In plastic CNC machining, acrylic is often used to manufacture various parts. I often encounter customers using acrylic to make products. Let’s take a look at why acrylic is chosen and how to complete the processing of acrylic parts.

What is acrylic?

Acrylic, with the chemical name polymethyl methacrylate, abbreviated as PMMA, is a transparent plastic material widely used in both industrial and consumer fields. It is commonly referred to as “organic glass” and has superior performance compared to ordinary glass. Chemical structure: It is a thermoplastic material that is shaped by heating, solidified by cooling, and processed repeatedly.

The characteristics of acrylic

Acrylic can be widely used because of its outstanding comprehensive properties:

- Excellent optical performance: The light transmittance is as high as 92%, superior to that of ordinary glass. It has excellent light guiding ability and UV resistance, and does not yellow over a long period of use.

- Lightweight and high strength: The density is approximately 1.18 g/cm³, half that of glass. Its impact resistance is 10-17 times that of glass.

- Good processability: It is easy to be cut, engraved, drilled, bent and thermoformed, suitable for various manufacturing processes.

- Weather resistance and chemical resistance: It can withstand various dilute acids, alkalis, oils and salt solutions.

- Excellent surface hardness and luster: The surface is wear-resistant and can be polished to a mirror finish, presenting an elegant appearance.

- Safe and environmentally friendly: After breaking, it does not form sharp fragments and can be 100% recycled.

What are the processing techniques of acrylic?

Acrylic can be processed in various ways. These include CNC machining, laser cutting, injection molding, plastic extrusion, hot bending, etc. Depending on the design of the 3D model, the manufacturing process may require one or more techniques to be completed.

It is mainly divided into the following categories:

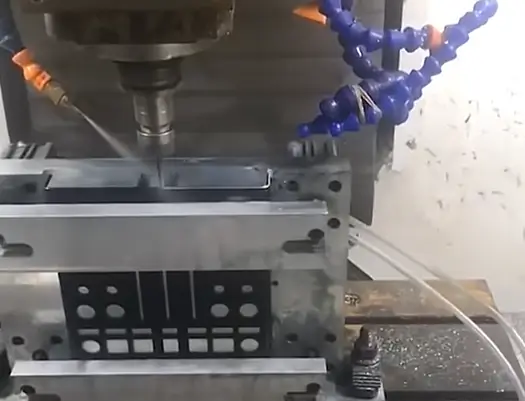

1. CNC machining: This is the preferred method for manufacturing high-precision, complex-shaped parts. Through computer-controlled milling machines, lathes, or engraving machines, cutting, drilling, and engraving are carried out, achieving precise dimensional tolerances and excellent surface finish, making it highly suitable for prototype production and small-batch manufacturing.

2. Laser cutting and engraving: Utilizing a laser beam for rapid, precise two-dimensional cutting and surface engraving, with smooth edges (with slight melting marks), it is suitable for making signs, decorations, and precise patterns.

3. Hot bending: After heating the acrylic sheet to a softening temperature of approximately 150-160°C, it is bent into various arcs and angles through molds or free bending, cooled and fixed to obtain the target shape. It is widely used in display stands, light boxes, and architectural decorations.

4. Injection molding: The molten acrylic particles are injected into the mold by an injection molding machine, cooled to obtain complex-shaped and uniformly sized parts, suitable for large-scale production, such as car lamp covers, instrument panels, and cosmetic containers.

5. Extrusion molding: The molten acrylic is continuously produced through custom-shaped mold openings, resulting in long strips, tubes, or specific cross-sectional shapes of profiles.

6. Bonding and polishing: Using a special acrylic adhesive (such as chloroform) for seamless bonding. Edges can be polished to a crystal-like transparency effect through flame polishing or mechanical polishing.

The advantages of making parts with acrylic

Extremely high transparency, a wide range of rich and vibrant colors, and excellent surface gloss can greatly enhance the appearance texture and modernity of the product.

Lightweight, it can reduce the overall weight of the product; excellent impact resistance improves durability and safety; good insulation performance is also suitable for electrical components.

Compared to glass, it is easier to process, safer, and consumes less energy. Through processes such as CNC, the conversion from design to finished product can be achieved quickly, shortening the development cycle.

Strong weather resistance, long outdoor service life; smooth surface, easy cleaning and maintenance.

