I still remember the first time I tried to find the best CNC machining services.

I had a part design in hand—just a simple idea—but I didn’t know where to go or who to talk to.

I stood in my small workspace, staring at my drawing, wondering, “Now what?”

Maybe you’ve felt that way too.

You might be a factory owner needing parts fast, a product designer building a prototype, or a buyer trying to find the right supplier.

Since then, I’ve worked with all kinds of CNC providers—some good, some frustrating. I’ve learned what makes a service reliable, helpful, and worth using again.

If you’re looking for more than just a name on a list, you’re in the right place.

This article will show you the 10 best CNC machining services I’ve come across. I’ll also explain what CNC machining is, how it works, its key parts, and where it’s used.

Let’s jump in!

Quick Comparison

Before we dive into each service in detail, here’s a quick side-by-side look at the 10 best CNC machining services. This table gives you a fast overview—what each process does best, where it’s used, and when it might be the right fit.

| CNC Service | Best For | Key Strengths | Common Materials | Typical Use Cases |

| CNC Milling | Flat or block-shaped parts | High precision, clean edges, accurate drilling | Aluminum, steel, brass, plastic | Brackets, housings, panels, heat sinks |

| CNC Turning (Lathe Work) | Round or cylindrical parts | Symmetrical shapes, clean threads, fast turning | Aluminum, brass, steel | Shafts, bushings, threaded parts, fittings |

| CNC Drilling | Repeatable, accurate holes | Consistent depth, flexible tooling | Metals, plastics | Mounting holes, pass-throughs, tapping prep |

| CNC Prototyping | Early-stage design and testing | Fast turnaround, no tooling cost, real materials | Aluminum, steel, plastic | Concept models, test fits, sample reviews |

| CNC Wire EDM | Sharp internal corners, hard materials | No pressure, extreme accuracy | Tool steel, titanium, carbide | Mold cavities, dies, medical parts |

| CNC Engraving | Permanent labels and markings | Fine detail, durable results | Aluminum, plastic, brass | Logos, serial numbers, safety labels |

| CNC Knurling | Grippable or textured round surfaces | Clean pattern, adds function and finish | Steel, aluminum, brass | Knobs, handles, thumb screws, fasteners |

| CNC Grinding | Fine finishing and tight tolerances | Smooth finish, surface correction | Steel, carbide, hard metals | Tooling, bearing surfaces, sealing areas |

| 5-Axis CNC Machining | Multi-surface, angled, or curved parts | Fewer setups, precise from all angles | Metals, plastics | Aerospace parts, turbine blades, deep pockets |

| CNC EDM (Sinker/Die) | Delicate, precise shapes in tough metals | No tool wear, high detail, clean cuts | Hardened steel, titanium | Fine holes, aerospace parts, mold features |

Now, let’s take a closer look at each CNC service, one section at a time.

1. CNC Milling

CNC milling was the first services I asked to do—and it’s still one of my favorites.

It’s flexible, fast, and perfect when need detailed cuts. CNC stands for Computer Numerical Control. Milling means cutting material with a rotating tool, kind of like a high-speed drill that moves across a block of metal or plastic.

Advantages

- Great for Both Small and Large Batches: Works well for one-off prototypes or high-volume runs.

- Works With Many Materials: Handles aluminum, steel, brass, copper, and plastic easily.

- High Accuracy: Offers tight tolerances for precise, detailed parts.

- Smooth Surface Finish: Produces clean cuts and refined surfaces with little need for extra polishing.

Common Applications

- Brackets and Housings: Often used in mechanical assemblies with mounting holes and shaped edges.

- Custom Panels: Ideal for control boxes or enclosures with slots, holes, or face cutouts.

- Heat Sinks: Great for cutting fins and channels into aluminum blocks.

- Test Fixtures: Useful for holding or aligning parts during inspection or testing.

Is This the Right Service for You?

Yes, CNC milling is a strong choice if your part starts as a flat or block shape and needs detailed shaping, drilling, or pocketing. It’s ideal for both prototypes and production parts that require accuracy and consistency.

If you’re looking for a reliable provider, MachMaster offers CNC milling backed by hands-on expertise and fast turnaround times.

