A while ago, a customer sent me a sketch and asked:

“Can you make this part?”

I said, “Sure, we’ll machine it.”

They paused. “Wait—what does that mean?”

That moment stuck with me. It made me realize a lot of people aren’t quite sure what CNC machining actually is and that’s totally fine.

But if you’re working on a project, placing an order, or trying to get a part made, it helps to know a bit about what’s going on behind the scenes.

So, in this quick guide, I’ll walk you through:

- What CNC machining means

- What the process looks like

- Why it’s trusted for precision and repeatability

- What to expect when you work with a CNC shop

You don’t need to become an expert.

Just get familiar with the basics—so you can make smarter decisions for your next project.

So let’s start!

1. What is CNC Machining

Are you trying to turn your product idea into a product? Need parts that match exact specs, every single time?

That’s where CNC machining comes in.

CNC stands for Computer Numerical Control. Instead of relying on hand-operated tools, CNC machines follow programmed instructions to cut, drill, or mill with precision.

CNC machining is ideal for:

- Rapid prototyping

- Small to large batch production

- Tight tolerance parts

- Metal and plastic parts that need fine details

I used to think it was just about speed. But what really matters is how it helps you stick to design specs, reduce scrap, and hit your deadlines.

And whether you’re building a new product or sourcing custom parts, understanding what CNC machining does is your first step.

2. How Does CNC Machining Work?

CNC machining works by using a computer to control cutting tools that shape raw materials like metal or plastic into final parts.

Everything starts with a digital design. This is usually a 3D model created in CAD (Computer-Aided Design) software. That model is then turned into G-code, which is a set of instructions the machine can follow.

G-code tells the machine:

- Where to move

- How deep to cut

- What tool to use

- How fast to operate

Once the code is loaded, the machine uses motors and drives to control the cutting tool and the material. The tool moves in multiple directions—left/right (X), forward/back (Y), and up/down (Z)—to carve the part exactly as designed.

The tool can cut, drill, mill, or turn depending on the type of machine and the part geometry.

CNC machining is known for:

- High precision

- Consistent repeatability

- Fast turnaround for both prototypes and production

It can use it on a wide range of materials, from aluminum and steel to plastics and composites.

The entire process is automated, but skilled operators still play a role. They handle setup, monitor cuts, and inspect parts for quality.

In short, CNC machining turns your sketch into digital file, then into a real part—accurately, consistently, and efficiently.

3. Core Components of CNC Systems

Knowing what are the components of CNC and how they work—makes it easier to understand what happens during machining.

Here are the core components:

Controller

The controller works like the brain. It reads instructions and sends signals to the rest of the machine. It processes the G-code and decides what moves to make.

If something goes wrong, the cause often comes from the controller—or from how it read the program.

Drive System

The drive system includes motors and gears. These move the machine in different directions:

- X-axis: left and right

- Y-axis: forward and backward

- Z-axis: up and down

Every move needs to be accurate—sometimes to a fraction of a millimeter. That depends on steady, reliable motion.

Machine Tool

This is the part that actually cuts, drills, or shapes the material. Depending on the job, the tool might be a spinning mill, a sharp lathe insert, or even an electric spark (like in EDM).

Tool choice matters. It affects speed, finish, and accuracy. I’ve learned the hard way that the wrong tool can ruin a good part—or wear out too fast.

Spindle (The Cutter’s Grip)

The spindle holds and spins the cutting tool.

You’ll hear things like:

- RPM (rotations per minute)

- Tool holder

- Collet

Higher RPMs help with faster, cleaner cuts—especially on soft materials like aluminum or plastic.

Understanding these parts can help you speak the same language as your manufacturer—and spot problems before they start.

4. Different Types of CNC Machining Processes

You need to know what type of CNC process your project will use before you send it to a manufacturer.

Why? Because not every machine fits every part.

