I didn’t know what “copper CNC machining” meant.

All I knew was—I needed a part made from copper. And I thought getting it done would be simple.

But supplier after supplier started throwing out words I didn’t understand.

Things like “tool wear,” “thermal conductivity,” and “chip control.”

I kept thinking, Is copper really that hard to machine?

Turns out, it is.

And if you’re in the same boat, this guide is for you.

In this article, I’ll walk you through the basics—what copper CNC machining actually is, why it’s different from other metals, and what you need to know to get good results.

So let’s start!

1. Copper Grades for CNC Machining

Before I worked with copper, I thought metal was metal.

But after a few failed parts and confusing calls with suppliers, I realized something: not all copper is the same.

If you’re getting copper parts made by CNC machining, the grade matters more than you think. It affects how well the part can be machined, how it performs, and how much it costs.

Let’s look at the three most common grades used for CNC work.

C110: Electrolytic Tough Pitch

This is the copper most people think of.

It’s about 99.9% pure. That means it has very high electrical and thermal conductivity. Great for parts like busbars, grounding straps, and connectors.

But here’s the catch: it’s tough to machine.

Because it’s so pure and soft, it tends to gum up your tools. It also builds heat fast, which can ruin the finish if you’re not careful.

So, while it’s a solid choice for conductivity, be ready for longer run times and more tool wear.

C145: Tellurium Copper

This one’s been a lifesaver for some of my jobs.

C145 has a tiny amount of tellurium, a chemical element added to make the copper easier to cut. It doesn’t affect strength too much, and it still has very good conductivity—just slightly lower than C110.

If your part doesn’t need the absolute highest conductivity, C145 might be a better bet. It’s much easier on machines and tooling.

C147: Sulfur-Bearing Copper

This one’s less common, but you might still run into it.

It has a bit of sulfur in it, which also improves machinability. It’s used in some electrical parts, especially when clean threads or smooth holes are needed.

But because it’s not used as often, it might be harder to source.

So which one should you choose?

That depends on your part. Does it need top-level conductivity? Or are you more focused on cost and machinability?

Knowing your copper grade ahead of time can save you a lot of back-and-forth with your machinist. It also helps avoid mistakes later on.

2. CNC Methods Best Suited for Copper

I used to think any CNC machine could handle copper.

Then I watched my first copper part get milled—and overheated—because I used the wrong method for the job.

Copper is soft, but it’s tricky. It builds heat quickly and tends to stick to tools. So choosing the right CNC method makes a big difference.

Here are four methods that work well, depending on your part type and goals.

Milling

Milling is one of the most common methods. It uses a rotating tool to remove material from a flat surface.

It works great for:

- Heat sinks

- Brackets

- Slots and pockets

If your part has mostly flat features, or you need sharp corners and smooth edges, milling is usually the way to go. Just be sure to talk with your machinist about speeds and cooling. Copper needs special care to avoid tool wear.

Turning

If your part is round or has threads, turning is better.

Turning spins the copper rod while a cutting tool shapes it. It’s perfect for:

- Electrical connectors

- Round pins

- Bushings or spacers

I’ve used turning for tight-diameter parts, and it gave me clean, consistent results.

