds precision well

- Stainless steel: Tougher and harder to cut cleanly

- Plastics: Can melt or warp if things get too hot

Hard materials can wear down tools fast. Soft ones might not hold shape as well. Both impact surface finish and how close you can get to your design.

Tooling and Fixturing

Even the best machine fails if the tooling is wrong.

- Sharp tools: Dull tools drag across the surface and leave rough edges

- Stable tools: If the tool wobbles or shifts, precision drops fast

- Proper fixturing: Holding the part tightly in place stops movement during cutting. Vibration or shifting causes errors, even if the toolpath is perfect

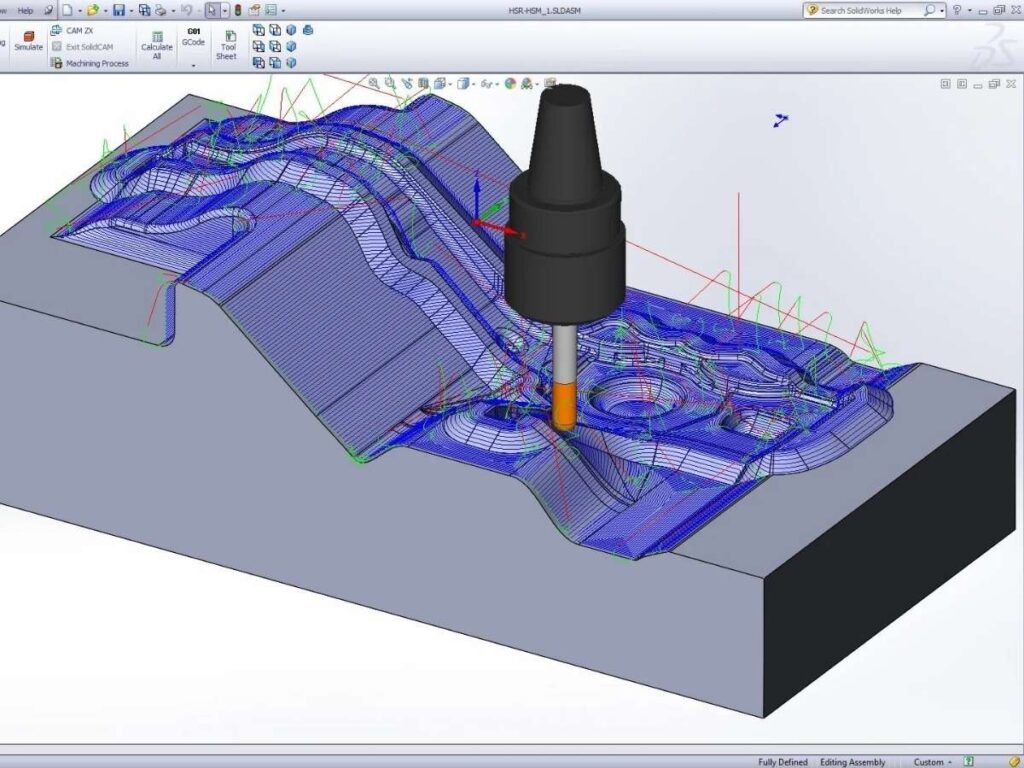

Operator Skill and Programming

Even with great equipment, results depend on the person behind it.

- CAM software: This creates the instructions the machine follows. Better software = cleaner paths

- G-code: These are the actual commands. Precise G-code avoids jerky moves or skipped lines

- Tool calibration: Setting the tool length and offsets by hand takes skill. A small mistake here throws off the whole job

Environment and Temperature Control

This part often gets overlooked—but it matters.

- Room temperature: Heat causes materials to expand. Cold makes them shrink. Even a few degrees can change part size by microns

- Controlled environment: Precision shops often control the room’s temperature and humidity to keep cuts stable

I’ve seen parts pass inspection in the morning and fail in the afternoon—all because the shop got warmer.

If you’re aiming for tight tolerances, don’t just look at the machine. Look at everything around it. That’s how you get real CNC machining precision.

3. Types of Precision CNC Machining Processes

When I first started working with precision parts, I thought one machine could do it all. But over time, I realized: each process has its own purpose. Some work better for small details. Others for long, smooth cuts.

If you want the right results, you have to choose the right method.

Turning

Turning works best for round parts like shafts, pins, or bushings. If your part spins or rotates in its final use, turning is often the right choice.

