I remember the night I got a call from an aerospace client.

His prototype failed testing again.

Not because of poor design. Because he used the wrong material.

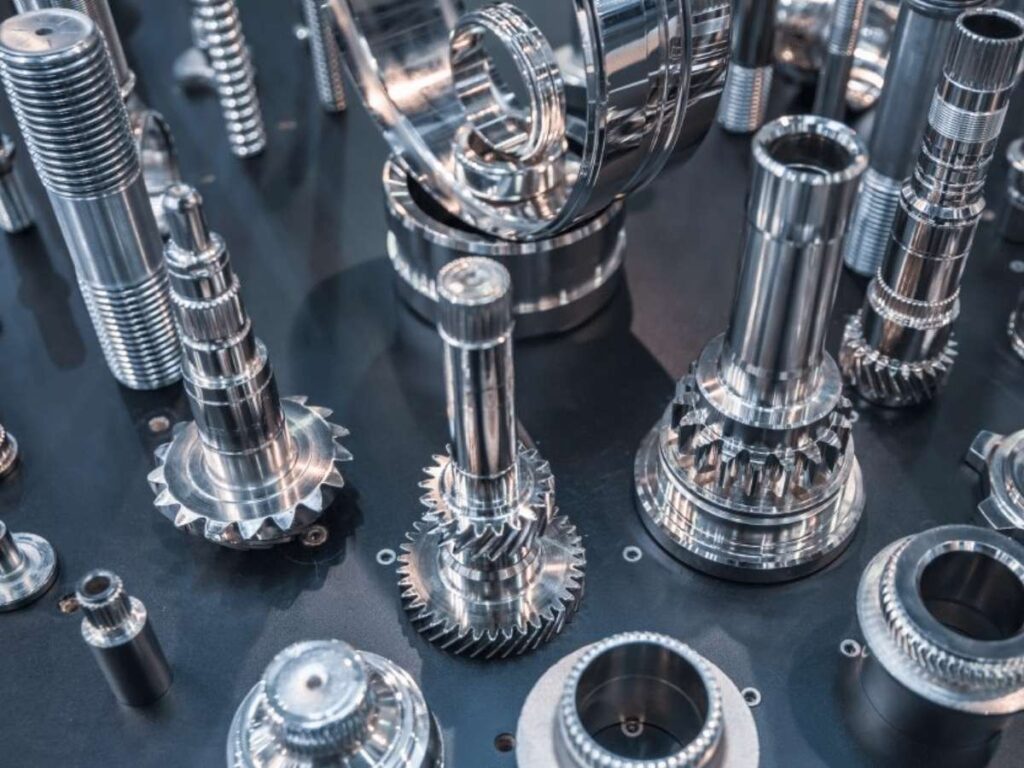

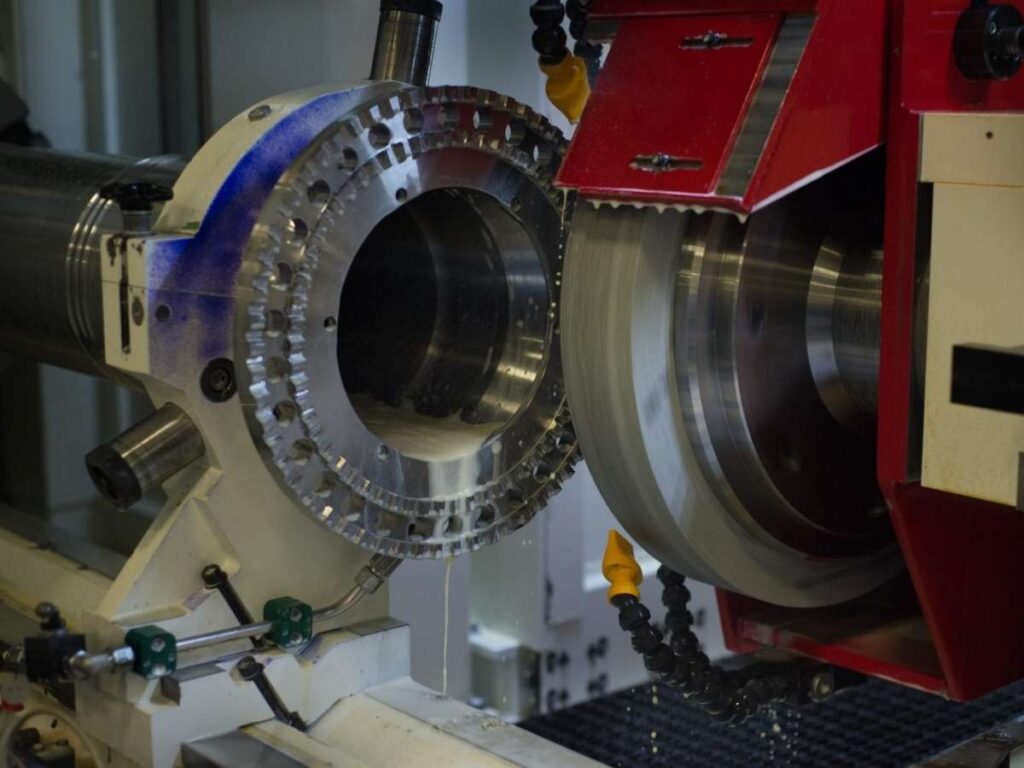

As someone who’s worked with CNC machining, I’ve seen this happen more times than I’d like. Material choice isn’t just about strength. It’s about precision, temperature resistance, weight and cost.

If you’re here, you’re probably trying to avoid that same mistake.

You want to know which materials are actually used in real aerospace projects. And which ones are worth your budget.

In this article, I’ll walk you through the top 10 CNC materials used in aerospace. By the end, you’ll have a clear list so you can choose the right one with confidence.

Let’s jump in!

Quick List

Need a fast breakdown before we get into the details? This guide gives you a quick view of the core properties and common uses of each material.

| Material | Key Properties | Common Aerospace Uses |

| Titanium Alloys | High strength-to-weight ratio; resists heat and corrosion | Jet engines, landing gear, structural brackets |

| Aluminum Alloys | Lightweight; easy to machine; cost-effective | Fuselage panels, wing structures, avionics enclosures |

| Stainless Steel | Strong; wear-resistant; corrosion-resistant | Fuel system parts, sensor housings, hydraulic fittings |

| Inconel | Extreme heat and pressure resistance; oxidation-proof | Turbine blades, exhaust systems, combustion liners |

| Nickel Alloys | Maintains strength under heat; high fatigue resistance | Rocket motor parts, turbine shafts, high-temp seals |

| Magnesium Alloys | Ultra-lightweight; good vibration damping | UAV bodies, electronics casings, interior panels |

| Cobalt-Chromium Alloys | Tough under friction and heat; excellent wear resistance | Bearings, thrust washers, engine shrouds |