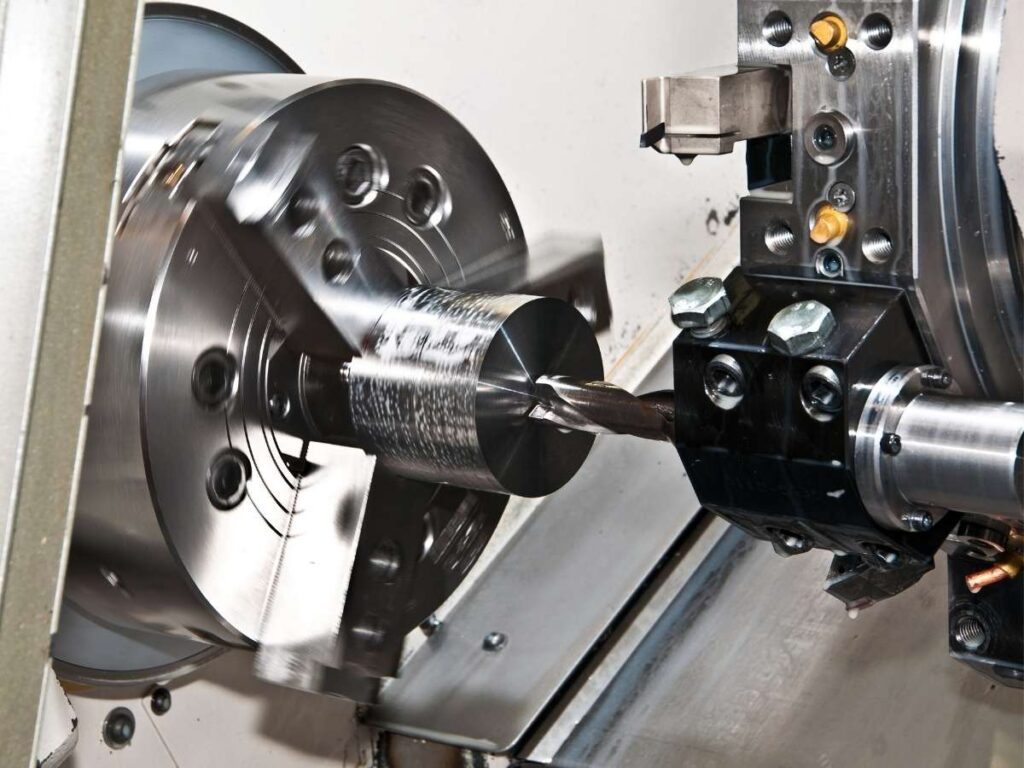

2. CNC Turning (Lathe Work)

When I needed a part with perfect threads and a smooth round finish, CNC turning was the answer. Unlike milling, which cuts across a flat surface, turning uses a lathe. The material spins, and the cutting tool shapes it while it rotates.

It’s like sharpening a pencil—but with extreme control. The result is a smooth, round part that’s even and accurate all the way around.

Advantages

- Perfect for Round Profiles: Best choice for creating rods, tubes, and parts with circular cross-sections.

- Quick and Efficient: Removes material fast, especially with aluminum or brass.

- Thread Cutting Made Easy: Handles both internal and external threads with clean results.

- Consistent Symmetry: The spinning motion produces even, balanced shapes every time.

Common Applications

- Rotating Shafts: Used in motors, gearboxes, and pumps.

- Bushings and Sleeves: Often needed in machines with moving joints.

- Custom Threaded Parts: Like fasteners or adaptors that don’t come off the shelf.

- Pipe Components: Makes clean threads for sealing and connection.

Is This the Right Service for You?

When a part needs round geometry, a clean surface, or matching threads, CNC turning is often the best fit. It works well for both simple and complex designs that need balance and smooth motion.

3. CNC Drilling

CNC drilling might seem basic—but it’s one of the services I rely on the most.

This process uses a rotating drill bit, controlled by a CNC machine, to make accurate holes at exact positions. There’s no need to mark or measure by hand. Everything is driven by the CAD file, and the machine follows it down to the decimal point.

Advantages

- Accurate Hole Placement: No guesswork—holes go exactly where they’re supposed to.

- Repeatability: Every part has holes in the same place, with the same depth and size.

