You ever spend hours dialing in a setup only to scrap the first three parts?

I’ve been there.

I was holding a thin-walled aluminum sleeve with hard jaws. The setup looked fine. The indicator was happy. But the part? Crushed, every time. We lost a full shift trying to “tweak” the pressure.

That was the day I finally gave soft jaws a real chance.

If you’re reading this, maybe you’re tired of parts slipping. Or you’re chasing tolerances that never stay put. Maybe you’re wondering if soft jaws are worth it, or just more work.

This article is your answer.

I’ll walk you through what soft jaws are, how they’re used, when they make a difference, and how to machine them right. I’ll also share what’s worked and what’s cost me.

So, let’s start!

1. What Are Soft Jaws?

If you’ve ever struggled with slipping parts or crushed edges, you’re not alone. I’ve been there, frustrated, rechecking setup after setup, wondering what I missed. That’s how I first stumbled into soft jaws. And they changed the way I run parts on a CNC lathe.

So, what are they?

Soft jaws are replaceable clamping jaws made from materials like aluminum, mild steel, or even plastic. They’re called “soft” because they’re much easier to machine than the hardened jaws that come with most chucks.

You use them to hold your part securely without damaging it. The trick is: you machine the jaw itself to match the shape of your part. That’s where the real advantage lies.

2. Hard Jaws vs. Soft Jaws

Before we go further, let’s take a step back and compare them to what you might be using now.

Hard jaws are made from tough, wear-resistant steel. They last a long time and are great for general holding. But they don’t adapt well. You’re stuck with their standard shape unless you add extra fixturing.

Soft jaws, on the other hand:

- Can be bored or milled to match your part’s profile

- Offer better contact and grip

- Reduce surface damage, especially on softer materials

That’s why soft jaws are often called consumables. You machine them for one job, then re-bore or replace them for the next. They don’t last forever, and that’s the point, they’re meant to serve a specific setup.

So when should you use each?

Use hard jaws for quick setups and repeat parts with simple shapes.

Reach for soft jaws when:

- You need precision

- Your part has thin walls

- The surface finish matters

- The geometry isn’t easy to grip

You might ask: “Is it worth the extra time to machine soft jaws?”

From my experience, yes. Every time I’ve tried to cut corners, I ended up paying for it in scrap or downtime.

Soft jaws are one of those tools that seem simple but they give you control when you need it most.

3. Why Soft Jaws Matter in CNC Turning

Once you know what soft jaws are, the next step is understanding why they’re so useful in real-world machining. It comes down to one thing, better control over your part.

Precision and Repeatability

In CNC turning, your results depend on how consistently you can hold the part. If the part shifts, even slightly, everything else your cut, your dimensions, your finish, falls apart.

Soft jaws help lock in the part exactly where it needs to be. Because you machine the jaws to match your part’s shape, each piece sits in the same spot every time. That’s repeatability.

You don’t need to chase offsets. You don’t need to guess. You just run the job.

Protecting Part Surfaces

Soft jaws also protect the part from damage.

Hard jaws can leave marks or crush delicate features. That’s especially true with soft metals like aluminum or parts that don’t have much wall thickness.

Soft jaws spread the clamping force more evenly. That means:

