We once lost a major order over 0.05 millimeters.

That’s about the width of a human hair. But for a client in aerospace, it was everything. The part didn’t meet spec. The machine was fine.

The mistake? A small fixture slip and a missed double-check.

That was years ago. It taught us something: in aluminum machining, precision and safety are always linked. You can’t have one without the other.

Since then, we’ve helped factories fix that problem, over and over again. We work with shops that run 24/7. We’ve walked the floors. We’ve seen the pressure. And we know how it feels when one mistake shuts everything down.

This article gives you clear steps. No jargon. Just what you need to know to stay safe and hit your tolerances.

You’ll learn how to avoid the common errors that throw off accuracy. You’ll also get simple methods that help keep operators and machines protected.

So let’s begin!

1. Key Safety Hazards in CNC Aluminum Machining

When you’re cutting aluminum, safety might not be the first thing on your mind.

It should be.

Aluminum is soft compared to steel. It cuts fast. But that speed comes with risks, ones that can hurt your team, your machines, and your timeline.

I’ve been on shop floors where one small oversight turned into a three-day delay. A tool cracked during a roughing pass. It flung a chip so fast it cracked the machine window. No one got hurt, but that was luck, not planning.

Let’s make sure you don’t need luck.

Spinning Tools and Sharp Edges

Every CNC machine is a moving hazard. Spindles spin up to 18,000 RPM. One slip, one loose shirt sleeve, and you’ve got an injury.

And those aluminum parts? They come off sharp, especially if burrs aren’t removed right away.

Tip: Always pause before reaching into the machine. Are tools stopped? Edges safe to touch?

Flying Chips and Debris

Aluminum makes long, curly chips. If your feed rate or toolpath is off, they’ll bunch up or come out hot.

I’ve seen operators take chips to the cheek because they opened the machine too soon. Eye protection isn’t optional, it’s survival.

Coolant Hazards

Coolant keeps your part cool and smooth. But it’s also slippery. Left on the floor, it’s a fall waiting to happen. And if mist escapes the machine, it can cause skin or breathing issues.

Reminder: Keep coolant nozzles clean, and never ignore a leak.

Tool Breakage at High RPM

Tools wear. Tools fail. When they do it mid-cut, especially at high RPM, they can break apart. That’s not just a ruined part. It’s a hazard.

A friend once had a carbide bit shatter on him during a finishing pass. He was behind the safety window, but the sound alone made the whole team jump.

Now he swaps tools early, not late.

2. Essential Safety Protocols in the CNC Shop

You can’t control every variable. But you can set the standard for how your team works.

I’ve been inside shops where safety was just a poster on the wall. No hearing protection. Guards propped open. Coolant puddles near foot pedals.

That’s not just dangerous. It affects focus. And when people aren’t focused, precision slips.

Personal Protective Equipment (PPE)

If you’re running aluminum, your team should already be wearing these:

- Safety Glasses: Aluminum chips can curve and bounce.

- Cut-Resistant Gloves: Use during loading, unloading, and deburring.

- Steel-Toe Shoes: Even small aluminum stock hurts when dropped.

- Hearing Protection: Especially during dry cuts or tool changes.

Note: Not all gloves are machine-safe. Make sure they don’t snag.

Machine Safeguards Matter

Interlocks are there for a reason. So are emergency stops. The problem? People get too comfortable and start bypassing them.

Don’t.

If someone props open a door to “save time,” that’s a signal, not just a shortcut. It tells you where your real risk starts.

Shop Layout and Housekeeping

Clean shops produce better parts. That’s just a fact.

Here’s what I’ve learned:

- Don’t allow chip piles under machines

- Label chip bins and waste areas

- Mop up coolant daily, not just “when someone slips”

- Keep walkways open, clutter stresses people out more than you think

One factory we visited had taped walk paths in yellow and red zones. Operators said they felt safer, and incidents dropped after two weeks.

Safety Supports Precision

You’re not just keeping people safe. You’re also keeping machines aligned, tools in check, and your process flowing.

And when your team trusts their space, they pay more attention to the work.

Start with safety. The precision follows.

