I once took on a small rust-removal job using crushed glass. Thought it would be perfect.

It wasn’t.

The glass cut too deep. Left pits in the surface. I had to redo everything with a softer abrasive and it cost me time and money.

That mistake stuck with me.

Since then, I’ve tested just about every blasting media out there glass, garnet, slag, walnut shell, you name it. I’ve seen how the wrong choice can ruin the finish or slow down the job.

So if you’re wondering which abrasive to use for your next sandblasting project, I get it. It’s not as simple as “blast and go.”

In this guide, I’ll walk you through 10 different abrasives what they’re good at, where they struggle, and how to match each one with your job.

By the end, you’ll know how to choose the right material based on your surface, the finish you want, and the budget you’ve got.

So let’s begin!

1. Silica Sand (Quartz)

I still remember using silica sand on a rusted steel frame. It was cheap and easy to find. The results looked great at first.

But after every job, I’d feel the scratch in my throat. The dust hung in the air, and I didn’t think much of it. Until later.

Over time, I started digging deeper. That’s when I learned what silica dust actually does to your lungs.

Applications

- Removing rust, old paint, and scale

- Works best on steel and concrete surfaces

- Often used in construction and maintenance work

If you’re blasting heavy machinery or prepping concrete, silica sand cuts fast and cleans deep.

What Makes It Stand Out

- Very aggressive strips thick coatings quickly

- Inexpensive one of the lowest-cost abrasives

- Still easy to find in some areas

Back in the day, this was the standard. Most jobs started with a pile of quartz sand.

Takeaway Notes

But here’s the risk fine silica dust.

When silica sand breaks apart, it releases particles that can cause silicosis. That’s a serious lung disease. It builds up over time and causes scarring in your lungs. Breathing gets harder. There’s no cure.

- OSHA (U.S.) limits how much silica dust workers can be exposed to

- EU laws ban or restrict it in many countries

So before you choose silica sand, check your local rules. You don’t want to get caught using something that’s already banned.

Even if it’s still legal, I’d say think twice. I made the switch years ago. Garnet and crushed glass do a cleaner job and I don’t leave coughing.

2. Aluminum Oxide

I remember prepping steel parts for a client who needed a clean finish before coating. I’d used other abrasives before cheaper ones. But the paint kept peeling, and I couldn’t figure out why.

Then I switched to aluminum oxide.

It made all the difference. The surface came out with a sharp texture. The coating stuck better. And the finish held up much longer.

That’s when I started using aluminum oxide for my tougher jobs.

Applications

- Surface prep for painting or coating metal

- Deburring sharp edges on steel and alloy parts

- Etching for better coating adhesion

- Cleaning hard metals like titanium, stainless steel, and carbon steel

It’s especially useful when you’re working with dense materials that need a clean, even surface.

What Makes It Stand Out

- Highly Reusable: You can recycle it several times without losing performance

- Available in Many Grit Sizes: From coarse to fine, based on the finish you need

- Creates a Sharp Profile: This helps paints and coatings stick better

You’ll find it useful whether you’re doing rough blasting or fine finishing. It all depends on the grit size.

Takeaway Notes

Aluminum oxide costs more than basic abrasives like sand or slag. But that doesn’t mean it’s a bad deal.

It’s actually a smart long-term choice, especially if you’re blasting often or working in a shop.

Here’s why:

- You can reuse it multiple times, so it lasts longer

- It produces a consistent surface finish with every use

- It’s more efficient in closed-loop or recovery blast systems

- You get less dust, which makes cleanup easier

- Better surface prep means coatings last longer

If you’re doing production work or care about finish quality, aluminum oxide is worth it. I’ve used the same batch across several jobs, and the performance barely dropped.

