“What’s the difference between injection and blow molding?”

Someone asked me that in a meeting years ago.

I remember feeling stuck.

That moment made me realize something important: I needed to learn more.

So I started asking questions. I visited factories. I talked to mold makers, engineers, and designers. I watched parts being made—small pieces, hollow shapes, and solid forms.

Slowly, it all began to click.

Since then, I’ve worked on projects where choosing the right molding method saved time and money. I’ve also seen what happens when someone picks the wrong one.

If you’re here, maybe you’re facing a similar moment. You’re trying to choose the best process for your part or product.

This article is here to help you with that choice.

You’ll learn what injection molding and blow molding are, how they work, and when to use each one. By the end, you’ll have the knowledge to move forward—with confidence and fewer surprises.

Let’s get started!

1. What Is Injection Molding

If you’ve ever held a perfectly smooth, solid plastic part in your hand, maybe a gear knob, a laptop shell, or a phone case—chances are, it was made using injection molding.

I remember the first time I visited a factory floor and saw the process in action. Molten plastic was shot into a mold with such precision, it felt like watching engineering and artistry collide.

The result? Perfect parts. No seams. No fuss. Just ready-to-ship quality.

Injection Molding Overview

It’s a manufacturing process where molten plastic is injected into a solid mold to create parts that are often complex, detailed, and incredibly durable.

At MachMaster, we create molds that are custom-built and precision-machined. Think of them as the backbone of your production line. Once the mold is made, the machine does the rest. Over. And over. And over.

That’s where the magic (and efficiency) happens.

Key Features

If you’re weighing options for a product or component, here’s what makes injection molding stand out:

- Ultra-Precise Results: Ideal for parts that need exact dimensions and clean finishes

- Made for Solid Parts: Not hollow or flexible, but solid, stable, and consistent

- High Tooling Costs: But don’t let that scare you. You’ll recoup it fast at scale

- Great for Complex Designs: Tight tolerances, internal ribs, fine textures? No problem

In short, it’s built for serious production, especially when you need to deliver thousands or millions of perfect parts without sacrificing quality.

Application

This method is the go-to in industries where consistency and durability are non-negotiable. You’ll find injection-molded parts in:

- Automotive: Dashboards, clips, knobs, panels

- Consumer Electronics: Remote controls, laptop shells, charging docks

- Medical Devices: Syringe bodies, casings, clamps

- Consumer Goods: Toys, kitchen tools, packaging elements

If your part needs to look good, feel right, and function perfectly, injection molding delivers.

You’re not just choosing a production method here. You’re investing in scalability, brand consistency, and supply chain control. And if you’re launching a new product line or scaling up? This might just be your best friend.

2. What Is Blow Molding

The first time I walked through a packaging facility, I saw hundreds of plastic bottles popping out of machines like clockwork. Uniform, lightweight, ready to ship. I asked the plant manager how it all worked, and he smiled and said, “Simple. Blow molding.”

That stuck with me.

Because when your product is hollow, like bottles, tanks, containers, nothing beats the speed and efficiency of blow molding.

At Machmaster, we use blow molding every day to help bring these kinds of products to life—fast, simple, and built to scale.