Here’s a breakdown of the most common CNC machining processes we use—and what each one is best for:

CNC Milling

CNC milling uses a rotating cutting tool to remove material from a fixed workpiece. The machine moves the tool in multiple directions—X (side to side), Y (front to back), and Z (up and down).

This allows it to shape parts with flat surfaces, holes, curves, and complex profiles.

The workpiece is typically mounted on a table that either stays fixed or moves slightly depending on the machine type (3-axis, 4-axis, or 5-axis).

CNC milling is great for:

- Flat surfaces

- Slots and pockets

- Drilled or tapped holes

- Complex 3D geometries with depth and angles

Milling is one of the most versatile processes I used for both simple and highly detailed parts.

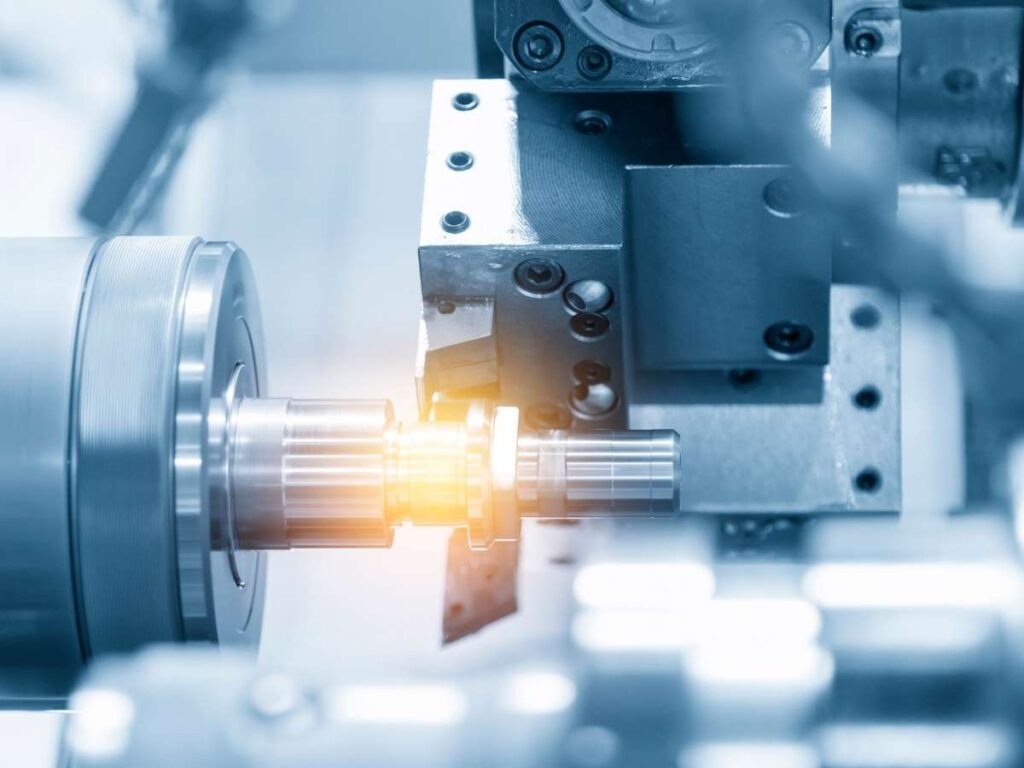

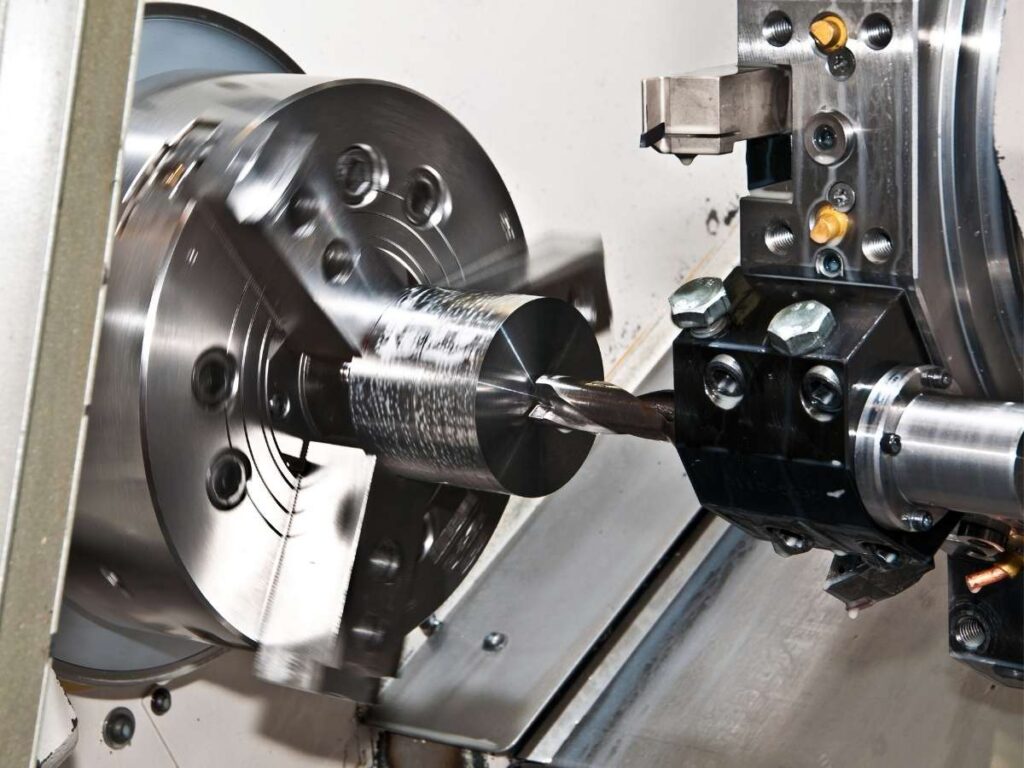

CNC Turning

CNC turning works differently from milling. In this process, the workpiece rotates while a stationary cutting tool moves along its surface.

It’s commonly used for round or cylindrical parts that need consistent shapes around a central axis. The machine can perform external cutting, internal boring, threading, and grooving.

CNC turning is great for:

- Shafts

- Bushings

- Rollers

- Tubes

- Threaded parts (external or internal)

Turning is ideal for producing round components with high accuracy, especially in medium to high volumes.

CNC Drilling

CNC drilling creates precise round holes using a rotating drill bit. The drill is aligned vertically and moves straight into the material.