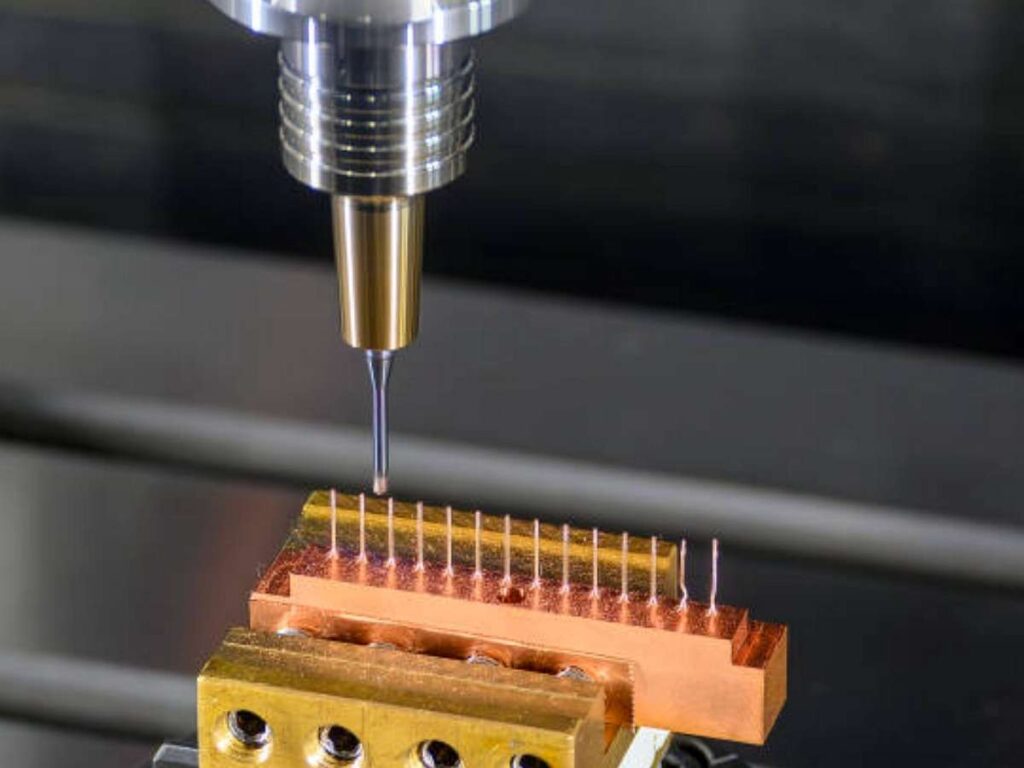

EDM: Electrical Discharge Machining

This one surprised me the first time I saw it.

EDM uses electrical sparks to cut metal—without touching it. That means no tool pressure or heat buildup.

It’s slow, but great for:

- Thin walls

- Tight corners

- Intricate patterns

If you’re working with complex shapes or tiny details, EDM is worth looking into.

Swiss Machining

Swiss machines are built for precision. They hold the part steady while the tools move around it.

You’ll want this if you need:

- Small parts

- Long runs

- Tight tolerances

It’s common in medical and electronics work, where size and accuracy matter most.

So, which method fits your part?

It depends on size, shape, and volume. If you’re unsure, ask your supplier what methods they use. That one question can save you from weeks of frustration.

3. Design Tips for Copper CNC Machining

I remember the first copper part I sent out for machining.

The machinist looked at my drawing and said, “This might be a problem.”

He was right. I had deep pockets, tight tolerances, and thin walls. All of which made the job more expensive and harder to finish.

If you’re designing for copper, there are a few simple tips that can save you time, money, and frustration.

Let’s break it down.

Best Practices for DFM (Design for Manufacturability)

Design for Manufacturability, or DFM, means creating parts that are easier to machine. With copper, small changes to your design can make a big difference.

Here’s what’s worked for me:

- Avoid deep pockets: Copper doesn’t clear chips easily. Deeper cuts make it worse.

- Keep walls thicker: Thin walls can vibrate, which affects surface finish and precision.

- Add fillets: Rounded corners help tools move smoothly. It also reduces chatter.

- Don’t over-tolerance: Copper is soft and hard to machine tightly. If it’s a conductive part, ask yourself—Does it really need ±0.01mm? If not, loosen it up.

These changes can also make quoting faster and help you get more reliable results.

Copper-Specific Toolpath & Setup Tips

Now let’s talk about the actual machining process.

Copper behaves differently than aluminum or steel. It grabs heat fast and sticks to tools. So setups need to be planned carefully.

Tips that have helped me:

- Use shallow step-downs: Smaller cuts reduce heat and tool stress.

