I used to think milling and grinding were just two words for the same thing.

Maybe you’ve thought that too.

Back when I first started visiting machine shops, I’d stand there pretending I know everything.

Truth was, I didn’t really know what made milling different from grinding. That gap in my understanding ended up costing us on a project—both in time and money.

Now, after years of talking to factory owners, engineers, and even people building school projects, I’ve learned the real difference. I’ve messed up enough times to know what matters and what doesn’t.

That’s why you can trust me to keep this super simple.

In this article, you’ll find out what milling and grinding are, how each one works, and why you’d pick one over the other.

By the end, you’ll have a clear, simple way to tell them apart so you can make better calls on your next project.

So let’s get started!

Quick Comaprison Chart

Here’s a fast glance at both methods. This chart will frame the differences before we unpack each one in detail.

| Feature | Grinding | Milling |

| Main Goal | Smooth finish, tight tolerances | Fast material removal, shaping complex forms |

| Material Removed | Very small amounts (microns per pass) | Larger chips, more material removed per pass |

| Surface Finish | Very fine, often mirror-like | Visible tool marks; good enough for most parts |

| Typical Tolerance | Very tight (±0.0002 in) | Standard (±0.005 in) |

| Best Materials | Hardened steel, carbide, tool steel | Aluminum, brass, mild steel, plastics |

| Part Movement | Part may move slowly or stay still | Tool moves in X, Y, Z axes |

| Heat Control Needed | High (requires coolant and wheel dressing) | Moderate (chip removal handles most heat) |

| Cycle Time | Slower, with more control | Faster for open shapes and rough cutting |

| Typical Sequence | Used after milling or heat treatment for finishing | Usually the first step in machining |

| Common Uses | Seals, sliding surfaces, tight-fitting parts | Brackets, housings, pockets, threads, 3D contours |

Now that you’ve seen the snapshot, we’ll dig into grinding first and milling right after.

1. What is Grinding?

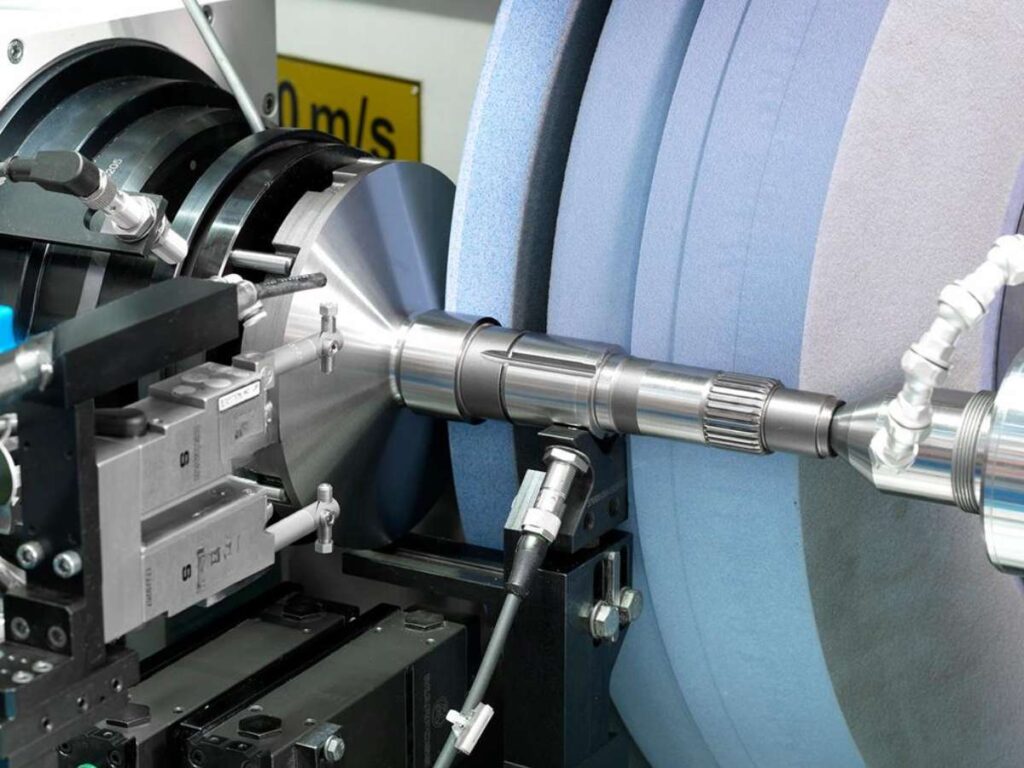

Grinding is a precision machining process that removes material from a workpiece using a rotating abrasive wheel. It’s commonly used to create smooth finishes or to meet very tight tolerances especially during final machining stages.

If you’re managing production or sourcing machined components, you’ll want to consider grinding in the following cases:

- Your part needs a high-quality surface finish

- You’re working with hardened materials that are difficult to cut

- Your tolerance requirements are too tight for milling or turning

- You’re removing small amounts of material with a focus on control

How Grinding Works

The grinding wheel spins at high speed. The workpiece is either held still or moved beneath the wheel. Small chip fractions of a millimeter are removed with each pass.