Application of acrylic

Acrylic was first synthesized in the 1930s and has since become the preferred material for replacing glass and for manufacturing various transparent and semi-transparent products. The application scope of acrylic is extremely wide, almost penetrating every aspect of modern life.

Business and Exhibition:Shop windows, display stands, price tags, retail display props.

Architecture and Decoration:Soundproof windows, light-catching domes, shower rooms, stair railings, interior decorative panels.

Advertising and Signage:Outdoor billboards, light boxes, illuminated letters, company logos, signs.

Transportation and Traffic:Car taillight covers, motorcycle windshields, aircraft portholes, subway barriers.

Optics and Instruments:Camera lenses, telescope lenses, dashboard covers, microscope slides.

Medical care and Health:Disinfection trays, baby incubators, dental equipment, and Windows for testing instruments.

Home and daily use:Aquariums, furniture accessories, photo frames, lamps, stationery.

What type of acrylic is used for CNC machining?

CNC machining has high requirements for the uniformity, stability and processing performance of the materials. The most commonly used and recommended type is cast acrylic sheet.

Why cast acrylic is the first choice?

1. High molecular weight and stable performance: The casting process makes the molecular structure more uniform and reduces internal stress. During CNC cutting, it is less likely to deform, crack or produce silver streaks.

2. Excellent machinability: The chips generated during cutting are clean and neat, easy to discharge, and can achieve clear and smooth cutting edges. The subsequent polishing effect is excellent.

3. Excellent optical effect: The transparency is the highest. After processing and polishing, it can recover to a surface close to the optical level, suitable for high-quality appearance parts.

4. Wide range of thickness and size options: The thickness range of the sheet is wide, meeting different requirements from precision thin-walled parts to thick structural parts.

Other types of considerations

Extruded acrylic sheet: The cost is relatively low, but the molecular weight is lower. When heated during CNC processing, it is more likely to soften and stick to the cutting tool. The edge polishing is slightly more difficult than that of cast sheets. It is usually used for components where the requirements for optical performance and edge effect are not extremely strict.

Impact-resistant modified acrylic: Modified with a reinforcing agent to enhance toughness, but this may result in a slight loss of transparency and affect the polishing effect of the cutting edge. It is only selected in special cases where additional impact resistance is required.

Core techniques for CNC machining of acrylic

Heat control

The preferred method is to use compressed air for cooling: Utilize 6-8 bar of dry and clean compressed air and direct it towards the cutting point. The air not only cools but also effectively removes chips, preventing the heated chips from re-heating the workpiece.

Cutting tool selection

Single-edge helical milling cutter: This is the “gold standard” for machining acrylic. The single-edge design reduces friction and heat accumulation, and the large helix angle facilitates smooth chip removal, resulting in the cleanest cutting edge. It is particularly suitable for fine processing and contour cutting.

Double-edge milling cutter: It can be used for rough machining, but it must be sharp and the feed rate needs to be increased accordingly to prevent excessive heat generation due to friction.

Definitely avoid using multi-edge (such as 4-edge) milling cutters: The more edges, the greater the friction heat, which is very likely to cause acrylic to melt and stick together.

Cutting parameters

Speed and feed: The goal is to have the cutting tool “bite” into the material and then quickly retract, reducing the contact time. A common misconception is to have an excessively high rotational speed while the feed rate is too slow, which is equivalent to using the tool to rub against the material and will inevitably result in melting.

Formula reference: For a φ3mm single-edge milling cutter, a rotational speed of 18,000 RPM can be attempted, combined with a feed rate of 1,200-1,500 mm/min.

Simple test: The ideal chip that should be cut out should be fluffy, curled, cool, and a fine white strip. If it is in powder form or in the form of molten small balls, it indicates that the parameters need to be adjusted.

Layered cutting strategy: For materials thicker than 6mm, it is strictly forbidden to cut through in one go. Instead, a layered cutting method using small cutting depths and multiple tool paths should be adopted. For example, when machining a 10mm thick plate, it can be completed in 4-5 layers, with each layer having a cutting depth of 2-2.5mm.

Clamping and stress control

Acrylic has poor rigidity and improper clamping can cause cracking and deformation.

