A VP I worked with once turned down a factory’s offer because he thought injection molding sounded “too cheap to be any good.” A few weeks later, he found out it was exactly what his team needed to save time and hit their numbers. He wasn’t happy.

But I get it.

A lot of people hear the term and think it means “low quality.”

That’s not always true—and it can cost you if you don’t look closer.

I’ve worked with car companies for years, helping them figure out which manufacturing methods actually fit their goals. Some want fast results. Others need something strong and long-lasting. And many just don’t want to waste money or time on the wrong process.

If you’re looking into injection molding for your next part, this guide is for you.

We’ll go over:

- What automotive injection molding really is

- How it works

- Where it shines—and where it doesn’t

By the end, you’ll know if it’s right for your project—or not.

Let’s dive in!

1. What is Injection Molding?

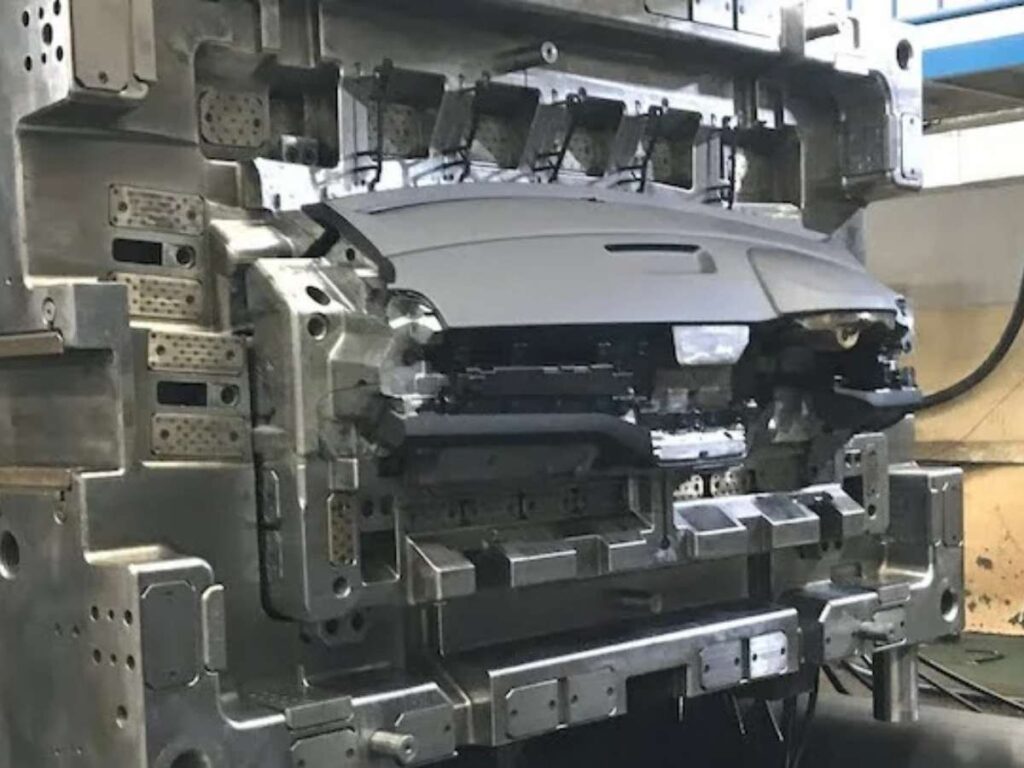

Let’s start with the basics. Injection molding is more than just squirting plastic into a mold. It’s a high-pressure, high-precision process where every second counts.

The steps typically include:

- Clamping: The two halves of the mold are pressed together in preparation.

- Injection: Melted thermoplastic is pushed into the mold cavity.

- Cooling: The mold stays clamped while the part solidifies.

- Ejection: Once cooled, the mold opens and ejects the finished part.

All of this can happen in under a minute. And when you’re producing thousands of identical parts, that cycle time becomes a major factor in productivity and cost.

What makes injection molding stand out is its repeatability. You can run the same mold hundreds of thousands of times and get near-identical parts every time.

In an industry like automotive, where safety and quality regulations are strict, this level of consistency is non-negotiable.

2. Benefits of Injection Molding for Automotive Parts

Over the years, I’ve seen how injection molding offers a mix of reliability, speed, and material flexibility that’s hard to match with other processes.

Whether you’re producing a few thousand parts or scaling into the millions, the advantages stack up quickly.

Consistency and Precision

Injection molding excels at delivering tight tolerances and repeatable dimensions across thousands of parts.

