A client brought me a batch of custom black-anodized panels that had been done by another shop.

Out of 800 pieces, more than 300 were rejected—uneven coating, streaks near the edges, and visible burn marks across the surface.

The root cause?

Their supplier skipped proper surface prep and racked the parts incorrectly during anodizing. They lost time, money, and trust with their own customers. All because the basics were overlooked.

I run a full-service operation that specializes in black aluminum anodizing.

From surface prep to sealing, I handle every step in-house and know exactly how to control color, coverage, and durability, even on tricky parts with tight tolerances.

In this article, I’ll walk you through the anodizing process the right way. I’ll show you what matters most, where other shops cut corners, and how to avoid finish failures before they cost you.

So, keep reading!

1. Why Choose Black Anodized Aluminum?

There’s just something about black anodized aluminum that feels like a level-up. The moment you see it, it gives off this sleek, professional vibe—like it means business.

But what really impressed me wasn’t just the look. It was how tough and reliable it turned out to be when things got real.

Here’s what stands out about it:

- Bonded Protection: Black anodizing isn’t a coating—it becomes part of the metal. That gives it way more staying power than paint or powder.

- Tough Under Pressure: It holds up against scratches, corrosion, and rough environments without losing that clean, matte finish.

- Premium Without the Fuss: It instantly makes parts look high-end, but the real value is how well it performs in the long run.

- Weather-Resistant Finish: Whether it’s rain, heat, or just time doing its thing, black anodized aluminum keeps its cool—literally and visually.

- A Statement of Quality: Using it tells your clients or customers you don’t just care about how something looks. You care about how it lasts.

When you’re making parts that need to stand out and hold strong, this finish delivers on both fronts. It’s not overkill.

It’s just the right choice when you want to build something that’s going to last.

2. Benefits of Black Anodizing Aluminum

Black anodizing isn’t just about making your aluminum look sharp. It fundamentally changes the surface of the metal to make it stronger, more resistant, and longer-lasting. Here are some of the practical reasons teams I’ve worked with choose it again and again.

Improved Corrosion Resistance

Once the anodizing process is done, the aluminum forms a thick oxide layer that acts like built-in armor. This layer resists oxidation, pitting, and general corrosion far better than raw aluminum.

I’ve seen this especially useful in marine and food processing environments where moisture is a constant. The black dye doesn’t impact this corrosion resistance. In fact, it enhances it by absorbing heat in outdoor settings.

This makes it a good option when longevity and exposure are both concerns.

Wear and Scratch Resistance

When you’re working with parts that will be handled, mounted, or moved around, surface durability matters. The anodized finish is significantly harder than bare aluminum, resisting scratches and everyday wear much more effectively.

MachMaster recommends anodizing for parts that see regular contact or environmental exposure, especially when long-term appearance and performance are priorities.

This is one reason why black anodized camera gear and tactical tools hold up so well even after years of abuse. I’ve had suppliers tell me their returns dropped simply by switching to anodized parts. The durability boost means fewer headaches after shipping and installation.

Consistent Look Over Time

One underrated perk is how long the finish holds up visually. Unlike painted or powder-coated surfaces, anodizing won’t flake, peel, or show uneven fading. The color becomes part of the metal, so it doesn’t wear away with time.

For any business selling premium or precision-engineered products, that long-term consistency really helps maintain brand perception. Customers notice when things age gracefully.

UV and Weather Resistance

One reason outdoor equipment manufacturers love black anodizing is its stability under sunlight. While many coatings chalk or fade under UV rays, anodized aluminum stays sharp and consistent.

I’ve seen black handrails and signage that look fresh even after years outside. The finish also resists rain, sleet, and temperature swings better than painted aluminum.

Low Maintenance, Easy to Clean

No one wants to baby-sit their gear. Black anodized aluminum doesn’t require constant polishing or touch-ups.

A basic wipe with a soft cloth or mild cleaner is enough to keep it looking sharp. For display systems, lab instruments, or industrial consoles, that’s a big deal.

The finish hides small blemishes and doesn’t pick up smudges the way polished metal does.

3. Types of Black Anodizing Finishes

Different types of anodizing deliver different results. I’ve seen teams surprised when their glossy black prototype turned out matte, or when a supposedly “hard” finish scratched under pressure.

Knowing the differences upfront helps you plan smarter.

Type I (Chromic Acid Anodizing)

This is the lightest type and isn’t commonly used for black finishes. It’s mostly seen in aerospace, where minimal dimension change is critical. The layer it produces is thin and not ideal for dye absorption. You’d only use this for black anodizing if you’re working under strict aerospace specs.

Even then, the color might not be as rich or consistent as with other methods.

