You ever lose an hour chasing a problem that turns out to be a bad clamp?

I have.

I was machining a set of small aluminum bushings. Everything looked right, toolpath was smooth, speed and feed? Checked. But one part kept coming out slightly off. Just enough to fail inspection.

Turns out, my soft jaws had worn down, just enough to cause a shift under load.

If you’re trying to figure out which clamping method is right for your parts, or why your tolerances keep drifting, you’re in the right place.

In this article, I’ll walk you through the types of CNC lathe clamping systems, what they’re best for, and how to get the most consistent results. By the end, you’ll know how to hold your parts the right way and save yourself from rework headaches.

Let’s start!

1. What Is CNC Lathe Clamping and Why It Matters

Let’s start with the basics.

Clamping is how you hold a workpiece steady during CNC lathe machining. Sounds simple, right? But it’s one of the most important steps in the entire process.

Without solid clamping, even the best machine and the sharpest tool can’t save you. The part needs to stay still while it’s being cut. Any movement, no matter how small, can ruin the job.

Good clamping helps you:

- Cut with precision

- Repeat results across batches

- Avoid tool damage

- Protect the operator

It also keeps your parts consistent and safe to work with. If you’re trying to reduce scrap and improve part quality, this is where it starts.

What Happens If Clamping Is Done Wrong

I once had a part shift during finishing. Just a hair.

The surface came out scratched. Tolerance? Blown. We had to remake the whole batch. And it was because I didn’t double-check the setup.

Bad clamping can cause:

- Slippage while cutting

- Dents or scratches on the surface

- Parts coming out the wrong size

- Tool breakage or worse, injury

Ever had to stop a machine mid-cycle because the part spun out? It’s not fun. And it’s dangerous.

Key Industries and Users Who Depend on Proper Clamping

Some industries rely heavily on precision. If you’re in any of these, clamping can make or break your production:

- Aerospace

- Automotive

- Mold making

- Custom part manufacturing

Even hobbyists and engineering students need solid setups. One bad clamp can throw off a school project or damage a home machine.

2. Types of CNC Lathe Clamping Systems

Once you understand why clamping matters, the next step is figuring out which clamping method to use. The right choice depends on your part’s shape, size, and material. It also depends on your production needs.

Let’s break down the common types.

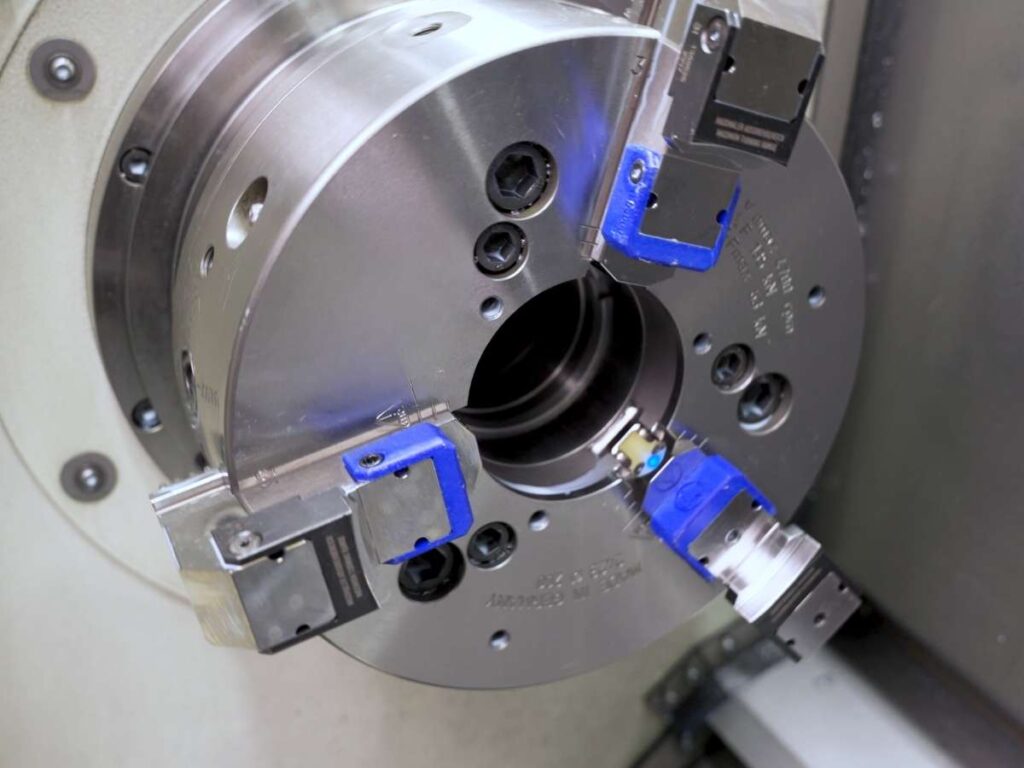

3-Jaw Chucks

These are the go-to clamps for round or symmetrical parts. They’re fast and easy to set up, which saves time.

