You know that feeling when everything looks right on your screen, but when the parts arrive, something’s just, wrong?

The color’s off. The shine feels cheap. Or the surface scratches the first time someone touches it.

I’ve been there, too.

Years ago, I ran a small bike parts business. We put so much time into the design. But the finish? That’s where we messed up.

One year we chose anodizing. The next, electroplating. Both taught me something. One was the better choice — but I didn’t know that at the time.

If you’re trying to figure out which one’s right for your project, I made this for you.

In this article, I’ll share what I wish I had known back then. What each finish does. How they look. How they hold up. And how they affect your budget.

Keep reading to learn more!

Quick Comparison Chart

Choosing between anodizing and electroplating isn’t just a technical call—it’s a business one.

Whether you’re a product designer or a factory owner balancing cost with compliance, this side-by-side comparison will give you quick, clear answers to the big questions.

Use this chart as a reference point when you’re aligning your finish with your priorities.

| Feature | Anodizing | Electroplating |

| Chemical and Functional Differences | Converts the surface into an oxide layer; becomes part of the metal itself. Non-conductive, porous, and dyeable. | Adds a separate metal coating to the surface via electric current. Conductive, customizable, reflective. |

| Durability and Wear Resistance | High wear resistance, especially with Type III (Hard Anodizing). Won’t peel or flake; integrated into base metal. | Depends on metal and thickness. Can chip or degrade if improperly bonded or exposed to abrasion. |

| Cost Comparison | Lower per-part cost for aluminum parts, especially in large batches. Simple process, fewer chemicals. | Cost varies by plating metal (e.g. chrome, gold). Higher labor, chemical, and environmental management costs. |

| Environmental and Regulatory Considerations | Generally eco-friendly and easier to comply with RoHS, REACH, and local regulations. Lower waste and fewer toxic materials. | Often involves hazardous materials (e.g. hexavalent chrome, cyanide). Requires careful waste handling, air control, and documentation. |

1. What is Anodizing?

I still remember the first time I held a part that had just been anodized.

It looked simple—smooth, matte, metallic. But when I learned what actually happened to that surface, I realized: this wasn’t just a finish. It was protection, identity, and durability—all in one.

If you’re making decisions around product performance or finish, you need to understand anodizing. Because if you get this part wrong, the cost shows up later—in customer complaints, reworks, or early product failures.

Let’s break it down.

Key Process Details

Anodizing isn’t a coating. It’s a chemical transformation.

Here’s what actually happens:

