I remember the time I sent one simple drawing to three CNC shops.

Guess what? I got three different quotes and each one said I needed a different machining process.

One said CNC turning. The second said 5-axis milling. The third asked if I’d thought about laser cutting.

That’s when it hit me: if you don’t really understand how these methods work, it’s easy to get lost or make the wrong call.

If you’re in that spot right now—getting quotes, not sure which process fits your part—I totally get it.

I’ve been there. I’ve worked with engineering teams, handled supplier talks, and made a few mistakes myself.

This article is here to make things easier for you. I’ll walk you through 10 common types of CNC machining. I’ll explain how each one works, what it’s good at, and when to use it—or when to skip it.

By the end, you’ll know exactly how to choose the right method for your product or project. No guesswork. No confusion. Just the info you actually need.

So let’s begin!

Quick Comparison Chart

This table gives you a side-by-side look at 10 types of CNC machining. Use it as a guide to see what fits your part before we break down each process in detail.

| CNC Process | What It Does | Best For | Limitations | Key Takeaway |

| CNC Milling | Rotating tool cuts a stationary workpiece | Flat surfaces, pockets, and complex shapes | Not great for cylindrical parts; setup adds cost | Most versatile—great for many parts |

| CNC Turning | The spinning part is shaped by a stationary cutting tool | Round parts like shafts and bushings | Limited to symmetrical parts; not for 3D shapes | Fast and efficient for round, repeatable parts |

| CNC Swiss Turning | Sliding headstock turns small parts with tight control | Micro parts: medical screws, connectors | Expensive; tricky setup for beginners | Ideal for small, high-volume precision work |

| CNC EDM | Sparks erode material—no contact cutting | Hardened steel, deep cavities, fine details | Only works on conductive materials; slow | Best for tough materials and detailed internal cuts |

| CNC Wire EDM | Thin wire cuts precise 2D shapes using spark erosion | Thick metals, dies, aerospace, sharp inside corners | Needs start hole; only 2D cuts | Perfect for tight profiles in hard materials |

| CNC Plasma Cutting | High-speed plasma jet melts and blows away metal | Fast cutting of sheet steel or aluminum | Heat can distort thin parts; rougher edges | Great for quick, mid-precision sheet metal cuts |

| CNC Laser Cutting | Focused laser melts or vaporizes material | Thin sheets, engraving, and clean edges | Not for thick parts; some plastics can discolor | Best for fast, detailed work on thin materials |

| CNC Waterjet Cutting | High-pressure water (with or without grit) cuts material | Rubber, foam, stone, metal without heat | Slower; edges less polished than laser | Best cold-cutting method for heat-sensitive jobs |

| CNC Grinding | Abrasive wheel refines surface for precision and polish | Tool sharpening, tight fits, mirror finishes | Slow; used mostly for finishing, not shaping | Used when ultra-precision or smooth surfaces are needed |

| CNC Router | Spinning bit cuts wood, foam, plastic, and soft metal | Furniture, signs, large sheets of soft material | Not for hard metals; less precise than milling | Great for soft materials and creative applications |

Now that you’ve seen the overview, let’s explore each process one by one.