But they have limits. If your part has an odd shape or needs perfect alignment, this may not work well.

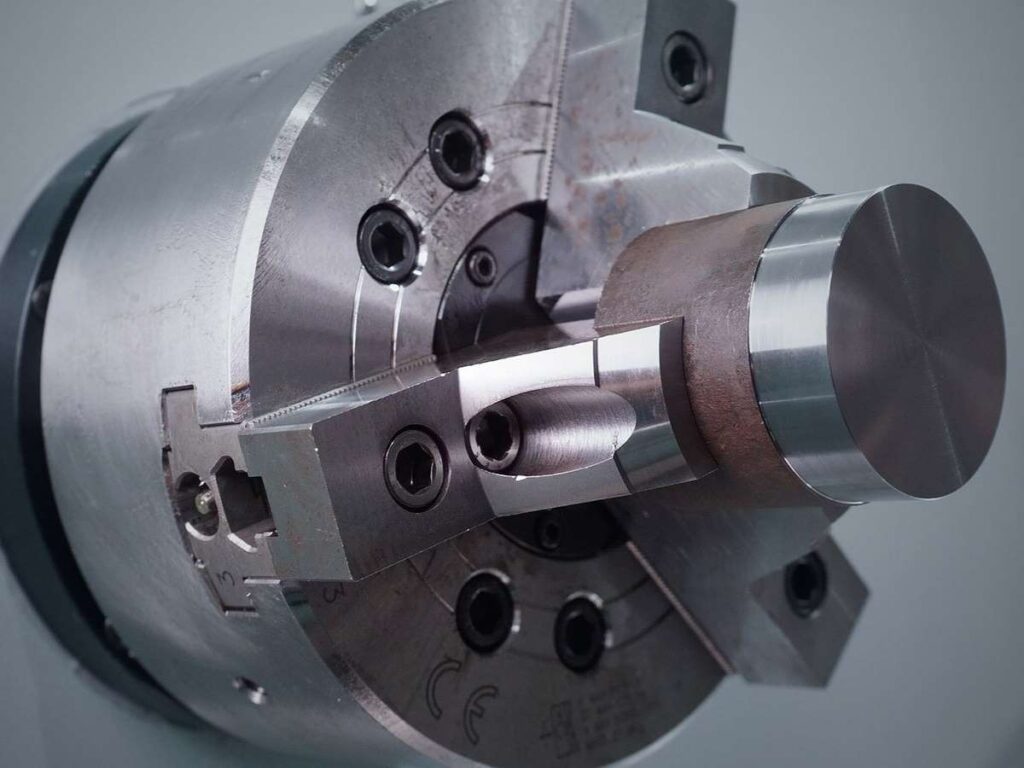

4-Jaw Independent Chucks

This setup gives you more control. It’s perfect for square parts or jobs that need offset machining.

You’ll need to center the part manually. That takes more time, but you get better precision.

Collet Chucks

Working with small, fragile parts? Collet chucks are a great choice.

They hold the part evenly and with high accuracy. That helps prevent damage and keeps your tolerances tight.

Soft Jaws

These are custom-machined to fit your specific part.

They’re a great option if you’re working with finished surfaces or parts that mark easily.

