I used to think the sheet metal fabrication process was only for tough machinists in noisy shops.

Then one day, I got my first real project. I had to figure out how a simple metal bracket was cut and bent, or risk wasting a lot of money.

It felt scary. I didn’t want to look clueless in front of suppliers or my own team. Maybe you feel that way too.

Over the years, I’ve learned by asking tons of questions, watching skilled workers up close, and cleaning up mistakes that cost time and cash.

That’s why I made this guide for you. It shows the sheet metal fabrication process in clear steps. No fancy words. No guessing.

By the end, you’ll know what happens to turn flat metal into strong, useful parts. You’ll be ready to plan better, ask smart questions, and maybe save yourself from a few headaches.

Let’s dive in!

Quick Guide

Before diving deep, here’s a quick snapshot of the entire process. This gives a bird’s-eye view of what each step covers so you know what’s coming.

| Step | What to Do |

| Step#1 Design and Blueprint Creation | Accurate drawings, bend lines, hole positions, and DFM (Design for Manufacturability) |

| Step#2 Material Selection | Match material to function, environment, cost, and availability |

| Step#3 Cutting Sheet Metal | Choose the right cutting method; account for kerf, file formats, and part spacing |

| Step#4 Punching and Notching | Use for holes, slots, and corners; faster and cleaner for repeat features |

| Step#5 Bending and Forming | Plan bend radius, grain direction, and reliefs; confirm shop tooling |

| Step#6 Assembly and Joining | Select welds, fasteners, or tabs; ensure alignment and fit-up in design |

| Step#7 Surface Finishing | Choose finish for corrosion, function, or looks; plan for thickness or tolerances |

| Step#8 Inspection and Quality Control | Check dimensions, welds, surface, and critical fits before approval |

Let’s break down each of these steps next, starting from design all the way through final inspection.

Step#1 Design and Blueprint Creation

Every good part starts with a plan.

And in sheet metal fabrication, that plan is your blueprint.

CAD stands for Computer-Aided Design. It’s the software used to create 2D or 3D models of your part. Think of it as your part’s map. Without it, no one knows where to start.

So, what makes a good design?

Here are the basics:

- Exact measurements (length, width, thickness)

- Hole locations and sizes

- Bending lines

- Assembly points

- Material type (if known)

Ask yourself: Will someone reading this know exactly what I want?

That’s a good sign you’re on track.

Sometimes, clients ask us to help improve their drawings. We review tolerances, which are the allowed variations in size.

For example, ±0.1 mm means your part can be off by a tenth of a millimeter and still be OK.

Getting the design right saves time, money, and headaches down the line.

And honestly? It makes your life a lot easier.

Step#2 Material Selection

You can have the best design but if you pick the wrong material, it won’t matter.

At MachMaster, material selection is part of the build itself. It shapes durability, performance, and long-term success.

How to Choose the Right Sheet Metal

Start by asking yourself what conditions the part will face. This helps you pick the right material for the job.