- Stick with climb milling: It gives a cleaner finish and helps with chip removal.

- Choose coated tools: Carbide with a coating or diamond tools—last longer with copper.

- Run high-pressure coolant: It stops chips from welding to your cutter.

If you’re working with a machinist, ask them to walk through your drawing with you. Even five minutes of feedback can lead to a cleaner part, faster lead time, and fewer mistakes.

4. Copper CNC Applications You Should Know

I didn’t always understand why people chose copper.

It’s heavier than aluminum. It’s harder to machine. It’s more expensive.

But after working on a few specific projects, I started to do them.

Copper isn’t for everything—but when it’s needed, it matters.

Let’s look at where copper CNC machining really shines—and when it might not be the right call.

High-Performance Use Cases

Copper’s biggest advantage is how well it handles heat and electricity.

That makes it a top choice for parts where conductivity is critical.

Here are a few examples I’ve seen firsthand:

- Heat sinks and thermal transfer components: Copper pulls heat away fast. Ideal for electronics.

- RF and microwave components: Its electrical properties are perfect for high-frequency signals.

- Precision medical equipment: Some surgical tools use copper for its conductivity and antibacterial qualities.

- Electric vehicle components: Busbars, terminals, and connectors often use machined copper.

- High-voltage switchgear parts: These need clean cuts and reliable conductivity. Copper delivers both.

If your part needs to handle a lot of heat or current, copper is often worth the extra effort.

When NOT to Use Copper

That said, copper’s not always the right fit.

Ask yourself a few questions:

- Is weight reduction more important than conductivity? If yes, aluminum is better.

- Do you need faster machining and lower cost? Brass or plastic might do the job.

- Does your part need tight tolerances, but doesn’t require copper’s benefits? Another metal could be easier.

I once specced copper just because I thought it “looked better.”

Big mistake. The cost went up and the machinist wasn’t happy.

So think about your project goals. If performance depends on heat or electricity, copper’s a smart bet. If not, there may be a simpler path.

5. How Much Does Copper CNC Machining Cost?

The first time I ordered a copper part, I expected the price to land somewhere near what I paid for aluminum.

It didn’t.

The quote came back much higher. And I couldn’t figure out why until I looked into the details of copper machining.

If you’re trying to understand where the cost comes from—or just want a ballpark number—this will help.

Key Cost Drivers

Here’s what pushes the price up:

- Material cost: Copper typically runs $10 to $30 per pound, depending on grade and source.

- Tool wear: Copper sticks to tools. That means shops go through more tooling, which adds to the job cost.

- Slower machining: Compared to aluminum, copper cuts much slower. The machine stays on longer, and that time isn’t free.

- Setup and complexity: Complex parts need more programming and setup. More time = more cost.

Average Cost

So, how much can you expect to pay?

- Most copper CNC machining projects cost between $75 and $200 per hour.

- A simple part, like a flat bracket or connector, might cost $60 to $120 per piece.

- A complex part like a heat sink or tight-tolerance insert can cost $200 to $500+, especially for low volumes.

That’s the typical range I’ve seen after working with various shops in the U.S. and abroad. If your part is small, simple, and runs in batches, you’ll land on the lower end. If it’s detailed or requires special handling, expect higher numbers.

How to Reduce Costs

Want to save money? Here’s what’s worked for me:

- Use C145 instead of C110. It’s easier to machine and less demanding on tools.

- Combine multiple parts in one order. Volume helps.

- Simplify wherever you can: thicker walls, fewer pockets, and looser tolerances.

- Ask for DFM (Design for Manufacturability) feedback before production. One conversation can save you hundreds.

Copper CNC machining isn’t cheap. But once you know the cost drivers—and what you can tweak—you’re in a better position to plan your project and avoid overpaying.

If you’re unsure how to lower machining costs, you don’t have to figure it out alone. MachMaster helps customers simplify parts, choose the right copper grade, and move from design to production with fewer surprises.

