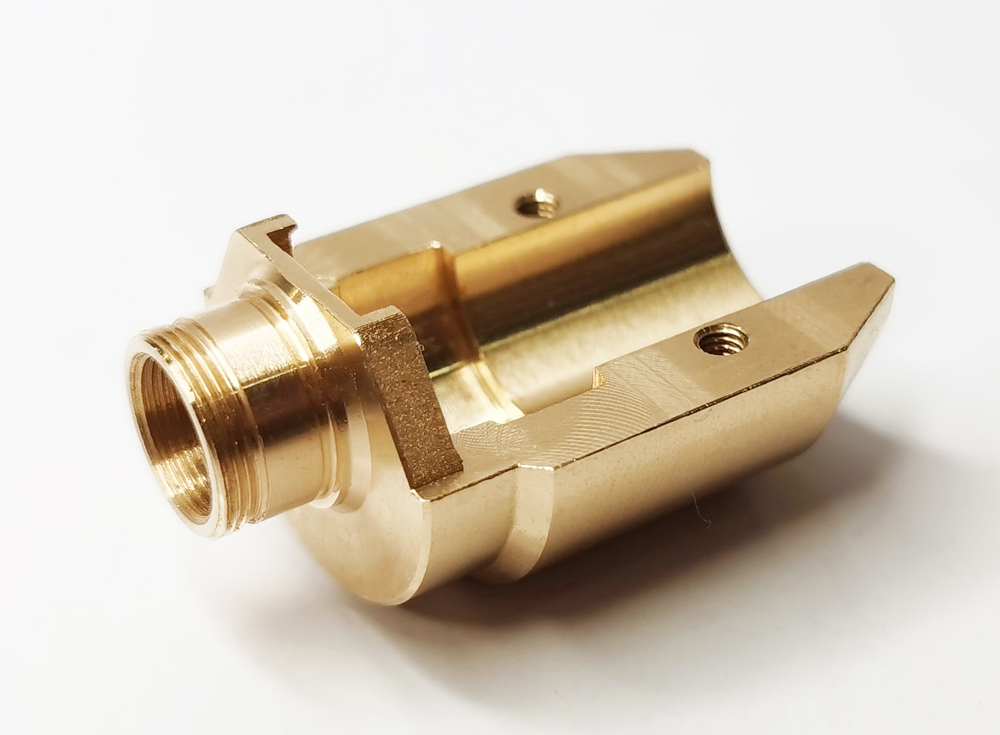

Bronze isn’t just another metal to be machined. It’s a strategic engineering choice for applications where failure is not an option—think propeller blades churning through saltwater or high-load bearings spinning in dusty environments. Successfully navigating a bronze CNC project requires more than just getting the dimensions right off the machine. It demands a holistic view of why the material is chosen, how to cut it effectively, and what must be done afterward to unlock its full potential.

This guide synthesizes decades of shop-floor experience to take you from material science to final finishing, ensuring your bronze components are not just made, but engineered for longevity.

Why Bronze? Decoding Its Niche in Precision Manufacturing

Understanding bronze’s behavior is the first step to mastering it. Primarily a copper-tin alloy, its key advantages—superb wear resistance, excellent corrosion immunity, and natural lubricity—are a direct result of its composition (often modified with lead, aluminum, or phosphorus). These same virtues dictate its machining personality:

- Gummy & Ductile: Leads to tough, stringy chips that promote built-up edge on tools.

- High Thermal Conductivity: Heat rapidly transfers to the tool and workpiece, demanding active thermal management.

- Abrasive: Hard alloying particles (e.g., tin phosphides) act as micro-abrasives, accelerating tool wear.

The Machinist’s Mindset: Your entire process must be designed for sharp cuts, aggressive chip evacuation, and constant heat control.

Machining the Major Alloys: A Targeted Approach

Treating all bronzes the same is a recipe for poor results. Here’s your shop-floor cheat sheet.

C93200 / SAE 660 (High-Lead Tin Bronze)

- Personality: The go-to for general bearings. Excellent machinability and anti-galling due to lead, but with moderate strength.

- How to Machine: The easiest to work with. Use sharp tools to prevent tearing the lead-rich matrix. Start at 80-120 m/min (260-400 SFM) with a 0.15-0.25 mm/rev feed.

- Key Post-Process: Stress relieving is critical for stability. Often plated with tin or indium for enhanced surface properties.

C95400 / C95500 (Aluminum Bronze)

- Personality: The “heavy-duty” option. High strength, exceptional corrosion/erosion resistance, behaves like mild steel.