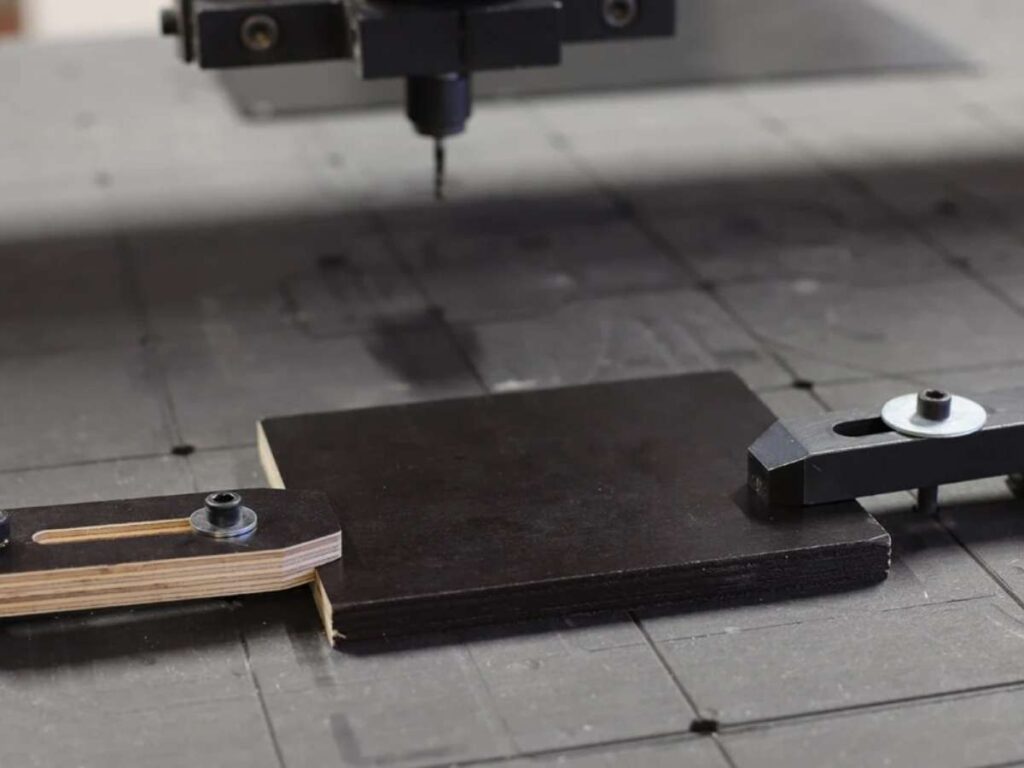

Magnetic or Vacuum Clamps

If your part is flat and light, these might work well.

Magnetic clamps only work on metal that attracts a magnet. Vacuum clamps need smooth, even surfaces to hold.

Hydraulic and Pneumatic Clamping

Running big batches? These are built for speed and repeatability.

You press a button, and the machine clamps automatically. It’s fast, and it keeps your results consistent.

3. How Clamping Affects Machining Accuracy and Surface Finish

Now that you know your clamping options, let’s talk about how they affect your results. Because clamping doesn’t just hold the part, it changes how the part behaves during machining.

If your clamping setup isn’t right, you’ll see it in the final cut.

Part Deflection and Deformation

I once clamped a thin aluminum ring too tight. Looked fine at first. But when I removed it from the chuck, it sprang out of shape. Total loss.

Thin walls and soft materials like aluminum or plastic bend easily under pressure. If you’re using standard jaws and heavy clamping force, the part can warp before the tool even touches it.

Try using:

- Soft jaws shaped to match the part

- Low-pressure settings if available

- Light spring clamping for fragile materials

It might take more setup time, but it saves you rework later.

Runout and Tolerance Loss

Runout is how much the part wobbles while spinning. Too much of it, and you’ll miss your tolerances.

If the part isn’t centered right, the tool won’t cut evenly. That affects every pass. Always check runout with a dial indicator before you hit start.

Even small errors here can ruin a tight-tolerance job.

Surface Damage

Hard jaws grip well but they can leave marks. And if you’re working with finished surfaces, that’s a problem.

You can avoid this by:

- Adding protective covers to your jaws

- Designing the part so the clamp touches a non-critical area

- Using soft inserts or rubber pads

4. Best Practices to Improve Clamping Efficiency

Even the best clamp won’t save you if the setup is rushed. I’ve learned this the hard way that clamping mistakes usually don’t show up until the machine’s already running.

Want to get better results, faster? Start with a smart setup.

Pre-Setup Checklist

Before clamping anything, take a moment to check your equipment. Dirt, oil, or leftover chips can throw everything off.

Here’s what to do:

- Clean the chuck, jaws, and part surface

- Choose the correct jaw type based on your part

- Adjust the clamping pressure if your machine allows it

- Use alignment tools like dial indicators to center the part

This takes a few minutes, but it prevents hours of rework.

Tips for Repeatable Setup

If you’re running multiple parts or the same job later, make your setup easy to repeat. Small adjustments can save big time.

Try this:

- Use locating pins or stops to line up the part quickly

- Set work offsets in your machine

- Record your jaw setup, torque settings, and clamping points in your CAM file

I started doing this after losing track of a custom soft jaw setup. Never again.

Avoiding Rework and Scrap

Before cutting, do a dry run.

- Watch for vibration

- Check if the part moves under tool pressure

- Listen for unusual noise during rapid moves

Even small shifts can wreck a part or damage your tool. Don’t wait for the finish pass to find out.

5. Choosing the Right Clamping System

Not every project needs the same setup. What works for mass production might slow you down in prototyping. And precision jobs? They come with their own set of rules.

Let’s walk through the main types of work, and what clamping makes the most sense for each.

For Prototyping and Low Volume

I remember building my first prototype batch using hydraulic clamps. It was overkill—and expensive.

If you’re testing a design or machining just a few parts, focus on flexibility. You might need to adjust things on the fly.

Try using:

- Manual 3-jaw or 4-jaw chucks

- Soft jaws that you can machine in-house

Avoid anything that locks you into a fixed setup. You’ll lose time trying to adapt it.

