Specifying anodizing isn’t always straightforward.

Do you go with the cheaper Type 2? Or play it safe with Type 3? What actually changes between the two?

I’ve asked all those same questions. I’ve worked on projects where getting it wrong meant wasted parts, unhappy clients, and long lead times.

You might be feeling the pressure, too. That’s why you’re here.

This article will give you a clear, simple breakdown of Type 2 vs Type 3 anodizing. I’ll walk you through how each process works, what it’s best at, and when it makes sense to spend more or save.

By the end, you’ll know what fits your needs. Whether that means better wear resistance, a clean finish, or just staying on budget.

So let’s get started!

1. What is Type 2 Anodizing?

Type 2 anodizing, also called decorative anodizing, uses sulfuric acid to build a thin oxide layer on aluminum. That layer usually ranges from 5 to 18 microns thick.

It gives the metal a clean finish and helps with coloring.

You’ve probably seen it on flashlights, bike parts, or phone cases parts that look good but don’t take much wear.

I still remember the first time I saw it used on a lighting fixture. Smooth, deep blue, almost shiny. The part didn’t need to be tough just look great. And it did.

So how does it perform? Here are the main benefits and limitations you should know before choosing it.

Benefits of Type 2

Why choose Type 2?

If your project calls for looks, speed, and lower cost, this type often works well.

You’ll get:

- A wide range of color choices

- A smooth, clean surface

- Faster lead times

- Lower cost compared to harder anodizing

Great for parts that aren’t exposed to rough conditions.

Limitations of Type 2

But it’s not perfect.

Here’s where Type 2 falls short:

- Less protection from scratches

- Lower corrosion resistance

- Doesn’t hold up well outdoors or under stress

I once used Type 2 on a small outdoor bracket. Within weeks, it lost its shine and started to pit. That’s when I learned just because it looks good doesn’t mean it’s built for wear.

So before you decide, ask:

Will this part face friction, water, or rough use?

If yes, you might need something stronger.

If not, and if you want a fast, clean, and affordable Type 2 be a solid option.

2. What is Type 3 Anodizing?

Type 3 anodizing is also known as hard anodizing.

It uses the same sulfuric acid as Type 2, but the process runs colder and at a higher electrical current. This builds a much thicker oxide layer on the aluminum usually between 25 to 150 microns.

That thickness isn’t just for show. It makes the surface harder, stronger, and more resistant to wear.

I remember the first job I worked on that called for Type 3. It was a batch of aerospace components small brackets used in a high-vibration environment. Cosmetic finish didn’t matter. What mattered was that the parts held up under stress. Type 3 was the right choice.

So how does this process perform in the real world? Here’s a look at what makes it work and where it has limits.

Benefits of Type 3

If you need strength and durability, Type 3 is hard to beat.

Here’s what you can expect:

- A harder surface that holds up against wear

- Strong resistance to corrosion

- Better performance in extreme or high-use settings

- Trusted for aerospace, military, and heavy-use industrial equipment

I’ve seen Type 3 parts survive long-term field use where Type 2 would fail in months.

Limitations of Type 3

That strength comes with trade-offs.

Here’s where Type 3 can be more difficult:

- Fewer color options (usually dark gray or black)

- Higher cost

- Slower turnaround

- The thick layer may need design changes to fit tolerances

I’ve had to rework drawings before because the added thickness threw off final dimensions. If your design is tight, you’ll need to plan for that.

So ask yourself: do you need toughness, or is the part mostly for looks?

If performance matters more than color or cost, Type 3 might be the better call.

3. Wear Resistance and Durability

When you’re choosing an anodizing process, you’re probably thinking: Will this finish hold up? Will it protect the part?

Those are the right questions.

Durability makes a big difference especially if your part gets touched, moved, or exposed to the elements.

Here’s how Type 2 and Type 3 anodizing compare in real-world use.

How Hard Is Each Type?

Let’s talk hardness first.

- Type 3 anodizing is tough. The surface can reach up to Rockwell C 60. That’s harder than mild steel. It resists dents, scratches, and scuffs—especially on parts that get knocked around or rubbed against other components.

- Type 2, on the other hand, is softer. It’s fine for parts that stay indoors and don’t face much wear. I’ve used it on light switch panels and camera brackets—things that need to look clean but don’t take abuse.

If your part sees daily handling or outdoor use, Type 2 might wear out faster.

Abrasion and Corrosion Protection

Here’s another area where the difference is clear.

Type 3 gives stronger protection against:

- Friction

- Salt spray

- Dust and grit

- High-use environments

Type 2 offers decent resistance—but not enough for harsh or abrasive conditions.