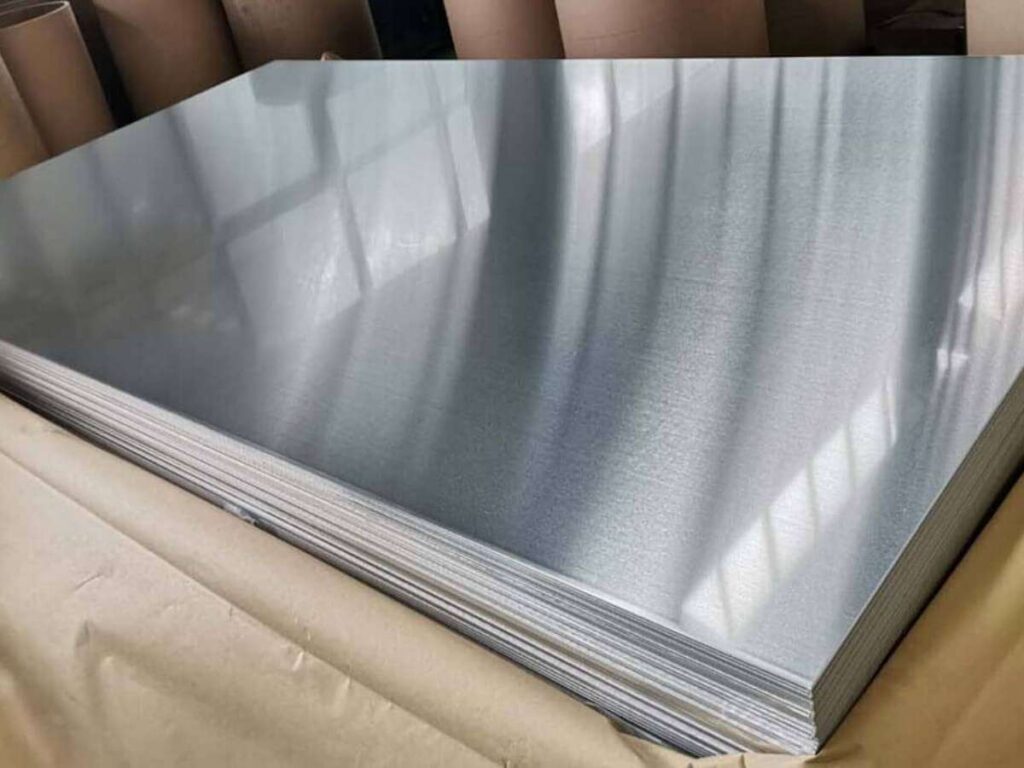

- Aluminum: This material is lightweight, resists corrosion, and bends easily, making it ideal for enclosures and covers.

- Stainless steel: It’s strong and rust-resistant, making it a good option for food equipment, medical parts, and outdoor use.

- Mild steel (cold-rolled): It is cost-effective and easy to work with, though it needs a protective finish to prevent rust.

- Galvanized steel: This steel is coated with zinc, which helps it resist rust in damp or outdoor conditions.

- Copper or brass: These are used when appearance or electrical conductivity matters, often in decorative parts or electrical components.

Choose based on the part’s use—not just habit or price.

What Else Should You Think About?

Beyond strength or corrosion resistance, several other factors also matter during selection.

- Cost: Some materials are priced higher, so your choice can affect the overall budget.

- Availability: Always check if the material and thickness you want are readily available from your supplier.

- Thickness options: Not every gauge is offered in every material type, which can limit your design.

- Finishing needs: Consider if you plan to paint, powder coat, or leave the part unfinished.

- Welding compatibility: Some materials are easier to weld than others, which affects your assembly process.

Picking the right metal isn’t just a technical step, it’s a smart business move. The better your material choice now, the smoother your manufacturer will do the job later.

Step#3 Cutting Sheet Metal

This is the stage where planning becomes production. Once your design is approved and the material is confirmed, the cutting process begins.

Cutting isn’t just about removing material. It’s about accuracy, consistency, and setting the tone for every step that follows.

Cutting Methods I Commonly Use

Here are the methods I can recommend based on project needs:

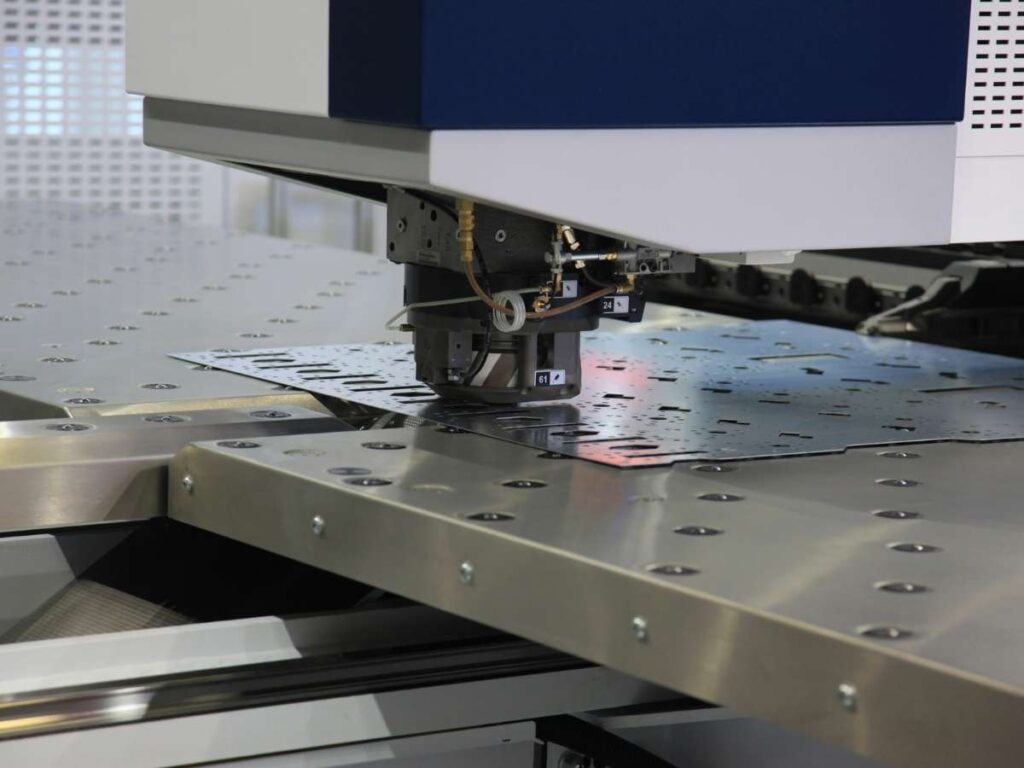

- Laser cutting: Offers high accuracy and smooth edges. Ideal for precision parts with tight tolerances.

- Plasma cutting: Suitable for thicker materials where speed matters more than edge finish.

- Waterjet cutting: Uses high-pressure water and abrasives. A good choice for materials that can’t handle heat.

- Shearing: Fast and efficient for simple, straight-line cuts. Best for flat parts with basic shapes.

- CNC punching: Useful for repeating hole patterns or simple cutouts in thinner sheet metal.

Each cutting method has its own role. The right one depends on the part’s geometry, material, and volume.

Key Considerations Before Cutting

I always ask these questions before selecting a cutting process:

- What is the material type and thickness?

- Are clean edges needed for appearance or assembly?

- How tight are the part tolerances?

- Is this a prototype or part of a production run?

- Will the cut areas be visible, painted, or welded later on?

These details help determine the most efficient and cost-effective cutting plan.

Cutting sets the foundation for everything that comes after—bending, welding, and finishing.

Talk to your supplier. Ask what they can handle. Choose the method that fits your part’s shape, thickness, and accuracy needs.

Step#4 Punching and Notching

Once the metal sheet is cut to size, the next step is creating the necessary openings.

That’s where punching and notching come in.

Skipping this step or doing it late in the process can lead to assembly delays, rework, or part rejection.

What Is Punching?

Punching is the process of forcing a shaped tool (the punch) through the sheet to make a hole or slot. The tool pushes the unwanted metal into a die below, creating a clean and fast cut.

We often use punching for:

- Mounting holes

- Key slots

- Repetitive hole patterns

- Tabs and knockouts

Punching is ideal for high-volume jobs that require accuracy and speed.

What Is Notching?

Notching removes a portion of the sheet from an edge or corner.

It’s especially useful when preparing a part for bending, fitting into tight spaces, or shaping an edge for a welded joint.

You might need notching if:

- Your part wraps around another structure

- Edges need to clear nearby components

- Welded joints require corner relief

It’s a small detail that makes a big difference in downstream operations.

Why It Matters to Your Project

When these features are done right, your parts fit together smoothly.

When they’re off—even by a little—it slows everything down.

Punching and notching help reduce secondary operations, keep assembly moving, and improve accuracy in the final build.

For businesses like yours, that means fewer delays, better fit, and smoother production. And that’s what we aim to deliver on every job.

Step#5 Bending and Forming

After cutting, punching, and notching, most sheet metal parts aren’t done yet.

They still need shape.

That’s where bending and forming come in.

This is how we take flat metal and give it structure, strength, and purpose.

What Is Bending?

Bending is a controlled way to create angles in sheet metal.