This is especially important for assemblies where parts need to fit together without manual adjustment.

Whether it’s a dashboard vent clip or a complex housing for electronic sensors, the accuracy is built into the process. Because the mold is precision-machined, the output stays stable over time with very little variation.

High Efficiency for Large Volumes

Once the mold is built and the process is dialed in, injection molding becomes incredibly efficient. A single machine can run 24 hours a day, churning out thousands of parts per shift with minimal oversight.

That means lower labor costs, faster production timelines, and the ability to meet high-volume demands without ramping up infrastructure.

Material Flexibility

Injection molding supports a huge range of thermoplastics and elastomers, allowing you to tailor the material properties to the exact needs of the part.

If you need high heat resistance, chemical durability, or UV stability, there’s a resin for that.

Many materials can also be reinforced with fillers like glass fibers to improve strength and stiffness. And for parts that require different textures, colors, or finishes, additives can be introduced directly into the molding process.

Lightweighting Potential

Vehicle weight is directly tied to fuel efficiency and emissions. Injection-molded parts offer a lightweight alternative to metal without sacrificing structural performance.

Components like brackets, housings, and panels can all be produced in durable plastics that help reduce overall vehicle mass.

This not only improves performance but also helps meet increasingly strict environmental regulations.

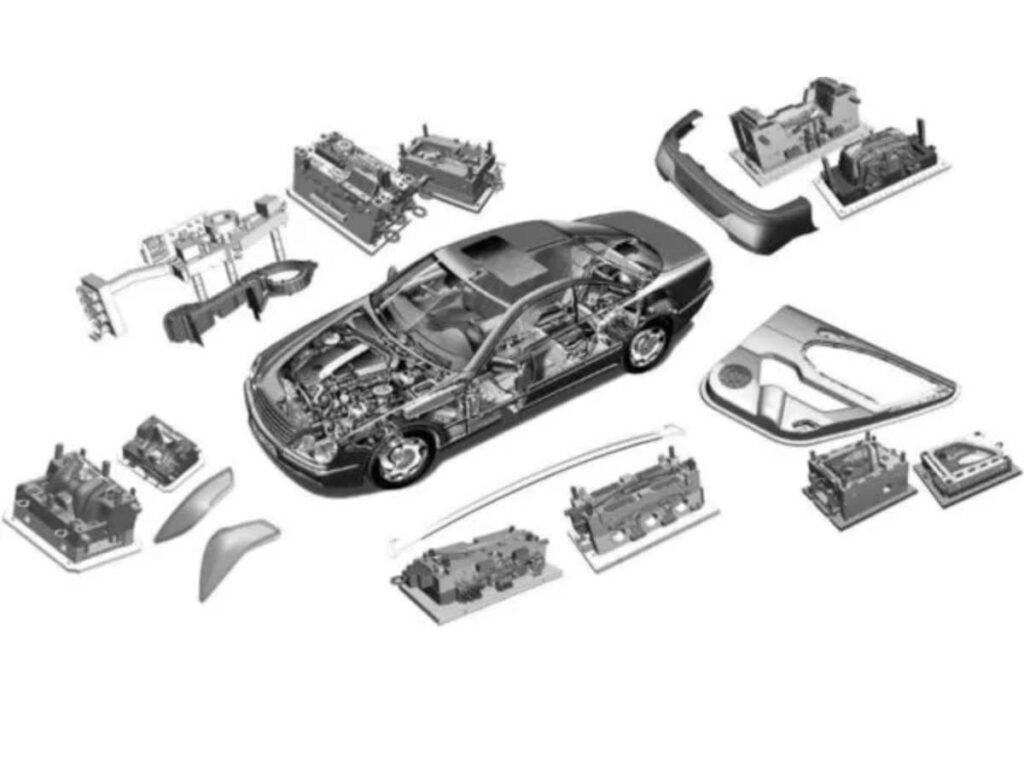

3. Common Automotive Parts Made Using Injection Molding

Once you start noticing them, you’ll realize injection-molded parts are everywhere in a vehicle. What makes injection molding so effective is its ability to produce complex, high-quality parts that fit precisely and perform reliably.

Let’s break down where these molded parts commonly appear throughout a car.

Interior Components

Most of the components you interact with inside a car are injection-molded. Dashboard panels, center consoles, glove boxes, door trims, and even air vents are typically made using this process.

These parts need to look good, feel solid, and hold up under years of wear, UV exposure, and temperature swings.

Injection molding also allows for textured surfaces, soft-touch finishes, and the tight tolerances that make everything feel refined and well-assembled.