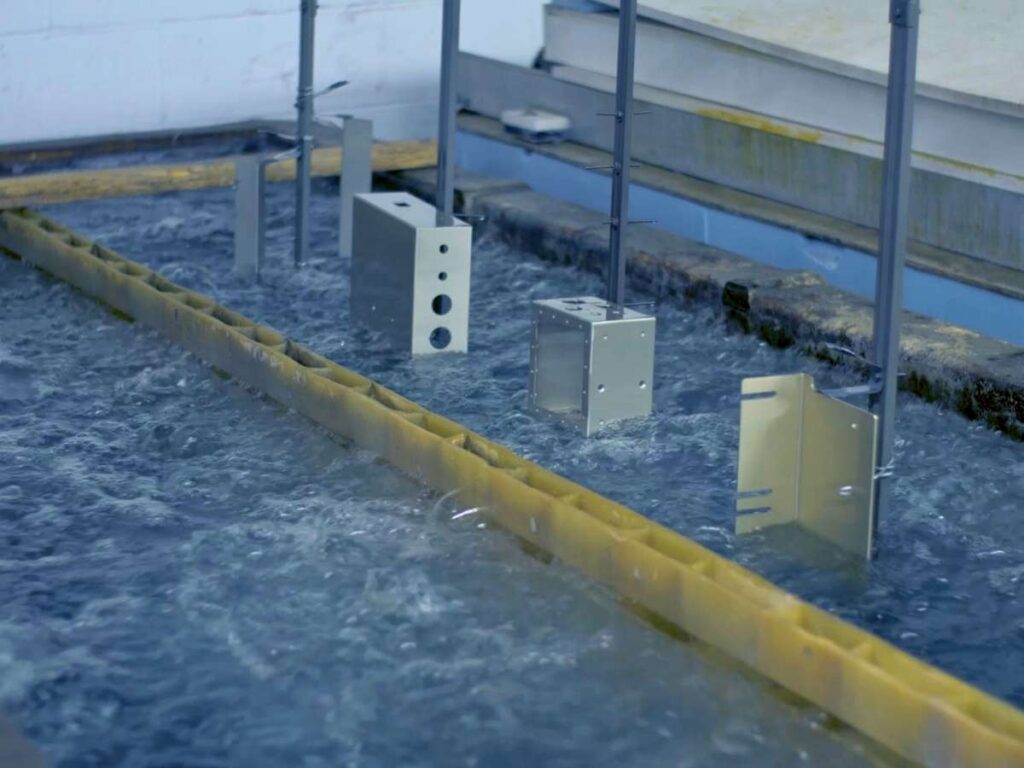

- You take a part, usually aluminum, and submerge it in an acid-based electrolyte bath.

- You run an electric current through that bath.

- Your part becomes the anode (hence the name), and that triggers an oxidation reaction.

The result? A tough, porous oxide layer forms on the surface. That layer is non-conductive, resistant to corrosion, and you can even infuse it with dye to achieve color without paint or plating.

That porous structure can be sealed, hardened, or left natural. It depends on the job you need it to do.

Metals That Can Be Anodized

Most of the time, you’ll be working with aluminum. That’s where anodizing shines.

But if your team’s working with specialized components, you can also anodize:

- Titanium – often used in aerospace or high-end medical

- Magnesium – lightweight, niche use cases

- Zinc – rarely, and only for very specific needs

Still, if you’re not using aluminum, you’ll want to confirm the metal’s compatibility before proceeding.

Types of Anodizing

Each type serves a different purpose. Your choice here directly impacts performance, cost, and aesthetics.

- Type I – Chromic Acid: Very thin. Mostly used in aerospace, where weight and precision matter more than appearance.

- Type II – Sulfuric Acid: This is your industry standard. Moderate wear resistance, accepts dye, great for consumer-facing aluminum products or structural parts.

- Type III – Hard Anodizing: When you need serious durability. It’s thicker, denser, and used in high-wear environments like tools, outdoor gear, or industrial components.

If you’re weighing your options between finishes, anodizing gives you a functional, reliable, and scalable solution, especially for aluminum-based designs.

And trust me, once you’ve seen what it can do in the field, you’ll never underestimate this process again.

2. What is Electroplating?

The first time I dealt with electroplating, I made the mistake of assuming it was just for looks.

It wasn’t until a batch of steel connectors corroded prematurely that I realized the finish wasn’t just cosmetic—it was critical protection. That lesson cost us money, time, and a hard conversation with a key customer.

If you’re designing, sourcing, or making products that rely on metal components, electroplating can make or break your product’s performance in the real world.

Let’s look at what’s really going on under the surface:

Key Process Details

Electroplating is the process of coating a metal part with a thin layer of another metal using electric current.

Here’s how it works:

- You place your part in a metal salt solution (the electrolyte).

- An electric current is applied.

- Your part becomes the cathode, and a metal, like nickel, chrome, or zinc, is deposited onto it from the solution.

What you get is a smooth, conductive, often shiny layer that protects the part underneath from corrosion, wear, or electrical resistance.

It’s especially useful when you want the strength of a base metal (like steel) with the properties of something more valuable or attractive (like gold, chrome, or copper).