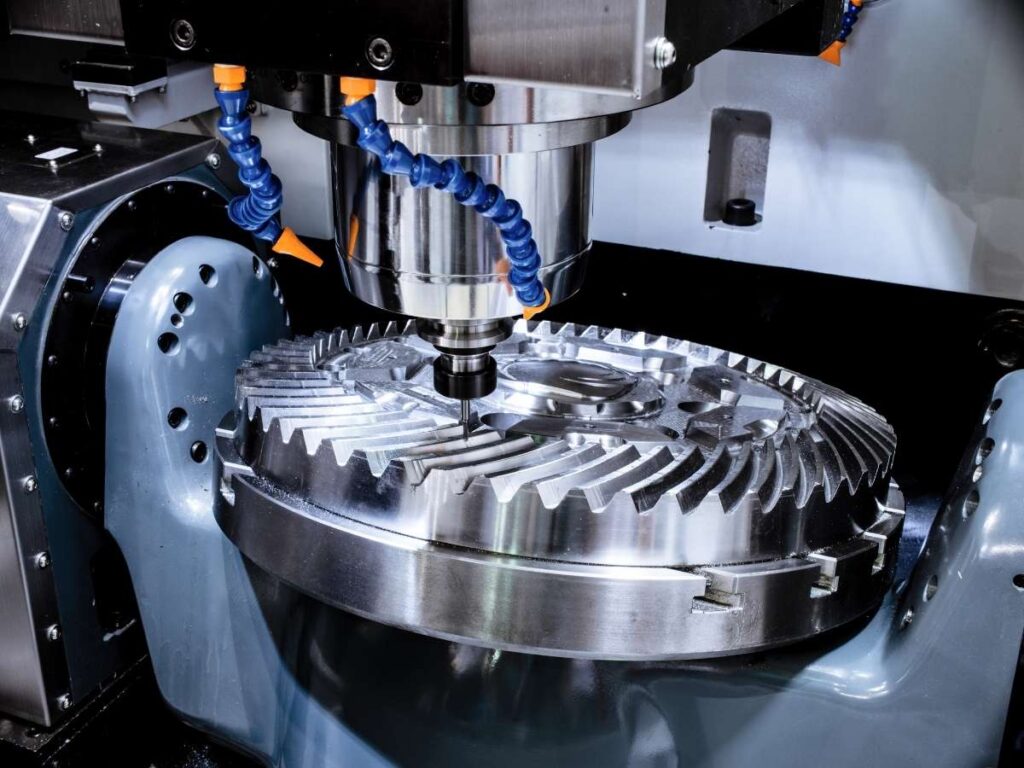

1. CNC Milling

When I first started working with CNC processes, milling was the one I turned to most. It felt familiar, flexible, and easy to build around—and over time, I saw why it’s often the first choice for many projects.

CNC milling uses a rotating cutting tool to remove material from a stationary workpiece. The material stays in place, and the tool moves across it, shaving off what you don’t need. It’s precise and controlled, kind of like carving—but with software doing the thinking and a spinning bit doing the work.

Depending on your part, you might use:

- 3-axis milling, which moves in straight lines across X, Y, and Z

- 4-axis, which adds rotation

- Or 5-axis, which can tilt and rotate for more complex angles

The more axes you use, the more freedom you get to machine tight corners, steep angles, and smooth contours in a single setup.

Best For

CNC milling works well for:

- Flat surfaces

- Pockets and slots

- Curved or angled features

- Holes and tapped threads

- Materials like aluminum, steel, brass, and plastics

- Jobs like prototypes, short-run production, and custom designs

At MachMaster, CNC milling is one of our most requested services—especially for small-batch prototypes and high-precision components. It’s a go-to process for flexible design changes and fast turnaround.

Limitations

Even though milling is versatile, there are times when it’s not the best fit:

- Not ideal for round parts, like shafts or pins—CNC turning is more efficient

- Setup can be time-consuming, especially if the part needs custom fixtures

- Small batch jobs may cost more, due to the extra work needed to prepare each setup

Key Takeaway

CNC milling is one of the most widely used and flexible machining processes. If you’re unsure where to begin, this is often the right place. It handles many materials and geometries, offers high precision, and works well for both short and mid-size runs.