- Fewer dents

- Less distortion

- Better surface finishes

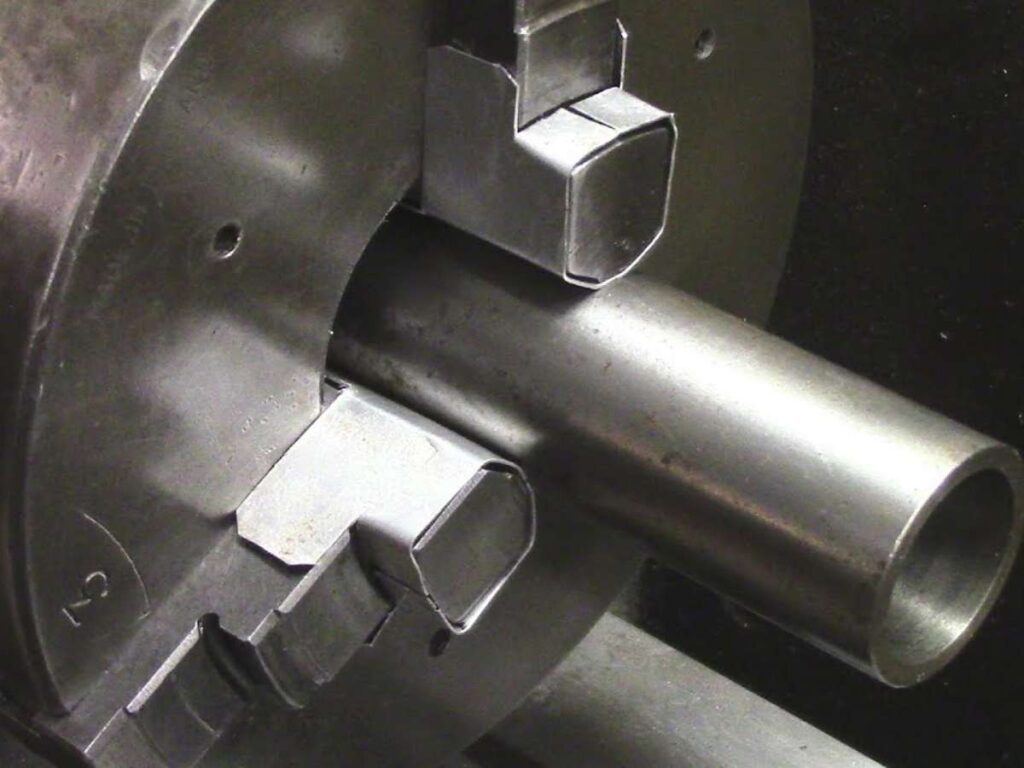

Clamping Odd-Shaped or Thin-Walled Parts

Some parts just don’t fit in a standard setup.

Thin rings. Flanges. Complex profiles. You can fight them or you can machine your jaws to fit. Soft jaws make that possible.

4. Materials Used for Soft Jaws

Once you understand why soft jaws matter, the next step is choosing the right material. That decision can make or break your setup—literally.

There’s no single “best” choice. It depends on what you’re clamping, how many parts you’re running, and the finish you’re after.

Let’s walk through the most common options.

Aluminum

This is the go-to for many shops, including mine.

Why? It’s easy to machine. Fast to bore. And gentle on the part.

But it wears out quickly, especially with high clamping force or abrasive chips. I usually reach for aluminum when I need a quick setup for a short run or delicate part.

Best for:

- Soft or finished materials

- Short production runs

- Prototyping

Downside:

- Low durability. You’ll be re-boring often.

Mild Steel

Tougher than aluminum. Still easy to machine. Lasts longer under pressure.

Mild steel is great for medium to high-volume jobs. You can hold tighter tolerances without re-boring after every few cycles.

Best for:

- Higher production volumes

- Parts that need consistent repeatability

Downside:

- Slightly more machining time

- Can leave marks on soft parts

Plastic (like Delrin or Nylon)

It might surprise you, but plastics can work well especially when the part is fragile or already finished.

They won’t mar the surface, and they’re fast to cut. But they don’t last long.

Best for:

- Very soft or polished materials

- Holding without damage

Downside:

- Low strength

- Deforms easily under high pressure

Bronze

Bronze strikes a balance between softness and wear resistance.

I’ve seen shops use it when they need something stronger than plastic but still gentle. It’s less common, but it has its place.

Best for:

- Specialized jobs needing surface protection

- Mid-volume production

Downside:

- Cost

- Can be harder to find in jaw blanks

If you’re running one prototype for review, aluminum might be perfect. If you’re holding hundreds of steel parts for a tight-tolerance finish cut, mild steel is probably the safer choice.

Material matters. Choose it like the part depends on it because it does.