- Flexible Tooling: Can use twist drills, countersinks, or step bits depending on the need.

- Efficient for Large Batches: Cuts down on time and labor, especially for parts with many holes.

Common Applications

- Mounting Holes: Important for attaching parts with screws, rivets, or bolts.

- Pass-Through Holes: Needed for wiring, fluid, or airflow in housings and panels.

- Tapping Prep: Drills the base hole for threaded features before tapping.

- Precision Location Holes: Helps align parts during assembly or welding.

Is This the Right Service for You?

I used to think a small misaligned hole wasn’t a big deal—until I had to remake an entire part because of it. If a part depends on clean holes in the right spots, CNC drilling is worth it. It brings peace of mind, especially when everything needs to line up.

This service fits best when your design calls for multiple holes with tight spacing, or when every part needs to be exactly the same.

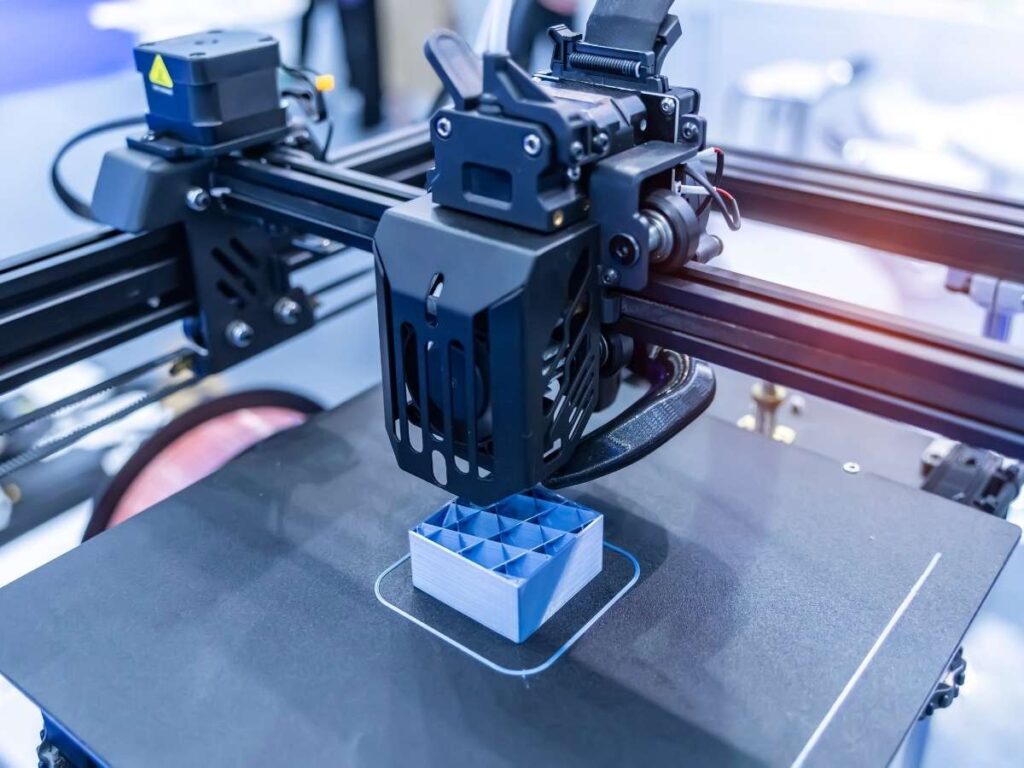

4. CNC Prototyping

CNC prototyping is all about speed, accuracy, and flexibility. It allows engineers and designers to turn a digital model into a real, testable part—quickly. There’s no waiting on expensive molds or tools. Just upload the design, choose the material, and the machine does the rest.

MachMaster offers fast and reliable CNC prototyping services to support early-stage development. This helps teams test ideas quickly, gather feedback faster, and fix issues before they become costly.

Advantages

- Fast Turnaround: Helps speed up design changes and testing within a few days.

- No Tooling Costs: Reduces waste and saves money during the early build phase.

- Real Material Testing: Works with aluminum, steel, and plastics used in final production.

- Accurate to Final Specs: Helps spot fit or performance issues before mass production.