What makes it precise:

- Holds tight diameters with repeatable accuracy

- High-end CNC lathes can achieve ±0.005mm tolerance

- Produces smooth surfaces along cylindrical features

Why it matters:

Use turning when you need perfect circles, clean threads, or concentric surfaces that fit like a glove.

Milling

Milling is ideal for complex shapes. If your part has holes, pockets, angled edges, or multiple surfaces, milling gives you that control.

What makes it precise:

- Multi-axis control (3-axis, 4-axis, or 5-axis) helps reach tight spots

- Delivers consistent shape and size across batches

- Produces a smooth surface finish on flat and angled planes

Why it matters:

Use milling when you need detail on more than one side of a part—or when your geometry is too complex for simpler tools.

EDM (Electrical Discharge Machining)

EDM is for small, sharp, or delicate features. It’s also a top choice when working with very hard metals that are difficult to cut with regular tools.

What makes it precise:

- Uses spark erosion, not blades

- Can hit ±0.002mm tolerance

- Works on materials like hardened steel and tungsten carbide

Why it matters:

Use EDM when precision is more important than speed—especially in mold making or micro-detail parts.

Grinding (Cylindrical and Surface)

Grinding is your go-to process after turning or milling—when you need to refine the surface or hit extra-tight tolerances.

What makes it precise:

- Removes very small amounts of material

- Improves surface finish dramatically

- Excellent for flatness and tight zones

Why it matters:

Use grinding when your part needs that final polish—or when even small unevenness can throw off the result.

Choosing the right method makes a huge difference. It’s not just about removing material. It’s about doing it the right way—so your parts turn out smooth, exact, and reliable.

4. Strategies for Improving CNC Machining Precision

I’ve had days where everything seemed to go right—until the part came out wrong.

The machine was fine. The drawing was fine. But the cut wasn’t. It took me a while to understand: precision doesn’t just come from good equipment. It comes from how you use it.

Here are some simple, effective strategies to help you get more accurate results every time.

Use of High-End CNC Machines

If you’re working with tight tolerances, the quality of your machine matters a lot.

What to look for:

- High RPM: lets you use smaller tools with clean finishes

- Encoder feedback: keeps the tool on the right path

- Rigid frame: prevents vibration that can ruin a cut

A shaky or slow machine might still work—but it won’t give you the kind of consistency precision demands.

Consistent Tool Maintenance and Calibration

One dull tool can throw off everything. I’ve seen it happen more than once.

What to do:

- Replace worn tools early: don’t wait until it’s too late

- Use touch probes: helps the machine find part edges more accurately

- Use tool setters: automatically measure tool length to reduce setup error

Even if you’ve got a good machine, bad tools lead to poor results. Keep them sharp, measured, and ready.

Optimize CAM Programming

You might not see the mistake in the software—but your part will show it.

What to check:

- Feed rate: too fast creates heat, too slow wastes time

- Tool paths: smooth curves reduce cutting pressure

- Cutting strategy: some patterns keep the tool cooler and more stable

Better programming means fewer surprises on the shop floor.

In-Process and Post-Process Inspection

If you only check parts after they’re done, you’re already too late.

Here’s what helps:

- CMM (Coordinate Measuring Machine): checks exact dimensions during or after machining

- FAI (First Article Inspection): confirms accuracy before full production starts

- SPC (Statistical Process Control): tracks change during the run

These checks let you fix problems early—before they turn into lost time or wasted parts.

If you want to improve CNC machining precision, don’t rely on just one thing. It’s a combination of smart choices, regular checks, and attention to detail.

Start small. Build habits. That’s how precision gets better—one step at a time.

5. CNC Precision vs Other Manufacturing Concepts

The first time I heard someone say, “That part is precise, but not accurate,” I was confused. How could that be? Don’t precision and accuracy mean the same thing?

