When a supplier once sent me a “polished” metal panel that looked dull and streaky, I knew something had gone wrong. Turns out, it was brushed, but no one told me.

That mix-up made me rethink how little most of us actually understand surface finishes.

If you’ve ever been confused by brushed vs satin vs mirror, you’re not alone—and that’s where this guide helps.

I’ve worked directly with manufacturers and finishers, and I’ve had to explain this to clients, vendors, and engineers alike.

I’ll walk you through what a brushing finish really is, how it looks, where it works best, and what you need to ask your supplier. This isn’t fluff, it’s meant to answer real production questions.

Because here’s the truth: a good finish can raise perceived value, and a bad one can kill a deal.

So let’s get into it!

1. What Is Brushing Finish?

If you’ve ever caught yourself running your hand across a piece of brushed metal, you’ll know exactly what I mean when I say: there’s something about it that just feels intentional.

The texture, the direction, the understated matte, it doesn’t scream for attention, but it sure leaves an impression.

Brushing finish, also known as satin finish or directional finish, is a mechanical surface treatment where an abrasive belt or wire brush is used to create a consistent pattern of fine lines on the material. These lines are always directional and usually go in one straight path.

Unlike polishing, which aims for shine, brushing gives a muted, linear texture.

The result is a dull sheen that reduces glare and hides small imperfections, fingerprints, or blemishes.

2. Benefits of a Brushed Finish

I used to think finishes were all about shine.

The more I used it in client projects, the more I saw how much it could actually do. It wasn’t just about how the product looked, but how it held up, how it felt, and how people responded to it.

Here are the benefits that made me a fan.

Hides Minor Scratches and Fingerprints

Brushed surfaces are great at hiding the little things: light scratches, fingerprints, smudges, and even dust. The fine, directional lines act like camouflage, making wear and tear less noticeable.

I’ve used it on panels that get handled every day, and they still looked good months later. That kind of durability matters when you’re putting products in busy environments.

It gives your work a longer-lasting, cleaner look without constant touch-ups.

Looks Professional Without Being Flashy

There’s something about brushed metal that always feels intentional to me. It doesn’t shine like chrome, but it still catches the light just enough to look finished and refined.

I’ve had clients say it made their products feel more premium without looking overly polished or flashy.

In business, that kind of balance between clean and classy makes a difference. It helps your product feel modern and high-end without stealing the spotlight.

Adds Subtle Grip and Texture

This one’s easy to miss until you feel it. The texture from brushing gives the surface just enough grip, making it easier to handle or use.

I’ve seen it used on tool housings, handrails, and equipment where grip matters, and it absolutely helps.

It’s not rough, but it adds that little bit of friction people don’t realize they need. It’s one of those small touches that improves usability without changing the look.

Requires Less Maintenance Over Time

I’ve worked on projects where the finish had to look good, but no one had time for constant cleaning. That’s where brushing really shines.

It hides fingerprints and dust much better than polished or glossy finishes, which means fewer complaints and fewer cleanups.

Over time, that’s a big win for both end users and maintenance teams. It’s a smart choice when you want things to look sharp with less effort.

3. Materials That Can Be Brushed

One thing I’ve learned from hands-on experience is that brushing isn’t limited to just one or two metals.

With the right tools and techniques, you can apply a brushed finish to a variety of materials and get very different effects depending on what you’re working with.

Below are some of the most common materials I’ve worked with that handle brushing well.

- Stainless Steel: This is easily the most popular material for brushing, and for good reason. It holds a clean, consistent grain and keeps its appearance even in high-touch or high-traffic areas.