Blow Molding Overview

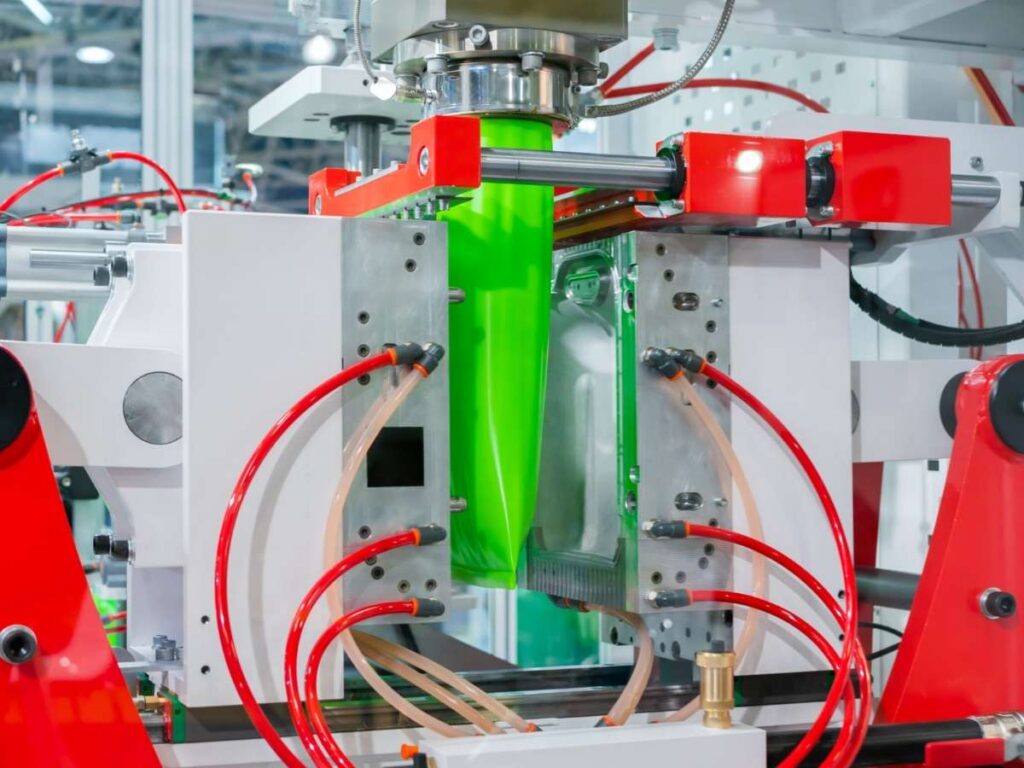

Blow molding is a manufacturing process that uses air pressure to expand heated plastic into a mold cavity, forming hollow parts.

Think of it like blowing up a balloon inside a mold. The plastic takes the shape of the mold walls, cools, and solidifies. The result? Seamless, lightweight, hollow parts that are fast to produce and cost-effective in volume.

Types of Blow Molding

Each method serves a slightly different purpose. Here’s a quick rundown:

- Extrusion Blow Molding: Best for larger containers like jugs and drums. A hot plastic tube is extruded, clamped in a mold, and inflated.

- Injection Blow Molding: Common for small, precise containers. A preform is injection molded first, then blown into shape.

- Stretch Blow Molding: Used for high-clarity, high-strength bottles (like PET water bottles). The preform is stretched before blowing, increasing strength and clarity.

Each type has its use case—your decision will depend on the product’s size, shape, and performance requirements.

Key Features

Blow molding shines when it comes to fast, repeatable production of hollow parts. Here’s what you can count on:

- Best for Lightweight, Hollow Containers: Ideal for single-piece, seamless structures

- Faster Cycle Times: High-speed runs for high-demand packaging

- Less Complex Molds: Simpler tooling compared to injection molding

- Limited Design Flexibility for Non-Hollow Items: Not suitable for parts with internal features or high-detail complexity.

Applications

Blow molding is the unsung hero behind many everyday and industrial items. You’ll find it in:

- Bottles and Containers: Beverage bottles, shampoo bottles, cleaning product packaging

- Fuel Tanks: Automotive and small engine fuel tanks

- Water Jugs and Coolers: Large-capacity, single-piece water storage containers

If your product needs to be lightweight, uniform, and produced in bulk, blow molding is likely your answer.

3. Part Shape and Structure

Here’s the truth: the shape and structure of your part can immediately determine which process is righ, and which one will waste your time and money.

I learned this the hard way during a packaging project where a product engineer insisted on injection molding a hollow container. The result? Warping, increased material use, and a second tooling round that could’ve been avoided if we had just matched the part with the right method from the start.

