When I first started working with sheet metal, I thought everyone needed it.

I was wrong.

I spent months reaching out to companies that didn’t really use it—or didn’t have the budget for custom parts.

It was frustrating. I felt like I was always busy, but getting nowhere.

If you’re here, you might be feeling the same way. You want to know which industries actually use sheet metal and are willing to invest in it.

I’ve been there—and I want to save you the time I lost.

In this article, I’ll share the 10 industries that truly benefit from sheet metal fabrication. These are industries where I’ve seen real projects, real demand, and real opportunities.

Whether you’re trying to grow your business, design a product, or just figure out where sheet metal fits—you’ll find clear answers here.

So let’s begin!

Quick comparison Chart

Before we explore each industry one by one, take a look at this side-by-side table. It gives you a clear view of the key uses, materials, and benefits for each field.

| Industry | Common Applications | Materials Used | Key Benefits |

| Automotive | Body panels, chassis parts, battery trays, heat shields | Aluminum, stainless steel, galvanized steel | Lightweight, durable, rust-resistant, cost-effective |

| Aerospace & Aviation | Fuselage panels, wing ribs, engine covers, cockpit panels | Aluminum alloys, titanium, nickel alloys, aluminum-lithium | High strength-to-weight ratio, heat-resistant, precise |

| Construction & Architecture | Roofing, cladding, ductwork, framing, architectural details | Galvanized steel, aluminum, copper | Weatherproof, fire-safe, customizable, long-lasting |

| Electronics & Enclosures | Control boxes, server racks, switchgear panels, brackets | Zinc-plated steel, anodized aluminum, pre-painted sheet, copper | EMI shielding, cooling support, compact, clean finish |

| Medical Equipment | Carts, machine housings, dispenser units, frames | 304 stainless steel, anodized aluminum, powder-coated steel | Easy to sanitize, corrosion-resistant, stable under pressure |

| Renewable Energy (Solar & Wind) | Solar panel frames, turbine covers, inverter boxes | Anodized aluminum, galvanized steel, weathering steel | Weather-resistant, lightweight, scalable, low maintenance |

| Agriculture & Farming | Tractor panels, hoppers, livestock gates, storage bins | Galvanized steel, mild steel, coated steel, aluminum | Tough, easy to clean, field-repairable, rust-resistant |

| Food & Beverage Processing | Prep tables, conveyors, racks, enclosures | 304/316 stainless steel, aluminum (dry zones) | Hygienic, chemical-resistant, smooth surface, long-lasting |

| Defense & Military | Vehicle panels, shelters, UAV frames, electronics enclosures | High-strength steel, 5052 aluminum, heat-treated alloys | Impact-resistant, lightweight, mission-adaptable |

| Consumer Products & Appliances | Appliance frames, electronics casings, furniture parts | Cold-rolled steel, brushed stainless steel, aluminum, EG steel | Sleek design, strong, cost-efficient, scalable |

Now that you’ve seen the big picture, let’s dig into each industry one by one and explore the details.

1. Automotive

I didn’t always pay attention to how cars were built—until I visited a factory floor for the first time.

Watching a team form sheet metal into hoods, battery trays, and underbody panels was eye-opening. The parts were strong, lightweight, and fast to make. That moment made me realize how central sheet metal is to the auto industry.

At MachMaster, we’ve seen this firsthand. Automotive clients often come to us needing precision parts that hold up under stress, yet stay lightweight and cost-effective.

If you’re in automotive, you’re likely using sheet metal already—or missing a chance to save money and improve your products.

Common Uses:

Sheet metal fabrication is used in many parts of a vehicle, including:

- Body Panels: hoods, fenders, roofs, and doors

- Chassis Components: engine mounts, supports, and brackets

- Exhaust System Parts: muffler covers and pipes

- Heat Shields: protect parts from engine heat

- Battery Enclosures: especially in electric vehicles

These parts need to be accurate, strong, and made at high volume. Sheet metal is a natural fit.

Materials Used:

- Aluminum: Lightweight and corrosion-resistant. Used in panels and structural parts to improve fuel economy.

- Stainless Steel: Strong and heat-resistant. Found in engine bays and exhaust systems.

- Galvanized Steel: Steel coated with zinc. Fights rust—useful for parts exposed to moisture or road salt.

Each material brings specific advantages, depending on where it’s used.

Key Benefits

- Strength without bulk

- Lower weight for better fuel efficiency

- Resistance to corrosion and weather

- Cost savings on high-volume parts

- Fast, repeatable production for scale

When you combine speed, cost control, and part quality, it’s clear why automakers rely on this process.