For Mass Production

Running high volumes means you need more than speed, you need consistency, part after part.

That’s exactly what MachMaster delivers, precision machining and custom production solutions with ±0.01mm tolerance, trusted by 500+ companies worldwide.

For High Precision Parts

If the part needs to hold tight tolerances, use a system that gives full control.

What helps:

- Collet chucks for even pressure

- Custom fixtures that reduce how much of the part is clamped

- Checking alignment before every run

It takes extra effort, but it’s worth it when accuracy counts.

6. Clamping Considerations for Specific Materials

Different materials behave differently under pressure. Some are soft and mark easily. Others need more grip. Choosing the right jaw material and pressure makes all the difference.

I’ve learned this the hard way one material, one clamp setup, and suddenly you’re dealing with dents, melt marks, or misalignment. The table below can help you avoid that.

| Material | Challenges | Best Clamping Practices |

| Aluminum | Prone to denting and surface damage | – Use soft jaws or plastic inserts – Apply low clamping pressure – Clamp non-critical areas |

| Stainless Steel | Requires strong grip Risk of thermal expansion | – Use jaws with high grip – Apply more clamping force – Monitor part temperature during long runs |

| Plastics | Easily deformed or melted Sensitive to heat | – Use light pressure – Lower RPMs – Add support fixtures to reduce vibration |

Tip: Match your clamping method to the material you’re cutting. It might seem like a small detail—but it’s one that affects surface finish, accuracy, and part success.

7. How Clamping Impacts Product Design

If you’ve ever designed a part that looked perfect on screen but gave machinists a headache on the shop floor, you’re not alone. I’ve been there too. The issue? Clamping wasn’t considered early enough.

Good design doesn’t just focus on how the part functions. It also thinks about how it will be held and machined.

Allow Room for Clamping Surfaces

Clamps need somewhere to grip. But too often, there’s no space, just tight features and delicate finishes.

Here’s what helps:

- Add a little extra stock on non-critical areas

- Keep key features away from jaw contact points

- Use sacrificial tabs if needed

One time, I added small flanges just for clamping and saved hours of setup time. The part came out perfect, and we didn’t have to grip any critical surfaces.

Consider Machining Orientation Early

Before you finalize a design, think about how the part will sit in the machine. Can it be clamped easily? Can the tool reach all the features without flipping the part?

Try to:

- Design with a single setup in mind

- Avoid deep pockets that are hard to access

- Plan features so clamping won’t get in the way

This reduces reorientation and speeds up machining.

Communicate Clamping Needs in Technical Drawings

You might know how the part should be clamped but does your machinist?

Make it clear by:

- Marking clamping zones in the drawing

- Adding notes on surface finishes and tolerance sensitivities

- Pointing out features that must stay untouched

Clear drawings save time and prevent guesswork.

8. Common Clamping Problems and How to Fix Them

Even when you think you’ve got the setup right, problems can still show up. I’ve dealt with parts that slipped mid-cut, jaws that left marks, and setups that took way longer than they should have.

Most clamping issues have simple causes and simple fixes. Here’s a breakdown of what might go wrong and how to correct it.

Part Slips During Machining

You hit start, and somewhere in the middle of the cut, the part shifts. Now the dimensions are off, or worse, it crashes the tool.

Fix:

- Increase clamping force slightly

- Re-machine the jaws to match the part geometry

- Make sure the surfaces are clean and dry before clamping

A snug, even hold is key here.

Jaw Marks on Surface

You remove the part, and there they are—scratches or dents from the jaws. It’s frustrating, especially on finished surfaces.

Fix:

- Use soft jaws that are machined to match the part

- Add protective sleeves or rubber inserts

- Clamp on non-critical surfaces if possible

One batch I ran had visible marks. We switched to plastic inserts on the jaws and never had that issue again.

Excessive Runout

If your part wobbles as it spins, that’s runout. It messes with tool engagement and kills your tolerances.

Fix:

- Check jaw alignment with a dial indicator

- Clean out debris or chips in the chuck

- Replace worn jaws if needed

Always check runout before your first cut.

Setup Time Too Long

Clamping shouldn’t slow you down. But it can, especially when jaws need adjusting between jobs.

Fix:

- Use quick-change jaws or modular fixturing

- Standardize setups across similar part types

- Document jaw locations and part offsets in your setup sheets

Most clamping problems are avoidable. If something feels off, pause and take a second look. A small fix now can save a lot of wasted time and material later.

Conclusion

I’ve made the mistakes. I’ve lost time and parts.

Now you don’t have to.

This guide gave you:

- A clear view of what CNC lathe clamping really involves

- How to choose the right clamp for your project

- Tips to avoid surface damage, tolerance issues, and wasted setups

Ready to stop guessing and start getting repeatable results?

Contact MachMaster today to get support with your next job or custom part.