So let’s break this down clearly:

Injection Molding: For Solid, Complex Parts

Injection molding is designed for solid or solid-core parts. It handles high precision and tight detail because the molten plastic is injected under high pressure into a solid mold.

What does this mean for you?

- Your part can include ribs, bosses, threads, inserts, and fine textures

- It’s ideal for rigid structural components

- It supports multi-part assemblies where strength and stability matter

Injection molding is also more versatile when it comes to part geometry. Internal support features, snap fits, and layered structures are all fair game, as long as the mold is engineered properly.

If you’re designing panels, enclosures, handles, gears, or brackets, this is your go-to.

Blow Molding: For Seamless, Hollow Forms

Blow molding, on the other hand, is purpose-built for hollow parts. Think containers, tanks, bottles—anything that needs an internal cavity.

Here’s what it does best:

- Forms seamless, one-piece hollow shapes

- Maintains consistent wall thickness on symmetrical, rounded items

- Avoids joints or seams that could cause leaks or failures

However, blow molding doesn’t support internal ribs or intricate surface features. You’ll be limited in terms of fine detail and internal complexity.

If your part needs to hold liquid, carry air, or minimize weight, blow molding makes the most sense, structurally and economically.

4. Design Complexity

Design is where vision meets reality, and where the wrong manufacturing method can kill that vision fast.

I worked with a startup once that had this gorgeous industrial design for a consumer gadget. Tight seams. Internal clips. Snap-fit closures. They chose blow molding because it seemed faster and cheaper.

What they got? Warping, weak edges, and a redesign that cost them three weeks of launch time.

They had a great design. They just chose the wrong process.

Injection Molding: Built for Precision and Detail

Injection molding is the go-to when your design is technically demanding. It’s engineered to support:

- Tight Tolerances: Consistent from part to part, with near-perfect dimensional accuracy

- Fine Surface Textures: From matte finishes to detailed logos

- Internal Features: Ribs, gussets, snap fits, and undercuts

- Multi-Part Assemblies: Clean joins, tight fits, and consistent alignment

- Overmolding or Insert Molding: Embedding components like fasteners or electronics

If your product needs to snap, click, align, or seal perfectly, injection molding gives you the control you need.

This is why it’s used in automotive interiors, medical devices, high-end consumer electronics, and complex enclosures. It gives your designers room to innovate without compromise.

Blow Molding: Best for Simplicity and Speed

Blow molding trades complexity for speed and uniformity. It’s perfect when the design doesn’t need tight internal tolerances or intricate surface features.

Its strengths lie in:

- Uniform Wall Thickness: Especially for rounded, symmetrical forms

- Single-Piece Construction: No seams or secondary joins

- Lightweight Geometry: Hollow and fluid-friendly

- Simpler Mold Designs: Faster to make, easier to scale

But here’s the catch: you’re limited to external features. Want internal threads, precise mechanical fits, or layered structures? Blow molding just can’t get you there.

So if you’re designing a bottle, a tank, or a low-detail hollow part? Blow molding is fast and effective.

If you’re designing something that requires detail, integration, or assembly, you’ll hit a wall.

5. Tooling and Equipment Cost

The first time I priced out a mold for injection molding, I thought the quote was a typo. 5 figures, just for the tooling. But once we ran the numbers over a full production cycle, that cost turned into one of the best investments we made.

That’s the reality: tooling is where the money starts, and if you’re not ready for it, it can catch you off guard.