| High-Strength Steels | Load-resistant; great fatigue performance | Landing gear, hinges, tool mounts, actuator housings |

| Composites | Lightweight; customizable; fatigue and corrosion resistant | Satellite mounts, UAV arms, shock-absorbing components |

| Engineering Plastics | Chemically resistant; non-conductive; precise to machine | Cable brackets, fluid seals, avionics insulation panels |

That’s the big-picture view, now let’s get into the real-world performance of each material, starting with titanium.

1. Titanium Alloys

The first time I worked with titanium alloys. I was nervous. The material felt tough. The machine tools didn’t like it. But once the part came out, it looked perfect. Strong, smooth, and light in the hand.

Titanium alloys are made by mixing titanium with small amounts of other metals like aluminum and vanadium. This blend makes the material even stronger and more stable, especially when things get hot.

Types of Titanium Alloys Used in Aerospace

Titanium alloys are split into different groups based on their structure: alpha, beta, and alpha-beta alloys. In aerospace, alpha-beta types are used most because they offer the right mix of strength and flexibility.

Here are the most common types:

- Ti-6Al-4V (Grade 5): This is the most widely used titanium alloy in aerospace. Made of 90% titanium, 6% aluminum, and 4% vanadium. Strong, corrosion-resistant, and heat-stable used in everything from engine parts to structural brackets.

- Ti-6Al-4V ELI (Grade 23): A cleaner version of Grade 5 with lower oxygen content. Slightly better fracture toughness. Often used in parts that require extra reliability, like landing gear or pressurized housings.

- Ti-3Al-2.5V (Grade 9): Easier to form and weld than Grade 5. Used in hydraulic systems, tubing, and small structural parts that don’t need maximum strength.

- Ti-5Al-2.5Sn: An alpha alloy with good high-temperature strength. Common in jet engines and exhaust components where heat resistance is critical.