Common Metals Used for Electroplating

Different plating metals serve different purposes:

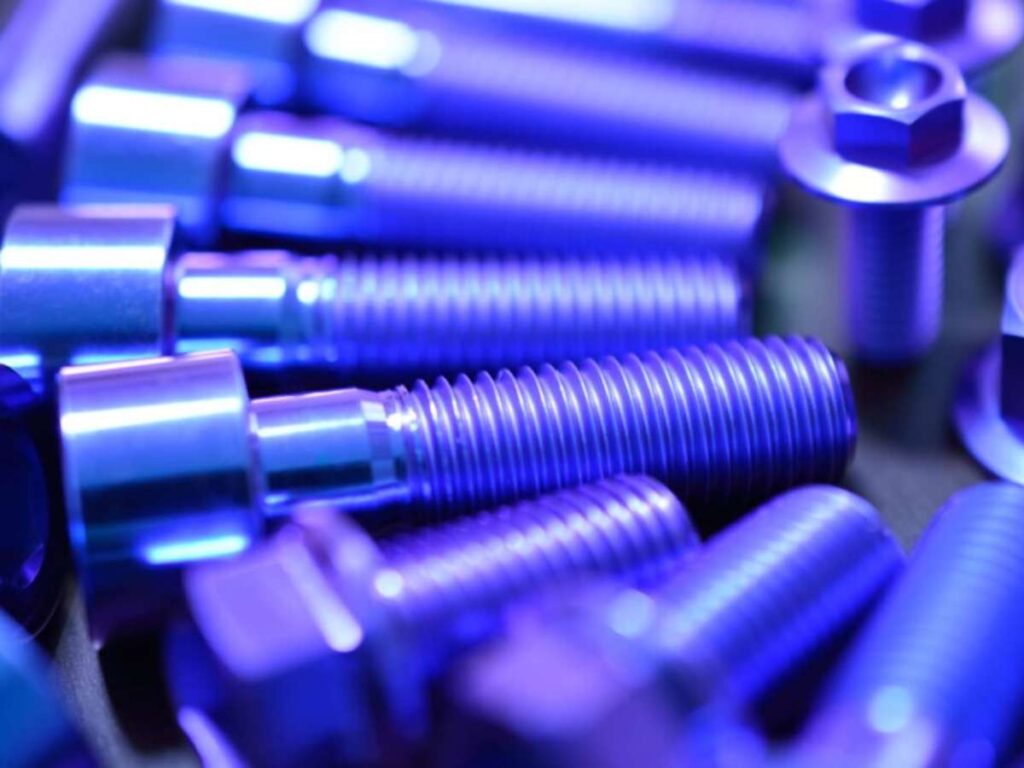

- Nickel – corrosion resistance, durability

- Zinc – sacrificial protection for steel

- Chrome – aesthetics and hardness

- Gold / Silver – conductivity, luxury finish

- Copper – often used as a base layer in multi-step plating

If you’re building a product where appearance, conductivity, or corrosion resistance matters, chances are, electroplating is part of your equation.

Application

You’ll see it in:

- Automotive parts

- Electrical connectors

- Plumbing fixtures

- Tools and fasteners

- Decorative components (jewelry, trim, hardware)

And yes, we offer this service at MachMaster, helping manufacturers apply high-quality, industrial-grade electroplating that meets both spec and schedule.

3. Chemical and Functional Differences

This is where things get real.

On the surface, anodizing and electroplating might look like they do the same job—protect metal, improve appearance, maybe add some durability.

But chemically, they’re doing two completely different things. And that matters—especially when your product’s performance is on the line.

Anodizing: Transformation from Within

Anodizing doesn’t “coat” the metal. It changes the surface of the metal itself.

- The oxide layer that forms is part of the original metal, not something added on top.

- It’s non-conductive, porous (at first), and can be sealed or dyed.

- It’s lightweight and won’t peel, flake, or chip like paint or coating might.

If you’re working with aluminum, this creates a natural barrier against corrosion, and you still get a clean, professional finish, without extra materials.