Common Applications

- Concept Models: Useful for visualizing designs during early development.

- Test Fits: Checks part alignment, size, and interaction with other components.

- Functional Testing: Allows early builds to be tested under real conditions.

- Sample Reviews: Helpful when clients need to review a part before approval.

Is This the Right Service for You?

This is a smart choice when your project is still being figured out. I’ve caught mistakes in the prototype stage that would’ve cost thousands if they’d gone to full production. CNC prototyping gives a safe, affordable way to make changes early—before problems grow.

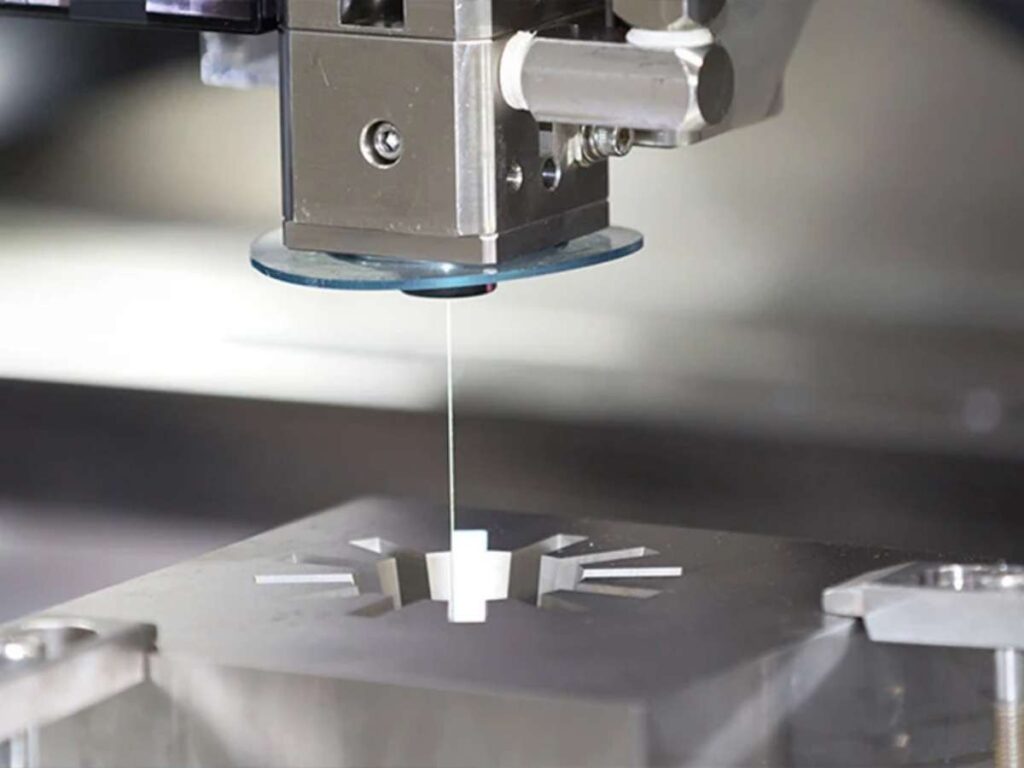

5. CNC Wire EDM

CNC wire EDM felt like magic the first time I saw it in action. A thin wire cuts through metal—without even touching it. No drills. No blades. Just a wire and electric sparks doing the work.

EDM stands for Electrical Discharge Machining. In wire EDM, a metal wire carries electric current. That current creates tiny sparks between the wire and the part, melting the metal in super fine, controlled cuts. The process happens inside a tank filled with deionized water, which cools and flushes away melted material.

It’s not fast, but it’s incredibly precise.

Advantages

- No Tool Pressure: Perfect for delicate or thin parts that could bend or warp under force.

- Very Tight Tolerances: Cuts with extreme accuracy—even for complex shapes.

- Works on Hard Metals: Can cut tool steel, titanium, and hardened materials.

- No Contact Cutting: Reduces tool wear and keeps part surfaces smooth.

Common Applications

- Mold Components: Ideal for sharp corners and detailed cavities.

- Punch and Die Sets: Used in stamping and forming tools.

- Medical and Aerospace Parts: Handles materials that are tough and heat-resistant.

