In today’s fast-paced manufacturing environment,precision, speed, and cost-effectiveness are crucial.

Whether you’re a startup developing new products or an established company scaling up production, outsourcing CNC machining services can offer significant advantages. So, what exactly are the benefits of outsourcing CNC machining?

Let’s explore why choosing to outsource CNC machining is a smart strategic move.

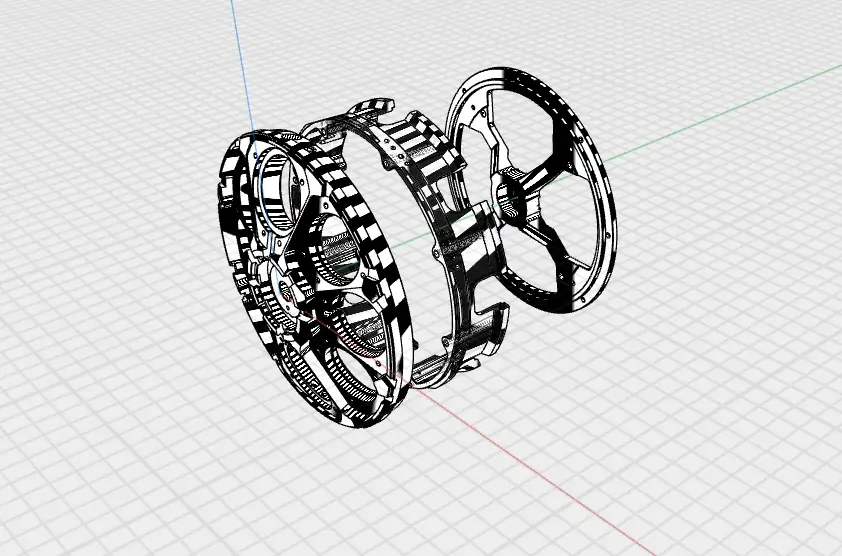

Acquiring advanced technology without huge investment

You don’t need to purchase your own equipment for manufacturing parts.If you cooperate with a professional CNC machining manufacturer, you can immediately gain access to state-of-the-art three-axis, four-axis, and five-axis milling and turning machines without investing a large amount of capital.

This is especially valuable for small and medium-sized enterprises that require high-precision parts but lack the budget for in-house machining equipment.

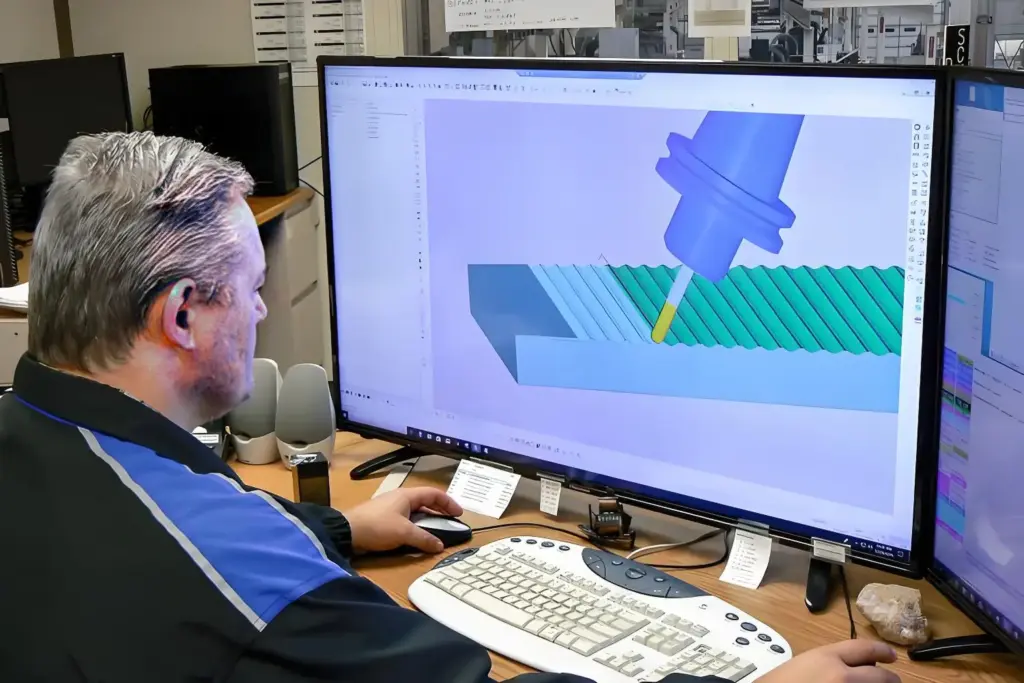

Access expert knowledge on demand

Reputable CNC machining factories employ experienced engineers, machinists, and quality control experts in precision manufacturing. Their experience across various industries, including consumer electronics, aerospace, and medical devices, means they can provide valuable design for manufacturability (DFM) feedback, material selection advice, and process optimization that your internal team may not possess.

Scalability and flexibility

Unsure of your sales result? Maybe you need 10 prototypes today and 10,000 next quarter? Contract manufacturers can scale production up or down to meet your needs. This flexibility eliminates the risk of underutilized equipment or overburdened staff during peak periods. It also allows you to respond quickly to market changes or customer demands.

Faster time to market

Speed is crucial. Most CNC machining service providers offer fast turnaround times. some manufacturers can even deliver functional prototypes in as little as 2-5 days. With streamlined workflows, automated quoting systems, and dedicated production lines, outsourcing can accelerate your development cycle, from concept to finished part. Machmaster’s rapid prototyping workshop can complete simple parts in just one day.

cost-effectiveness

In addition to avoiding upfront equipment costs, outsourcing CNC machining can also reduce expenses in the following areas:

- Machine maintenance and calibration

- Tooling and consumables

- Energy consumption

- Employee training and management costs

You only need to pay for the outsourced parts you need, typically at competitive unit prices.

especially when leveraging economies of scale through experienced suppliers.

The quality is stable and reliable, and meets the standards

Certified CNC machining partners strictly adhere to quality standards (such as ISO 9001, AS9100, or ISO 13485 for the medical industry). They utilize advanced inspection tools, such as coordinate measuring machines (CMMs) and optical scanners, to ensure that every part meets your drawing tolerances.

down to the micron. This consistency is crucial for regulated industries where no errors are acceptable.

Focus on your core competencies

Outsourcing CNC machining allows your internal team to focus on what they do best, whether it’s R&D, marketing, or customer service. You can invest your time and resources in innovation and growth instead of managing workshop operations.

When is outsourcing the best option?

- Medium to low volume production

- Complex geometric parts requiring multi-axis machining

- Small batch prototypes or transitional tooling

- Entering new markets lacking local manufacturing infrastructure

- Handling excess capacity during peak periods

sum up

Outsourcing CNC machining is not only delegating tasks; But also it’s a strategic partnership. The right supplier becomes an extension of your engineering team, providing precision parts with reliable, fast, and professional service. As manufacturing continues to evolve with automation and digital integration, leveraging external CNC machining capabilities will remain a key driver for increased agility and competitiveness.

Are you ready to streamline your production process?

Partner with Machmaster, a CNC machining company with extensive experience, transparent communication, and a commitment to quality—and accelerate your product development cycle.

Machmaster offers a range of manufacturing services including CNC machining, injection molding, sheet metal fabrication, die casting, and 3D printing.