If your business deals with vehicles, sheet metal fabrication isn’t just useful—it could be the key to making your production better, faster, and more affordable.

2. Aerospace and Aviation

The first time I visited an aircraft maintenance hangar, I noticed something strange.

So many of the parts—inside and out—were made from thin metal sheets. Not bulky. Not heavy. Just strong, lightweight panels held in place with precision.

That day stuck with me. It made me realize just how important sheet metal fabrication is in aerospace and aviation.

If you’re in this field, you already know: every ounce matters. And sheet metal plays a big part in keeping aircraft light, strong, and safe.

Common Uses:

- Fuselage Panels: the main body shell of the plane

- Wings and Wing Ribs: internal supports that help carry loads

- Engine Components: like covers, ducts, and mounts

- Interior Panels: used for walls, overhead bins, and flooring

- Brackets and Supports: hold everything together behind the scenes

These parts need to be strong but lightweight. They also need to handle vibration, pressure, and fast temperature changes.

Materials Used:

- Aluminum Alloys: These aren’t just regular aluminum. They’re blended for added strength while staying light. Grades like 2024 and 7075 are common in wings and frames.

- Titanium: Used in landing gear, fasteners, and engine components. It handles pressure and heat better than almost anything else.

- Nickel Alloys: Less talked about, but vital near engines and heat shields. These resist temperature changes and thermal fatigue.

- Aluminum-Lithium: A newer material. Even lighter than standard aluminum, with the same toughness. Popular in next-gen aircraft designs.

Different alloys serve different zones—based on vibration, load, and temperature.

Key Benefits

- Weight Reduction: Less weight means better fuel efficiency and lower cost.

- Durability: These metals can handle high pressure, heat, and vibration.

- Corrosion Resistance: Important for flying through different climates.

- Fast Production: Once a part is designed, it can be shaped and cut quickly.

- Cost Control: Sheet metal helps reduce waste and speed up assembly.

If you’re building aircraft, handling repairs, or even designing components, sheet metal fabrication is probably part of your toolkit.

3. Construction and Architecture

I remember walking through a building site during a stormy afternoon.

While most materials sat covered in plastic, the sheet metal flashing and siding stood exposed—completely unfazed by wind or rain.

That moment showed me just how reliable this material is in construction.

If you’re in building or design, you’ve likely seen sheet metal in ways you didn’t even realize.

Common Uses:

- Roofing and Flashing: directs water away from the structure

- Wall Cladding: outer panels that protect and decorate buildings

- HVAC Ductwork: metal channels for heating and cooling systems

- Window and Door Frames: slim, clean, and long-lasting

- Custom Fixtures: stair rails, counters, and facade details

Many architects also use it for decorative touches. It adds a modern, sleek finish without adding bulk.

Materials Used:

- Galvanized Steel: Coated in zinc, this steel resists rust. It’s perfect for outdoor parts exposed to moisture.

- Aluminum: Lightweight and corrosion-resistant. Easy to cut and bend. Used a lot in custom trim and paneling.

- Copper: Less common but very durable. You’ll often see it in high-end roofing or historical buildings because it ages well.

Each metal is chosen based on its look, strength, and exposure to the elements.

Key Benefits

- Weather Resistance: won’t warp, swell, or rot

- Fire Safety: metal doesn’t burn like wood or plastic

- Flexible Design: cuts and forms into almost any shape

- Low Maintenance: no repainting or sealing needed

- Fits All Scales: works for homes, skyscrapers, and everything in between

If you’re designing or building structures that need to last—and still look good—sheet metal fabrication gives you real options.