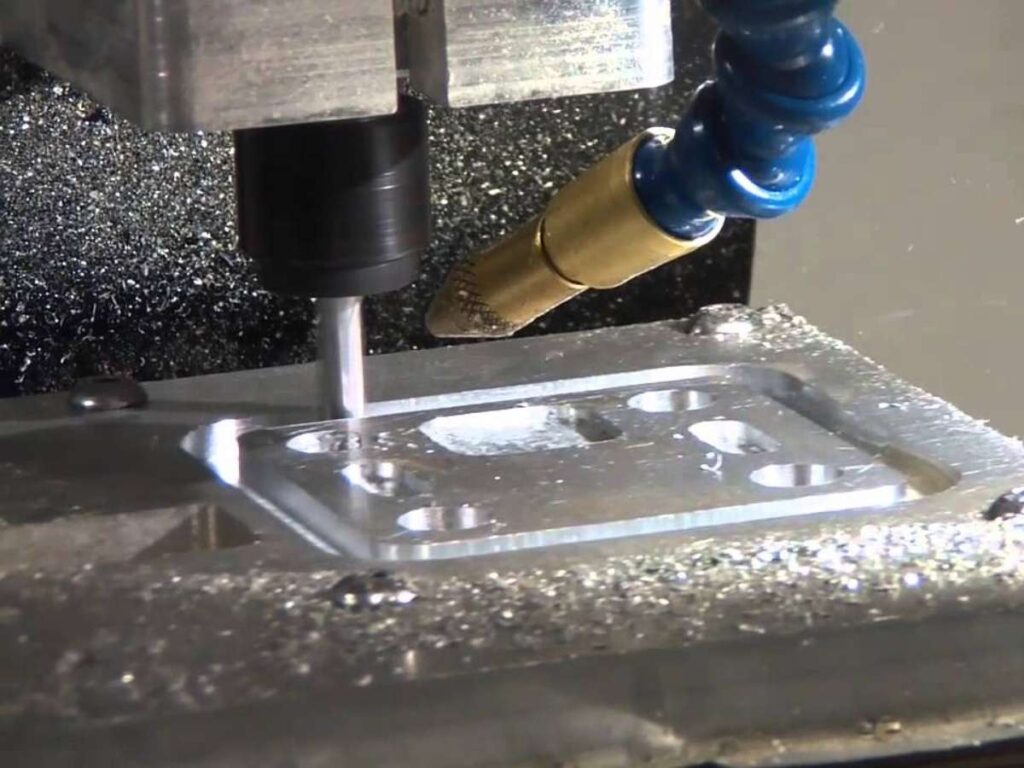

3. Proper Machine Setup

You can have the best CNC machine on the floor, but if the setup’s off, your part’s off too.

I once visited a shop that was chasing tolerance issues for weeks. Turned out the spindle was just slightly misaligned, less than 0.1 mm. But that tiny gap ruined every precision cut they made.

Fixing the setup fixed the problem.

Machine Calibration and Alignment

Don’t assume your machine is still square just because it was last week. Aluminum jobs especially need tight repeatability.

Here’s what to stay on top of:

- Spindle Alignment: Check for any vertical or horizontal drift.

- Tool Offsets: Reset zero points before every job, don’t carry over values.

- Probing Systems: Use regularly to catch wear or shift early.

A small error in your baseline affects the whole cut.

Fixture and Workholding Safety

Aluminum is soft. That makes it easy to cut, but easy to move too.

Make sure:

- Clamps are snug but not over-tight (which can deform soft stock)

- Fixtures match your part size, no big gaps or extra play

- Parts sit flush, no rocking or air gaps

We’ve seen chatter marks disappear just from switching to a low-profile vise. Sometimes it’s not your program, it’s your hold.

Coolant and Lubrication Systems

Aluminum loves to gum up tools if you don’t use coolant right.

Check:

- Coolant lines are aimed at the cutting edge

- Flow is steady, no sputtering or dry passes

- Reservoir is clean, aluminum particles can build up over time

A clogged coolant line once stalled an entire weekend run for one of our clients. That’s a silent hazard, until it’s not.

4. Material Handling Best Practices

Handling aluminum may look simple. It’s not heavy like steel. It’s easy to move. But that ease can lead to carelessness.

I remember watching a new hire drop a raw aluminum plate. Not from high up, just waist level. It landed on a corner and dented the edge.

We didn’t catch it until the part failed inspection after machining. One tiny dent had thrown off the entire profile.

Since then, I’ve looked at material handling with fresh eyes.

Before Machining

The job starts before the part hits the table.

Make sure you:

- Inspect Raw Stock: Look for warping, dents, or corrosion.

- Store Aluminum Properly: Keep it dry and covered. Stack it flat to avoid bending.

- Keep Materials Separated: Don’t stack aluminum near steel. They can react over time and cause surface damage.

Damaged aluminum may look usable, but it often cuts unevenly.

During Machining

The part is still vulnerable while it’s on the machine.

Use caution when:

- Clearing Chips: Never use bare hands. Use a chip brush or hook.