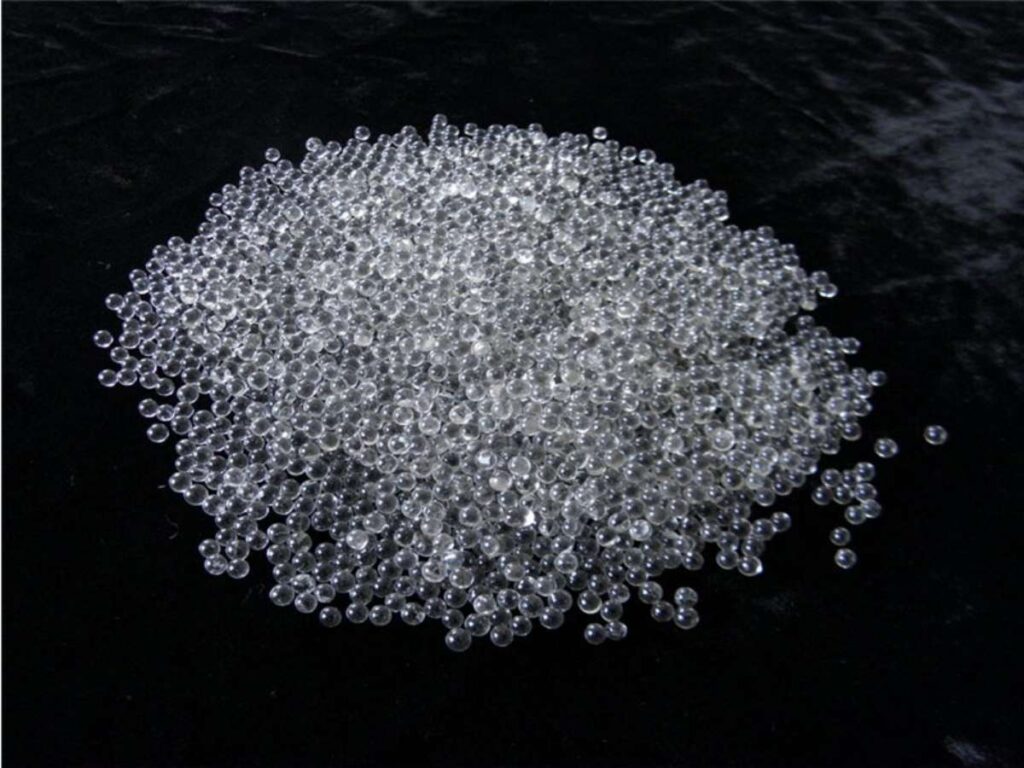

3. Glass Beads

The first time I used glass beads, I wasn’t trying to strip paint. I just wanted to clean and smooth a stainless steel part without scratching it.

What I got was a soft, satin-like finish. It looked clean without looking rough.

That’s when I realized: glass beads don’t cut they polish.

They’re not meant for deep blasting. Instead, they’re best for light cleaning, finishing, and creating that soft matte texture you often see on stainless or aluminum.

Applications

- Polishing metal surfaces without removing base material

- Great for cosmetic finishes on aluminum, brass, and stainless steel

- Common in aerospace, automotive, and medical equipment work

- Also used to remove light oxidation and blending tool marks

If you want something to look clean and feel smooth, glass beads are a strong option.

What Makes It Stand Out

Glass beads don’t last forever. They break down faster than harder abrasives like aluminum oxide. But they’re clean, safe, and contain no free silica which lowers the health risk.

Here’s what you should know:

- Best used in blast cabinets or enclosed systems

- Can be recycled a few times, but not as much as tougher media

- More expensive than basic abrasives, but better for finish work

- Not ideal for paint removal or deep rust

- Choose bead size based on how soft or textured you want the surface

If your goal is surface prep with a nice finish not heavy stripping glass beads are worth trying.

Takeaway Notes

If you’re thinking about using glass beads, keep this in mind:

- Not for paint stripping or deep rust removal

- Better to finish work than aggressive blasting

- Choose the bead size based on how smooth you want the surface

- Costs more than basic media, but gives better cosmetic results

- Works best on softer metals or parts with fine detail

Glass beads don’t just clean they restore. If your goal is to make something look fresh without wearing it down, give them a try.