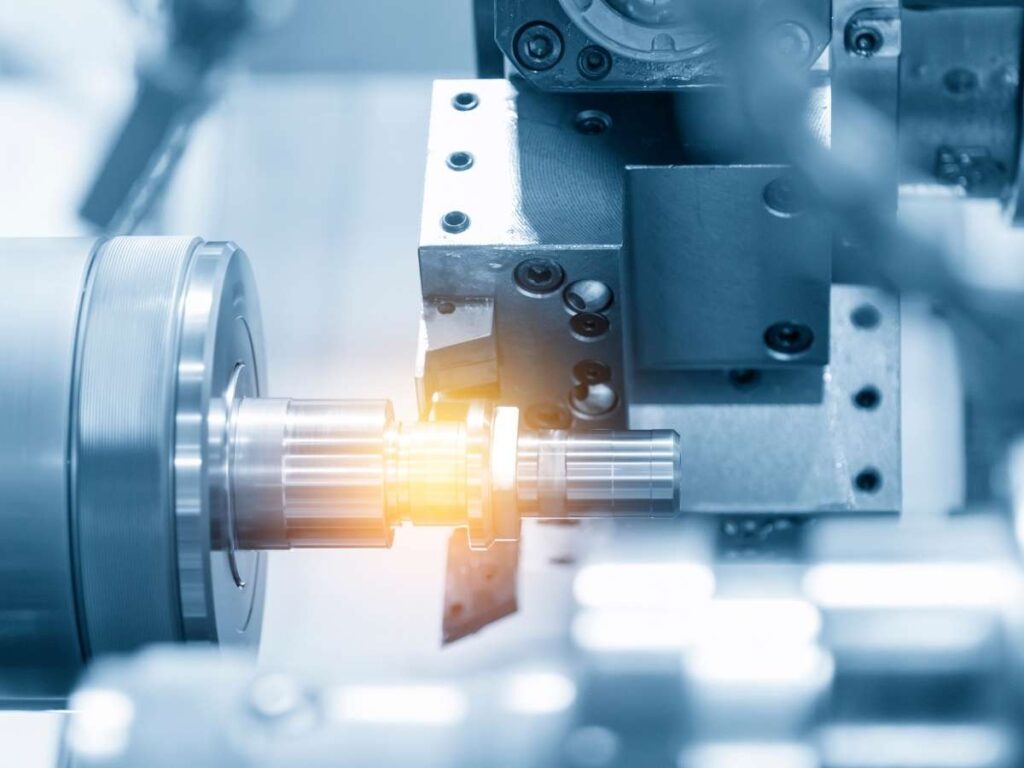

2. CNC Turning

The first time I used CNC turning, I was making a batch of small metal shafts. Milling would’ve taken too long—and cost too much. Turning saved the project.

CNC turning is different from milling. In this process, the workpiece spins while a stationary cutting tool shapes it.

The material rotates at high speed. The tool stays still, carefully trimming the outside, the inside, or even cutting threads. It’s a great way to make parts that are round, smooth, and repeatable. Everything is controlled by code, just like milling—but the motion is flipped.

Best For

Turning is ideal when your part is:

- Round or tubular

- Symmetrical along its center

- Repeated in large quantities

Some common examples include:

- Shafts

- Bushings

- Pulleys

- Pins

- Collars

Turning works fast. You can produce hundreds or even thousands of parts quickly, especially if you’re using bar stock (long rods of material fed into the machine).

It’s also great when you need tight tolerances and a clean surface finish—important in industries like automotive, aerospace, and medical equipment.

Limitations

Still, turning isn’t for every part.

It doesn’t work well for:

- Flat or boxy parts

- Shapes with odd angles or complex 3D surfaces

- Asymmetrical designs that need multiple setup changes

If your part isn’t round—or doesn’t rotate cleanly—you’ll need a different method like milling or 5-axis machining.

Key Takeaway

Use CNC turning when your part is round and symmetrical, and you want to make a lot of them—fast. At MachMaster, we recommend CNC turning for customers who need reliable, high-volume production of shafts, bushings, and precision round parts. It’s one of the most efficient paths to consistent quality at scale.