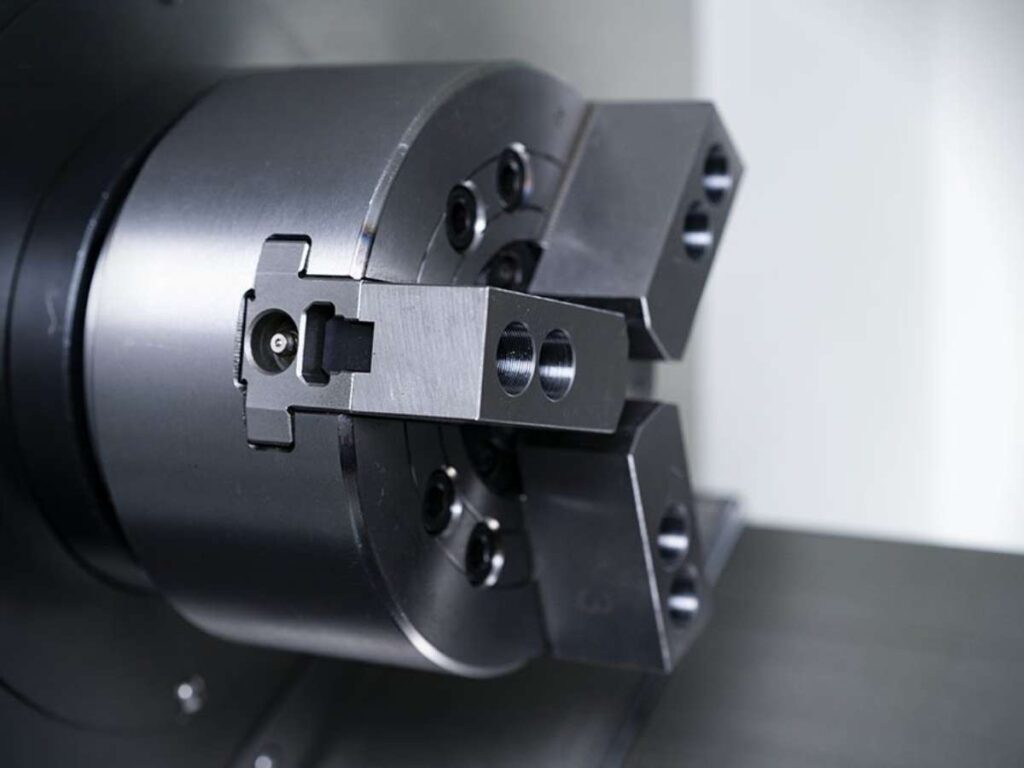

5. Types of Soft Jaws

Not all soft jaws are built the same. The right choice depends on your machine, part geometry, and how you manage changeovers. This table lays it all out in one place.

| Category | Type | Best For | Pros | Cons |

| Chuck Configuration | 2-Jaw Soft Jaws | Rectangular or irregular parts | Simple clamping for odd shapes | Limited contact points; less common |

| 3-Jaw Soft Jaws | Round parts | Self-centering; fast setup | Limited flexibility for non-round parts | |

| 4-Jaw Soft Jaws | Off-center or square parts | Independent jaw adjustment | Slower and more manual setup | |