- Opening Machine Doors: Wait until the spindle stops. Even soft aluminum chips can scratch or cut if they fly out.

- Rotating or Repositioning: Keep your hands away from sharp edges, especially mid-cut or during a dry run.

A moment of rushing here often leads to rework or worse, an injury.

After Machining

Even finished parts can be risky.

Best practices:

- Use Gloves for Handling: Machined aluminum has burrs and sharp edges.

- Deburr Right Away: Don’t let sharp edges pile up in bins.

- Stack Parts Carefully: Aluminum scratches easily. Surface marks can ruin anodizing later.

One shop I worked with lost an entire batch to surface damage from poor stacking. The parts were dimensionally perfect, but unusable after finishing.

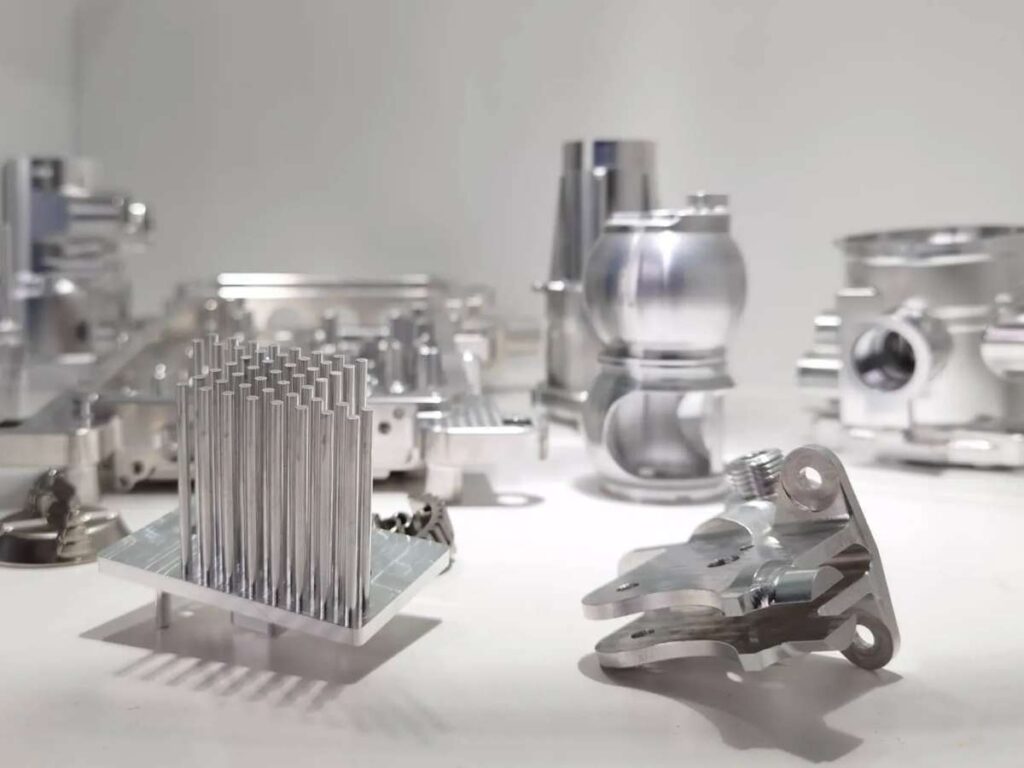

5. Tooling Selection and Maintenance

The tool you choose affects everything, surface finish, accuracy, cycle time, and even safety.

I remember visiting a shop where the machinist was proud of stretching tool life. One end mill had lasted through dozens of aluminum runs. It looked fine. But the parts? They had inconsistent edges and tiny shifts in profile. Not enough to fail visibly, but enough to trigger problems in assembly.

They didn’t see the wear until we showed them under magnification.

That taught me: don’t wait for a tool to fail. Know what it’s doing before it does damage.

Choosing the Right Tool for Aluminum

Aluminum is soft, fast to cut, and sticky. That stickiness creates heat, and that heat can ruin edges quickly.

- Use carbide tools instead of high-speed steel, they hold up better under heat.

- Pick 2- or 3-flute end mills. Fewer flutes mean better chip evacuation.

- Look for polished or coated finishes that prevent chips from welding to the tool.

I’ve seen part quality jump just from switching to a mirror-finish end mill. The chips flowed better. The cuts got cleaner.

Recognizing Tool Wear Early

Not all wear is obvious.

A part might still pass inspection, but if your tool is dull, it starts pulling the material instead of cutting it. That leads to more vibration, more heat, and more stress on the spindle.