- Beta Titanium Alloys ( Ti-10V-2Fe-3Al): Strong and more flexible than alpha-beta types. Used in advanced aerospace parts that require deep forming or high fatigue resistance.

Typical Aerospace Applications

Titanium alloys are found in both airframes and engine parts. Here are some typical examples:

- Jet Engine Components: Titanium is used in fan blades, discs, and casings. These parts face constant heat and pressure and need to stay strong without adding weight.

- Landing Gear Structures: It absorbs shock while reducing overall mass. Its resistance to impact makes it reliable for rough landings and high-stress conditions.

- Wing and Fuselage Connectors: You’ll use titanium where strength and stiffness matter across long spans. It helps reduce the aircraft’s total weight without compromising safety.

- Hydraulic System Parts: In high-pressure systems, titanium offers corrosion resistance and wear protection you need, especially when dealing with aggressive hydraulic fluids.

Titanium isn’t the cheapest or easiest to machine, but if you’re building parts that can’t fail, it’s one of the smartest choices you can make.

2. Aluminum Alloys

One of our aerospace clients was rushing a prototype for a flight test. They needed something that was light, strong, and quick to machine.

We went with a 7075 aluminum alloy and had the part ready in under 48 hours.

Aluminum alloys are made by combining aluminum with elements like copper, magnesium, silicon, or zinc. These mixes improve the metal’s strength and machining performance without adding much weight.

Types of Aluminum Alloys Used in Aerospace

Aluminum alloys are grouped into series based on their main alloying element. In aerospace, a few specific types are used more often because they offer the right mix of strength, weight, and machinability.

Here are the most commonly used types:

- 2024 Aluminum (2xxx Series): High strength and good fatigue resistance. Often used in fuselage skins and wing structures. Less corrosion-resistant, so it usually needs a protective coating.

- 6061 Aluminum (6xxx Series): Balanced strength, corrosion resistance, and machinability. Easy to work with, making it a good option for structural parts and interiors. Not as strong as 2024 or 7075.

- 7050 Aluminum (7xxx Series): Higher strength and better corrosion resistance than 7075. Common in bulkheads, wing skins, and structural components that require durability under stress.

- 7075 Aluminum (7xxx Series): Very high strength comparable to some steels. Used in landing gear and high-load structural areas. Less corrosion-resistant than 7050, but great for weight-critical designs.

- 7475 Aluminum (7xxx Series): A more formable version of 7075 with improved fracture toughness. Often found in aerospace skin panels and frames.

Typical Aerospace Applications

Aluminum alloys are everywhere in aerospace. Here’s where you’ll see them most:

- Fuselage Skins and Panels: Lightweight but tough, aluminum gives the structure and longevity flight crews count on.

- Wing and Tail Structures: These parts demand stiffness and minimal weight. Aluminum delivers both.

- Seating Frames and Cabin Interiors: Aluminum keeps the cabin light while supporting passengers and equipment safely.

- Electronic Enclosures and Brackets: Great for thermal performance and lightweight structural support in avionics.

Aluminum may not beat titanium when temperatures soar but when you need reliable machining, fast turnaround, and solid strength, it’s often your best move.

3. Stainless Steel

Stainless steel is a steel alloy that contains at least 10.5% chromium, which helps form a protective surface layer. This layer defends against rust, chemical wear, and extreme temperatures. They offer a solid mix

While heavier than titanium or aluminum, stainless steel is the go-to material when durability and resistance to wear matter most. At MachMaster, they value stainless steel for what it brings to mission-critical parts, consistent strength, clean finishes, and long-term reliability where it counts.

Types of Stainless Steel Used in Aerospace

Not all stainless steels behave the same. Each one gives you different benefits depending on the job. Here are the most commonly used types in aerospace:

- 304 Stainless Steel: One of the most commonly used grades. Gives you good corrosion resistance and easy machining. Best for general structural or non-critical aerospace parts.

- 316 Stainless Steel: Contains added molybdenum for better corrosion resistance, especially in salty or chemical-heavy environments. Great for fuel system components and fluid-handling parts.

- 17-4 PH (Precipitation Hardening): A high-strength stainless steel that you can heat-treat for tight control. Ideal when your part needs mechanical strength and stable dimensions.

- 321 Stainless Steel: Comes with added titanium, which boosts its ability to resist high temperatures. You’ll see it often in exhaust parts or systems exposed to constant heat cycling.