Type II (Sulfuric Acid Anodizing)

The most common option for black anodizing, especially when looks matter as much as function. This method produces a moderate oxide layer that holds black dye well and gives consistent results.

I’ve seen teams use it for everything from electronics enclosures to lighting equipment. The key is to manage expectations—this type balances cost and performance but isn’t the most rugged. Still, it’s a fantastic choice when you want visual impact and decent wear resistance.

Type III (Hardcoat Anodizing)

This one’s all about durability. It produces a thicker, harder oxide layer, often used for industrial tools, automotive parts, and military components.

Black dyes can be harder to achieve here due to the density of the oxide layer, and the color may come out darker or more muted. Still, I’ve seen hardcoat black finishes hold up in conditions where other finishes would wear down in months.

If you’re working in harsh conditions, Type III is worth the investment.

4. Best Aluminum Alloys for Black Anodizing

This is where many projects run into problems. You can have the best finish in the world, but if the alloy underneath doesn’t play nice, you’ll still get blotchy results or weak coatings.

I’ve seen it happen, so here’s what you need to know.

- 6061 – The Industry Sweet Spot: This is the alloy I recommend most often. It machines well, anodizes beautifully, and produces a consistent, dark black finish. It’s cost-effective and versatile, used everywhere from bike parts to aerospace brackets.

- 5052 – Great for Formed Parts: This alloy works well for bending and forming applications. It anodizes okay—not as dark as 6061, but acceptable for many business applications. I’ve seen it used in signage, instrument panels, and curved enclosures where shape matters more than a deep black tone.

- 7075 – Strong but Tricky: This high-strength alloy is common in aerospace and defense sectors. It’s extremely durable and lightweight, but anodizing results can be inconsistent. You’ll often get a grayish-black tone instead of jet black, which might be a deal-breaker for visual applications.

- 2024 – Avoid If Possible: This one is high in copper, and that doesn’t play well with anodizing. The result is a blotchy, uneven black that looks unprofessional. It might be fine structurally, but it’s not good for visible or consumer-facing components.

- Cast Aluminum – Generally Poor for Anodizing: Most castings contain silicon, which causes the surface to turn patchy or speckled after anodizing. If you’re locked into cast parts, consider powder coating or painting instead.

5. Limitations and Considerations

No finish is perfect, and black anodizing has its quirks. I’ve had to walk clients through issues ranging from part distortion to mismatched colors, all things you can avoid if you plan ahead.

Color Inconsistency Across Batches

Even when the process is well-controlled, slight color variation can happen between different production runs. Factors like bath temperature, dye concentration, and alloy batch can all shift the final appearance. This is especially important when you’re doing large assemblies or replacement parts.

Always request sample parts if consistency is crucial. Keeping the same anodizer across orders can help reduce variation.

Dimensional Changes Are Real

Anodizing adds thickness, not a ton, but enough to matter for tight-tolerance components. Depending on the type, the oxide layer can grow from 0.001 to 0.004 inches.

If your part needs to fit inside a housing or mount, that extra material can cause interference.

Plan for it in your design phase.

Electrical Conductivity Loss

Anodizing is great for insulation, but not if you need conductivity. Once anodized, the surface becomes non-conductive, which can cause problems in grounding or sensor installations.

I’ve seen shops forget this and then scramble to add grounding screws post-process. Masking critical contact points during anodizing is the best workaround.

Alternatively, machine those areas afterward.

Can’t Be Touched Up Easily

Unlike paint or coatings, you can’t just grab a brush and patch damaged anodizing. If the surface is scratched or worn, re-anodizing is your only real option. That can add time and cost.

So if field repairs or heavy wear are likely, consider whether anodizing is still your best route—or design in removable components that are easy to swap out.

6. Common Applications of Black Anodized Aluminum

You’d be surprised how many industries rely on black anodized aluminum daily. Once you know what to look for, you’ll start spotting it in tools, machines, and displays all over your workspace and beyond.