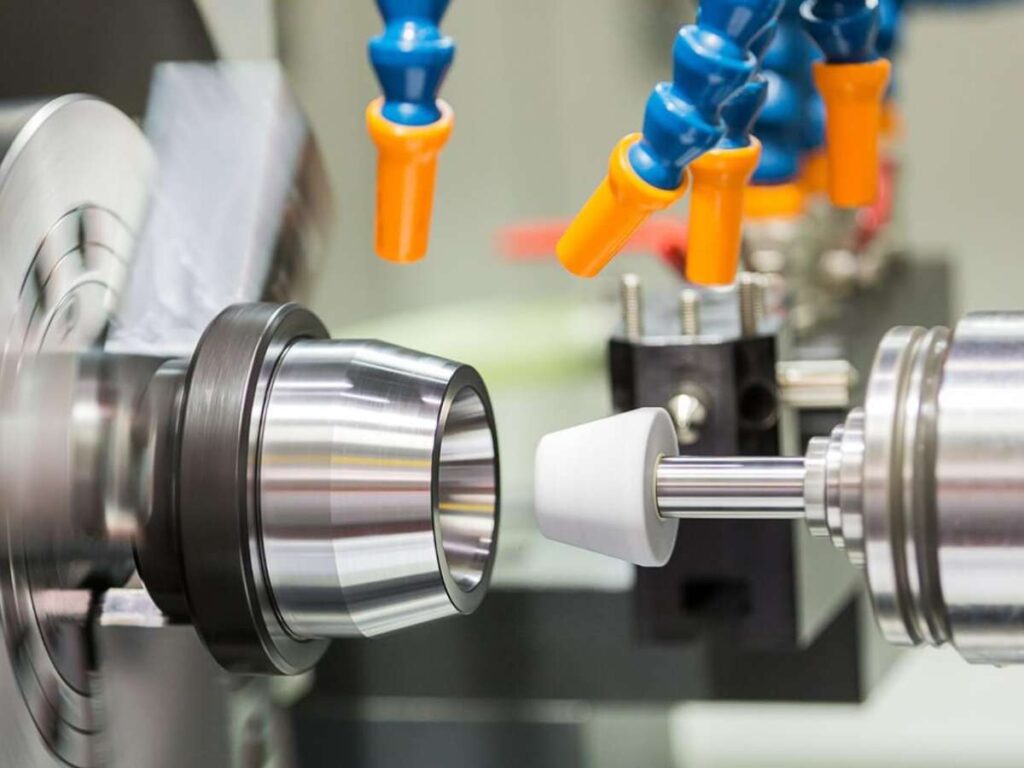

3. CNC Swiss Turning

Watching a Swiss machine at work shows you just how precise CNC can get. The part moves smoothly, the tools stay tight to the surface, and every cut land exactly where it should be. That’s what makes this method stand out.

CNC Swiss turning is a special kind of CNC turning.

In a standard lathe, the cutting tool moves while the part spins. But with Swiss turning, the bar of material slides back and forth through a guide bushing, while the tool stays close and steady.

This setup gives more support and control, especially for small, thin parts. It also lets the machine do several operations in one go—like cutting, drilling, and milling—without needing to stop or move the part to a different setup.

Best For

Swiss turning is made for small, high-precision parts. You’ll see it used in industries like:

- Medical: screws, pins, bone anchors

- Electronics: tiny connectors, contact points

- Aerospace: small shafts, bushings, sleeves

- Watchmaking and instruments: gear pins, springs, fine rods

It’s the right choice when your part:

- It is long and narrow

- Has tight tolerances

- Needs to be made in large quantities

- Must be consistent from one piece to the next

I’ve seen projects with 10,000 parts—all identical, all perfect—thanks to this process.

Limitations

Swiss turning is powerful, but it comes with a few downsides:

- Higher cost of machinery compared to regular lathes

- Setup is more complex, which can slow things down if you’re just getting started

- Not ideal for large or simple parts—other methods may be faster and cheaper

Key Takeaway

CNC Swiss turning is perfect when you need tiny parts with extreme accuracy—and a lot of them. If your work involves small-scale components for medical, aerospace, or electronics, this is one of the best tools you can use.

4. CNC EDM (Electrical Discharge Machining)

There was a job I worked on that needed super sharp corners—tight spots no cutter could reach. Regular tools just couldn’t do it. That’s when EDM made all the difference.