- 15-5 PH Stainless Steel: Very similar to 17-4 PH, but it offers better toughness and corrosion resistance. Perfect when you’re making precision aerospace parts with strict tolerance requirements.

Each type plays a different role. Picking the right one depends on how much strength, corrosion resistance, and cost your part can handle.

Typical Aerospace Applications

You’ll find stainless steel in places where you need strength, sealing, and long-term reliability. Here are a few examples:

- Fuel System Components: Use it in pumps, valves, and housings. Stainless handles jet fuel pressure and fights corrosion at the same time.

- Fasteners and Clamps: Holds parts steady under shifting loads and vibration. Strong threads and long life make a difference here.

- Sensor and Instrument Housings: Protects electronics in tough environments. Blocks out moisture and manages heat buildup.

- Hydraulic Fittings: Handles pressure and keeps fluids sealed in. Even with heat and pressure changes, these fittings stay leak-free.

Stainless steel may not be your lightest option but if you care most about strength, precision, and durability, it’s one of the most dependable choices you can make.

4. Inconel

Inconel is a group of nickel-based superalloys known for their excellent performance in extreme heat, high pressure, and corrosive environments.

What makes Inconel different is its ability to resist oxidation, creep, and thermal fatigue. This makes it well-suited for aerospace parts that operate inside or near engines where temperature and stress are constant.

While it’s difficult to machine due to its toughness, Inconel is often selected when parts must survive both heat and high-stress conditions over long service cycles.

Types of Inconel Used in Aerospace

Different grades offer different strengths depending on heat, stress, and environment. Here are some you’ll likely work with:

- Inconel 718: The most commonly used Inconel in aerospace. Delivers great fatigue strength, creep resistance, and weldability up to 700°C. If you’re machining engine mounts or turbine parts, this one holds its shape under pressure.

- Inconel 625: Excellent corrosion resistance and high-temperature strength. You’ll see this one in exhaust systems, high-pressure ducts, or parts that face chemical exposure.

- Inconel X-750: Precipitation-hardened for extra toughness. Best for turbine blades, springs, and bolts that take on heat and vibration without losing form.

- Inconel 600: Strong against oxidation and carburization. Great for engine seals or thermal zone parts that need to stay reliable in heat-intensive environments.

Each grade has a place. Your choice should depend on whether heat, pressure, or corrosion is the bigger concern for your part.

Typical Aerospace Applications

You’ll find Inconel in areas where most metals simply can’t hold up. These are the zones that see constant heat, force, and motion:

- Turbine Blades and Discs: Withstand high RPMs and intense heat. Inconel keeps its strength where failure isn’t an option.

- Exhaust Ducts and Seals: Corrosive gases and thermal shock are no match. Inconel stays sealed, strong, and dimensionally stable.

- Fasteners and Springs: Used in joints and assemblies that get hot and shake constantly. Inconel fasteners hold tension and resist fatigue long term.

- Combustion Chamber Liners: These face heat, stress, and chemical attack. Inconel keeps them working where lesser alloys would fail.

Inconel won’t go easy on your tools. You’ll need the right feeds, sharp inserts, and patience at the spindle.

But when you’re making parts for high-heat zones or long-life cycles, Inconel is a material you can count on.

5. Nickel Alloys

There was a time we were troubleshooting a turbine component that kept deforming during high-temp testing. It passed every simulation but failed in real-world heat. Switching to a nickel alloy changed everything. The part held up flight after flight.

Nickel alloys are materials made mostly from nickel, mixed with other elements like chromium, iron, or molybdenum to improve their performance in tough environments. These alloys are built to resist heat, corrosion, and long-term mechanical stress.

They’re heavier and harder to machine than materials like aluminum but when the job involves high temperatures, fuel exposure, or fatigue from repeated stress cycles, nickel alloys often outperform.

Types of Nickel Alloys Used in Aerospace

Nickel alloys come in many forms, but here are the ones most commonly used in aerospace machining:

- Alloy 625: Highly resistant to corrosion and oxidation. Often used in chemical systems, exhaust parts, and ducting exposed to heat and pressure. I’ve machined it for gas flow systems, it holds shape, even when the heat is relentless.

- Alloy 718: A high-strength, precipitation-hardened nickel alloy that holds its mechanical properties at temperatures up to 700°C. Used in turbine components, discs, and fasteners. It’s tough on tools, but the results are worth it when precision and strength matter.