Electroplating: Applying a Protective Metal Skin

Electroplating, on the other hand, adds a new metal onto the surface.

- That outer layer is separate from the base metal—it’s a coat, not a conversion.

- You can make a steel part look like gold, boost conductivity, or protect it with zinc.

- But because it’s an added layer, adhesion quality matters. If it fails, that coating can crack, peel, or flake under stress.

That doesn’t mean it’s inferior—it just means the right process control and application are critical to long-term performance.

4. Durability and Wear Resistance

Here’s the hard truth: if the surface doesn’t hold up, your product won’t either.

And when that happens, it’s your reputation, not just your finish, that takes the hit.

So let’s break down what you’re really getting from anodizing vs electroplating when it comes to strength, wear, and long-term performance.

Anodizing: Built to Withstand

Anodizing gives you a surface that’s part of the metal, not something sitting on top of it.

- Especially with Type III hard anodizing, you get a layer that’s exceptionally wear-resistant, often harder than tool steel.

- It doesn’t chip or peel because there’s nothing “on” the surface to separate.

- It resists scratches, friction, and abrasive contact, making it ideal for moving parts, tools, or exposed components.

The trade-off? It can be a bit brittle under impact and won’t flex like softer coatings.

But if your goal is to build something that lasts, takes a beating, and keeps going, anodizing is a serious contender.

Electroplating: Depends on the Metal

With electroplating, durability depends on the plating material you choose.

- Hard chrome plating offers excellent wear resistance and is common in industrial tools, pistons, and valves.

- Zinc or nickel offer great corrosion resistance, but not much abrasion protection.

- And because it’s an added layer, if the bond is weak or gets damaged, the finish can crack, wear off, or expose the base metal.

That said, when done right, a plated layer can extend part life significantly, especially in non-contact or decorative applications.

5. Cost Comparison

You know this already; it’s never just about the cost per unit.

It’s about total value: performance, reliability, rework risk, and long-term lifecycle. Still, price matters, especially when you’re scaling up.

Let’s break down what you can expect from a cost standpoint, not just between anodizing and electroplating, but across the key factors that drive those numbers.

Process Costs

Anodizing

- Typically more cost-effective for aluminum parts, especially in high volume.

- Simple, scalable, and doesn’t require expensive plating metals.

- Energy use is moderate, and labor can be streamlined.

Electroplating

- Can be more expensive upfront, depending on the plating metal (nickel, chrome, gold, etc.).

- Requires precise process control and sometimes multi-layer plating (e.g. copper > nickel > chrome).

- Higher labor, chemical disposal, and safety requirements can increase operating cost.

Verdict: Anodizing tends to be cheaper per part for aluminum-heavy operations. Electroplating gets pricier, especially with premium metals.

Material Compatibility and Part Geometry

Anodizing

- Works best with aluminum. Limited use with other metals.

- Not ideal for parts with internal cavities or blind holes, as the coating may not form evenly.

Electroplating

- Works on most conductive metals—steel, copper, brass, etc.

- Better for complex shapes since the metal coating reaches tight spaces with proper setup.

Verdict: If your parts are aluminum and relatively simple, anodizing is cost-effective. For diverse materials or intricate designs, electroplating is more versatile—but that versatility costs more.

Lifecycle Cost and Longevity

Anodizing

- Long-lasting surface. No peeling or flaking.

- Minimal maintenance = lower cost over time.

- Reduced product failure or return rates.

Electroplating

- Dependent on adhesion and metal choice.

- Poor prep or thin plating = rework or early wear.

- Some plated finishes may tarnish, corrode, or degrade if exposed long-term.

Verdict: Anodizing offers stronger long-term ROI, especially in high-wear or harsh environments.

Volume and Production Scale

Anodizing

- Very scalable—great for large batches.

- Fewer material costs = better margins on high-volume runs.

Electroplating

- Cost per part drops at volume, but chemical use and regulation create added complexity.

- If using precious metals, price volatility can hit your margins.

