One bad batch cost me $4,000.

We misaligned the part. Just slightly. But it was enough to scrap everything.

That’s the moment I started researching automated CNC solutions. I wanted a system that reduced human error. One that didn’t depend on one person’s hands or habits.

Since then, I’ve tested dozens of machines. Talked to operators. Helped teams switch from manual to auto.

And now I’m sharing what I’ve learned with you.

In this article, you’ll find:

- A simple definition of auto CNC machining

- Real benefits like faster cycle times, repeatable accuracy, and easier scaling

- Tips to help you know if it fits your goals

By the end, you’ll have what you need to move forward—smarter and with less risk.

So let’s dive in!

1. What Is Auto CNC Machining?

Auto CNC machining is CNC machining but smarter.

At its core, it’s the same thing: a computer tells a machine what to cut, where, and how fast. But with automation added in, the machine can now do more by itself.

Instead of stopping to change tools, move parts, or check alignment, an auto CNC machine handles those steps on its own.

Let’s break that down.

What Does “Auto” Really Mean?

The “auto” in auto CNC machining stands for automation. It means the machine has features that cut down on manual work.

Here are some of the features you might see:

- Automatic tool changers – swap out tools without stopping the machine

- Robotic arms – load and unload parts

- Pallet changers – switching out workholding setups quickly

- Bar feeders – feed material into the machine

- Part ejectors – remove finished parts

- Sensors – detect tool wear, part position, or errors

These tools let a machine run longer, with fewer people watching over it.

Why It Matters

I remember visiting a supplier who ran parts all weekend with no one in the building. The shop lights were off. But the machines? Still running.

That’s called lights-out machining. And it’s only possible with automation.

Here’s what automation helps you do:

- Run jobs with less supervision

- Lower labor costs

- Shorten cycle times

- Produce parts overnight or during breaks

For example, a pallet changer might cut setup time in half. A robotic arm might load dozens of parts while your team focuses on inspection.

Auto CNC machining isn’t just about machines working faster. It’s about building a process that works smarter.

Less downtime. Fewer errors. More output.

If you need to grow without hiring more people or just want more consistent results, auto CNC machining could be the answer.

2. How Auto CNC Machining Works

Auto CNC machining sounds complex. But at its core, it’s just regular CNC machining with smarter tools doing more of the work.

Instead of stopping to swap parts, change tools, or measure dimensions by hand, the machine handles those steps by itself.

Everything runs smoother. And faster.

Let’s look at how it actually works.

Key Automation Features

These are the tools that make auto CNC machining possible.