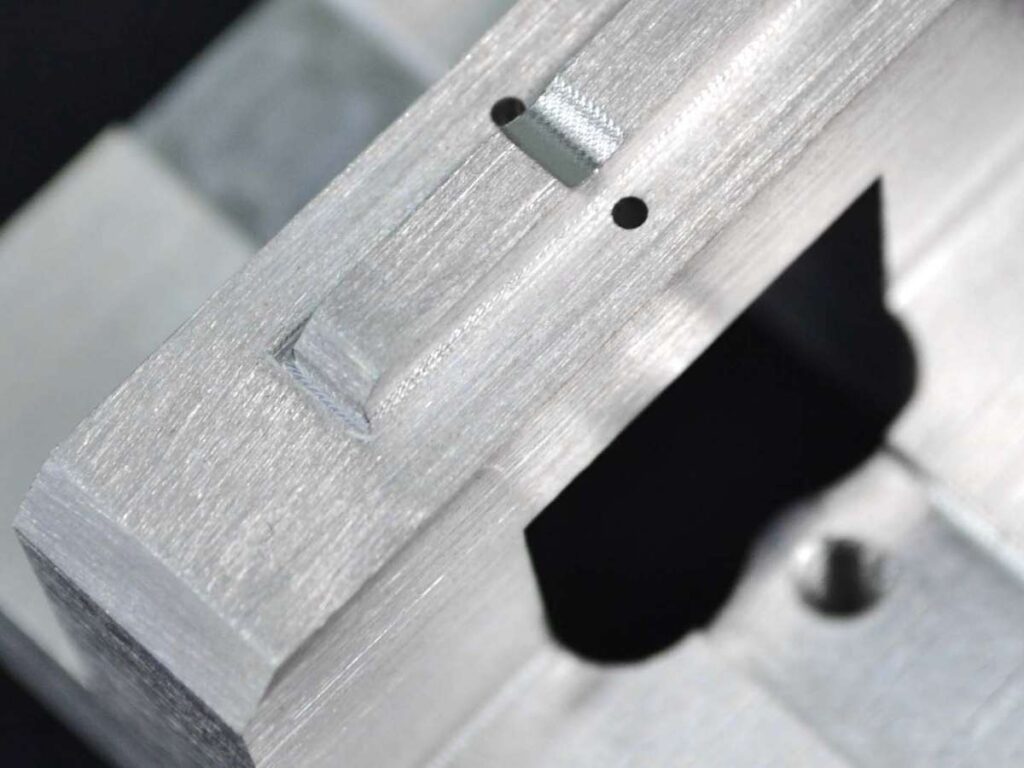

- Aluminum: Aluminum is lightweight, easy to work with, and responds well to brushing when you use the right grit and pressure. I’ve used it for everything from display panels to machine housings where weight and finish both matter.

- Brass: Brushed brass has a warm, high-end look that works beautifully in interior design and decorative fixtures. It’s softer than steel, though, so I always take care not to over-brush and lose the surface detail.

- Copper: Copper offers a rich, reddish tone that looks especially good with a directional finish. Brushing helps tone down the shine while keeping the color and character intact.

- Titanium: Titanium can be more expensive, but it holds up incredibly well and takes on a brushed texture that feels both modern and tough. I’ve used it in aerospace components and high-end gear where both looks and durability mattered.

- Carbon Steel: While not as corrosion-resistant as stainless steel, carbon steel can still be brushed effectively for a raw, industrial look. I usually recommend applying a sealant or coating afterward to protect the surface from rust.

- Zinc and Zinc Alloys: Zinc is a softer material, so it needs a gentler brushing process to avoid uneven patterns or gouging. I’ve mostly seen it used in hardware components where the brushed finish adds a little more design value.

- Plastics (select types): Certain plastics, especially harder, high-performance types, can take on a brushed finish using fine abrasives or sanding techniques. I’ve mostly done this during prototyping phases or to add texture to grip surfaces.

4. Brushed Finish Variations

Early on, I assumed all brushed finishes looked the same.

But once I started working across different industries and seeing parts side by side, I realized how much variation there really is.

If you’re choosing a finish for your product, these are the variations worth knowing about.

Standard Linear Brushing

This is the finish most people picture when they think of brushed metal. It has a consistent, straight-line pattern that runs in one direction, usually created with an abrasive belt. I’ve used this type on panels, housings, and enclosures where a clean, uniform look was important. It’s reliable, predictable, and gives off that classic brushed metal appearance.

Cross Brushing

Cross brushing is a little more aggressive and creates a grid-like or crisscrossed texture on the surface.

This is done by brushing in one direction, then brushing again at an angle or perpendicular to the first pass. I’ve recommended this finish for parts that need added grip or a more textured feel.

It also gives a more industrial look that works great for functional components.

Non-Directional Brushing

This finish doesn’t follow a specific grain pattern, which gives it a softer, more matte appearance.

I’ve mostly seen it used in custom jobs where the goal was to reduce reflectivity without emphasizing any one direction.

It’s not as common in mass production, but it can be perfect for high-end or design-focused products. The finish feels smooth and balanced without drawing too much visual attention.

Pad Finish (Scotch-Brite™ Style)

This version is created using non-woven abrasive pads instead of belts or wheels, which results in a blended, low-sheen surface.

I’ve used it on aluminum sheets and trim where I wanted a softer look without visible grain lines. It’s especially useful when you want a finish that hides imperfections but still feels refined.

It doesn’t look as sharp as linear brushing, but it’s great for blending and subtle textures.

5. Key Applications of Brushed Finishes

If your business is building anything that gets handled, touched, or noticed, brushing might be the smartest surface choice.

Here are some real-world places where this finish earns its keep.

Commercial Appliances and Equipment

Brushed stainless steel is a go-to for surfaces that need to look good while standing up to heavy use. I’ve worked on food prep tables and refrigeration units where cleaning happens multiple times a day.

Brushed finishes hold up, resist smudging, and don’t scream for attention with every fingerprint.

That makes them perfect for high-traffic equipment that still needs a polished, professional vibe.