- How to Machine: Requires rigid setups and power. Expect higher cutting forces. Reduce speeds to 50-90 m/min (165-300 SFM). Use durable carbide grades.

- Key Post-Process: Solution treatment & aging (precipitation hardening) is essential to achieve its published mechanical properties. Often chemically passivated (black oxide) for marine use.

C52400 (Phosphor Bronze)

- Personality: The “spring” bronze. Outstanding fatigue strength, elasticity, and good conductivity.

- How to Machine: Extremely prone to smearing and BUE. Requires razor-sharp, polished tools with high positive rake.

- Key Post-Process: Low-temperature stress relieving after machining. Frequently electroplated with tin, silver, or nickel for electrical or soldering applications.

C17200 (Beryllium Copper)

- Personality: The premium performer. Can be heat-treated to achieve strengths over 200 ksi while maintaining high conductivity.

- How to Machine: Machine in the soft, annealed condition. Use sharp tools and positive geometry. Control fine, curly chips.

- Key Post-Process: Mandatory solution treatment & aging to achieve its legendary strength. Must be performed under controlled conditions.

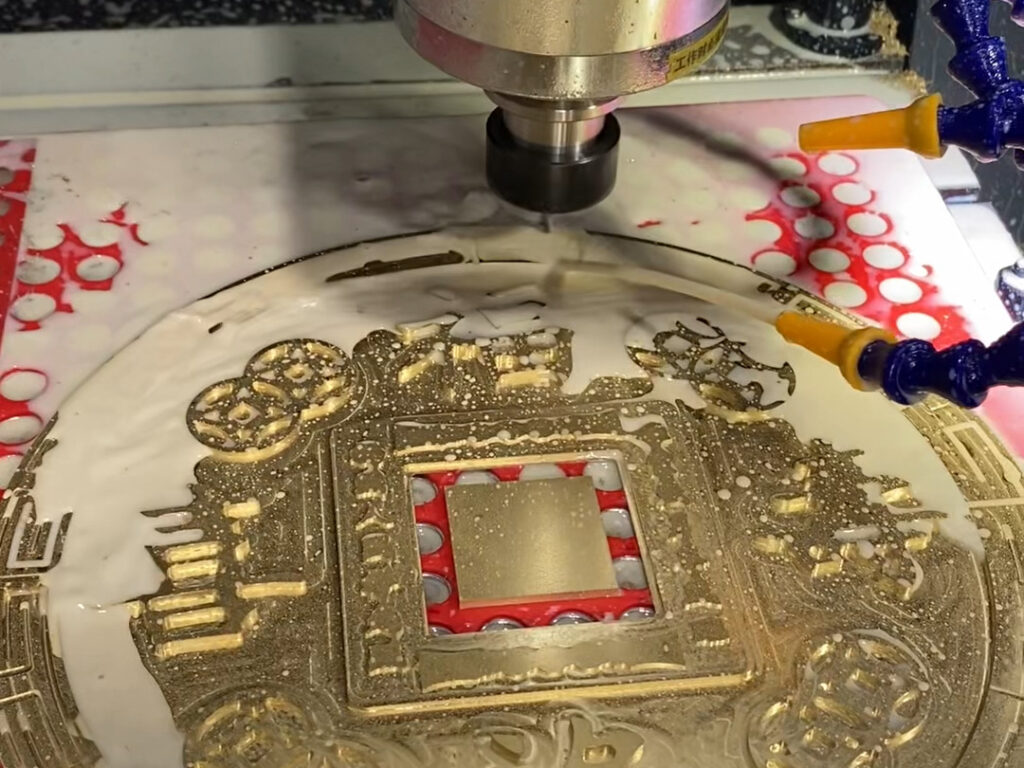

The Core of Quality: Proven Machining Parameters & Tips

These are battle-tested starting points for a common alloy like C93200. Adjust from here.

- Cutting Speed (Vc): 60 – 150 m/min (200 – 500 SFM). Softer bronzes (high lead) can use higher speeds; harder alloys (aluminum bronze) need slower speeds.

- Feed Rate: 0.10 – 0.25 mm/rev (0.004 – 0.010 IPR). A higher feed produces a thicker chip that better manages heat and minimizes work hardening.

- Depth of Cut: Can be robust—1-4 mm (0.040-0.160″) for roughing is typical with a stable setup.

Pro-Tips from the Shop Floor:

- Tooling: Sharpness is non-negotiable. Use positive rake inserts. For long runs, PCD (Polycrystalline Diamond) tooling offers phenomenal life on non-ferrous bronzes.

- Coolant: Flood coolant, aimed correctly. It’s for cooling and chip evacuation. For finishing, a high-pressure air blast can prevent staining.