Injection Molding: High Upfront Cost, Low Unit Cost

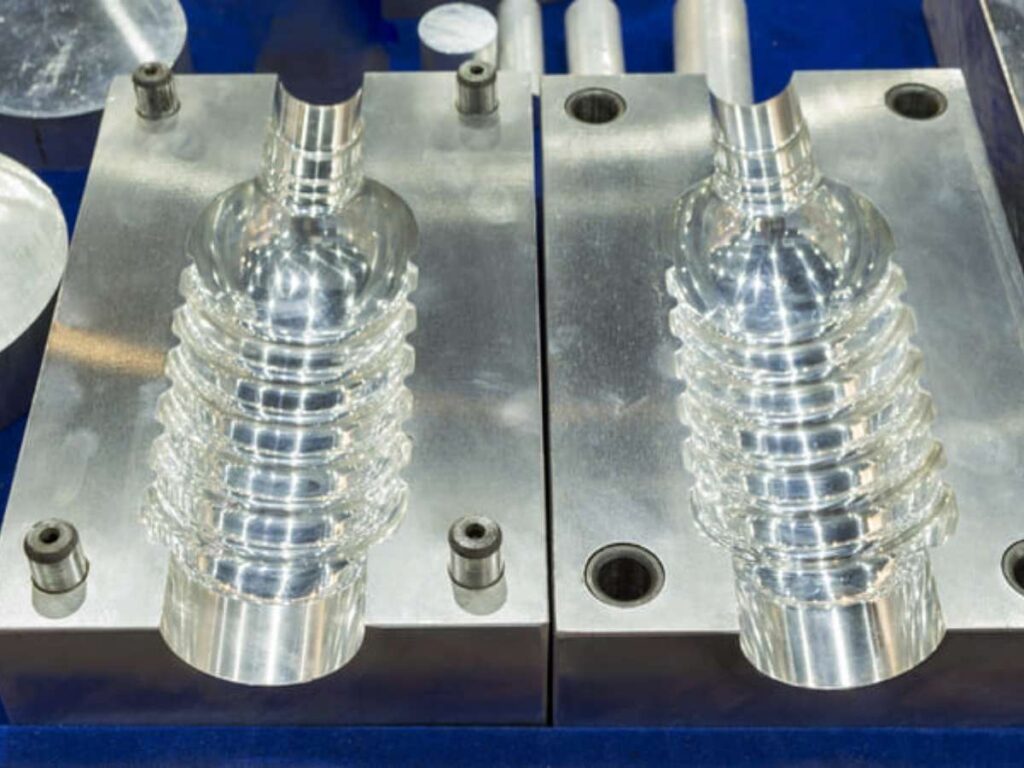

Injection molding requires high-precision steel or aluminum molds, often CNC-machined to exact tolerances. These molds are designed to run hundreds of thousands to millions of cycles.

Here’s what to expect:

- Tooling Cost: $5,000–$100,000+ depending on complexity, size, and number of cavities

- Tooling Time: 4–12 weeks on average

- Equipment Cost: Injection molding machines are expensive but highly efficient once set up

- Maintenance: Periodic mold maintenance is required, but molds can last years if treated properly

So yes, the barrier to entry is higher, but the per-unit cost drops significantly over time.

If you’re planning large-scale production, injection molding becomes extremely cost-effective once you’re past the initial investment.

Blow Molding: Lower Entry Cost, Simpler Setup

Blow molding uses less complex, lower-cost molds, especially in extrusion and stretch variants. That’s because the process doesn’t need the same level of precision or part complexity.

Here’s what that looks like:

- Tooling Cost: $1,000–$25,000 depending on type and size

- Tooling Time: 2–6 weeks on average

- Equipment Cost: Blow molding machines vary but are generally lower-cost per station

- Maintenance: Simpler molds mean fewer breakdowns and faster changes

For bottles, containers, and high-volume hollow parts, blow molding offers a fast, cost-accessible way to scale production with less upfront risk.

6. Cost and Time Considerations

When you’re choosing between injection molding and blow molding, it’s not just about the tooling. You also need to factor in per-unit cost, cycle time, lead time, and overall scalability.

I’ve worked with teams that focused only on tooling cost, and ended up blindsided by slow production cycles and missed delivery windows. That’s why looking at the full production picture is essential.