Architectural and Interior Design

From elevator doors to wall panels and public counters, brushed metal is everywhere in modern architecture. I’ve had clients choose it specifically to get that clean, high-end look without adding glare or distraction.

The subtle grain adds texture and interest, especially in spaces with a lot of lighting.

It also blends well with other materials like glass, wood, and concrete, which makes it a favorite for architects and designers.

Automotive and Aerospace Components

Brushed aluminum and stainless steel are commonly used in trim pieces, dashboards, and control panels.

I’ve seen this finish add a premium feel to automotive interiors while keeping reflections to a minimum, which is a safety benefit too.

In aerospace, brushed surfaces are valued for their low reflectivity and ease of inspection. When you need something lightweight, strong, and sharp-looking, brushing checks all the boxes.

Tools, Fixtures, and Industrial Equipment

Brushed finishes aren’t just for looks in this category—they actually serve a function. I’ve used brushing on handles, tool bodies, and machine components where grip and wear resistance were critical.

The texture gives a tactile feel that helps with control, especially when gloves or moisture are involved.

It also hides dings and scratches from daily use, which keeps equipment looking better for longer.

Furniture, Lighting, and Decorative Hardware

This is where brushed finishes get to be both functional and stylish. I’ve seen brushed brass and aluminum used on cabinet pulls, table frames, and custom lighting fixtures to add a refined but modern touch.

It’s popular in both retail and hospitality spaces where visual impact matters.

The finish makes a product feel high-end without going overboard, and it works across a variety of design styles.

6. Challenges and Limitations

Brushed finishes have a lot going for them, but they’re not without their issues.

I’ve run into these problems firsthand, and knowing them upfront can save time, money, and rework.

- Inconsistent Grain Direction Across Assemblies If the brushing direction doesn’t match across joined parts, the result looks sloppy. I’ve had to reject entire assemblies because of this simple but noticeable mismatch.

- Easier to Damage During Handling The finish can scratch or scuff during transport or machining, especially if it’s not protected. I always recommend adding a peel-off film during production to avoid last-minute surface fixes.

- Not Ideal for Harsh Environments Without Protection Brushed surfaces can trap moisture and debris, which increases the risk of corrosion over time. I’ve seen this happen when parts weren’t sealed or coated before outdoor use.

- Limited Visual Impact Compared to Polished or Coated Finishes Some clients expect it to shine like chrome, but it doesn’t. Brushed finishes have a low-gloss, muted look that’s subtle by design.

- Repairing Damage Isn’t Always Simple Once the grain is damaged, you can’t just spot-fix it without it standing out. Most of the time, you have to re-brush the whole surface to restore the look.

- More Setup and Process Control Required Achieving a consistent brushed finish takes the right grit, pressure, and pass count. I’ve seen shops rush through it and end up with streaky, uneven results.

7. Brushed Finish vs Other Surface Treatments

Brushed finish isn’t the only option out there, and depending on your product needs, another treatment might serve you better.

Here’s how it stacks up against some of the most commonly used surface finishes in terms of appearance, function, and practicality.

| Surface Treatment | Appearance | Durability | Maintenance | Best For |

| Brushed Finish | Matte, directional grain; subtle and modern. | Good scratch resistance but prone to surface wear if unprotected. | Low maintenance; hides fingerprints and smudges well. | Consumer appliances, tools, architecture, and equipment. |

| Polished Finish | High gloss, reflective, mirror-like surface. | Scratches easily and shows wear quickly. | High maintenance; every smudge and mark is visible. | Decorative parts, luxury goods, and showpieces. |

| Bead Blasting | Uniform, matte texture with no grain. | Good for even surfaces, but can reduce corrosion resistance if untreated. | Easy to maintain, but texture can trap dirt. | Industrial parts, enclosures, and interior components. |

| Anodizing (Matte/Glossy) | Colored or clear finish with optional sheen; often used with aluminum. | Excellent corrosion resistance and surface hardness. | Very low maintenance once sealed. | Electronics, aerospace, and outdoor aluminum parts. |

| Powder Coating | Thick, colored outer layer; smooth or textured. | Highly durable and weather-resistant. | Easy to clean; doesn’t show wear quickly. | Outdoor equipment, machinery, and automotive parts. |

| Electroplating | Shiny or matte metallic layer (nickel, chrome, etc.). | Excellent protection if properly applied. | Varies by metal; usually easy to maintain. | Decorative hardware, electrical connectors, and corrosion-prone parts. |

Conclusion

When I first noticed the texture of a brushed finish, I didn’t know how much it mattered. Now I use it on purpose, and I hope you will too.

You’ve learned the what, why, and how of brushed finishes.

You’ve seen where they shine and where they don’t. The rest? That’s in your hands now.

Start now with MachMaster. Your all-in-one CNC and surface finishing partner. Contact us today.