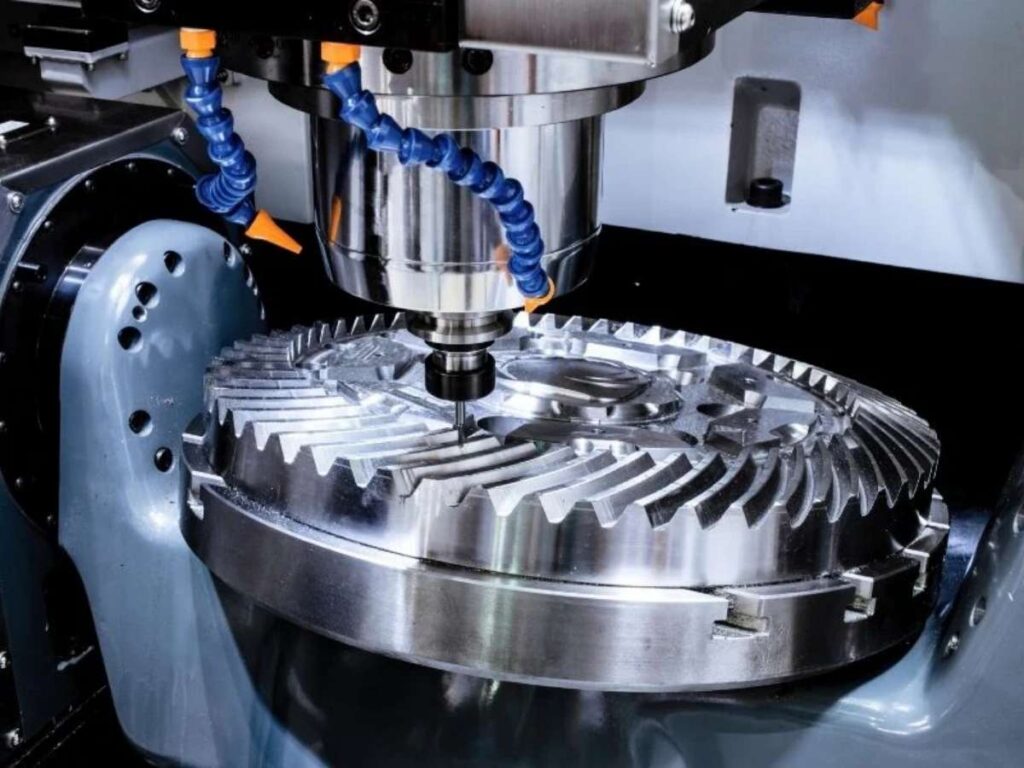

Automatic Tool Changers (ATC)

This is one of the most common features.

- The machine switches tools on its own

- No need for an operator to stop the cycle

- Helps when a part needs many tools or setups

You load your tools at the beginning. Then the machine picks what it needs at the right time.

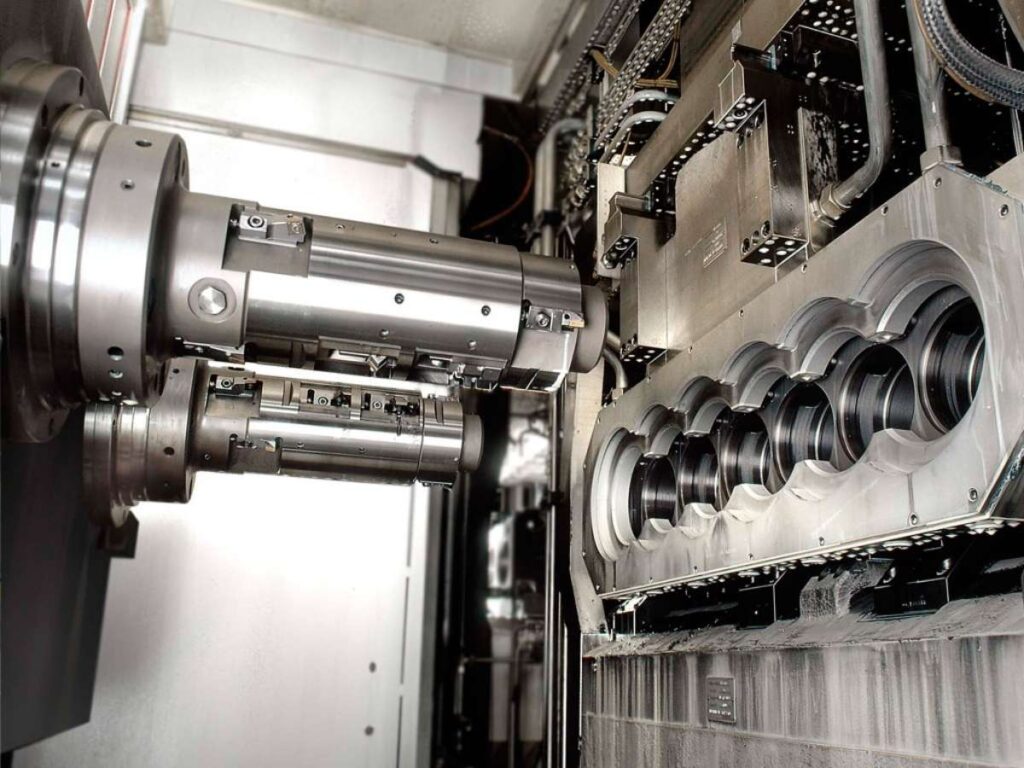

Robotic Loading and Unloading

This is a big one for busy shops.

- Robotic arms pick up raw material

- Then place finished parts in a bin or tray

- Useful for high-volume or overnight runs

I once visited a shop where one operator oversaw three machines. Each had a robot arm. Parts were being made while he checked quality or packed boxes. That’s the power of automation.

