It was supposed to be a simple part.

I had the drawings, the tolerances looked good, and the supplier was ready.

But then the tooling engineer emailed me and said, “We found an undercut.”

That one feature just a small groove, turned a basic mold into something far more complex.

At the time, I didn’t fully understand the problem but I quickly learned how much an undercut can affect tooling, timing, and overall cost.

If you’re here, maybe you’ve heard the same thing from your supplier or maybe you’re just trying to catch problems before they start.

Either way, this article will help. I’ll explain what an undercut is in injection molding, how it affects your part and mold, and what your options are moving forward.

By the end, you’ll have the insight you need to make better decisions before you commit to production.

Let’s begin!

1. What Is an Undercut in Injection Molding?

Let me take you back to one of my earliest product runs.

I was working on a small plastic clip. It seemed simple but once the mold opened, the part wouldn’t eject. It stayed stuck. The supplier called me and said, “This clip has an undercut.”

At the time, I had no clue what that meant. I just knew something had gone wrong.

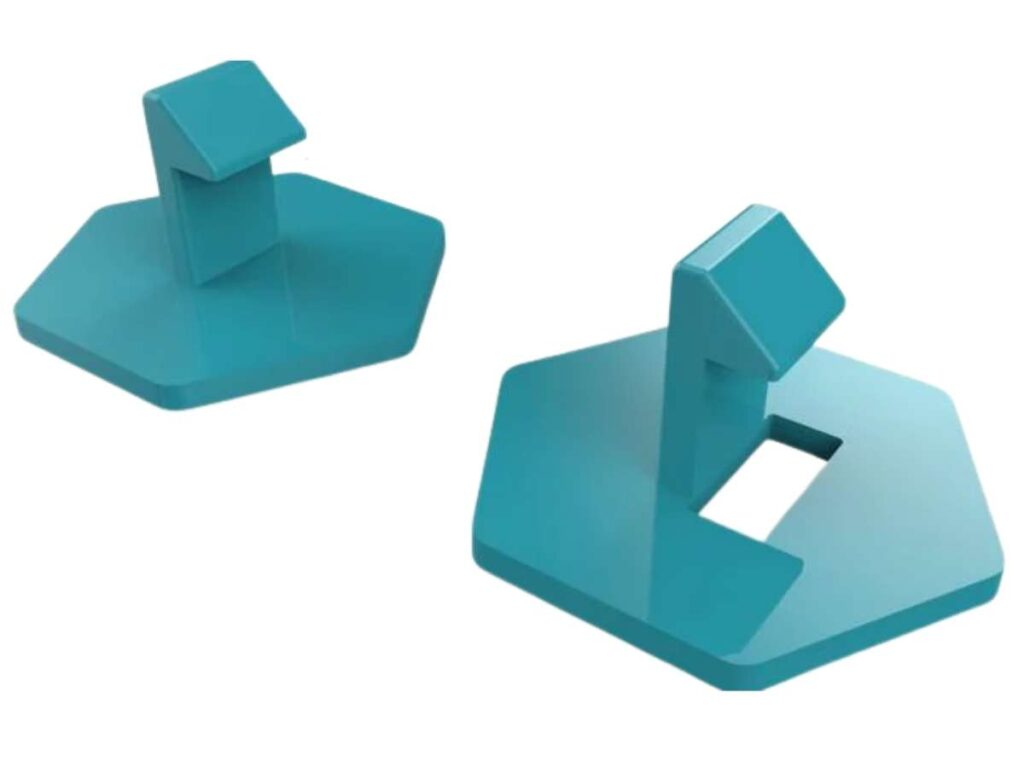

An undercut is a part feature that blocks the molded piece from coming out of the mold in a straight line. That’s a problem because most injection molds open in two halves. The mold pulls apart, and the part should pop out. But when there’s an undercut, something holds the part in place and keeps it from releasing.

Here’s a simple way to picture it:

Imagine pulling a fishing hook through a piece of fabric. The barb catches. You can’t pull it straight out without tearing the material. That’s what an undercut does inside the mold.

Undercuts can look like:

- Side holes

- Snap-fit tabs

- Small ledges or grooves

- Internal threads or slots

These features might seem harmless, but they make the tool more complex and affect cost and lead time.

So why does this matter for you?

Because if your part has an undercut, you’ll need special tooling or design changes. That’s why catching it early can save you a lot of frustration.

Have you checked your part for these tricky spots? Or asked your supplier if they see any undercuts?

It’s better to ask now than pay for changes later.

2. Common Features That Cause Undercuts

Now that you know what an undercut is, the next step is spotting what causes it.

This is where many business owners get tripped up. On a screen, the part looks clean. Everything fits. But hidden in the design are features that block the mold from releasing the part.

I’ve made this mistake myself. I once approved a design that had a side hole for a mounting pin. I didn’t think much of it. But it created a major undercut. The mold needed side actions, which added time and cost.

Here are some of the most common features that cause undercuts:

- Side holes or through-holes: If they go sideways across the part (instead of straight up or down), the mold can’t pull away cleanly.

- Latches, hooks, or snap-fit joints: These are great for function, but they often create overhangs that trap the part inside the mold.

- Recessed logos or side details: Any detail cut into the side can act like a hook, especially if it’s deep or angled.

- Threads or internal grooves: These features twist or grab the mold surface and won’t release without movement or rotation.