Exterior Trim

Exterior pieces like grilles, mirror housings, and bumper moldings are often made using injection molding because they need to balance visual appeal with outdoor durability.

These parts must withstand sunlight, rain, temperature extremes, and road debris without losing their form or color.

Molded plastics with UV-stable additives and impact resistance make this possible.

Under-the-Hood Parts

The engine bay is one of the most demanding environments in any vehicle, but injection-molded plastics still find a strong foothold here.

Components like air intake systems, battery trays, reservoir tanks, and fuse box covers are all commonly molded.

These parts must perform under heat, vibration, and chemical exposure, so they are made with specialized high-temperature thermoplastics. With the right material and design, injection-molded parts can match or even outperform traditional metal counterparts in this space.

Electrical Housings

Modern vehicles rely on hundreds of electronic components, and each one needs protection.

Injection molding is used to produce enclosures for sensors, relays, connectors, and modules that must stay sealed against moisture and dust.

These housings often include complex internal geometries to hold circuit boards in place and keep electrical paths aligned.

Safety Components

Even some of the most safety-critical plastic parts in a vehicle are made using injection molding. Items like airbag covers, seatbelt retainers, and child safety seat anchors must meet strict regulatory standards.

These parts are engineered and tested to perform under extreme conditions. Injection molding allows manufacturers to create strong, reliable parts with consistent dimensions that meet both mechanical and legal requirements.

4. Key Materials Used in Automotive Injection Molding

Choosing the right material can make or break an automotive part.

I’ve seen projects succeed because the resin was carefully matched to the part’s demands, and I’ve also seen failures when shortcuts were taken.

Below are the most commonly used materials in automotive injection molding:

- Polypropylene (PP): A cost-effective, flexible plastic widely used for interior trims, battery cases, and fluid containers. It offers good chemical resistance and insulation properties but may require additives for UV protection.

- Acrylonitrile Butadiene Styrene (ABS): Known for its strength, impact resistance, and paintability. Commonly used in dashboards, pillar trims, and steering column covers where a balance of toughness and aesthetics is required.

- Polycarbonate (PC): A clear, high-strength material often found in headlamp lenses and interior light covers. It offers excellent optical clarity and heat resistance but can be brittle without modification.

- PC/ABS Blend: Combines the rigidity of PC with the flexibility of ABS. Often used for instrument panels and structural interior components that need both durability and a refined finish.

- Nylon (Polyamide, PA): A strong and wear-resistant plastic, especially when reinforced with glass fibers. Ideal for under-the-hood parts like gear housings, cable guides, and radiator end tanks.

- Thermoplastic Elastomers (TPE): Rubber-like materials used for seals, gaskets, and soft-touch components. They provide flexibility, weather resistance, and excellent rebound, making them great for vibration-dampening applications.

- Polyoxymethylene (POM or Acetal): Known for its low friction and dimensional stability, this is used in gears, fuel system parts, and door lock mechanisms. It’s resistant to moisture, solvents, and wear.

- Polyethylene (PE): Occasionally used for containers, tubes, and fluid system parts. It offers flexibility and chemical resistance, especially in low-pressure applications.

- Polybutylene Terephthalate (PBT): A semi-crystalline plastic used in electrical connectors and sensor housings. It’s heat-stable and resistant to oils and fuels, making it ideal for engine bay electronics.

- Polyphenylene Sulfide (PPS): A high-performance resin used in applications demanding extreme heat, chemical resistance, and dimensional stability. Found in transmission components and under-the-hood electrical housings.

- Styrene Acrylonitrile (SAN): Similar to ABS but with better chemical and UV resistance. Often used in transparent parts or decorative trims where clarity and hardness are needed.

- Polyurethane (PU): Used in foam form for seats and armrests or in rigid form for exterior parts. It’s durable and impact-resistant, with good flexibility and finish.

- Liquid Crystal Polymers (LCPs): Used for ultra-precise electronic components in tight spaces. These are niche but valuable in advanced driver assistance and sensor systems.

5. Design Considerations for Automotive Molded Parts

When it comes to injection molding, good design is what separates a smooth production run from costly rework.

These core considerations will help ensure your design is both functional and mold-ready.

Include Proper Draft Angles

Every molded part needs draft angles to release cleanly from the mold.

Without these slight tapers, the part can stick and drag during ejection, leading to surface defects or damage. Even a degree or two of draft can make a major difference in production consistency.

It’s a small detail, but it has a huge impact on tool longevity and cycle time.

Keep Wall Thickness Uniform

Inconsistent wall thickness is one of the most common mistakes in part design. Thicker sections cool at a different rate than thinner ones, which often leads to warping, sink marks, or internal stress.