- Precision Slots and Holes: Great for parts that need narrow, deep cuts.

Is This the Right Service for You?

Wire EDM is a good fit when regular cutting tools just won’t work. I’ve used it when the part was too hard to mill or too fragile to clamp. It’s slow—but when accuracy matters more than speed, wire EDM gets it done right.

6. CNC Engraving

CNC engraving is where precision meets personality. At first, I only used it to mark serial numbers on small aluminum parts. Nothing fancy—just clean, readable text. But that one step made the entire part feel more complete. Since then, I’ve used engraving for branding, labeling, and even to mark safety instructions.

This service uses a fine cutting tool to carve directly into a part’s surface. It can create letters, numbers, logos, and even custom shapes. Because the engraving is part of the material itself, it doesn’t peel, scratch off, or fade over time.

It’s a great way to add lasting detail without adding anything extra.

Advantages

- Permanent Marking: Engraved text and images won’t wear off like paint or stickers.

- Sharp, Clean Details: Produces fine lines and accurate shapes, even on small parts.

- Works on Many Surfaces: Compatible with metals, plastics, and coated materials.

- No Extra Materials Needed: No glue, labels, or added coatings—just a clean, carved mark.

Common Applications

- Part Numbers and IDs: Helps with tracking and quality control.

- Logos and Branding: Adds a professional touch that lasts.

- Safety and Instruction Labels: Perfect for panels, tools, or machines that need long-term markings.

- Decorative Text or Patterns: Adds texture and design to both functional and consumer products.

Is This the Right Service for You?

If your part needs to be labeled, tracked, or branded—and that mark needs to last—CNC engraving is worth considering. It helped me make parts look finished. There’s something about clean, permanent markings that gives a part more confidence and clarity. Whether it’s for function, branding, or safety—engraving brings detail that stays.

7. CNC Knurling

CNC knurling surprised me. A simple cylinder went into the lathe—and came out with a perfect diamond-textured grip. It didn’t just look good. It felt right in the hand.

Knurling isn’t about cutting; it’s about pressing. A special tool rolls across the surface and deforms the material into a pattern. The most common types are diamond and straight knurls. Both create raised textures that improve grip and add a finished look to round parts.

It’s done on a CNC lathe, often right after turning is complete. The machine rolls the tool with steady pressure, keeping the pattern even and consistent across the surface.

Advantages

- Improved Grip: Adds texture for better handling—especially on knobs, handles, and tools.

- Clean, Consistent Pattern: The machine applies even pressure for uniform results.

- Adds Visual Appeal: The raised pattern gives parts a finished, professional look.

- No Extra Material Needed: Uses the part’s surface—no coatings or attachments.

Common Applications

- Tool Handles: Helps prevent slipping, even when hands are oily or wet.

- Knobs and Dials: Adds grip and style for electronics, machinery, or instruments.

- Thumb Screws: Makes it easier to turn by hand without tools.

- Custom Hardware: Used on fasteners or fittings where grip and look matter.

Is This the Right Service for You?

Knurling is useful when your part needs to be gripped, twisted, or turned by hand. It’s a small feature, but it often makes a big difference in comfort and function. When grip matters, and the part needs a touch of texture, CNC knurling is the go-to choice.

8. CNC Grinding

Some parts need more than just good dimensions—they need a flawless surface. That’s where CNC grinding comes in. This process uses a high-speed abrasive wheel to remove very small amounts of material with extreme precision.

It’s most often used at the final stage of machining to improve flatness, surface finish, and accuracy. The goal isn’t to shape the part—it’s to perfect it. That level of detail matters in parts that move, seal, or wear over time.

I didn’t fully appreciate grinding until a finished part didn’t sit flat—and caused a tiny wobble in an assembly. We fixed it with one pass on the grinder. The result felt like night and day.

Advantages

- Excellent Surface Finish: Creates ultra-smooth and polished surfaces.

- Tight Tolerances: Ideal for final sizing with high precision.

- Good for Hard Materials: Works well on steel, carbide, and other tough metals.

- Removes Minor Imperfections: Cleans up small warps or distortions left from earlier machining.

Common Applications

- Tooling Components: Helps meet strict specs for dies, molds, or gauges.