Here’s a side-by-side breakdown to help you compare both methods:

| Factor | Injection Molding | Blow Molding |

| Tooling Cost | High ($5K–$100K+) | Moderate to Low ($1K–$25K) |

| Tooling Lead Time | 4–12 weeks | 2–6 weeks |

| Per-Unit Cost | Very low at scale ($0.50 or less) | Low to moderate at scale ($0.10–$2.00) |

| Cycle Time | Slower (10–60 seconds per part depending on size) | Faster (1–30 seconds depending on bottle/container size) |

| Setup Time for Production | Longer (more complex mold alignment and calibration) | Shorter (simpler setup, fewer moving parts) |

| Changeover Time | High (slower to switch molds or modify tooling) | Low (easy to switch out dies or make quick adjustments) |

| Production Volume Efficiency | Excellent for high-volume, repeat production | Excellent for high-volume hollow parts |

Key Takeaways

- Injection molding is more efficient once you’re running at scale. You pay more upfront, wait longer to launch, but save massively over time, especially with complex or high-value parts.

- Blow molding gets you moving faster and cheaper. It’s built for speed, especially for lightweight, high-volume containers or packaging where design complexity is minimal.

- If you need to prototype fast or launch quickly, blow molding is easier to start with. If you’re ready for long-term, high-volume consistency, injection molding is a better investment.

7. How to Choose Between Injection and Blow Molding

Choosing between injection molding and blow molding isn’t just a technical call, it’s a strategic one. The process you pick affects everything: part performance, production costs, lead times, scalability, and even how competitive your product is in the market.

So before you commit to tooling or start production, take a step back and evaluate your needs from every angle. Below are the key factors to guide that decision, based on real-world use cases and proven results:

Start with the Shape

This is the simplest—and most decisive—factor. Look at the structure of your part. Is it hollow, or is it solid?

Blow molding is designed to produce hollow forms. It uses air pressure to shape a heated plastic tube inside a mold, making it ideal for fluid containers and parts with an internal cavity. You get a seamless, lightweight product that doesn’t require complex joins.

Injection molding, on the other hand, creates solid parts by filling a rigid mold with high-pressure molten plastic. This allows for more intricate designs, internal structures, and stronger final parts.

If you’re trying to create a hollow part using injection molding, you’ll likely need to add cores, inserts, or assemble multiple pieces afterward, which adds cost and time.

Ask yourself:

- Does your part need to hold liquid or air?

- Is weight reduction a key priority?

- Do you need one seamless shell?

If yes, blow molding is likely your answer.

Design Complexity

Design is where the two methods really separate.

Injection molding supports highly detailed, multi-feature designs. It works with precision molds that can accommodate undercuts, threads, mounting bosses, living hinges, and tight internal tolerances.

Blow molding, by contrast, is much more limited. It’s optimized for smooth, uniform wall thicknesses and rounded shapes. If you need a part with flat surfaces, tight fits, or complex geometry, you’ll likely run into structural and cosmetic limitations.

Compare Cost and Volume

Now let’s talk numbers. Tooling and production costs are often the first concerns for any project, and for good reason. The wrong decision here can eat into your margins or slow down your break-even point.

Injection molding requires a larger upfront investment, but pays off in volume.

Blow molding costs less to start. Simpler molds and lower tooling costs make it more accessible, especially for medium-volume production or early-stage product launches.

Here’s a breakdown of what to consider:

- Injection Molding Pros:

- Low cost per part at high volumes

- Long mold life and repeatability

- Precision and complexity built in

- Blow Molding Pros:

- Lower initial tooling cost

- Faster mold turnaround

- Scales well for simple, hollow parts

If your budget is tight and your product is simple, blow molding is a practical entry point. But if you’re building a product line that needs consistency and scale, injection molding becomes more economical over time.

Conclusion

Now, you know the difference.

Injection molding. Blow molding.

What they do. When to use them. Why it matters.

I started with questions, and found answers through real projects, trial and error, and the help of good people. If you’re here, you’re already on the right path. You’re asking the same smart questions I once did.

You don’t need to have all the answers today. But you do need to make the next move.

Need help deciding?

Contact us today and let’s talk about your idea.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.