Verdict: Anodizing wins on batch efficiency. Electroplating makes more sense when specific properties (like conductivity or finish) justify the added cost.

6. Environmental and Regulatory Considerations

You don’t just need a finish that performs.

You need one that keeps your operation compliant, your supply chain clean, and your brand safe from regulatory backlash—or worse, customer distrust.

More companies are being asked: “What’s your environmental impact?” And surface finishing plays a big role in the answer.

Let’s talk about what anodizing and electroplating really mean for compliance, sustainability, and waste control.

Anodizing: Cleaner and Easier to Regulate

Anodizing is generally seen as the more environmentally responsible process.

- It doesn’t involve heavy metals or precious metal salts.

- Waste is easier to neutralize and treat.

- Energy usage is moderate, and many facilities can run closed-loop systems for water and acid recycling.

From a compliance standpoint:

- Easier to meet RoHS, REACH, and local environmental standards.

- Fewer hazardous byproducts = lower permitting and reporting obligations.

If you’re trying to reduce your environmental footprint—or meet a client’s sustainability requirements—anodizing is a low-friction solution.

Electroplating: High Value, High Risk

Electroplating brings more complexity—and scrutiny.

- Many processes use toxic or regulated substances (like hexavalent chromium, cyanide-based baths, or nickel compounds).

- Waste treatment is chemical-intensive and tightly monitored.

- Worker safety, air emissions, and wastewater management are all under the microscope.

From a regulatory perspective:

- RoHS and REACH compliance requires extra effort—especially for European exports.

- Some metals used in plating (e.g. lead, cadmium) are banned or restricted.

- Disposal of spent baths or filters can require hazardous waste licensing.

That said, modern plating facilities—like ours at MachMaster—invest heavily in closed-loop systems, air filtration, and advanced waste treatment to meet strict global standards.

Electroplating can be done cleanly, but only with the right partners and process control.

7. How to Choose Between Anodizing and Electroplating

At this point, you’ve seen how these two processes stack up.

But now comes the question that actually matters to you and your team: Which one should you choose—for your product, your budget, and your supply chain?

Here’s a practical decision-making guide to help you choose with clarity and confidence.

Start With the Base Material

The metal you’re working with often makes the decision for you.

- If you’re using aluminum, anodizing is typically the smarter, more cost-effective route.

- If your part is steel, copper, brass, or a mixed-metal assembly, electroplating is often the only compatible option.

Tip: If you’re still in the design phase, this is your moment to optimize material choice based on your desired finish.

Factor in Long-Term Wear and Environment

Where will this part be used—and how hard will it be pushed?

- Outdoor? Coastal? Marine? Anodizing handles this beautifully, especially for aluminum housings or frames.

- High-touch, friction-heavy parts? Hard anodizing is your best friend.

- Decorative but low-wear parts? Electroplating offers more shine and variety.

Tip: If your product is in the hands of the customer, wear shows up as complaints. Choose a finish that supports trust in the long run.

Understand Regulatory and Industry Standards

If you’re supplying to medical, aerospace, electronics, or EU markets, compliance may narrow your options.

- RoHS, REACH, and ISO specs often restrict certain plating materials.

- Anodizing usually passes compliance with fewer complications.

- Electroplating can work—but you need the right partner with documentation and clean processes.

Tip: Ask your finish supplier directly: “Can you provide full compliance documentation for this application?”

Conclusion

Choosing the right finish doesn’t have to be confusing.

You now know what anodizing and electroplating are, how they’re done, and where each one shines.

When we fixed our finish process, our customers noticed — and trusted us more.

You can have that same edge.

Use what you learned here. Whether you’re designing, buying, or building, you’ve got the tools now.

So, which will it be for your next project?

If you’re still unsure, I’ve been there. Contact us today — I’ll help you weigh your options.

Explore More of Our Resources

If you’re searching for more choices, explore our full collection of products. We’ve picked out some great options for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.