4. Steel Grit

If you’ve ever had to clean thick rust or scale off steel, you know how tough it can be.

I’ve been there too.

I once spent hours blasting a large steel beam with a softer abrasive. Nothing worked fast enough. The rust just clung to the surface. Then I tried steel grit and everything changed.

You could see the difference after just one pass. The rust peeled back, and the surface looked fresh and rough ready to coat.

If you’re taking on a tough surface prep job, steel grit is what you want.

Applications

You’ll get the best results with steel grit when you use it for:

- Blasting off heavy rust, mill scale, or thick paint

- Preparing steel before painting or coating

- Cleaning up tanks, ship hulls, bridges, and large equipment

- Tough jobs in metal casting, repairs, or foundry work

If the metal is thick and the job is big, this abrasive makes it faster and easier.

What Makes It Stand Out

- Steel grit is made from hardened steel. It’s sharp, heavy, and angular

- It cuts deep and leaves a textured surface that coatings can grip

- You can choose different grit sizes, depending on how rough you want the finish

- It works best in blast rooms or closed systems not great for open-air use

You’ll notice right away how aggressive it feels. It doesn’t just clean. It digs in.

Takeaway Notes

Steel grit isn’t for every job. But if you’re blasting thick steel or cleaning something industrial, it’s a smart pick.

Here’s why it’s worth considering:

- You can reuse it many times, which saves money over time

- It’s more expensive at first, but cost-effective for repeat use

- It’s too aggressive for soft metals or thin parts

- It gives you a rough surface great for epoxy or powder coatings

- You’ll need high pressure to get the best performance

If you want speed, power, and a strong surface profile, steel grit delivers. You just have to match it with the right job.

5. Steel Shot

If you want to clean metal without cutting it into it, steel shot might be exactly what you need.

I first used it while working on a project that needed surface strength, not roughness. The goal wasn’t to strip paint or remove rust. It was to strengthen the metal and give it a smooth finish.

Steel shots helped me do both.

Applications

Steel shot works best when you need to:

- Polish metal surfaces without damaging the material

- Perform shot peening a process that strengthens metal by tapping it repeatedly

- Clean casting parts and remove surface stains or flash

- Work on automotive parts, rail tracks, or industrial tools

If you’re not looking to rough up the surface but still want it clean and strong, steel shot is a great fit.

What Makes It Stand Out

- Made from round steel balls smooth, not sharp

- Doesn’t cut into the surface, it compresses it

- Helps relieve stress in metal parts, especially in engines or springs

- Leaves a polished, bright finish

- Works well in wheel blasting systems (not usually used in hand-held setups)

What makes steel shot different is how it hits the surface. Instead of cutting, it gently hammers the surface over and over. This builds up strength in the outer layer of the metal.

That process is called peening. It’s often used in industries where fatigue cracks or part failure would be a big problem.

Takeaway Notes

If you’ve never used steel shot before, here are a few things to think about:

- Not for deep rust or heavy paint removal

- Reusable many times great for shops with recovery systems

- Needs higher energy blasting equipment, like a wheel blaster

- Best for hard metals like steel or iron

- More about strength and finish than surface removal

I’ve used it for tools, gears, and welded parts. Every time, it leaves the metal looking bright and makes it more durable too.

6. Garnet

Garnet has become one of my favorite abrasives for a reason. It’s clean, sharp, and surprisingly easy to work with.

I remember blasting a steel handrail coated in old paint and rust. With garnet, the surface came out smooth but not slick. The grit bit in just enough to give the new paint something to grab but without tearing into the base metal.

And the air? Much clearer than what I was used to.

Applications

You can use garnet for:

- Removing rust, paint, and scale

- Surface prep before coating or welding

- Cleaning stone, concrete, or brick

- Precise blasting in shipyards, buildings, and waterjet systems

It’s strong enough to cut through buildup, but won’t destroy the surface underneath.