Pallet Systems & Workholding

Changing setups eats time.

Pallet changers help with that:

- Swap out setups in seconds

- Let the machine keep cutting while you prepare for the next job

- Improve machine uptime

You get more done without rushing the setup process.

In-Process Probing & Inspection

Sensors check the part during the cycle.

- Measure holes, heights, and surfaces

- Catch mistakes before the job ends

- Reduce scrap

Instead of waiting for post-inspection, the machine catches problems right away.

Integration with Software

Hardware helps. But software is what keeps everything running in sync.

CAM + Scheduling Tools

- CAM software: creates efficient toolpaths

- Job schedulers: line up work in the best order

- Integrated systems: assign jobs to open machines

With the right setup, you can plan a full day or full week of jobs. And let the machines do the rest.

That’s how some shops run lights-out shifts with just one person checking in now and then.

3. Benefits of Auto CNC Machining

If you’ve ever stayed late to finish a job because the machine needed constant attention, you’ll understand the value of automation.

Auto CNC machining isn’t just about high-tech features. It’s about solving problems—ones you probably deal with every day.

Let’s look at the real benefits.

Improved Efficiency

Auto CNC machines are built to run longer with less help. That means:

- You can run multiple shifts without adding staff

- Machines keep cutting even during breaks or overnight

- Automatic tool changes and pallet swaps save time between jobs

- Labor cost per part drops

I remember one week where we had back-to-back orders. The auto CNC ran nonstop. All we had to do was reload stock and inspect parts. Everything else? The machine handled it.

At MachMaster, this is exactly how we help our clients. Our automated lines run with minimal supervision—keeping lead times short and output steady.

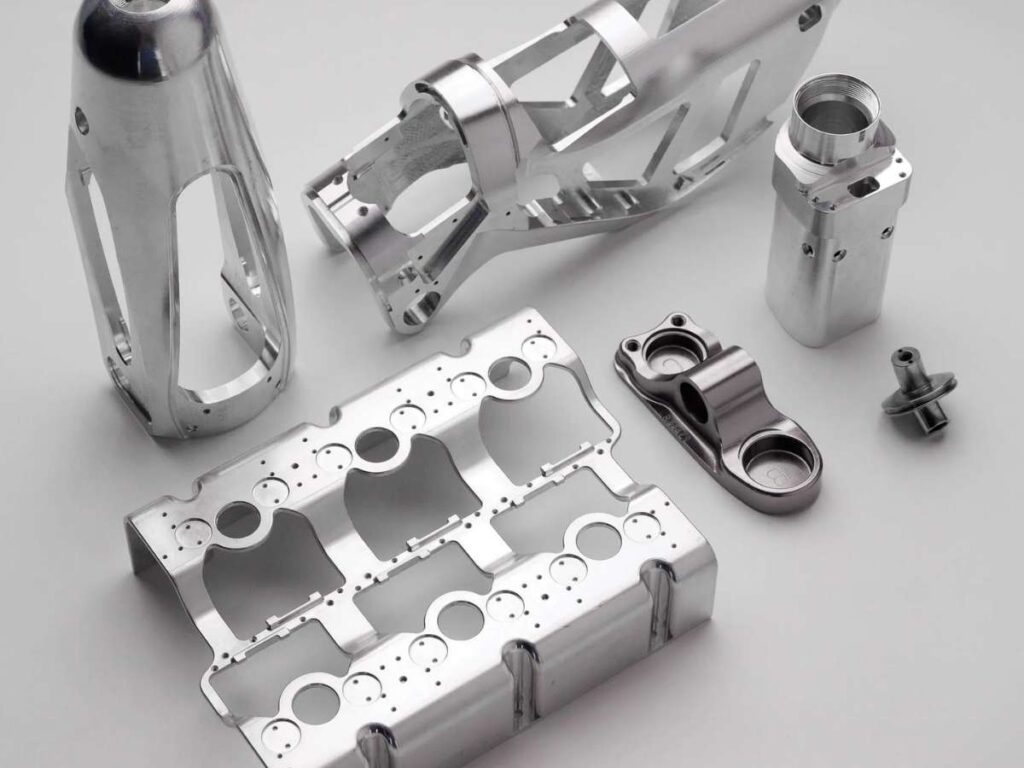

Consistent Part Quality

Manual setups can be hit-or-miss. One small mistake, and a whole batch is off.