CNC EDM, or Electrical Discharge Machining, is a process that uses electrical sparks to shape metal.

Instead of cutting with a spinning tool, EDM erodes the material. A thin wire or electrode gets close to the part, and tiny sparks jump across the gap. Each spark melts and removes a bit of metal.

The part and the tool never touch. It’s all done by spark and heat. The machine controls everything with extreme precision.

There are 2 main types:

- Wire EDM: uses a thin wire to cut complex shapes through a part

- Sinker EDM: uses a shaped electrode to burn a pattern onto the surface

Both are great when you need fine detail and clean edges.

Best For

You’ll want to use EDM when the job calls for:

- Sharp inside corners

- Deep, narrow cavities

- Thin walls or slots

- Hard metals, like hardened steel, titanium, or carbide

- Tooling and molds that need exact detail

EDM is common in industries like:

- Injection mold making

- Aerospace

- Medical tools

- Precision stamping dies

If your part is hard to cut with traditional tools, EDM is a smart option.

Limitations

There are a few downsides to keep in mind:

- Only works on conductive materials if the material doesn’t carry electricity, EDM won’t touch it

- Slower than other methods, especially for large cuts or deep shapes

- More expensive per part, since it takes longer and uses consumable wires or electrodes

That said, quality and accuracy often make up for extra time.

Key Takeaway

CNC EDM is perfect for jobs where fine details, sharp corners, and tough metals are involved. If you’re building a mold, a precision die, or a part from hardened steel—and need it to be just right—EDM is worth a serious look.

5. CNC Wire EDM

CNC Wire EDM is one of those processes that can do what others can’t. I’ve seen it cut thick, hardened steel into detailed shapes with almost no effort—no force, no mess, just clean lines and precision.

CNC Wire EDM stands for Wire Electrical Discharge Machining. Instead of cutting with a blade or tool, it uses a thin wire and controlled electrical sparks.

Here’s how it works:

- A thin metal wire (usually brass) acts as an electrode

- Sparks jump from the wire to the metal part

- Each spark melts and removes a small bit of material

- The wire moves along a programmed path, cutting a shape through the part

- The process is non-contact, so there’s no pressure or vibration

Because of how it works, Wire EDM is great for getting clean, accurate cuts in hard materials without changing their shape or surface.

Best For

Wire EDM is used when you need:

- Tight internal features and 2D profiles

- Thick materials cut all the way through

- Sharp corners or narrow slots

- Precision cuts in hardened steel, titanium, or carbide

It’s especially common in:

- Die-making

- Stamping tools

- Aerospace parts

- Medical components

Limitations

Even though it’s powerful, Wire EDM has some limits:

- Only works with conductive materials—non-metal parts can’t be machined

- Limited to 2D profile cuts—you can’t shape full 3D forms with it

- Requires a start hole—you’ll need to drill into the part before cutting

- Slower than other CNC methods, especially for deep or complex shapes

Key Takeaway

If you’re working with hard metals and need tight-tolerance internal cuts, CNC Wire EDM is a smart option. It’s slower, but when precision matters—especially on thick or heat-treated parts—it delivers results few other methods can match.

6. CNC Plasma Cutting

If you’ve ever seen bright sparks flying across a metal sheet, chances are it was plasma cutting. The speed, the light, the clean slice—it’s fast, loud, and powerful. I’ve used it on projects where speed mattered more than tight tolerances, and it never disappoints.

CNC Plasma Cutting uses a high-speed jet of ionized gas, called plasma, to melt and cut through metal.

The gas is heated until it becomes electrically conductive. Then, the plasma arc forms between the torch and the metal, creating enough heat to slice through it cleanly.

Here’s how it works:

- Compressed gas (like air or nitrogen) is forced through a small nozzle

- An electric arc turns the gas into plasma, which reaches temperatures over 20,000°C

- The plasma jet melts the metal, while the high-speed gas blows it away

- A CNC system guides the torch to cut the shape you want

It’s fast, and it works well on conductive metals—especially sheet forms.