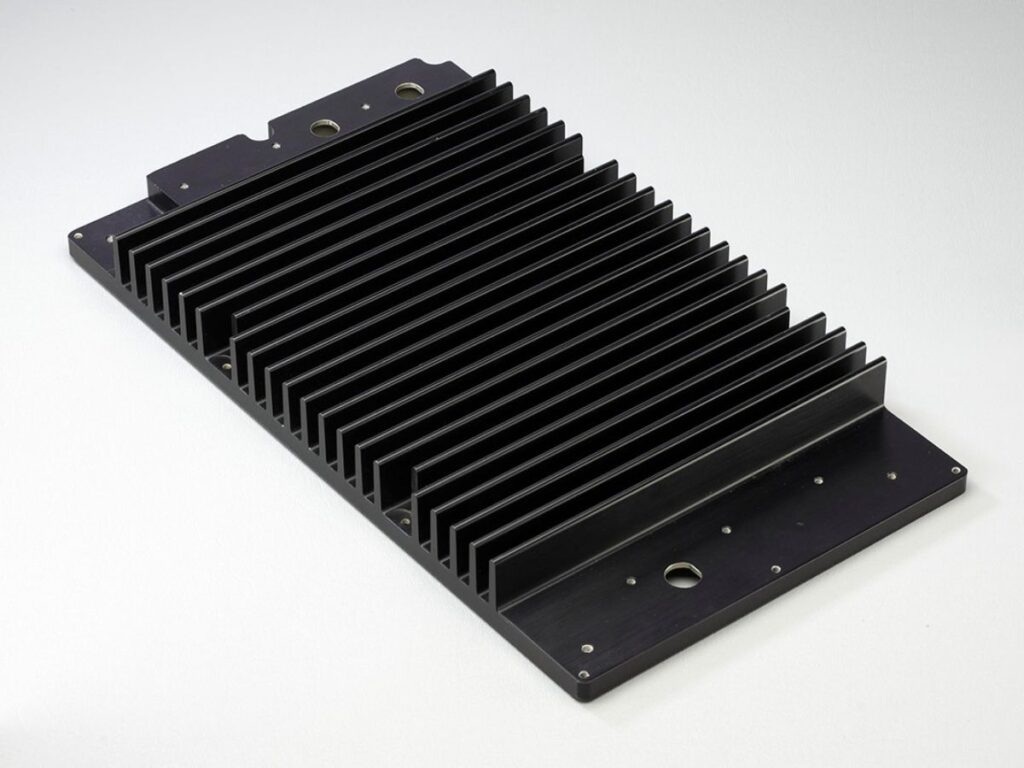

- Electronics and Tech Enclosures: It provides EMI shielding, heat dissipation, and a professional matte look all at once. ’ve worked with clients who use black anodized panels to reduce screen glare and eliminate visual distractions. It makes a difference in both form and function.

- Architectural Hardware and Fixtures: From railings to window trims, anodized aluminum holds up outdoors without constant maintenance. It looks modern, withstands weather, and resists fading. I’ve seen it used in office buildings, airports, and even solar panel frames.

- Medical and Laboratory Equipment: Black anodizing is non-reactive and clean-looking, which makes it ideal for surgical trays, microscope components, and lab housings. It’s also resistant to sterilization chemicals and heat. That’s why it shows up in autoclave-safe parts and medical carts.

- Defense and Tactical Gear: Here, stealth and strength go hand in hand. I’ve seen black anodized aluminum in rifle mounts, optics housings, and field tools. It doesn’t reflect light, it holds up under abuse, and it performs in tough environments. When every ounce and inch counts, anodized aluminum delivers.

- Retail Displays and Custom Fixtures: For businesses selling high-end products, presentation matters. Black anodized frames and platforms make displays look sharp without distracting from the product. I’ve helped brands upgrade their point-of-sale look just by switching to this finish.

7. 3 Tips to Consider When Choosing Black Anodized Aluminum

Before you commit, pause and run through these tips. I’ve used them as a checklist in sourcing discussions and they’ve saved more than a few teams from costly rework.

#1 Match the Finish to the Use Case

If your part needs to withstand friction, go Type III. If it’s mostly aesthetic, Type II is fine.

Your anodizer can recommend the best route, but it helps to know what you’re asking for. For decorative pieces, request gloss samples and verify under showroom lighting.

If ruggedness is the goal, ask for matte and test with basic abrasion tools.

#2 Confirm the Alloy Before You Cut

Don’t assume all aluminum behaves the same. Ask your fabricator which alloy they’re using, and double-check its compatibility with black anodizing.

At MachMaster, this step is standard practice—verifying alloy selection early helps avoid surprises in finish quality and performance.

A small change, like switching from 6061 to 5052, can affect both finish color and strength. If you’re not sure, anodize a test part before committing. That small step can prevent a warehouse full of unusable parts.

#3 Plan for Touch Points and Assembly

Anodizing creates a non-conductive surface and adds thickness.

If your parts need to ground, slide into mounts, or accept fasteners, you need to machine or mask those areas. I’ve seen projects delayed simply because the designer didn’t account for this.

Bring it up with your shop early. It’s cheaper to prevent issues than to fix them later.

Conclusion

I’ve seen black anodizing take a plain aluminum bracket and turn it into something that looks engineered, not just produced.

That’s the real magic here.

We’ve talked alloys, finishes, pros, cons. Now you’re equipped to make smarter decisions.

So what’s stopping you?

Contact MachMaster today. We’ll guide your custom project from raw part to perfectly finished product, every step of the way.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.