I once saw a Type 2 anodized part used in a marine setting. Within weeks, the finish started fading and pitting. It looked fine at first, but it just wasn’t built for that kind of exposure.

Use Cases by Industry

So where does each type actually show up?

Type 2 is often used for:

- Camera housings

- Kitchen utensils

- Electronic casings

Type 3 is a better fit for:

- Rifle receivers

- Marine equipment

- Hydraulic cylinders and valves

Some parts need to look nice. Others need to last.

That’s why knowing your use case matters. Choosing the right anodizing type could mean the difference between a clean finish or a part that fails too soon.

4. Appearance: Color, Finish & Feel

Sometimes, how a part looks and feels matters just as much as how it performs. If you’re making a customer-facing product—or anything that needs visual appeal—pay close attention to this section.

Here’s how Type 2 and Type 3 anodizing stack up in terms of color, finish, and texture.

Color Options

If you’re looking for bright, vibrant colors, Type 2 anodizing is the clear winner.

Because the oxide layer is thinner, it accepts dyes much more easily. That means you can get a wide range of finishes like:

- Red

- Blue

- Green

- Gold

- Purple

I’ve used Type 2 on aluminum parts that needed to match a company’s branding. The colors came out rich and even—and they stayed that way indoors.

Type 3 anodizing is a different story.

It’s thicker and more dense, which makes it harder for dyes to soak in. Most Type 3 finishes end up looking:

- Dark gray

- Black

- Sometimes dark bronze

And the finish? It’s usually matte or dull—not shiny.

So, ask yourself: Do I need this part to stand out with color? Or do I care more about toughness?

Surface Texture and Finish

This is something many people overlook: how the surface feels in your hand.

Type 2 parts are usually:

- Smooth

- Slick

- Polished-looking

They glide under your fingers. Great for decorative items or anything that needs a clean, finished look.

Type 3 parts feel a bit different. Because the oxide layer is thicker, the surface can:

- Feel slightly gritty

- Add texture

- Offer better grip

That roughness actually helps in some cases. I once spec’d Type 3 for a handheld control panel, and the added grip made it feel more secure.

So, if looks and feel matter in your final product, weigh these differences carefully. It might change your choice.

5. Thickness, Tolerances & Fit

Sometimes, it’s not the look or durability that causes problems. It’s the fit.

If you’ve ever had an anodized part that wouldn’t go together during assembly, you already know how frustrating this can be. I’ve been there. I once had to re-machine a whole batch of parts because I didn’t account for anodizing thickness.

Let’s break down what actually happens during the process—and how it affects final dimensions.

Coating Thickness

Both Type 2 and Type 3 build up a layer of aluminum oxide. That’s the protective shell that gives anodized parts their finish and strength.

Type 2 coatings are thinner. They typically measure between:

- 0.0002 inches to 0.001 inches

Type 3 coatings are much thicker. They can go up to:

- 0.004 inches

But here’s the part many people miss: the coating doesn’t just add material on top.

Half of the thickness grows outward, and the other half grows into the metal itself. That’s important for precision parts.

Tolerance Planning

If you’re working with tight fits, clearances, or press fits, you’ll want to plan ahead.

Type 3 anodizing can eat into your tolerance. That thick coating might:

- Make holes too small

- Throw off thread depths

- Interfere with sliding or rotating parts

Designers often need to adjust machining sizes to allow for that added build-up. I’ve seen shops get caught off guard especially when they switch from Type 2 to Type 3 without redrawing the part.

If your parts need precise fits after anodizing, MachMaster can help. We machine parts with ±0.01mm tolerance and account for surface treatments from the start—so you don’t have to fix it later.

6. Cost, Lead Time & Supplier Availability

Choosing the right anodizing process isn’t just about performance. Sometimes, the final decision comes down to price, timing, and who can actually do the work.

I’ve had projects delayed because a shop couldn’t handle Type 3 anodizing. I’ve also had prototypes finished in just a few days with Type 2. The process you choose can impact your entire timeline.

Let’s look at what you can expect on the cost and supply side.

Type 2 – Lower Cost, More Accessible

If you’re on a budget or working on a quick-turn project, Type 2 is often the way to go.

It’s:

- Cheaper

- Faster

- Easier to find

Many anodizing shops support Type 2 because the setup is simpler. It uses standard equipment and lower current, which keeps energy and labor costs down.

You’ll also see faster lead times. Some parts can be done in a few days.

It’s great for:

- Prototypes

- Small batches

- Consumer parts that don’t need extreme durability

When I needed anodizing for a small camera accessory, I chose Type 2. It looked great, and I got the parts back in a week. No delays. No stress.

Type 3 – Higher Cost, Specialized

Type 3 is a different story.