A lot of times, I use grinding after milling. I don’t shape the part with it. I use it to clean up the surface, make it more exact, or hit a really tight size.

Grinding makes heat. I’ve burned my share of parts learning that. That’s why I always make sure there’s:

- Coolant systems to manage heat buildup

- Dressing tools to clean and reshape the wheel

- Secure fixtures to keep the part stable

If your team is chasing tight sizes or buying parts that have to pass strict checks, grinding is something to think hard about. I’ve skipped it before, and trust me, once parts start failing, it’s a lesson you only need once.

2. What is Milling?

When I first stepped into a machine shop, I was amazed by how fast milling machines could cut away metal. It felt like magic seeing a block slowly turn into a real part.

If you’re handling product development or sourcing parts, milling is likely where the part’s shape begins. It’s often the first step before finishing or heat treating.

How Milling Works

The cutter rotates while moving along one or more axes:

- In 3-axis machines, the tool moves up/down (Z), left/right (X), and forward/backward (Y)

- In 4-axis and 5-axis machines, the tool or table can also rotate, adding even more flexibility

These machines are controlled by computer programs (CNC—Computer Numerical Control), which means repeatability and consistency across parts.

Milling is often the go-to method for removing large amounts of material quickly. And because it supports a wide range of tooling, it can handle:

- Flat surfaces

- Slots and pockets

- Contours and 3D shapes

- Threads and holes

- Complex geometries

CNC milling machines come in 3-axis, 4-axis, and even 5-axis setups. They work on everything from aluminum and stainless steel to plastics and composites.

3. Material Removal Process

Understanding how grinding and milling remove material isn’t just about machine specs. It’s about knowing what part needs from the very first cut.

Milling: Cuts Material Quickly

Need to remove a lot of metal in a short time? That’s where milling shines.

Milling uses a spinning cutter with sharp edges. The tool rotates and moves across the workpiece, carving out chunks of material with each pass. These chips are thick and visible—sometimes even hot to the touch.

Milling works best when:

- You need fast material removal

- Your design has slots, holes, or 3D shapes

- You’re using softer metals like aluminum or mild steel

It’s common in prototyping or when shaping the rough form before finishing.

Grinding: Removes Tiny Amounts Slowly

Grinding isn’t about speed—it’s about control.

It uses a wheel made of abrasive grains. These grains act like thousands of tiny cutting edges. Instead of slicing off big chunks, they wear the surface down a little at a time.

This makes grinding perfect for parts that need:

- A very smooth finish

- Tight tolerances (think ±0.001 inch or better)

- Fine detail on hard metals like stainless steel or carbide

I once had a stainless-steel valve part that came back from milling with visible marks. We sent it for grinding, and it came back clean—smooth, shiny, ready to ship. Grinding fixed what milling couldn’t.

4. Surface Finish Quality

Surface finish often gets overlooked—until it becomes the problem.

I learned this the hard way. We once delivered a batch of brackets that met dimensional specs but had rough surfaces. The client rejected them. Not because of size, but because the parts would scratch their mating components. That’s when I started paying attention to finish—not just form.

Milling: Good Enough for Most Jobs

Milling can give you a decent finish—especially with the right tools and feeds. But it won’t match the smoothness of grinding.

You’ll often see fine tool marks on the surface. For many parts, that’s just fine. I’ve sent out plenty of milled parts that worked great without any touch-ups.

But sometimes, those marks can be a problem. I’ve had customers reject parts for small scratches that didn’t affect function—but they did affect appearance.

Milling finish is fine when:

- You’re okay with visible tool paths

- The part gets painted or coated later

- It doesn’t need a perfect seal or tight sliding motion

Grinding: Smooth, Clean, and Precise

Grinding creates a surface that’s flat, clean, and smooth. Almost mirror-like.

That’s because grinding removes tiny amounts of material evenly. No chatter. No ridges. Just fine control.

I remember a time we ground a mold insert that had to be near perfect. No tool marks, no scratches. The client was happy—and that repeat order still comes in every quarter.

Grinding finish is best when:

- The surface needs to seal, slide, or reflect

- You’re working with hard metals or heat-treated parts

- The final look matters to the customer

5. Tolerance and Accuracy

Getting the right size isn’t enough. Sometimes, the part has to fit within a tiny margin—known as tolerance.

Tolerance is how much variation you can allow in a part’s size and still have it work. Accuracy is how close you get to the size you want.

Milling: Good for Standard Tolerances

Milling can hit pretty tight tolerances, especially on a good CNC machine.

But it does have limits.

Tool wear, machine vibration, and material movement can all affect the outcome. If you’re holding ±0.005 inch or more, milling usually gets the job done.

I’ve made thousands of parts this way—brackets, blocks, covers. They came out just fine for general assembly and fixtures.

Milling works when:

- You need basic to moderate precision

- Your parts don’t need a super-tight fit

- Speed matters more than perfection

Grinding: Best for Tight Tolerances

Grinding is built for precision.