6. Mistakes to Watch Out For

I’ve made every mistake in the book with copper CNC machining.

Some of them cost me time. Others cost me a lot more.

If this is your first time working with copper, or if you’ve had issues in the past, here are some common problems to avoid.

Choosing the Wrong Copper Grade

Not all copper is the same.

If you’re trying to get a part machined and you pick C110 (pure copper), don’t be surprised if the quote is high and the lead time is long. It’s tough to machine. Some shops even avoid it.

For better results, ask about machinable grades like C145. It’s still conductive but cuts cleaner and faster.

Over-Tolerancing Unnecessary Features

This is something I didn’t understand at first.

I once spec’d ±0.01 mm on every hole—just to “be safe.”

The shop called me and said, “Do you really need this level of accuracy on non-critical holes?”

Truth is, I didn’t. That tight tolerance added machining time and cost for no reason.

So think about where precision matters. If it’s a mounting slot or decorative edge, you can probably relax the numbers.

Working With the Wrong Supplier

Copper isn’t like aluminum or steel.

You need a shop that knows what they’re doing. I’ve worked with suppliers who said yes to the job, but clearly had no experience. The result? Burned tools, poor surface finish, and delays.

Always ask if they’ve machined copper before.

Ignoring Thermal Expansion

Copper holds heat.

If your part is big, thin, or has long cuts, it can warp. That’s why cooling is critical.

Talk with your machinist about how heat might affect the part—and what they’ll do to manage it.

Copper has a lot to offer, but it’s easy to mess up if you’re not careful. Catching these mistakes early can save you from stress, wasted parts, and blown budgets.

7. What to Look for in a Copper CNC Supplier

Finding a good CNC supplier is hard enough. Finding one that’s comfortable with copper? That’s even harder.

I’ve worked with shops that were great with steel or aluminum but completely struggled with copper. The finish looked rough. The dimensions were off. One job even had visible tool marks that weren’t supposed to be there.

Copper takes a different kind of experience.

So if you’re sourcing copper parts, you need to ask the right questions upfront. Here’s how to do it.

Supplier Evaluation Checklist

When you’re looking at potential suppliers, ask yourself:

- Do they list copper as a material they specialize in?

- Can they show experience machining grades like C110 or C145?

- Do they offer DFM (Design for Manufacturability) feedback specifically for copper?

- Can they hold tight tolerances for high-performance parts like heat sinks or RF components?

Even a short phone call can help you spot red flags early.

Certifications That Matter

Depending on your project, certifications can tell you a lot about how a shop runs.

Here are a few worth asking about:

- ISO 9001: General quality management

- ISO 13485: For medical parts, especially if precision and cleanliness are key

- ITAR: Needed if you’re working on defense or aerospace parts

If your parts fall into these industries, make sure the shop is properly certified.

Tips for RFQ Success

Want a faster quote with fewer back-and-forth emails? Help the supplier understand what you need:

- List the exact copper grade you want, like C145 or C110

- Add any surface or finish requirements (like plating or passivation)

- Explain what the part is used for if tolerances are critical

One time, I left out the grade and just said “copper.” The shop assumed brass. That mistake set the project back a week.

The right supplier makes a big difference. Ask good questions. Share clear details. And work with someone who knows how to handle copper—the results will show.

If you’re looking for a partner with real experience machining copper, MachMaster can help. We work with C110 and C145 regularly and support precision copper parts across electronics, medical, and industrial projects.

Conclusion

I didn’t know much about copper CNC machining at first. Just that I needed a part—and got a quote I didn’t expect.

Now you know more than I did.

You’ve learned the copper grades, machining methods, design tips, pricing, and how to avoid costly mistakes.

So what’s next?

Take your part drawing, apply what you’ve learned, and talk to a shop that knows copper.

You’re closer than you think.

Need help figuring out where to start?

Contact us today. Let’s make your copper project real.