With auto CNC machining, you get repeatable results.

- Tolerances stay tight—often ±0.01mm or better

- Machines repeat the same moves every time

- Sensors catch errors early

Whether you’re running 10 parts or 10,000, the quality stays steady.

Lower Long-Term Costs

Yes, auto CNC machines cost more upfront. But over time? They pay for themselves.

- Less rework

- Fewer scrap parts

- More output per hour

- Fewer operators needed for the same work

If you’re running high-volume jobs or tight delivery windows, that return adds up fast.

Safer Operations

I’ve seen too many accidents from manual part handling. Fingers near spindles. Heavy lifting. Quick tool swaps under pressure.

Automation makes things safer.

- Robotic arms move parts not people

- Automatic tool changers keep hands away from cutting areas

- Less physical strain on your team

This isn’t just about production. It’s about protecting your crew.

Auto CNC machining helps you work faster, safer, and smarter.

If you’re ready to scale or just tired of doing everything by hand, these machines offer a real path forward.

4. Real-World Applications of Auto CNC Machining

Auto CNC machining isn’t just for giant factories.

It’s being used by startups, small shops, engineers, and even hobbyists. If you’ve ever needed a part made quickly and accurately—this technology can help.

Let’s break down where it really shines.

High-Volume Production Runs

Auto CNC machines are perfect for jobs that need lots of the same parts.

Here are a few common uses:

- Consumer electronics: phone housings, heat sinks, and brackets

- Automotive parts: engine mounts, transmission covers, brake plates

- Custom enclosures: for electronics, sensors, or small machines

One of my clients used to make engine brackets by hand. They could do about 20 a day. After switching to auto CNC with a bar feeder and pallet changer, they were hitting over 200 daily—without hiring anyone new.

Rapid Prototyping with Tight Timelines

When speed matters, auto CNC machining helps teams move fast.

It’s used for:

- Medical devices: handles, housings, and alignment jigs

- Aerospace: test parts for air flow or vibration studies

- R&D teams: quick builds for design review or testing

A friend working in medical design told me how their first product run took weeks with manual machines. But once they switched to auto CNC, they had working samples for two days. That speed made all the difference.

Custom Parts for E-commerce, Hobby, or DIY Projects

Auto CNC isn’t just for big companies.

It’s used by people making:

- Knife blanks

- Bicycle parts

- Tripod mounts and camera gear

- Personalized mechanical items like gears, grips, or fixtures

I’ve seen hobbyists build side businesses just by automating small runs. With a good setup, you can build 50 parts overnight while you sleep.

Whether you’re making one prototype or ten thousand parts, auto CNC machining gives you speed, consistency, and freedom to grow.

5. Limitations of Auto CNC Machining

Auto CNC machining can save time, boost output, and cut costs—but it’s not perfect.

There are some real downsides, and you should know them before jumping in.

Let’s break it down honestly.

Setup Time and Costs

The biggest hurdle? Getting started.

- Auto CNC machines cost more upfront

- You’ll need to buy extras like tool changers or robots

- Programming is more detailed and takes longer at the beginning

I remember our first auto setup. It took three days just to get the code right. We had to test tool paths, fine-tune the sensors, and double-check clearances.

But once it ran smoothly, it kept going for weeks. No touch-ups. No delays.

Still, you should be ready for a slow start and a bigger check.

Not Ideal for Highly Custom or One-Off Jobs

Auto CNC works best when jobs repeat.

If your parts change all the time, full automation may slow you down.

- Some jobs still need manual setups or inspection

- Very complex parts may not work well with automated arms or probes

- Low-volume, high-mix production can make automation inefficient

For example, if you’re making just one prototype with tight tolerances, manual machines might get it done faster.

When Manual or Hybrid Setups Make Sense

Sometimes, less automation is better.