Best For

Plasma cutting is often used when you need:

- Quick cuts through steel, aluminum, or stainless steel

- Medium-level accuracy without needing super fine detail

- Projects in industries like:

- Construction: for structural steel parts

- Automotive: for body panels and brackets

- Metal art: signs, wall pieces, decorative cutouts

It’s also a great option for hobbyists or shops that need to move fast without investing in more complex tools.

Limitations

Plasma cutting isn’t perfect for every job. Some things to consider:

- Creates a heat-affected zone (HAZ)—thin metals may warp from the heat

- Not ideal for tight tolerances—you won’t get clean corners or super fine cuts

- Rougher edges compared to methods like laser or waterjet

So if your part needs sharp detail or tight fits, this may not be the right tool.

Key Takeaway

CNC Plasma Cutting is great when you need to cut metal sheets quickly and affordably—especially for parts where rough-to-mid precision is okay. If you’re working with steel or aluminum and speed matters more than fine detail, plasma is a solid choice.

7. CNC Laser Cutting

There’s something satisfying about watching a laser slice through material without even touching it. I’ve used it for jobs that needed fine detail, smooth edges, and no cleanup afterward. When looks matter as much as function, laser cutting is hard to beat.

CNC Laser Cutting uses a high-powered laser beam to cut or engrave material.

The laser is focused through a lens until it reaches a small, intense point. That point gets hot enough to melt, burn, or vaporize the material instantly.

Here’s how it works:

- A laser source creates a beam of light

- The beam is focused through a lens

- The focused laser cuts through the material

- A CNC system moves the beam along the programmed path

There’s no physical contact: that means no tool wear and highly consistent results.

Best For

Laser cutting works best when your part:

- Uses thin materials (like sheets under 10mm)

- Needs tight detail or engraving

- Must have smooth, finished edges

It’s great for:

- Metals: stainless steel, aluminum, or brass

- Plastics: acrylic, polycarbonate

- Wood: signs, patterns, or decorative panels

I’ve seen laser cutting used in everything from control panels to custom furniture. It’s fast, accurate, and easy to repeat.

Limitations

Laser cutting has a few limits to think about:

- Not ideal for thick materials: the cut slows down, and edges may char

- Some plastics can melt or discolor: heat can affect the surface

- More expensive than plasma: not always cost-effective for large, simple parts

If your job doesn’t require fine detail, there may be faster options.

Key Takeaway

CNC Laser Cutting is a smart choice when you need speed, precision, and clean edges on thin materials. If you’re working with wood, plastic, or metal sheet—and want results that look sharp and professional—laser cutting gets it done.

8. CNC Waterjet Cutting

Sometimes, heat causes more problems than it solves. I’ve worked with materials that warp, melt, or lose strength when exposed to high temperatures. That’s when CNC Waterjet Cutting becomes a real advantage.

CNC Waterjet Cutting uses a high-pressure stream of water to cut through materials.

In some cases, the machine adds an abrasive like garnet to the water to help it cut harder surfaces. The stream moves at extremely high speeds—strong enough to slice through metal, stone, or rubber without creating any heat.

Here’s how it works:

- Water is pressurized up to 60,000 psi or more

- The stream is focused through a narrow nozzle

- Abrasive particles may be added for extra cutting strength

- A CNC controller guides the jet along the desired shape

It’s called a cold cutting method because it doesn’t use heat, which helps avoid material damage.

Best For

Waterjet cutting is perfect when you’re working with materials that don’t react well to heat. You’ll often see it used for:

- Composites: carbon fiber, fiberglass

- Soft materials: rubber, foam, plastic

- Hard materials: stone, ceramics, metal plate

- Laminated sheets: multiple layers that melt or shift under heat

If you need clean cuts without burning, melting, or discoloration, this method is a solid choice.

Limitations

Even though waterjet cutting is versatile, there are a few trade-offs:

- Slower than laser or plasma: especially for thick or dense materials

- Can leave a slightly rougher edge: not always suitable for fine finishes

- Higher running cost: abrasives and water pumps add to the expense

It’s not the fastest or cheapest process—but for sensitive materials, it gets the job done right.