What Makes It Stand Out

- Made from natural garnet rock hard, sharp, and dense

- Low dust leaves the air clearer and the space cleaner

- Reusable several times if collected and recycled properly

- Available in many grit sizes depending on the surface finish you want

- Leaves a bright, clean texture that’s easy to coat or paint

When garnet hits the surface, it doesn’t shatter as quickly as other media. That keeps the grit sharp and effective longer. You get a consistent finish without the mess.

I’ve used it on steel, concrete, and even delicate brickwork. The control and clarity it offers make it a reliable choice across different jobs.

Takeaway Notes

Here’s why you might want to keep garnet on your shelf:

- Non-toxic no free silica dust

- Safer to breathe, especially in enclosed spaces

- Costs more up front, but pays off with reuse

- Cleaner finish, with less post-blast cleanup

- Ideal for sensitive job sites or indoor blasting

If you’re tired of thick dust clouds and gritty cleanup, garnet is worth trying. It gives you power, precision, and a cleaner workday.

7. Plastic Abrasive

There are times when you want to strip something clean but not scratch it up.

That’s where plastic abrasive comes in. It’s tough enough to remove paint and coatings, but gentle enough to leave the base material untouched.

I’ve used it on plastic housings, soft aluminum parts, and even some aerospace components. Every time, I was surprised at how clean the finish looked without any of that harsh, cut-up texture you get from harder abrasives.

Applications

Plastic abrasive works best for:

- Removing paint, coatings, or decals from soft surfaces

- Cleaning fiberglass, plastic, or aluminum parts

- Jobs in aerospace, automotive, or electronics work

- Prepping parts that need to stay smooth or keep tight tolerances

If you’re blasting something lightweight or easy to damage, this material gives you control without going too far.

What Makes It Stand Out

- Made from recycled plastic (usually polyester or acrylic)

- Soft and lightweight won’t dig into the surface

- Cut coatings only, not the material underneath

- Available in different shapes and sizes for different finishes

- Leaves a smooth, even texture that feels clean to the touch

Plastic abrasives are ideal when the surface matters just as much as the finish. You don’t want scratches. You want the coating gone, but the shape and detail stay sharp.

Takeaway Notes

If you’re working with fragile or detailed parts, plastic abrasive can save you time and mistakes.

Here’s why it works so well:

- Low risk of damage to delicate surfaces

- Reusable several times in enclosed systems

- Little to no heat buildup, which protects sensitive materials

- Works best in dry blasting cabinets

- Not for rust or heavy corrosion, but great for controlled surface work

When you want control and a clean finish without the bite plastic abrasive is the way to go.

8. Walnut Shells

If you’ve ever needed to clean something without scratching it, walnut shell blasting is worth a look.

The first time I tried it, I was working on an old engine part with delicate threading. I needed to remove grease and carbon buildup but not damage the surface.

Walnut shells did the trick. The media felt light in the hand, almost soft, but it cleaned the part like a charm.

Applications

Walnut shells are great for:

- Cleaning engines, molds, or soft metals

- Removing grease, carbon, paint, or light coatings

- Polishing wood, fiberglass, or plastic without cutting

- Common in restoration work, automotive shops, and aviation maintenance

If you’re dealing with parts that have fine detail or can’t take heavy blasting, walnut shell media gives you a gentle option.

What Makes It Stand Out

- Made from crushed walnut shells biodegradable and natural

- Non-abrasive won’t damage or etch the base surface

- Leaves a smooth, matte finish without rough texture

- Comes in different grit sizes for soft or detailed work

- Creates low dust, so it’s cleaner than some other soft media

The texture is almost powdery when crushed fine, but still gritty enough to scrub away grime. I’ve used it on wooden furniture and cast aluminum housings with great results.

The surface came out clean but not raw. You could run your fingers over it without feeling sharp edges or scratches.

Takeaway Notes

Walnut shell blasting is all about control and surface care.