Flexible pressure equalization clamping: Place hard wood, PVC or thick rubber gaskets between the workpiece and the metal fixture to distribute the pressure.

Vacuum suction is the ideal choice: For flat parts, using vacuum suction cups can provide uniform support and clamping force, significantly reducing the risk of deformation and edge cracking.

Prevention of deformation during processing sequence: Perform the internal cavity processing of all holes and grooves first, and then cut the outline shape last. This way, the overall rigidity of the material can be maximally maintained until the final step.

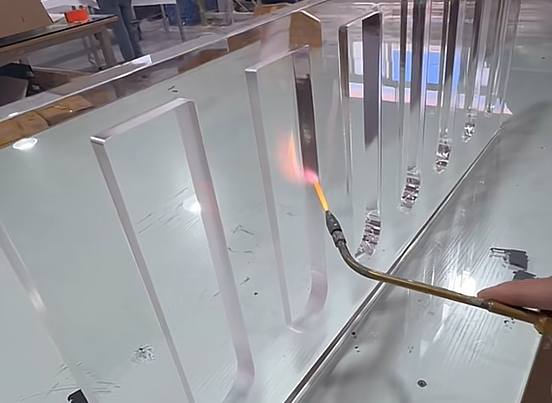

Achieving a surface treatment with perfect edges

The edges after CNC cutting are usually semi-transparent and frosted, requiring a second treatment.

Flame polishing:

Applicable to: Straight or large arc-shaped edges.

Technique: Use a dedicated propane polishing gun and adjust it to a pure blue flame. The edge of the workpiece needs to pass through the outer flame of the flame (the hottest part) horizontally and at a constant speed, with a brief contact (0.5-1 second). The material’s own melting and flow will form a smooth surface. A too slow speed will cause bubbles.

Mechanical polishing:

Applicable to: Workpieces with complex shapes or those that are concerned about flame deformation.

Step-by-step sandpaper method: Use 400 mesh → 600 mesh → 1000 mesh → 1500 mesh → 2000 mesh sandpaper in sequence and wet grind in the same direction.

Ultimate polishing: Use plastic-specific polishing paste and cloth wheel, and polish at low speed until a mirror finish is achieved.

CNC machined acrylic quick reference sheet

| FAQ | Root Cause | Solution |

|---|---|---|

| Edge melting, wire drawing | Overheating (speed/feed mismatch, dull cutting tool) | Increase the feed speed, reduce the rotational speed, inspect and replace the cutting tools |

| A foggy white haze appears on the surface. | Vibration or tool deflection | Shorten the tool overhang, reinforce the clamping of the workpiece and the tool, and check the accuracy of the spindle. |

| Cracking during processing or after processing | Internal stress release or excessive mechanical stress | Use casting plates to reduce the clamping force, add soft gaskets, and optimize the tool path to minimize sharp turns. |

| Inconsistent dimensional accuracy | Thermal expansion or tool deviation | Maintain the environmental temperature stable, adopt layered cutting and laser cutting strategies, and use thicker and shorter cutting tools. |

| Poor quality of the inner wall of the hole or the bottom of the deep cavity | Poor chip removal, with excessive heat accumulation | Use compressed air to forcefully blow off the chips, adopt the “pecking” cycle, and reduce the single cutting depth. |

Summary & Recommendations

For most precision parts, prototypes, optical components and high-quality display items that require CNC processing, it is advisable to opt for cast acrylic sheets to ensure the best processing results and product quality. When ordering materials, you can clearly inform the supplier of the requirements for “CNC precision machining”.

FAQ

Should we choose cast acrylic or extrude acrylic?

The preferred option is cast acrylic. It has a high molecular weight, low internal stress, and is less prone to deformation or cracking during processing. After edge polishing, its optical effect is excellent, making it an ideal choice for precision CNC machining. While extruded plates have a lower cost, they are more susceptible to heat softening and the processing quality is not as good as that of cast acrylic.

How to bond the acrylic components?

Use a special acrylic adhesive (such as chloroform/trichloromethane). It causes the contacting materials to melt slightly and fuse together, forming a nearly invisible and strong joint. The operation should be carried out in a well-ventilated area, and the adhesive should be applied precisely using a dropper bottle.

What are the common colors of transparent acrylic?

Transparent red, blue, green, amber, and smoky gray.