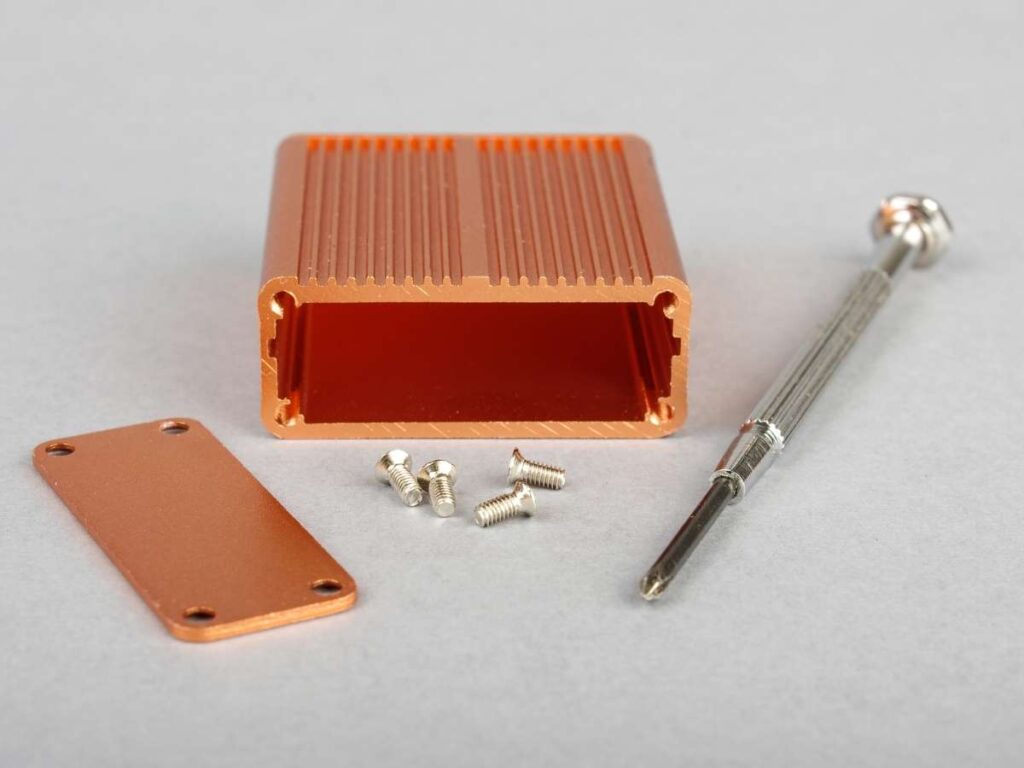

4. Electronics and Enclosures

A few years ago, I helped rework housing for a piece of monitoring equipment. The original plastic shell warped over time, and the internal components kept overheating.

You might’ve been in the same spot—struggling with parts that don’t last or don’t protect what’s inside.

Switching to sheet metal solved that for us. And it could do the same for you.

Common Uses:

- Enclosure boxes for power supplies or control panels

- Data racks for telecom, servers, and storage systems

- Custom casings for tools, meters, or chargers

- Wall-mounted panels with access ports

- Backplates and covers that support wiring or shielding

If you need strong protection, proper airflow, and clean design—sheet metal is a good option.

Materials Used:

- Zinc-plated Steel: This has a thin zinc coating that gives you a cleaner look and some added rust resistance. Great for indoor enclosures.

- Anodized Aluminum: A smooth, hard surface that’s resistant to scratches. Also helps prevent signal interference.

- Pre-painted Sheet Metal: Saves time on finishing. Used when appearance matters right out of the box.

- Copper (used selectively): It’s pricey but highly conductive, sometimes used in shielding or ground plates.

Each metal serves a purpose—whether it’s conductivity, appearance, or long-term wear.

Key Benefits

Here’s what makes this method work so well for electronics:

- Protects your components from heat, impact, and dust

- Helps reduce electromagnetic interference

- Fits exactly to your design—vents, ports, fasteners, all in place

- Can be made in small batches or scaled fast

- Add a polished, professional finish that your customers notice

If you’re building anything with power, signals, or sensitive tech, sheet metal fabrication gives you a solid foundation.

And once you use it, you’ll see just how much easier it makes your job.

5. Medical Equipment

I worked on a hospital cart that was falling apart after just a few months.

It rattled down the hallway. Its plastic edges chipped and cracked. It looked worn out—even though it was brand new.

We rebuilt it using smooth, powder-coated sheet metal. The wheels rolled quieter. The handles felt solid in your grip. Cleaning became easier—just one swipe with disinfectant, and it looked brand new again.

If you’re in healthcare, you already know: your equipment doesn’t just need to work. It needs to feel dependable in your hands and look clean in every room.

Common Uses:

- Imaging Machine Covers: sleek panels that shield X-ray and MRI systems

- Rolling Carts: with drawer handles you can grip with gloves on

- Bedside Brackets and Arms: strong enough to support heavy screens or lights

- Wall Units: holding oxygen controls, sanitizer pumps, and emergency buttons

- Protective Housings: clean-lined, sealed, and easy to wipe down

Each piece needs to be tough enough for daily use—and smooth enough for sterile spaces.

Materials Used:

- 304 Stainless Steel: Feels cool to the touch. Doesn’t rust. Wipes clean in seconds.

- Anodized Aluminum: Light, but strong. Has a smooth, matte surface that doesn’t hold fingerprints.

- Powder-coated Steel: Feels firm and finished. Comes in medical-grade colors like soft gray or white, blending into clean environments.

Each one looks, feels, and functions in a way that supports patient care.