I use a press brake, which pushes the metal into a die using high force.

It works well for:

- Simple angles (like 90° bends)

- Clean folds

- Flanges or tabs that connect other parts

Accuracy here is key. Even 1 mm off can throw off your assembly.

What Is Forming?

Forming is a broader term.

It includes curves, rolls, and more complex shapes—not just straight lines.

We use different tools depending on your part’s shape and thickness.

Sometimes it’s a roller. Sometimes it’s a custom press brake setup.

Forming is useful when:

- You need curves or rounded edges

- Your part shape gives it structure or stiffness

- A weld-free solution is better for strength or looks

What We Look at Before We Bend or Form

Here’s what we always check before we bend your part:

- Material type: Some metals crack if bent too sharply

- Sheet thickness: Thicker metal needs a larger bend radius

- Grain direction: This affects flexibility and cracking risk

- Tolerances: Bends shift hole positions, so we plan layout early

I’ve had clients send us great designs—but without enough room for bending. A small adjustment upfront saved them rework later.

Step#6 Assembly and Joining

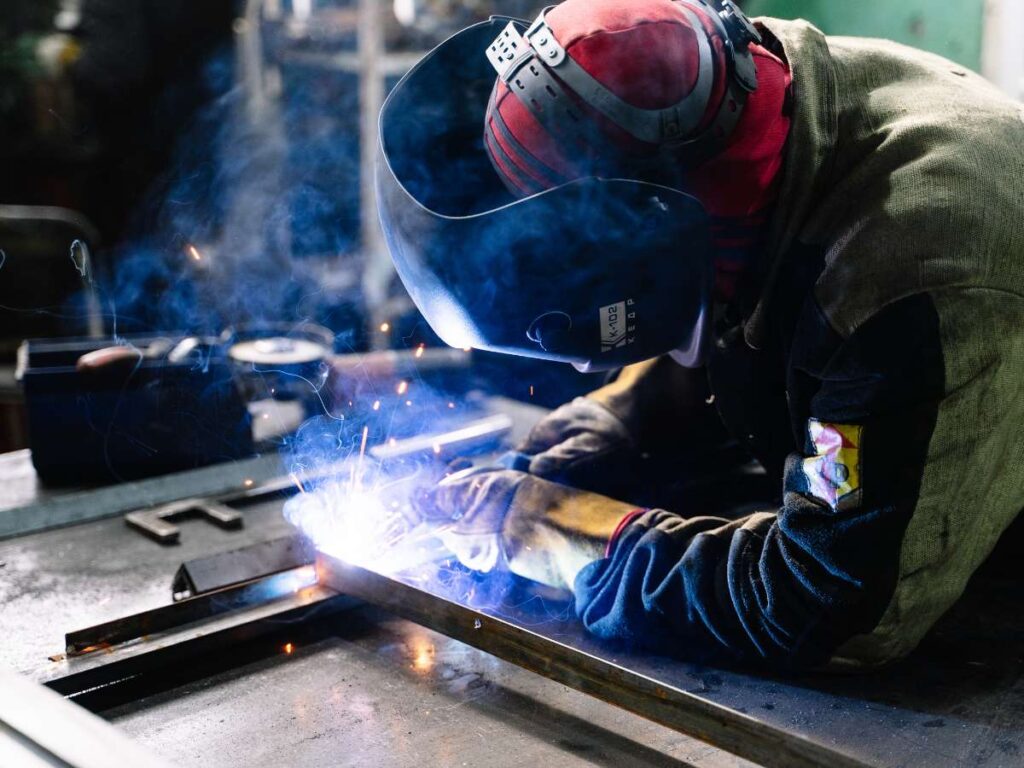

Once the parts are cut and formed, they need to come together.

I’ve had projects where the parts were perfect—but the way they fit? Not even close. Misaligned holes. Weld joints too tight. Missing hardware specs. It all traced back to poor planning at the assembly stage.

Common Joining Methods in Sheet Metal Projects

Different builds require different joining techniques. Each method affects strength, cost, and production time.

- Welding: Strong and permanent. Great for frames, brackets, and structural parts. Requires flat, clean joints.