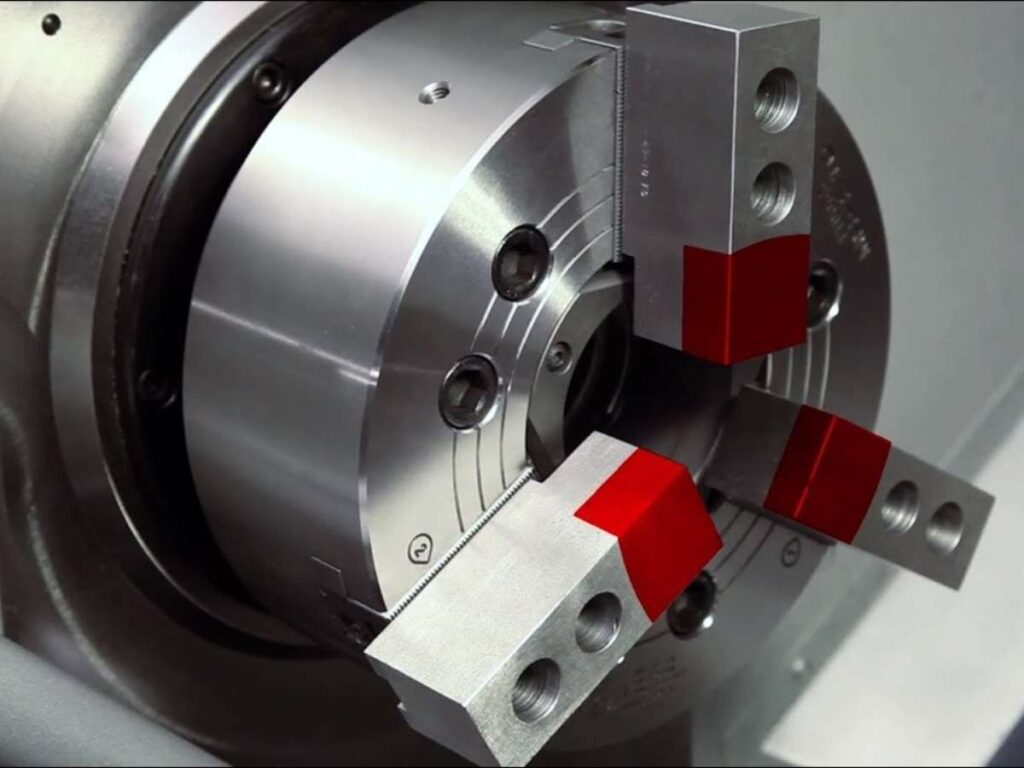

| Jaw Style | Standard Soft Jaws | General use; short runs | Easy to machine; widely available | Not ideal for fragile or thin-walled parts |

| Pie Jaws | Thin-walled or delicate parts | Wraps around part; reduces distortion | Higher cost; less common | |

| Mounting Design | Bolt-On Jaws | General holding applications | Reliable; used in most shops | Takes longer to change out |

| Quick-Change Jaws | Jobs with frequent changeovers | Reduces downtime; tool-free swaps | Higher initial cost | |

| Contact Shape | Segment Jaws | General gripping | Simple, flexible design | May cause part marking; less support |

| Wraparound Jaws | Thin-walled or sensitive parts | Full part support; prevents deflection | Slower setup; needs precise boring |

6. How to Machine Soft Jaws

Once you’ve picked the right soft jaw type and material, it’s time to machine them. This part matters a lot. Poorly machined jaws can throw off your tolerances, grip, and finish. The good news? You can do it right with a few simple steps.

Start with Concentricity

To hold your part accurately, the jaws need to match its shape and be centered. This is called concentricity.

You don’t take the jaws off to machine them. Instead, you bore them while they’re mounted on the lathe. That way, they’re aligned to the same spindle centerline your part will sit on. It’s one of the best tricks in the book.

Use Boring Rings

Boring rings hold the jaws tightly together during machining. They simulate the clamping pressure used in a real cut.

Without rings, your jaws may shift slightly. That’s enough to throw things off. So don’t skip this step, it makes a big difference.

Offset Boring for Eccentric Parts

What if your part isn’t centered?

You can machine the jaws off-center. This is called offset boring, and it’s useful for holding parts like cams, tubes with side holes, or anything that’s not symmetric.

You’ll need to adjust the chuck position or set offsets in your program.

Reference Jaw ID to Part ID

When boring soft jaws, the inside diameter (ID) you cut should match your part’s ID. That gives you the most contact and helps avoid distortion.

If your part has a step, groove, or feature, you can machine that into the jaws too. It saves setup time and improves repeatability.

Toolpaths and Feeds/Speeds

Keep it simple:

- Use a boring bar or small OD tool

- Choose light cuts to avoid jaw flex

- Use 0.003″–0.005″ per pass on aluminum

- Go slower for steel around 200–300 SFM with light feed

Always verify tool clearance, especially with small jaws or odd profiles.

7. Common Applications

Soft jaws aren’t just for special cases. They show up in everyday machining more often than you might think. Whether you’re clamping something fragile or chasing tight tolerances, soft jaws give you control where it counts.

Let’s look at where they really shine.

Thin-Walled Tubing and Aerospace Parts

This is where soft jaws earn their keep.

Thin-walled parts bend easily under pressure. Hard jaws can crush them or leave clamp marks. That’s a big problem in aerospace, where even a small defect means rework—or scrap.

Soft jaws give you more surface contact. You can machine the jaws to hug the part just right. Less pressure. Less distortion. Better results.

I’ve seen teams switch to soft jaws mid-project after losing too many thin tubes. The fix was immediate: cleaner finishes and parts that actually passed inspection.

Second Ops That Need Tight Tolerances

After a part is turned, sometimes you need to hold it again to cut another feature. This is called a second operation.