- Alloy X (HX): Known for strength at extreme temperatures and good fabricability. It’s found in afterburners and combustion chambers. I remember using this for a repair on a jet engine liner ran smooth once the right tooling was dialed in.

- Waspaloy: A nickel-based superalloy with excellent creep resistance. Common in turbine blades and shafts. Machining it takes experience, it responds best to slower feeds and sharp inserts.

Typical Aerospace Applications

You’ll use nickel alloys where temperatures stay high, fatigue is constant, and failure’s not an option. Some of the most common applications include:

- Turbine Blades and Shafts: These spin hot and fast. Nickel alloys hold shape and strength without warping.

- Combustion Liners and Chambers: Flames and pressure? No problem. Nickel resists cracking and thermal breakdown.

- Exhaust Components and Ducts: These parts flex with heat cycles. Nickel gives you the thermal range you need.

- Fuel System Housings: These alloys hold up against corrosive fuels and pressure. I’ve used Alloy 625 in parts exposed to jet fuel, it’s rock solid even after long test runs.

Nickel alloys demand more from the machinist, but they give back in reliability. When failure isn’t an option and conditions keep pushing the limit, these alloys don’t just hold up, they finish the job.

6. Magnesium Alloys

I used to think magnesium alloys were too soft for anything beyond consumer electronics. But after machining a batch of aerospace enclosures for a lightweight drone project, my opinion changed. The material held up better than expected, cut clean, and made a noticeable impact on the final weight.

Magnesium alloys are made by mixing magnesium with aluminum, zinc, or rare earth elements to improve strength, heat resistance, and durability.

While they don’t offer the same raw strength as titanium or nickel, magnesium alloys are ideal for parts that don’t carry heavy loads but still need to hold up under heat, vibration, or environmental stress.

Types of Magnesium Alloys Used in Aerospace

You’ll find several magnesium alloys used in aerospace, especially for components where light weight matters more than raw load capacity:

- AZ91D: A popular go-to. It gives you a solid strength-to-weight ratio and decent corrosion resistance. You’ll often use it for housings and light brackets.

- Elektron 21: Designed for aerospace and motorsports. It holds up well under heat and creep. I used it in a vibration-damping panel and it outperformed expectations.

- ZK60: Stronger than most. If you’re working on structural parts that need better fatigue resistance, this one’s a reliable choice.

- WE43: A rare-earth alloy with excellent thermal performance. Perfect when you’re building something that faces temperatures above 200°C, like engine casings.

Typical Aerospace Applications

Magnesium really shines when reducing weight matters more than handling force. Here are a few use cases that prove its value:

- Rotor Housings in UAVs: Magnesium’s weight advantage helps you keep drones light and nimble, extending flight time. I’ve used it on aerial test platforms where every gram counted.

- Vibration-Damping Frames and Supports: Its natural damping makes it ideal for camera mounts or sensitive brackets. You’ll get less shake and clearer data during flight.

- Inspection Port Covers and Tool Access Panels: These see frequent use but little stress. With magnesium, you get lightweight, easy-access panels that speed up maintenance.

- Protective Shells for Sensors: It’s strong enough to shield sensitive electronics but light enough not to drag performance. If EMI shielding with weight limits is your challenge, magnesium is often the answer.

Magnesium won’t be the hero in every aerospace job, but in the right application, it can quietly do its job and keep systems lighter, cooler, and easier to handle. Once I saw what it could do on smaller UAV systems, I started using it a lot more especially when performance came down to grams.

7. Cobalt-Chromium Alloys

Cobalt-chromium alloys aren’t as commonly discussed as titanium or aluminum in aerospace shops, but they play a quiet, important role. The first time I machined one, I wasn’t expecting much, it looked dense and uncooperative. But once it hit the grinder, the performance told a different story. It was tough, sure but it held its shape and surface finish far better than expected.

These alloys are made mostly from cobalt and chromium, with small amounts of molybdenum, nickel, or iron added for specific property enhancements.

Types of Cobalt-Chromium Alloys Used in Aerospace

These aren’t your everyday structural alloys, they’re chosen when things get hot, tight, and wear-prone:

- CoCrMo (Cobalt-Chromium-Molybdenum): You’ll get top-notch hardness and wear resistance here. I’ve used it where there’s constant sliding or contact, it held up without visible wear.

- Stellite 6: Known for its corrosion and abrasion resistance. You’ll want this in high-temperature zones where others break down.