Key Benefits

- Tough under pressure—no cracking, no sagging

- Silent and smooth—rolls quietly, opens easily

- Built to clean—resists harsh cleaners without losing color or finish

- Custom fit—every hole, edge, and surface made just right

- Looks professional—no rough edges, no guesswork

When you’re designing tools for healing spaces, you want parts that hold up under stress—and feel solid, safe, and clean. Sheet metal fabrication gives you that. Every time.

6. Renewable Energy (Solar & Wind)

During a visit to a wind farm, I stood near the base of a turbine.

The tower felt cool, solid, and smooth beneath my hand. Nearby, solar arrays tilted toward the sky—each one mounted on clean, sharp-edged frames. All made with sheet metal.

If you’re working in solar or wind energy, you know these systems need more than good tech. They need strong, weatherproof parts that won’t quit in heat, cold, or storms.

Common Uses:

- Solar Panel Frames: hold the panels steady through wind and rain

- Mounting Brackets: for rooftops, poles, and ground racks

- Wind Turbine Housings: cover and protect sensitive parts

- Battery Cabinets: keep energy storage units safe and dry

- Inverter Boxes: hold electrical parts that connect power to the grid

These parts face sun, wind, dust, and moisture—every single day.

Materials Used

- Anodized Aluminum: Lightweight and tough. The finish adds a hard layer that protects against sun and salt.

- Galvanized Steel: Strong and zinc-coated. Stands up to storms and humidity, great for structural mounts.

- Weathering Steel (also called COR-TEN): This one forms a stable, rust-like layer that actually protects the surface underneath. Often used in rural or coastal areas.

Each metal is picked for how it holds up to weather—and how easy it is to shape and install.

Key Benefits

- Survives wind, rain, heat, and cold

- Cuts down weight without losing strength

- Fits tight deadlines and custom project needs

- Reduces maintenance over time

- Keep costs steady on large installations

If you’re part of the energy shift—designing solar fields or wind towers—sheet metal is one of the most reliable tools you can use.

It keeps your parts strong, your systems clean, and your future powered.

7. Agriculture and Farming

If you work the land, you already know—your equipment doesn’t get a break.

You deal with dust, rain, bumps, and long days. Parts wear out fast if they’re not built right.

That’s where sheet metal can help you.

Whether you’re running a small farm or managing acres of crops, you need parts that last. Sheet metal fabrication gives you that strength without making things too heavy or too expensive.

Common Uses:

- Tractor and Harvester Panels: protect moving parts and make maintenance easier

- Feed and Seed Chutes: guide material without jamming

- Battery and Engine Enclosures: keep dirt and moisture out

- Storage Bins: for chemicals, feed, and grain

- Livestock Gates and Panels: built strong and safe for animals

If you need something tough that you can wash down and put back to work—sheet metal is a good fit.

Materials Used:

- Galvanized Steel: The zinc coating helps stop rust, even in wet fields or humid barns.

- Mild Steel: A good all-purpose option. Strong and easy to weld if something breaks.

- Powder-coated Steel: Adds color and weather protection, especially for outdoor use.

- Aluminum: Used in lighter parts that need to resist rust, like transport trays or tool holders.

You choose based on how much weight, weather, and wear the part will face.

Key Benefits

- Takes a beating without bending or cracking

- Cleans up fast with water or pressure spray

- Cuts downtime when it’s made to fit right

- Saves money over time thanks to durability

- Works in both custom and high-volume jobs

If you rely on your tools to keep the farm moving, sheet metal might be one of the smartest upgrades you can make.

8. Food and Beverage Processing

If you’re in food production, you already know how strict things can get.

Clean surfaces. Easy-to-wash parts. No place for bacteria to hide.

You can’t cut corners—not when people’s health is involved.

That’s why you’ll often turn to sheet metal. It gives you clean, tough, and reliable parts that stand up to daily use—and daily scrubbing.

Common Uses:

- Work tables and prep stations

- Sinks and splash guards

- Mixers, bins, and conveyors

- Enclosures for control panels or machines

- Cooling racks and storage shelving

You need smooth surfaces and tight fits. No sharp edges. Nothing that traps crumbs or grease.

Materials Used:

- 304 Stainless Steel: This one’s common in kitchens and plants. It doesn’t rust and has a smooth finish that’s easy to sanitize.

- 316 Stainless Steel: Even better for high-acid or salty environments, like seafood processing. More expensive, but tougher over time.

- Aluminum (in dry zones): Lightweight and non-rusting. Good for dry storage areas, but not ideal for wet or acidic use.

You pick based on what you’re processing and how often the part gets washed down.