- Chip Control: Implement peck cycles in drilling and consider programmed tool retractions in turning to break long, stringy chips.

Where Bronze Excels: Critical Applications by Alloy

Choosing the right bronze starts with the application. Here’s where each alloy shines.

| Application Sector | Why Bronze? | Recommended Alloy(s) | Key Performance Need |

|---|---|---|---|

| Bearings & Bushings | Self-lubrication, wear resistance, conformability, anti-galling. | C93200, C93400 (General) | Low friction, embeddability for contaminants. |

| Marine & Offshore | Superior resistance to seawater corrosion, biofouling, and cavitation erosion. | C95500, C95800 (Aluminum Bronze) | Strength in aggressive chloride environments. |

| Valves, Pumps & Chemical | Corrosion resistance to acids, alkalis, and steam; good strength. | C95400, C95500 | Reliability in corrosive fluid handling. |

| Wear Plates & Guides | High wear resistance, low coefficient of friction, dampens vibration. | C86300 (Manganese Bronze), C95400 | Abrasion resistance under high load. |

| Electrical Springs & Connectors | High elastic limit, fatigue strength, and good electrical conductivity. | C52100, C52400 (Phosphor Bronze), C17200 | Stable spring performance over millions of cycles. |

The Finishing Touch: Essential Post-Processing for Bronze Parts

The journey doesn’t end at the machine. Post-processing transforms a machined blank into a reliable component.

1. Heat Treatment (The Internal Upgrade)

- Stress Relieving (~300°C / 570°F): Applied to virtually all precision bronze components. Removes internal stresses from machining, preventing dimensional drift over time and improving fatigue life.

- Solution Treatment & Aging: Critical for Aluminum and Beryllium Copper alloys. This controlled thermal cycle (e.g., heating to ~900°C then quenching, followed by aging at ~550°C) radically increases tensile strength, hardness, and wear resistance.

2. Surface Finishing (Precision & Aesthetics)

- Polishing/Buffing: For decorative pieces or components requiring a smooth surface to prevent fouling.

- Honing/Lapping: Achieves ultra-tight tolerances and a superior surface finish for sealing faces or high-precision bearing bores.

3. Surface Coating & Functional Treatment

- Passivation/Chemical Blackening (for Aluminum Bronze): Creates a stable, corrosion-resistant oxide layer integral to the surface. A must for marine hardware.

- Electroplating:

- Nickel or Chrome Plating: Adds a hard, wear-resistant, and corrosion-resistant outer layer. Common for valve stems and decorative hardware.

- Tin or Silver Plating: Primarily for electrical connectors (phosphor bronze) to ensure solderability and low contact resistance.

- Impregnation: For porous cast bronze parts used in pressure applications, a polymer resin is used to seal microscopic pores.

4. Validation & Protection

- Balancing: Essential for any rotating component (e.g., impellers, fans) to prevent vibration.

- Pressure Testing: A non-negotiable final check for any valve, pump housing, or fluid manifold.

- Cleaning & Anti-Corrosion Packaging: Final parts are thoroughly cleaned and preserved with VCI (Vapor Corrosion Inhibitor) packaging or rust-preventative oils for shipment and storage.

Your Blueprint for Success: Design & Sourcing Guidance

To ensure your bronze project is a success from quote to delivery, consider this checklist:

- Specify the Environment: Always communicate the operating conditions (medium, temperature, load, speed) to your machining partner. It dictates the alloy and post-process.

- Mandate Stress Relief: For any part where dimensional stability matters, explicitly call out “Must be stress-relieved after machining” on your drawing or PO.

- Plan for Post-Processing Lead Time: Heat treatment and plating add significant time to the schedule. Factor this in during project planning.

- Partner with a Specialist: The complexities of material selection, machining, and thermal processing make bronze a prime candidate for working with an experienced, vertically-integrated machine shop.

Conclusion: More Than a Part – A Performance Solution

A successful bronze component is the product of an interconnected chain: strategic material selection, precision machining adapted to that material, and targeted post-processing that fulfills the design intent. By understanding this full spectrum, you move from simply ordering a part to engineering a durable, high-performance solution.

Facing a complex bronze machining challenge? Machmaster provides expert guidance through this entire process. From selecting the optimal alloy for your seawater, chemical, or high-wear application to executing precision CNC work and managing critical post-processing like heat treatment and plating—we ensure your bronze parts are built for the long haul.

Ready to engineer with bronze? Contact us or upload your drawings for a comprehensive manufacturing analysis and competitive quote. Let’s build something that lasts.