Key Takeaway

CNC Waterjet Cutting is ideal when you need to cut without heat, especially for parts that can’t handle burning or warping. If you’re working with mixed materials, soft surfaces, or heat-sensitive components, this is your go-to method.

9. CNC Grinding

There’s a point in some projects where good just isn’t good enough. That’s when I turn to CNC grinding. It’s not flashy or fast, but when a part needs that last bit of perfection, this process makes the difference.

CNC Grinding uses an abrasive wheel to remove very small amounts of material from the surface of a part.

Unlike cutting or milling, which shape the overall form, grinding focuses on refining the surface—smoothing it out, sharpening edges, or dialing in exact tolerances.

Here’s how it works:

- A rotating grinding wheel is made of hard, gritty material

- The wheel makes light contact with the part

- The part and wheel may both move under CNC control

- Material is removed gradually for high accuracy and smooth finishes

This process is often used at the end of production, not at the start.

Best For

Grinding is great when your job calls for:

- Tool sharpening: drill bits, cutting inserts, dies

- Tight-tolerance fits: shafts, bores, and mating parts

- Smooth surface finishes: mirror-like polish or ultra-flat faces

- Hard metals: including hardened steel and carbide

It’s common in industries like:

- Aerospace

- Medical

- Automotive

- Precision toolmaking

If your part needs to slide, spin, or seal perfectly, grinding can help you hit the mark.

Limitations

CNC grinding has a few limits to think about:

- Slower than cutting or milling: it removes very small amounts of material

- Not meant for shaping: it’s more for polishing, fine-tuning, or finishing

- Special wheels and setups: different materials need different grinding tools

If you’re still shaping your part, use other methods first—grinding comes last.

Key Takeaway

CNC Grinding is your final step when you need ultra-precision and perfect surface finish. If you’re aiming for tight tolerances, smooth movement, or exact polish, this process is essential.

10. CNC Router

When I worked on a custom furniture project, I needed something that could handle big sheets of wood—quickly and accurately. That’s when a CNC router became my go-to. It wasn’t built for metal, but for what I needed, it was perfect.

A CNC router is a computer-controlled cutting machine that uses a spinning bit to carve, shape, or cut softer materials.

It works a lot like a handheld router, but with more precision and automation. The machine moves the bit across the surface in multiple directions, based on your digital design.

Here’s what happens:

- The bit spins at high speed to cut or shape the material

- The machine moves along programmed paths (X, Y, and Z axes)

- A vacuum table or clamps hold your material in place

- The result: smooth cuts on large sheets with consistent accuracy

It’s often used for cutting full-size panels or detailed designs in non-metallic materials.

Best For

CNC routers are best when you’re working with:

- Wood: plywood, MDF, hardwood

- Plastic: acrylic, PVC, HDPE

- Foam: sign foam, mold foam

- Soft metals: like aluminum, but only in basic forms

Common uses include:

- Furniture and cabinetry

- Sign making and lettering

- Architectural panels

- Mold patterns and creative craft projects

If your job involves large sheets and detailed shapes, this machine can handle both.

Limitations

Even though routers are flexible, they do have some limits:

- Not rigid enough for hard metals: vibrations can affect cut quality

- Lower precision than CNC milling: not ideal for tight tolerances

- Bits wear quickly on harder materials: which adds to maintenance costs

For heavy-duty metal work or tiny precision cuts, milling is the better fit.

Key Takeaway

CNC routers are great for large-format cutting and creative projects using softer materials. If you’re making furniture, signs, or patterns—and need speed, scale, and flexibility—this tool is made for you.

Conclusion

Now you know what each CNC process does, where it fits, and why it matters.

Whether you’re building one part or 10,000, picking the right method saves time and money.

So—what’s stopping you?

Start now. Your part doesn’t cut itself.

Contact us today if you’re ready to turn that design into something real.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.