Holding a finished surface is tricky. You can’t afford to damage it. And you need it to sit in the exact same spot every time.

Soft jaws let you match the shape of the part, so it fits snug with no shift. That gives you reliable, repeatable clamping for critical cuts.

Prototypes and Small Batches

When you’re making just a few parts, you don’t want to spend hours building a complicated fixture.

Soft jaws are fast to machine. You can throw them in the chuck, bore a profile, and be cutting in minutes.

Perfect for:

- One-off parts

- Product development

- Low-volume R&D work

Short-Run Production

Let’s say you’re running 10–50 pieces. Not quite mass production, but not one-off either.

Soft jaws hit the sweet spot here. You get a custom fit without the cost or complexity of a full fixture. And you can re-bore the same jaws for another job later if needed.

If your part is delicate, complex, or short-run, soft jaws aren’t just helpful, they’re often the smartest choice. They give you the grip you need without the headaches you don’t.

8. Cost and Sourcing Considerations

Soft jaws may seem like a small part of your setup but their cost, lead time, and sourcing can impact your entire job. Whether you’re buying pre-made or cutting your own, it helps to know what you’re paying for.

Off-the-Shelf vs. Custom Machined

You’ve got two main options:

- Off-the-shelf soft jaw blanks

- Fully custom machined jaws

Soft jaw blanks come pre-cut to size, drilled, and ready for you to bore. They’re easy to find, and you can keep them in stock for quick jobs.

Custom jaws, on the other hand, are made to fit your specific part or chuck. You might need them for complex shapes or production jobs where repeatability matters most. They cost more—but can save time if your team is already stretched.

What Goes Into the Cost?

The cost of soft jaws depends on a few things:

- Material: Aluminum is cheaper, mild steel costs more, bronze is the most expensive.

- Machining time: Simple bores are quick. Complex profiles take longer.

- Labor: If you’re paying a machinist, time adds up fast.

Typical cost range for a set of soft jaws:

- Aluminum blanks: $15–$40

- Mild steel blanks: $25–$60

- Custom machined sets: $80–$200+ depending on complexity

Lead Time for Custom Jaws

Need something made from scratch? Be ready to wait.

Lead time for custom jaws from a shop can take:

- 2–4 days for simple shapes

- 1–2 weeks for complex profiles or high-volume runs

Need soft jaws but don’t have the time or tools to machine them yourself?

MachMaster can help. We offer custom jaw machining, CNC lathe services, and complete production support for high-precision jobs across electronics, aerospace, medical, and more.

9. Tips for Getting the Most from Your Soft Jaws

Soft jaws might seem simple, but the way you manage them can save hours of setup time and keep your parts more consistent. Here are a few lessons I’ve learned the hard way—and some habits that now save me time on nearly every job.

Re-Bore for Multiple Part Sizes

Don’t throw out a set of jaws just because one job is done.

If there’s enough material left, you can re-bore the same jaws for a new diameter. This is common in short-run shops where materials and budgets are tight.

Keep in mind:

- Don’t overcut on the first job

- Leave yourself room for future profiles

- Track how many times you’ve re-bored to avoid weakening the jaw body

Catalog Your Jaws

Ever wasted time re-machining a jaw you already had? I have. It’s frustrating.

Now I catalog all bored jaws by:

- Part number

- Job name

- Chuck size

- Bore size

A simple shelf system or labeled bin saves you from doing the same work twice.

Use Jaw Savers and Inserts

If you’re machining soft jaws often, consider using jaw savers. These are insert blocks you bolt onto your main jaws and machine instead. They cost less to replace and protect the body of your jaws.

You can also use aluminum or plastic inserts for holding finished parts without scratching them.

Manage Coolant and Prevent Rust

Jaws take a beating in the chuck especially from coolant.

To avoid rust and buildup:

- Blow off jaws after each job

- Wipe with a light oil before storage

- Check bolt holes and threads for trapped chips

A little care here keeps your jaws clean, safe, and ready for next time.

Conclusion

Holding the part right changes everything. It’s the difference between scrap and success.

In this guide, you’ve learned:

- What soft jaws are

- How to machine them

- Where they fit in your process

And maybe more importantly, you’ve seen how much control they give you.

So what’s the next job on your list? Could better jaws save you time or parts?

Contact us today. Let’s solve it together.