It requires:

- Special tanks

- Higher voltage

- Cold temperatures

That setup takes more energy and time, so the cost goes up. Not every supplier offers Type 3, which can lead to longer waits, especially if you need consistent quality for regulated industries.

Type 3 is best for:

- Aerospace

- Military parts

- High-wear industrial tools

Not every supplier offers Type 3, which can lead to longer waits—especially if you need consistent quality or certs for regulated industries.

That’s where a trusted manufacturer like MachMaster comes in. With ISO 9001 certification and advanced surface treatment lines, we handle both Type 2 and Type 3 anodizing with speed and precision even for high-spec parts.

7. Post-Processing Compatibility

Once your part is anodized, you might still want to do more. Maybe you need a logo engraved. Maybe you’re adding paint, a serial number, or pad printing.

Not every anodized finish works the same way after processing. Some are easier to work with. Others can fight you at every step.

Let’s look at how Type 2 and Type 3 compare after anodizing is done.

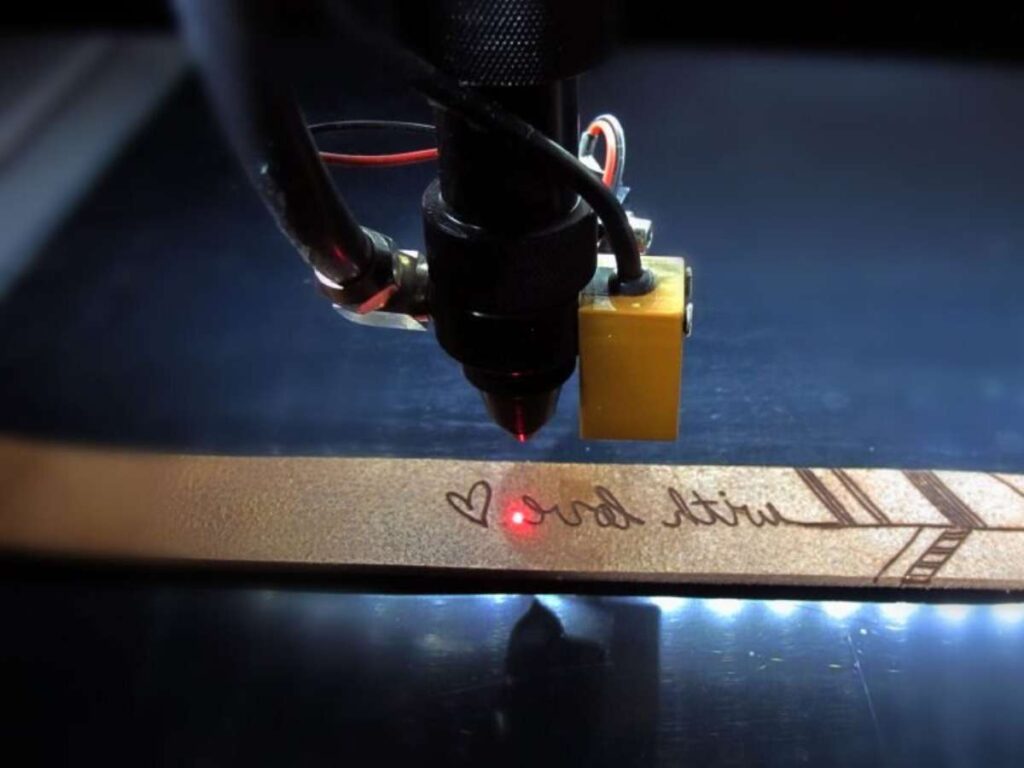

Can You Laser Engrave, Paint, or Print After?

Type 2 anodizing is more flexible for post-processing.

Because the oxide layer is thinner and smoother, it accepts:

- Dyes

- Laser engraving

- Ink printing

- Pad printing

- Paint

I’ve used Type 2 for batches that needed company branding on the surface. The results were crisp and consistent—especially with laser marking. The engraving pops nicely when done after anodizing, and the color contrast holds up indoors.

Type 3, however, can be trickier.

The surface is:

- Harder

- Thicker

- Sometimes more porous

That means it might not take ink or paint very well. It can be done, but it’s harder to control. Some coatings may peel or flake if not applied properly. Because of this, many shops skip extra finishes on Type 3 altogether. They leave the part as-is.

That’s not always a bad thing. Type 3 parts often serve in harsh environments. They don’t need branding—they just need to work.

So ask yourself: Will this part need extra finishing after anodizing?

If yes, you may want to stick with Type 2. It gives you more flexibility and better results with less hassle. And if you’re trying to avoid costly trial runs or touch-ups, that can make a big difference.