It’s easy to miss these during early design reviews. They look minor. But they change everything about how your tool is made.

3. Importance of Undercuts for Your Business

Before you decide whether to keep an undercut in your design, it helps to see how it actually affects your project.

I’ve had times where one small groove added weeks to the schedule. Other times, we removed a detail and shaved thousands off the tooling cost.

To make this clearer, here’s a side-by-side look at what changes when your part includes undercuts compared to when it doesn’t:

| Feature | Without Undercuts | With Undercuts |

| Mold Complexity | Simple 2-part mold | Requires side actions, lifters, or inserts |

| Tooling Cost | Lower | Higher due to added components |

| Lead Time | Faster mold build | May require more time to design and test |

| Production Speed | Faster cycle times | Slower due to manual steps or extra cooling |

| Supplier Flexibility | More vendors available | Fewer vendors can handle complex tools |

| Risk of Defects or Downtime | Lower | Higher due to wear and manual handling |

4. Should You Avoid Undercuts?

This is one of the most common questions I get from product teams and business owners. And the short answer is not always.

Some undercuts serve a real purpose. But if you don’t catch them early, they can throw off your timeline, budget, or tooling plan.

That’s why it’s important to talk with your design team or supplier during the DFM (Design for Manufacturability) stage. This is the point where your team looks closely at how the part will actually be made, not just how it looks in CAD.

A simple conversation now can save you from expensive surprises later.

When It Makes Sense to Keep Them

Some undercuts are functional and worth keeping. For example:

- Snap fits that hold parts together without screws

- Locking features that help with fast assembly

- Aesthetic details that give the product a cleaner look

If removing the undercut means adding more steps later like extra assembly or trimming, it may be smarter to keep it and build the tooling to handle it.

When It’s Better to Remove or Redesign

Sometimes, it’s just not worth the extra effort. You may want to remove or rethink undercuts if:

- You’re in the early prototyping stage and want a fast, low-cost part

- You’re running high volumes, and undercuts would slow production or increase failure rates

Design Alternatives to Eliminate Undercuts

Not sure how to redesign the part? Try these options:

- Modify the geometry so features align with the mold’s opening direction

- Split the part into two simpler pieces and assemble them after molding

- Add draft angles that help release the part without side action

These changes might look small on screen, but they can make a big difference in production.

5. Workarounds for Low-Volume or Prototype Production

Let’s say you’ve found an undercut in your design. You’re not ready to invest in a complex mold, but you still need parts for testing, customer samples, or even small-batch sales.

You have options.

There are several workarounds that can help you move forward without committing to full-scale tooling right away. Each comes with tradeoffs, but they can save you time and money while keeping your project moving.

Soft Tooling Options

One common approach is soft tooling. These are molds made from materials like aluminum or silicone instead of hardened steel.

- Aluminum molds can use manual inserts to work around undercuts. They’re faster to make and less expensive, though they wear out quicker.

- Silicone molds are useful for low-pressure molding or casting. They can pick up fine details and are great for short runs, but they don’t last long under heat and pressure.

This route is especially useful if you’re testing different designs or getting early user feedback.

3D Printed Molds or Parts

3D printing is another solid option. Instead of molding, you print the part directly.

- Some printed resins can handle sharp details, snap fits, and even flexible areas.

- Great for proving a concept before investing in tools.

Just know that printed parts often have different tolerances and surface finishes than molded ones.

Modular or Multi-Part Molds

This approach involves splitting your part or your mold into sections.

- Works well for MVPs or small launches

- Lets you run multiple versions with fewer upfront costs

But modular molds may impact part strength or appearance, especially at the joints.

Choosing the right workaround depends on your budget, timeline, and part function. What stage are you in right now?

6. Questions To Ask From Supplier

By now, you’ve seen how much an undercut can affect your mold, your timeline, and your cost. But what if you’re still not sure what to do?

That’s where your supplier comes in. A good supplier won’t just quote your part, they’ll help you think through your options.

But only if you ask the right questions.

Here are some key things to bring up during early conversations. These questions can help you catch problems early and avoid costly changes down the line.

Cost and Timeline

Before approving the mold, ask:

- “What’s the cost impact of keeping this undercut?”

- “How much longer will the mold take to build?”

These questions give you a clearer view of how this one feature affects your project. Sometimes the difference is small. Other times, it can double the cost or delay production by weeks.

Production Capability

Not every supplier has the tools or team to handle tricky features like undercuts. Ask:

- “Can your machines and team handle undercuts?”

- “Will this slow down cycle time?”

This helps you understand whether your part fits within their setup or if they’ll have to work around it manually.

If you’re looking for fast, flexible support from prototype to production, MachMaster is ready. We’ve delivered high-precision molded and machined parts for over 500 companies worldwide.

Alternatives

Even if you love your current design, it’s worth exploring simpler paths:

- “What would the part look like without this feature?”

- “Can we test a simplified version first?”

You don’t always need to commit right away. Sometimes it helps to test both options before making a final decision.

These questions can save you time, money, and stress before a single part is molded.

Conclusion

You came here with a question: What is an undercut in injection molding?

Now, you’ve got your answer. And more than that, you’ve got a plan.

You know what features cause undercuts, how they impact your mold, and what choices you have as a business owner.

This is where things shift. From confusion to clarity. From delays to action.

So what will you do with that knowledge? Whatever your next step is, take it with confidence.

Need a hand? Contact us now. We’re ready to help.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.