MachMaster addresses this early in the design review phase, helping optimize geometry for smooth material flow and consistent cooling. Keeping wall thickness uniform helps material flow evenly and reduces cooling time.

If structural strength is needed, it’s better to reinforce with ribs than to increase thickness.

Use Ribs and Bosses Strategically

Ribs can add stiffness without increasing weight or material cost, but they must be placed with care. They should be thin and properly spaced to avoid creating sink marks on the visible side of the part.

Bosses are usually used for fasteners, but poor placement can create weak spots or stress concentrations.

Adding fillets or radii at the base of ribs and bosses also helps improve strength and material flow.

Plan for Gate Placement and Tolerances

The gate is where molten plastic enters the mold, and its placement affects how the part fills.

Poor gate positioning can lead to cosmetic flaws, air traps, or incomplete fills.

You also need to factor in shrinkage during cooling, especially if your part fits into other assemblies. Injection molding offers great accuracy, but tolerances must be adjusted based on material and mold behavior.

6. Challenges in Automotive Injection Molding

Injection molding might seem straightforward once it’s up and running, but getting there is where most of the real work happens. The automotive industry leaves very little room for error, and the stakes are always high.

Here are 3 major challenges that businesses should prepare for from the start.

High Upfront Tooling Costs

One of the biggest barriers is the cost of the mold itself, which can run anywhere from tens of thousands to well into six figures.

These tools are made from hardened steel and require precise machining to ensure long-term performance.

If you need multiple revisions or overlooked design issues, the cost adds up quickly. That’s why it’s crucial to get the design right before steel is cut.

Complex Quality Requirements

Automotive parts need to meet tight dimensional tolerances, resist wear, and often comply with global safety standards.

Injection-molded parts must pass rigorous inspections, including visual, functional, and sometimes destructive tests.

Any variation from part to part could result in warranty claims or failures in the field. Quality control isn’t just a formality—it’s a vital step that protects your reputation and your bottom line.

Supply Chain and Material Risks

Even with a perfect mold and a strong design, you’re still vulnerable to material delays and global supply disruptions.

Specific automotive-grade plastics can be hard to source or may face long lead times during high-demand periods.

If your project depends on a single supplier or material, you risk production stoppages. It’s always smart to qualify alternative resins and build some flexibility into your sourcing plan.

7. 4 Tips to Consider When Choosing an Injection Molding Partner for Automotive Projects

Not all injection molding suppliers are built to meet the demands of the automotive industry. Choosing the right partner early on can save you from costly headaches later.

Here are 4 practical tips to guide your decision.

Verify IATF 16949 Certification and Automotive Quality Compliance

Any supplier serious about the automotive market should be certified to standards like IATF 16949.

This ensures their quality systems meet industry-specific requirements, especially around risk management and continuous improvement.

MachMaster maintains IATF 16949 certification as part of its commitment to delivering precision parts that meet strict OEM specifications. It’s not just a piece of paper—it’s a signal that they’re capable of meeting high-level expectations.

Ask to see their most recent audit results or documentation before moving forward.

Assess Their DFM Capabilities and Mold Flow Analysis Tools

A strong injection molding partner should do more than just run your parts—they should help you improve them.

Look for a team that offers DFM (Design for Manufacturability) reviews and mold flow simulations. This kind of early feedback can save weeks of revisions and thousands in tooling changes.

The best partners act like an extension of your engineering team, not just a vendor.

Examine Tooling Construction Standards and Maintenance Protocols

Some suppliers build their own tools in-house, while others outsource everything. In-house capabilities typically mean better control over quality, lead times, and ongoing tool maintenance.

Ask how they handle mold upkeep, refurbishing, and unexpected breakdowns. A neglected mold leads to inconsistent parts, so tooling support is just as important as the machines themselves.

Request On-Site Plant Evaluation or Digital Production Audit

There’s no substitute for seeing a shop’s workflow, cleanliness, and attention to detail up close. If you can’t visit in person, ask for a virtual plant tour or remote audit documentation.

You’ll get a better sense of how they manage production, QC, and logistics under pressure.

A transparent partner will be more than willing to show you how things really operate behind the scenes.

Conclusion

You’ve made it this far, so clearly, you’re not here by accident.

You came to learn about automotive injection molding, and now you’ve got answers. What it is. Why it works. How to get it done right.

You don’t need to figure it all out alone.

MachMaster is here to help with custom manufacturing solutions that move your business forward.

Contact us today and let’s get your next part off the ground.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.