8. Environmental & Compliance Factors

If your parts are being exported or if your company has sustainability goals this section matters more than you might think.

I didn’t think much about compliance until a customer in Europe asked for a RoHS certificate. I had to scramble to track it down. Since then, I always check before placing the order.

Let’s talk about how Type 2 and Type 3 anodizing stack up on environmental and regulatory points.

Is Either Type RoHS/REACH Compliant?

The short answer: yes, both Type 2 and Type 3 can be compliant.

But it’s not automatic.

To meet RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), the anodizing must be sealed and processed properly. This means using approved chemicals and avoiding harmful additives.

So if you’re sending parts to the EU or the US, it’s smart to:

- Ask your supplier directly for certification

- Request a compliance report with your order

- Let them know up front if your project requires it

I’ve found that good shops will usually have this ready, but they won’t always send it unless you ask.

Sustainability Notes

When it comes to energy use, Type 3 needs more:

- Higher voltage

- Longer processing time

- Colder bath temperatures

That means more electricity and more cooling systems to maintain those low temps.

Wastewater treatment can also vary. Different additives and rinses might be required depending on the finish and dye used.

Some anodizing shops now offer eco-friendly options. These might include lower-waste sealing baths, better water recycling, or energy-efficient lines.

If that matters to your brand, ask. It’s often available you just have to bring it up.

Bottom line: If your product will be judged on environmental or regulatory standards, don’t wait until the end to figure it out. Ask early, plan ahead, and avoid surprises.

9. Final Comparison Table

Still not sure which type fits your project best?

Don’t worry. You’re not alone. Sometimes all the details can blur together—especially if you’re trying to balance cost, lead time, and performance.

This table gives you a quick side-by-side view of Type 2 vs Type 3 anodizing. Think of it as your cheat sheet. I’ve used tables like this on team calls when we needed to make fast decisions. Simple, clear, and to the point.

Here’s a breakdown of the key differences:

| Feature | Type 2 Anodizing | Type 3 Anodizing |

| Cost | Lower | Higher |

| Appearance | Smooth, clean, often glossy | Dull, matte, may feel slightly rough |

| Durability | Moderate wear and corrosion protection | High wear and corrosion resistance |

| Thickness | 0.0002″ to 0.001″ | Up to 0.004″ |

| Color Range | Wide (reds, blues, golds, etc.) | Limited (mostly gray, black, dark bronze) |

| Ideal Applications | Consumer goods, electronics, prototypes | Aerospace, military, industrial equipment |

| Limitations | Not great for high-stress environments | Higher cost, longer lead time, fewer color options |

So what’s the takeaway?

If your project needs color, speed, or affordability, Type 2 might be the right fit.

If you care more about strength, durability, or function under stress, Type 3 is worth the investment.

No finish is perfect. But if you weigh what matters most to you—this table can help you get there faster.

10. Which One Should You Use?

After everything you’ve read, you might still be asking: So which one’s right for me?

That’s fair. The answer depends on what you’re building, how it’ll be used, and who it’s for.

Let’s go back to the basics for a quick recap.

Type 2 anodizing gives you:

- Lower cost

- Bright color options

- A smooth, clean surface

- Light to moderate wear protection

Type 3 anodizing offers:

- A harder, more durable surface

- Better corrosion resistance

- Longer lifespan under stress

- Fewer color options and higher cost

Still unsure? Here’s a quick guide based on who you are and what you care about.

Quick Decision Guide

- Business Owners: If product quality affects your brand’s reputation, go with Type 3. A worn-out finish says a lot—especially if customers are paying attention.

- Designers and Engineers: Think about tolerances, fit, and final appearance. If color matters, Type 2 gives more freedom. If your part takes abuse or needs grip, Type 3 might be better.

- Procurement Teams: Weigh lead time and cost. Type 2 is easier to source and faster to finish. But don’t forget to check whether your suppliers can actually handle Type 3.

- Personal Projects: Unless you’re stress testing parts or simulating final use, Type 2 usually works fine. I’ve used it for camera brackets, DIY gear, and sample pieces—and never had an issue.

So ask yourself: What matters more—looks, strength, or lead time?

Once you know that, the choice gets a lot easier.

Conclusion

I told you about the part that corroded after I picked the wrong anodizing. That mistake stuck with me.

Now, you don’t have to make the same one.

You’ve seen what each type does best. You know where it fits, how it feels, and what it costs.

So what’s next?

Start small. Review your drawings. Ask your supplier the right questions. Don’t wait for a failure to learn what works.

Need help figuring out the right finish for your part?

Contact us today. Let’s get it right—before you cut metal.

Dive Deeper Into Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.