It can hold tolerances down to ±0.0002 inch if needed. That’s why it’s used for tools, dies, and high-performance components.

I remember grinding some gauge blocks for a customer who checked every part under a microscope. No room for error. And we nailed it—because grinding lets you dial in that level of control.

Grinding makes sense when:

- You need very tight size control

- Parts must fit together with no gap

- Even tiny size errors cause problems

6. Material Compatibility

Not all materials respond the same way to grinding and milling. Material type plays a major role in determining which process will work better—both in terms of tool wear and final result.

Milling: Works Best on Softer Metals

Milling handles soft to medium materials really well.

Think:

- Aluminum

- Brass

- Mild steel

- Plastics

These materials cut fast. The tool slices through and keeps going without much wear. You get high material removal with low resistance.

I once ran a full batch of aluminum enclosures on a CNC mill. No broken tools. Clean cuts. We finished ahead of schedule.

Use milling when:

- Your metal isn’t too hard

- You need speed

- Tool life is a concern

Grinding: Handles Harder, Tougher Materials

Grinding is great for hard metals that can wear out regular cutting tools.

Materials like:

- Stainless steel

- Tool steel

- Hardened parts

- Carbide

These are tough on mills. But a grinding wheel? It wears them down slowly and evenly.

We had a hardened shaft job where mills kept chipping. Switched to grinding—and it worked like a charm. Clean, quiet, and under tolerance.

Use grinding when:

- You’re working with hard or heat-treated metals

- The material is brittle and can chip easily

- You need a very smooth surface

If you need to machine these materials efficiently and with confidence, MachMaster delivers reliable CNC milling services backed by experience, flexibility, and fast turnaround.

7. Speed and Cycle Time

Speed and time are often the deciding factors in a shop environment. Whether it’s for a production run or a one-off prototype, knowing how long each process takes helps plan the job better and manage resources.

Milling: Fast and Efficient

Milling is usually the faster process.

It removes big amounts of material in just a few passes.

I remember a job cutting aluminum panels. With a sharp end mill and high feed rate, I could finish each one in under five minutes. No grinding process could beat that.

Milling is ideal when:

- You need to cut quickly

- The part has a simple or open shape

- You want short cycle times for high volume

It’s a good match for production runs or prototypes that don’t need a super-fine finish.

Grinding: Slower, But More Controlled

Grinding takes more time—sometimes a lot more.

Each pass removes just a little. That’s what makes it precise.

On hardened parts or tight tolerances, I’ve had grinding jobs that took ten times longer than milling. But those parts were always on spec.

Grinding is better when:

- You need a smooth, accurate finish

- The part is heat-treated or very hard

- You’re doing final touches, not bulk removal

You trade speed for control—and sometimes, that’s the smarter choice.

8. How To Choose Between Grinding and Milling

I know that deciding between grinding and milling is more than comparing machines—it’s about understanding what the part needs, what the material allows, and what the end result must be.

This decision usually depends on four core factors:

Geometry and Part Requirements

Grinding is a good choice when your part needs to be extremely flat or have precise edges with little material removal. That includes:

- Gauge blocks

- Tooling shims

- Hardened inserts

These parts don’t require bulk shaping—but they do need perfect flatness and edge control.

Milling is a better option if your part has curves, angles, or pockets. CNC milling can shape complex forms efficiently and works well when you’re starting from raw stock or building out detailed geometry.

Material Type

Grinding works better with hardened, heat-treated, or difficult-to-machine materials such as tool steels, carbides, and ceramics. These materials resist cutting but can be abraded gradually with less tool damage.

Milling performs better on softer and ductile materials like aluminum, brass, and plastics. These can be machined at higher speeds with less stress on the cutting tools.

Surface Finish and Tolerance

If your part needs a tight tolerance (±0.005 mm or better) or a smooth finish (below 16 Ra), grinding is usually required.

Milling provides good results for parts that don’t need that level of precision. For brackets, housings, or internal components where a functional finish is enough, milling alone gets the job done.

Production Goals and Cycle Time

Milling is more efficient for removing material quickly, making it ideal for bulk cutting, shaping, and earlier production stages. It’s especially effective in high-volume scenarios where speed has a direct impact on cost.

If you are looking for the best milling services for your project, choose MachMaster. They support everything from one-off projects to full-scale production runs, always with quality in focus.

Grinding, while slower, is essential when the part reaches its final phase and demands high accuracy or consistent appearance. The additional time investment is often justified by the improved precision.

Conclusion

I’ve seen smart choices save projects—and rushed ones break them.

Now you’ve got the full picture:

What grinding and milling do, how they differ, and when each one wins.

This isn’t guesswork. It’s process clarity.

That’s what keeps deadlines, budgets, and quality on track.

Need help deciding on your next job?

MachMaster offers expert CNC machining services to help you choose the right method, avoid waste, and stay ahead.

Contact us today to get started with real solutions that fit your goals!

Recommended Reads for You

Need more ideas? Browse through our extended range of products and discover something new:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.