- Haynes 25 (L605): This cobalt-chromium-tungsten-nickel blend has great strength and oxidation resistance. Perfect for turbine engine parts and other hot-section components.

- Tribaloy Alloys: Contains cobalt, molybdenum, and silicon. Great for extreme wear areas. We’ve used this in bearing sleeves and valve seats that needed to survive long duty cycles.

Each type is built for a challenge, your choice depends on how much friction, heat, and durability you’re dealing with.

Typical Aerospace Applications

You’ll use cobalt-chromium alloys in parts that face friction and heat not the usual structural stuff. Here’s where they shine:

- Actuator Bushings and Bearing Sleeves: They handle rotation and repeated motion without galling or losing shape. I’ve seen them outlast both stainless and hardened steel during testing.

- Thrust Washers and Wear Pads: These live in high-contact zones. You’ll appreciate the surface hardness here, it reduces damage and maintenance.

- Turbine Shroud Segments: These help guide airflow while resisting heat cycles. The shape has to stay true cobalt-chrome can handle that load over time.

- High-Temperature Valve Seats and Seals: Seals that take the heat need material that holds its form. I’ve machined Stellite seats that stayed round, even after thermal shock.

Cobalt-chromium alloys aren’t friendly to cut. They wear tools fast and need precision feeds and speeds. But when your job depends on long-term wear resistance and thermal stability, these alloys deliver.

They might not make a lot of noise in the shop, but they’re the reason some of your toughest parts keep working long after others fail.

Did you know that Machmaster worked with this material long enough to know what it takes and how to get it right. From setup to final inspection, they machine cobalt alloys with precision and care.

8. High-Strength Steels

There’s something reliable about high-strength steel. It doesn’t always win attention like titanium or Inconel, but when structural integrity is the priority, it gets the job done.

I remember a project where we needed landing support hardware for a test aircraft. The team considered aluminum and titanium, but both failed under repeated load. We switched to high-strength steel and the testing phase finally moved forward.

Types of High-Strength Steels Used in Aerospace

Here are some of the steels you’ll come across when strength is non-negotiable:

- 4340 Steel: A chromium-nickel-molybdenum alloy. Tough and fatigue-resistant. Once heat-treated, it’s ideal for high-load shafts, landing gear, or anything facing repeated stress.

- 300M Steel: A stronger, silicon-enhanced version of 4340. If you’re working on military-grade actuators or landing gear, this one holds tight tolerances and handles stress well. I’ve machined it, it’s no walk in the park, but the part comes out strong and stable.

- 15-5 PH Stainless Steel: If you need strength and corrosion resistance together, this is a good choice. It works well for hydraulic shafts, pressure housings, and parts exposed to fluid systems.

- Maraging Steels (18Ni 300): These ultra-high-strength steels offer great dimensional stability. Perfect for aerospace tooling or structural hardware where accuracy under load matters.

Typical Aerospace Applications

You’ll use high-strength steels where the part faces repeated force, load, or shock. Here’s where they usually come into play:

- Landing Gear and Support Struts: These parts get hammered during takeoff and landing. High-strength steel gives them the backbone they need.

- Actuation and Hinge Assemblies: If you’ve got pivoting or load-bearing movement in a design, steel helps parts survive repeated cycles without losing shape.

- Rocket Motor Casings and Retainers: You’re dealing with pressure, heat, and safety-critical zones here. We once ran a maraging steel batch for this and the part stayed dimensionally locked through testing.

- Tooling and Fixturing for Aerospace Assembly: You want jigs and clamps that don’t deform. High-strength steel holds its form through repeated setups.

High-strength steel doesn’t try to impress, it just works.

If weight isn’t your main constraint and you need something that’s strong, consistent, and built to last, this material gives you confidence. It’s the quiet performer that keeps your structure stable under real-world conditions.

9. Composites

I had this customer brought in a carbon fiber panel for trimming, I paused. It wasn’t metal, and it didn’t cut like metal either. The fibers frayed, the finish chipped, and I had to rethink the entire setup. That job taught me something, composites require their own way of working, but when you get it right, the results are impressive.

Composites are engineered materials made by combining two or more elements usually a reinforcing fiber like carbon or glass and a matrix like resin or epoxy. This structure makes them strong, lightweight, corrosion-resistant, and easy to shape into aerodynamic forms.

Types of Composites Used in Aerospace

- Carbon Fiber Reinforced Polymer (CFRP): You’ll use this when you need something that’s both strong and ultra-light. It has excellent fatigue resistance and stiffness ideal for aircraft skins, wing components, and UAV parts.