Here’s what you should know:

- Works best in dry blast cabinets

- Not good for rust or hard coatings it’s too soft

- Reusable a few times, especially with good filtration

- Eco-friendly, you can toss used shells without toxic waste

- A smart choice for delicate or high-value parts

If you need to clean something gently without losing detail walnut shells are a solid, natural option.

9. Corn Cob

I looked at the part and thought, “There’s no way I can blast this without ruining it.”

It was an old aluminum nameplate. The paint was chipped, and the letters were faded. But it still had value just needed a fresh surface.

That’s when I reached for corn cob media.

It felt strange at first. Blasting with something so light? But after a few passes, the paint came off, and the letters stayed sharp. No gouges. No scratches. Just clean metal and a soft, natural glow.

Applications

Corn cob works best for:

- Polishing delicate surfaces like soft metals, wood, or plastics

- Removing grease, soot, and light paint

- Cleaning engine parts, tools, or antiques

- Prepping items for repainting or restoration without damage

If you’ve got something valuable, fragile, or full of fine detail this media gives you a safe way to clean it.

What Makes It Stand Out

- Made from ground-up corn cobs lightweight and biodegradable

- Low abrasive strength, so it cleans without cutting

- Leaves a warm, smooth finish that won’t feel rough or uneven

- Creates minimal heat, which protects sensitive materials

- Often used in dry blasting cabinets and restoration work

You won’t feel grit like with sand or glass. Instead, it’s more like a soft scrub. Think of it like using a stiff sponge instead of a wire brush.

I remember thinking, “This feels too gentle.” But the results spoke for themselves.

Takeaway Notes

Corn cob isn’t made for heavy jobs but it shines in light ones.

Here’s why you might use it:

- Won’t damage soft materials like brass or wood

- Great for polishing, not for removing rust or tough coatings

- Reusable, though it breaks down faster than harder abrasives

- Eco-friendly and safe to dispose of

- Best for indoor use, especially with dust collection systems

If you’ve got something that needs a soft touch, corn cob media gives you the control you need without sacrificing the surface underneath.

10. Silicon Carbide

“Go slow,” I told myself.

This wasn’t a normal blast. I was working with hardened steel, and the coating was thick. Nothing else had worked. I needed something sharper something that could cut through without wasting time.

That’s when I turned to silicon carbide. It didn’t just work it tore through the coating like it wasn’t even there.

If you’re handling the toughest surfaces, this is the abrasive you’ll want by your side.

Applications

Silicon carbide is a great fit for:

- Cutting through hard coatings, rust, and scale

- Etching stone, glass, or ceramics

- Cleaning tungsten, carbide tools, and hardened steels

- Jobs where precision and aggression both matter

If you’re blasting something hard and you need a clean, sharp finish this media delivers.

What Makes It Stand Out

- Made from synthetic crystal extremely hard and sharp

- Faster cutting than most abrasives on the market

- Available in fine to coarse grits depending on how deep you want to cut

- Leaves a sharp-edged profile, ideal for strong coating adhesion

- Works well in both dry and wet blasting systems

Takeaway Notes

Silicon carbide isn’t for casual jobs. But if you’re facing something tough, it’s one of the best tools out there.

Here’s why it stands out:

- Very aggressive removes material fast

- Long-lasting, even with heavy use

- It can be too sharp for soft metals or delicate parts

- Often used in industrial blasting systems

- Higher cost, but worth it when performance matters

If you’re dealing with glass, ceramics, or tough metal, and you don’t want to waste time silicon carbide cuts clean and gets the job done.

Conclusion

You’ve got goals. Cleaner parts. Faster work. Better results.

Now you’ve got the tools to back it up.

We covered 10 blasting abrasives from the soft touch of corn cob to the sharp edge of silicon carbide. You know what works, when to use it, and how it affects your finish.

So why wait?

Start your next job with confidence. Take control of your surface prep and stop second-guessing your materials.

At MachMaster, we work with teams like yours every day to match the right media to the right job.

Have you used any of these abrasives before? Which one are you ready to try?

Contact us today we can help you choose the right abrasive and get better results from the start.