- Bearing Surfaces: Prepares parts that need smooth motion and low friction.

- Cutting Tools: Sharpens and shapes edges with high accuracy.

- Hydraulic and Pneumatic Parts: Requires smooth sealing surfaces to avoid leaks.

Is This the Right Service for You?

Grinding is usually the final step, not the first. I’ve turned to it when nothing else could get the flatness or finish I needed. It helped me fix slight flaws in parts that were already close to perfect—but not quite there yet. If a part needs that next level of precision—whether it’s for fit, function, or finish—CNC grinding is the quiet hero that gets the job done right.

9. 5-Axis CNC Machining

There’s regular CNC machining—and then there’s 5-axis. I didn’t understand the difference until I worked on a part with curved surfaces, angles, and holes in weird spots. Standard machines couldn’t do it without flipping the part multiple times. That added time, errors, and headaches. 5-axis fixed all of that in one go.

This method uses a machine that moves in five directions—three linear (X, Y, Z) and two rotational (A, B). That means it can cut from almost any angle without stopping or repositioning the part. It’s fast, accurate, and great for complex geometry.

It took me a while to trust it. But once I did, it opened new design options I hadn’t thought were possible.

Advantages

- Fewer Setups: Reduces repositioning, which saves time and avoids mistakes.

- Complex Shapes in One Pass: Cuts curves, angles, and tricky features with less hassle.

- High Precision at All Angles: Delivers tight tolerances even on multi-surface parts.

- Shorter Lead Times: Faster machining with fewer tool changes and fewer steps.

Common Applications

- Aerospace Components: Handles parts with complex curves and tight specs.

- Medical Implants: Cuts shapes that follow body anatomy, like joint parts.

- Turbine Blades: Makes fluid, angled surfaces without re-clamping.

- Molds and Tools: Reaches deep pockets and complex shapes in one setup.

Is This the Right Service for You?

5-axis is ideal when part geometry is complex and multiple angles must be machined at once. I’ve used it when I needed high-quality results without wasting time on manual rework. It’s not always necessary—but when the part calls for it, nothing else compares.

10. CNC EDM (Electrical Discharge Machining)

EDM felt like science fiction. No cutting tools, no pressure—just a steady burst of sparks melting through metal. It didn’t look aggressive, but the result was precise, sharp, and clean.

CNC EDM, or Electrical Discharge Machining, removes metal by sending controlled electrical pulses between a tool and the workpiece. The spark jumps the gap, melts the material, and flushes it away using dielectric fluid. Unlike grinding or milling, there’s no contact. That makes it perfect for delicate or extremely hard materials.

- No Mechanical Contact: Reduces stress on thin or fragile parts.

- Works on Hardened Metals: Cuts tough materials like titanium or tool steel.

- Sharp Internal Corners: Reaches places milling tools physically can’t.

- High Accuracy and Detail: Perfect for tiny features and fine shapes.

Common Applications

- Injection Mold Cavities: Great for sharp edges and tight corners.

- Tool and Die Work: Used to create detailed forms in hardened steel.

- Aerospace Components: Useful for cutting high-temp, high-strength materials.

- Fine Holes and Slots: Ideal for deep, narrow, or non-round cuts.

Is This the Right Service for You?

EDM became my go-to when other methods reached their limit. EDM made it possible, with no tool wear, no chatter, and zero distortion. This service is the right call for you when extreme precision is needed—especially for hard, delicate, or intricate features that regular tools can’t reach.

Conclusion

Choosing the right CNC machining service isn’t easy—I’ve learned that through trial and error.

Now, you don’t have to guess. This guide walked through 10 key CNC services, what they do,and why each one matters.

Still unsure which process fits your part?

MachMaster can help you figure it out. We’ve supported designers, engineers, and sourcing teams with precise, fast, and reliable CNC machining.

Contact us today and tell us what you’re working on!

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

CNC Machining Types & Services:

- What is Precision CNC Machining?

- 5 Axis CNC Machining: What You Need to Know

- What Is Auto CNC Machining?

- Top 9 CNC Machining Services in China

Comparisons & Alternatives:

- CNC vs Manual Machining: What’s the Difference

- CNC Machining or Injection Molding? Know the Difference

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.