Key Benefits

- Withstands hot water, steam, and strong cleaners

- Smooth, sealed surfaces prevent bacteria buildup

- Easy to cut, bend, and shape for custom layouts

- Tough enough to handle drops, bumps, and fast-paced use

- Low maintenance—just wipe and go

If you’re building or upgrading your processing line, sheet metal helps you meet health codes, reduce downtime, and keep everything running clean and safe.

In food and beverage, that’s not just helpful—it’s non-negotiable.

9. Defense and Military

If you’re in defense, you know how fast things change in the field.

One day it’s transport logistics. The next, it’s protective gear or communication setups. You don’t just need strong parts—you need them fast, accurate, and field-ready.

That’s where sheet metal fabrication becomes a critical tool. It gives you the flexibility, strength, and speed to keep up with what your mission demands.

At MachMaster, we’ve supported defense suppliers with parts that hold up under real pressure—whether it’s heat, impact, or changing terrain.

Common Uses:

- Vehicle Panels: for trucks, armored carriers, and support vehicles

- Electronic Enclosures: protect sensitive equipment from heat and impact

- Racks and Cabinets: for tools, weapons, and communication systems

- Drone and UAV Parts: light frames and body structures

- Portable Structures: like shelters or field stations

Whether you’re moving supplies or building systems, you need gear that’s light, durable, and easy to deploy.

Materials Used:

- High-strength Steel: Thick and dense. Used in protective plating and structural components.

- 5052 Aluminum Alloy: Light, corrosion-resistant, and tough. Ideal for mobile units and airborne equipment.

- Heat-treated Alloys: Blended for ballistic protection and impact resistance in hostile zones.

- Powder-coated or Camo-finished Sheet: For durability and low visibility in the field.

You choose based on mission type, location, and mobility needs.

Key Benefits

- Tough under impact, shock, and heat

- Customizable for different field needs

- Light enough to move fast

- Fast to produce, even in limited runs

- Reliable in harsh conditions—wet, dry, or sandy

If you’re building equipment for the front lines—or for behind-the-scenes support—sheet metal helps you get there with fewer delays and better results.

And when your gear has to work under pressure, every layer of strength counts.

10. Consumer Products and Appliances

Pick up a toaster, open a laptop, or slide out the drawer of a filing cabinet—and you’ll likely touch sheet metal.

It’s everywhere. Not just inside electronics, but in the frame, the casing, and even the support brackets you don’t see.

I once helped troubleshoot a home appliance design that kept cracking during shipping.

Turns out, the plastic housing was too thin. Switching to a light-gauge steel shell didn’t just stop the damage—it gave the product a cleaner, more premium feel.

Common Uses:

- Appliance Bodies: washers, dryers, dishwashers, and refrigerators

- Electronic Enclosures: for routers, gaming consoles, and PC towers

- Cookware and Kitchen Tools: like oven interiors or grill liners

- Furniture Frames: including shelves, stands, and support rails

- Small Gadgets: smart home devices, chargers, and mounts

Wherever strength and a clean finish are needed, sheet metal fits right in.

Materials Used:

- Cold-rolled Steel: Smooth surface that’s great for painting or coating. Often used in colorful appliances or office items.

- Brushed Stainless Steel: Looks sleek and hides fingerprints. Popular in kitchen appliances and modern tech.

- Thin Aluminum Sheets: Lightweight and rust-proof. Works well in compact electronics or portable gear.

- Electro-galvanized Steel: Has a protective zinc layer. Adds life to internal parts that still need durability.

Each metal gives you a balance between style, strength, and cost.

Key Benefits

- Adds structure without bulk

- Delivers clean edges and tight bends for sleek design

- Easy to cut for vents, ports, and buttons

- Strong under impact and daily wear

- Affordable to scale—whether you’re making 10 or 10,000 units

Consumer products need to look good and last. With sheet metal, you get both—plus a finish that helps your product stand out on the shelf and hold up in someone’s hands.

Conclusion

From auto parts to wind turbines, sheet metal fabrication plays a powerful role in shaping modern industries.

You’ve seen where it’s used, why it works, and how different sectors benefit from it every day.

That hospital cart I helped redesign? It’s still in service—stronger and cleaner than ever.

Now it’s your turn to act. Whether you’re improving products or solving production problems, the right material can make all the difference.

Contact us today to get started!

Learn More: Recommended Reads

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

- Anodizing Service

- Cnc Milling Service

- Cnc Turning Service

- Injection Molding Service

- Cnc Machining Service

We’ve gathered a few more articles that could help you out. Check them out for more great advice:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.