Here’s where manual or hybrid CNC setups still help:

- Short-run, fast-turn jobs

- Shops that don’t run overnight

- Parts that require custom fixturing each time

One small shop I know keeps one auto CNC machine for large batches and a manual mill for one-offs. It gives them the best of both worlds.

Auto CNC machining is a strong tool. But it’s not always the right one.

If your work is flexible, fast-changing, or highly custom, a manual or semi-automated setup might give you better control.

6. Common Misconceptions About Auto CNC

When people hear “auto CNC,” they often think it’s too big, too expensive, or too advanced for their shop.

I used to think the same thing. I figured automation was only for large companies with deep pockets.

But over time, I learned those ideas aren’t always true.

Let’s clear up a few common myths.

“It’s Only for Big Factories”

This one comes up a lot.

People assume that unless you’re running hundreds of machines, automation isn’t worth it. But here’s the truth:

- Small shops use bar feeders to load stock

- Automatic tool changers come standard on many mid-level machines

- Probing systems help catch errors early even on one-off parts

I once visited a two-person shop that made camera mounts. They ran a single auto CNC lathe with a bar feeder. It ran through the night while they were home with their families. That shop wasn’t big but it was efficient.

Even if you’re not buying your own machine, many job shops and online services now offer auto CNC. You can still get the benefits without the full cost.

“It’s Too Expensive to Start”

Yes, there’s a higher upfront cost. That’s true.

But it’s also true that your cost per part goes down as volume goes up.

Here’s why:

- Setup is longer, but you don’t need an operator every minute

- Parts come out faster

- Mistakes and rework are less likely

And with contract manufacturing, you don’t always need to buy the machine.

You can send your design to a supplier who already has the setup. That means:

- No machine purchase

- No maintenance

- No floor space needed

Auto CNC isn’t just for factories. And it’s not out of reach.

Whether you’re running a small shop, working on a class project, or launching a product you can still use automation.

7. How to Choose an Auto CNC Machining Service

Picking the right auto CNC machining service can make or break your project.

I’ve worked with both great suppliers and… not-so-great ones. One time, I thought I found a solid shop. Their pricing looked fair, and the website had all the right words. But once production started, I realized they were doing everything manually. Delays stacked up. Tolerances slipped. And we had to start over—with a new vendor.

So how do you avoid that?

Let’s walk through it.

Ask the Right Questions

Don’t just ask if they do auto CNC. Go deeper.

Here are questions that help you see the real picture:

- What automation tools do you use? (Listen for tool changers, bar feeders, probes)

- What’s your cycle time and batch size range?

- Can you run overnight or unattended?

- Do you use toolpath simulation or error detection software?

These questions tell you how serious they are about automation not just buzzwords.

At MachMaster, these are questions we hear often and welcome. We use robotic arms, pallet changers, and real-time monitoring systems to deliver repeatable accuracy and faster lead times across both small batches and high-volume jobs.

Look for Indicators of Real Automation

Some suppliers say they do auto CNC, but still rely on a person for every step. Look for signs that they’re actually using automation.

Here’s what to check:

- Photos or videos of machines running without people nearby

- Mention of robot arms, pallet changers, or automated inspection tools

- Proof that they’ve handled large volume runs without delays

If all you see are manual machines and a few blog posts, you might want to keep searching.

I once found a supplier on a forum. Their shop looked small, but they had a robot arm loading a lathe and a pallet system on their mill. That told me they were serious and they delivered right on time.

The right auto CNC service gives you more than just parts.

It gives you speed, repeatability, and peace of mind.

So ask tough questions. Look for proof. And choose someone who’s set up to do the work right—even when no one’s watching.

Conclusion

That night I stayed late fixing setup errors? It doesn’t happen anymore.

Because once we switched to auto CNC, we stopped chasing problems and started getting ahead.

In this guide, you learned what auto CNC is, how it works, where it fits, and what to watch out for. You now know the tools, the benefits, and how to choose a service that actually delivers.

If you’re tired of delays, missed tolerances, or wasted labor this is your next step.

So what’s stopping you?

Reach out today and let’s build something that runs smoother, faster, and smarter.

Check Out These Additional Resources

For more in-depth knowledge, take a look at these recommended reads. We think you’ll find them useful:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.