You might notice:

- A sudden change in cut noise

- Edges that look rubbed instead of sheared

- Light burn marks or dull surfaces

One operator told me he could feel the change through the machine’s handwheel. That’s the kind of awareness you want to build

Tool Storage and Handling

Good tools can still go bad, if they’re mishandled.

Avoid letting them bump together in drawers. Don’t stack them loose on the bench. Even a small nick can ruin a sharp edge.

Instead:

- Store them in padded racks or trays

- Wipe off chips and coolant after use

- Keep them dry to prevent corrosion on holders and inserts

It only takes a few seconds to store a tool right. But it can save hours of wasted machining.

6. Quality Control Measures

You can’t machine aluminum parts on hope.

I worked with a team that was proud of their speed. Fast setups, fast cuts, fast deliveries. But when I looked closer, they were skipping most in-process checks. The results? A few perfect parts… and a few that didn’t even fit the jig.

They weren’t cutting corners on purpose, they just trusted the machine too much.

Trust is good. Verification is better.

Start With First-Article Inspection

Before you run the full batch, check that first part carefully. Measure it. Look at the surface. Test the fit if it’s part of an assembly.

One of the best shops I know spends more time inspecting the first part than running the next twenty. And they rarely scrap anything.

Even Machmaster, who offers CNC machining for high-precision aluminum parts, follows strict first-piece checks before scaling a job.

Check During the Run, Not Just After

In-process inspection helps catch tool wear, machine drift, or fixture movement before they affect a whole run.

You don’t need to overcomplicate it. Spot-checking dimensions after every few parts is usually enough. Use calipers, micrometers, or even go/no-go gauges, whatever makes sense for your part.

The key is to be consistent. Make it routine, not optional.

Look Beyond the Numbers

It’s easy to focus only on tolerance checks. But quality includes more than just size.

Things to look for:

- Burrs or sharp edges

- Scratches or dents from poor handling

- Surface finish that’s too rough or uneven

One shop we supported passed all their dimension checks, but their anodizer rejected an entire batch due to surface defects. It was a painful reminder that visual checks matter, too.

7. CNC Operator Training and Competency Standards

The machine is only as good as the person running it.

Years ago, I watched a skilled operator pause a job halfway through. Nothing was wrong on the screen. The part looked fine. But he heard something in the spindle, just a small change in sound. He stopped the machine, checked the tool, and found a tiny crack in the end mill.

If he hadn’t caught it, that tool could’ve broken mid-pass. The machine could’ve been damaged. Someone could’ve gotten hurt.

That kind of awareness doesn’t come from guessing. It comes from training and time.

Basic Operator Skills

Every CNC operator should understand the essentials before running any aluminum machining job.

That includes:

- How to read blueprints and follow part specs

- Basic G-code knowledge

- How to load tools and raw material correctly

- Running setup and zeroing out offsets

- Safe startup and shutdown procedures

These basics create a strong foundation, and reduce small errors that often lead to big problems.

Machine and Material Knowledge

Operators should know how aluminum behaves differently from other materials.

That means understanding:

- Correct feed and speed settings for aluminum

- How chip evacuation works

- Common tool choices for aluminum (2–3 flute end mills, polished carbide)

- What surface finish and tolerance levels are expected

Without this knowledge, you’ll see more tool wear, poor finishes, or out-of-spec parts.

Safety and Emergency Protocols

Safety training must go beyond just reading manuals.

Operators should know:

- What does each emergency stop does

- Where pinch points and hazard zones are

- What to do in case of a coolant leak, tool break, or machine fault

- Why never override safety interlocks or run with the door open

We’ve worked with shops that do short weekly drills just to keep these skills sharp. It’s a simple practice, but one that can save lives.

Ongoing Certification and Learning

Standards evolve. Machines change. Training shouldn’t stop at onboarding.

Encourage:

- On-the-job mentorship with senior operators

- Refresher sessions on tooling, materials, and safety

- Certifications from programs like NIMS (National Institute for Metalworking Skills) or OSHA safety modules

Shops like Machmaster often rely on internal training paths, backed by formal programs, to keep their teams up to standard across high-volume CNC operations.

Conclusion

That lost order over 0.05 mm? We never let that happen again.

Now you know why: precision and safety go hand in hand. You’ve learned where mistakes begin, at setup, tooling, training, and how to prevent them.

This guide walked you through every step: what to look for, how to act, and why it matters.

If you need help machining aluminum parts with consistent accuracy, Machmaster follows these same principles every day.

Start small. Set your standards. Build habits that hold.

Contact us today, and let’s make your next batch your best one yet.