Turns out—they don’t. And understanding the difference helped me avoid a lot of costly mistakes.

| Comparison Topic | Concept 1 | Concept 2 | Meaning / Key Difference | Example or Notes |

| Precision vs Accuracy | Precision | Accuracy | Precision = repeatabilityAccuracy = closeness to the target | Parts are all the same size, but slightly off location (precise, not accurate) |

| You can be precise without being accurate—and vice versa | Best case is being both precise and accurate | |||

| Precision vs Tolerance | Precision | Tolerance | Tolerance = how much a part is allowed to vary from the design size | ±0.01mm is tighter than ±0.1mm |

| Tight tolerance means more time, cost, and setup care | Loose tolerance = faster and cheaper, but less control | |||

| Precision = how closely you hit that allowed range every time | Precision keeps results consistent across many parts | |||

| CNC vs 3D Printing or Casting | CNC Machining | 3D Printing / Casting | CNC gives higher precision and tighter control over dimensions | CNC used for tight fits, critical shapes, smooth surfaces |

| 3D printing is faster for prototypes but less accurate | Best for early testing or complex internal shapes | |||

| Casting is rougher and often needs CNC finishing | Great for making blanks or basic part shapes before final machining |

6. Common Challenges in Achieving CNC Precision

Even the best machine won’t hold perfect precision forever. You might think once it’s dialed in, you’re all set. But small things can throw them off—slowly, and sometimes without warning.

I’ve been there. The part looks good at first. Then the next batch? Not so much. That’s why it helps to know what really causes precision issues.

Have you run into any of these?

Tool Wear and Vibration

Cutting tools don’t last forever. As they wear down, they lose their sharp edge. Instead of slicing cleanly, they start dragging and vibrating.

That small vibration may not seem like a big deal. But it adds up.

You’ll start to see:

- Dimensional drift

- Rougher surface finishes

- Small changes between parts

Tool wear is sneaky. You don’t notice until your parts are already off.

Thermal Expansion

Machines and parts heat up as they run. And with heat comes expansion.

Aluminum and plastics are especially sensitive. Even a few degrees of temperature change can stretch your dimensions.

You may see:

- Size changes during long runs

- Parts that shift slightly over time

- Tight fits becoming loose

If your shop doesn’t control heat, this can get out of hand fast.

Inconsistent Material Lots

Not all materials behave the same. One batch of plastic might cut smooth. The next? Full of chatter.

Differences in:

- Hardness

- Internal structure

- Tool response

can throw off your results—even if your setup didn’t change.

Poor Fixturing or Part Movement

If your part moves even a little during machining, it’s a problem.

What happens?

- Chatter and vibration

- Misalignment

- Poor surface finish

A solid fixture keeps things locked in. Without it, precision goes out the window.

Over-Specification by Designers

This one’s easy to overlook. You might think every measurement needs to be tight. But that’s not always true.

Tight tolerances:

- Raise your costs

- Slow down production

- Increase your scrap rate

If it doesn’t affect fit or function, loosen it up. Your machinist (and your wallet) will thank you.

7. How to Choose a High-Precision CNC Machining Service

Finding the right machining service isn’t just about price or delivery time. If you care about precision, you need to ask deeper questions. I’ve learned this the hard way after getting parts that “looked fine” but didn’t actually work.

So how do you choose a service that gets precision right?

Start with the basics.

Key Capabilities

Ask what their machines can do.

- Can they hold tight tolerances like ±0.01 mm or better?

- Do they run multi-axis CNC, Swiss lathes, or micro-CNC machines?

- Can they handle both small batches and large volume orders?

If you’re just prototyping, you want flexibility. If you’re scaling up, you’ll need repeatability.

Inspection Tools

Don’t guess—ask how they inspect parts.

- Do they use CMMs (Coordinate Measuring Machines), laser scanners, or optical comparators?

- Is inspection done by hand or is it automated?

- Do they provide first article inspections or full inspection reports?

I once worked with a shop that skipped inspection unless I asked. After that, I never forgot to ask again.

Certifications

Certifications don’t make a shop perfect—but they show a commitment to doing things right.

Look for:

- ISO 9001 for general quality

- ISO 13485 for medical work

- AS9100 for aerospace parts

Also ask about:

- In-house quality teams

- Written processes (SOPs)

- Material traceability and inspection records

At MachMaster, we’re ISO 9001 certified and follow structured internal checks on every job. That means you get consistent quality, clear records, and peace of mind.

Communication and DFM Support

Precision isn’t just technical—it’s also about how well they talk to you.

- Can they look at your drawings and suggest better tolerances?

- Will they tell you if something is over-designed or too costly?

- Do they help you avoid common mistakes?

Clear communication early on helps prevent rework later. And that’s something worth asking about before you place an order.

Conclusion

You’ve now learned what CNC precision really means, how to improve it, and how to choose the right service.

So where do you go from here?

You start. You ask questions. You choose partners who prove what they can do.

What’s holding you back from making that next move?

Stop guessing and start getting it right.

Contact us today and let’s make precision happen.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.