- Glass Fiber Reinforced Polymer (GFRP): Not as stiff as carbon, but more affordable. Great for non-structural components. You can use it for fairings, radomes, and interior panels with good success.

- Kevlar Reinforced Composites: If you’re dealing with high-impact or vibration-heavy areas like helicopter blades or cargo liners, Kevlar blends give you shock absorption and flexibility.

- Hybrid Composites: These combine materials like carbon and Kevlar to balance weight, strength, and resilience. If you’re working on a panel that needs cutouts and custom fittings, hybrid layers offer a reliable solution.

Typical Aerospace Applications

Composites shine in areas where every gram counts and performance can’t be compromised. Here are a few use cases you might not immediately think of:

- Satellite Components and Antenna Mounts: Carbon fiber is perfect for parts that need to stay stable in space, thanks to its low thermal expansion. You might trim brackets or shells on a small satellite build.

- Rotorcraft Interiors and Wall Panels: GFRP and hybrid composites help reduce cabin weight while improving noise control especially useful for passenger comfort.

- Cargo Hold Liners and Bay Doors: Kevlar’s resistance to impact makes it ideal here. When loads shift mid-flight, this material absorbs the hit without cracking.

- Tooling and Layup Molds for Aircraft Composites: You may find yourself machining high-temp composite blocks for molds. These can take repeated curing cycles, ideal when fabricating the same part multiple times.

Working with composites takes a different mindset, less about cutting force, more about fiber direction, resin behavior, and edge quality. But once those things are dialed in, the material opens up a lot of freedom. In many aerospace builds today, it’s not a question of if composites will be used, it’s where, how much, and how to machine around them.

10. Engineering Plastics

When you need lightweight, chemically resistant, and thermally stable parts that machine well, engineering plastics are your best bet. These high-performance polymers are built for structural and functional roles in aerospace systems, especially where metal would be too heavy, conductive, or prone to corrosion.

You’ll find them ideal for insulation, tight tolerances, and design flexibility. And when machined right, they deliver smooth finishes without sacrificing durability.

Types of Engineering Plastics Used in Aerospace

- PEEK (Polyetheretherketone): You’ll want this for high-heat zones or chemical environments. It’s strong, thermally stable, and tough to cut but the surface looks great when you get it right.

- Ultem (PEI – Polyetherimide): This one’s great for heat resistance and electrical stability. Use it for avionics brackets, insulation plates, and structural components in electronics.

- PTFE (Polytetrafluoroethylene): Need non-stick and low friction? PTFE works perfectly for seals, spacers, and linings in fluid systems. It’s soft, so machine it gently.

- Nylon (PA 6/6): When you need decent toughness without adding weight, go with nylon. It’s great for brackets and covers that don’t face heavy loads.

- Acetal (Delrin): You’ll like acetal for gears, bushings, or any part that needs moisture resistance and easy machining. We’ve used it in cabin systems with tight fit requirements.

Typical Aerospace Applications

You’ll mostly use engineering plastics for non-structural parts, insulation, or chemical-heavy environments. Here are some real examples you might run into:

- Wire Harness Carriers and Cable Supports: PEEK and Ultem keep things organized and signal-safe. I’ve routed complex wire sets with CNC-cut plastic brackets, they’re faster and lighter than metal ones.

- Seals and Fluid Flow Components: PTFE and PEEK shine here. Their chemical resistance means fewer failures in fuel and coolant systems over time.

- Interior Trim and Mounting Panels: Nylon and acetal let you customize easily. Perfect for panels that require frequent removal or access without damaging parts.

- Avionics Insulators and Connectors: Ultem works especially well in vibration-heavy areas. You’ll protect your boards and keep sensors stable with minimal added mass.

Engineering plastics aren’t just for cosmetic or temporary parts, they solve real design problems when metals fall short.

I’ve come to rely on them for parts that need to be light, clean, precise, and still hold up in demanding environments.

Conclusion

That titanium part I told you about? It passed every test. And the client never had that failure again.

You’ve now got a breakdown of 10 aerospace CNC materials, what they are, where to use them, and why they matter.

Each one plays a different role.

But the next move? That’s yours.

Whether you’re prototyping or scaling up, now’s the time to act with confidence. You know what works. Let’s build something that lasts.

Contact MachMaster today!