- Riveting: Fast and simple. Good for connecting thin sheets without heat. Often used in enclosures and panels.

- Bolting or screwing: Flexible for serviceable parts. Needs accurate hole placement and hardware spec.

- Tab and slot: Fast for repeatable assembly. Works well in high-volume production with minimal tools.

- Adhesives: Used when appearance matters or when heat can’t be applied. Slower but clean.

The method you choose depends on function, finish, and how the part will be used or handled.

How to Make Assembly Easier and More Accurate

Before you send files to the shop or request a quote, consider these:

- Confirm that holes align in every part that joins

- Add locating tabs or pins if parts must fit a certain way

- Choose joining methods that match the tools and skills at your supplier’s shop

Assembly is where design and manufacturing meet.

If you plan it right, your parts come together without extra drilling, grinding, or guesswork. If not, you’re paying for fixes—and delays.

Step#7 Surface Finishing

Once the part is built, it still isn’t done. That’s where finishing comes in.

Common Surface Finishes in Sheet Metal Projects

Your finish does more than improve looks. It protects the part, improves performance, and affects lifespan.

- Powder coating: Adds a durable, even layer of color. Great for corrosion resistance and a clean appearance.

- Painting: More flexible for color matching and touch-ups. Needs a primer layer and surface prep.

- Anodizing: Used mostly on aluminum. Improves corrosion resistance and adds a professional look.

- Plating (zinc, chrome, nickel): Adds a protective metal layer. Good for wear resistance and electrical conductivity.

- Brushing or polishing: Smooths the surface. Often used when appearance matters, especially on stainless steel.

The right finish depends on how and where the part will be used.

What to Decide Before Finishing

If you’re preparing for production, think about this early:

- Will the part be exposed to moisture, heat, or chemicals?

- Is appearance critical for your end user?

- Do you need electrical insulation or conductivity?

- Does the finish need to match existing parts or brand colors?

- Will the finish affect tolerances or fit (especially for coated or plated parts)?

Finishing is often the last step—but it’s not just cosmetic.

It protects your part, extends its life, and shows you’ve planned all the way through.

Step#8 Inspection and Quality Control

This is the final check—the part is made, but is it right?

That’s why inspection isn’t optional—it’s part of delivering a usable part.

At MachMaster, quality isn’t just a final step, it’s a core value. Every part they deliver is carefully inspected to meet expectations and hold up in the real world.

What Quality Control Looks Like in Sheet Metal Work

A proper inspection checks for more than just looks. It confirms your specs, tolerances, and function are met.

- Dimensional checks: Key sizes, hole positions, and bend angles are measured against your drawing

- Visual inspection: Surface finish, scratches, dents, and sharp edges are reviewed

- Fit checks: Parts are dry-fit or tested with mating parts if required

- Weld and joint inspection: Checks for cracks, gaps, or weak connections

- Coating thickness (if finished): Measured to confirm protection and appearance standards

Whether you’re producing one prototype or a full batch, these checks catch mistakes before they reach your line—or your customer.

What You Should Ask or Include

To make quality control work for your project, here’s what to plan ahead:

- Include tolerances in your drawings—don’t assume “close enough”

- List any critical dimensions or features that must be checked

- Ask if the shop follows ISO 9001 or other recognized quality systems

- Confirm inspection tools and methods used before production begins

- Request an inspection report if needed for documentation or traceability

Good parts aren’t just cut and bent—they’re checked, verified, and ready to go.

End the process with confidence. Quality control makes sure you don’t get surprises later.

Conclusion

So now you’ve seen the clear steps of turning flat sheet metal into solid, practical parts.

Remember that first bracket I worried over?

I don’t panic anymore and now, you don’t have to either.

You’re ready to talk to suppliers, spot problems early, and guide your team with real know-how.

And what will it take to get it right the first time?

Contact Machmaster today and let’s make sure your parts fit your project needs!

Recommended Reads for You

If you need more options, take a look at our full range of products. You might find just what you need:

- Anodizing Service

- CNC Milling Service

- CNC Turning Service

- Injection Molding Service

- CNC Machining Service

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.