Drilling can be performed on a dedicated CNC drilling machine or integrated into milling and turning setups. Hole depth, diameter, and spacing are controlled digitally, reducing errors in hole alignment and size.

CNC drilling is great for:

- Mounting holes

- Threaded holes (tapping can be done post-drilling)

- Bolt circles and hole patterns

- Electrical access holes or pass-throughs

Drilling is essential for parts that require accurate and consistent hole placement.

CNC Routing

CNC routing is similar to milling but designed for softer materials and lighter-duty applications. Routers operate at higher spindle speeds and are typically used on large sheets of material.

The machine uses a fast-moving tool to cut through flat panels with less resistance. It’s used when the part doesn’t need tight tolerances but still requires clean edges and repeatable cuts.

CNC routing is great for:

- Plastic sheets

- Acrylic and foam

- Wood and MDF

- Thin aluminum or composite panels

Routing is a cost-effective solution for cutting non-metal parts with fast turnaround and clean edges.

Choosing the right process depends on your part’s shape, material, and finish needs. Sometimes we combine two or three methods to get everything just right.

5. Materials Compatible with CNC Machining

CNC machines can handle a wide range of materials, but each one behaves differently under the tool. Some cut like butter. Others fight every millimeter of the way.

Here are the lists of materials compatible with CNC machining:

Common Metals Used

- Aluminum: It’s lightweight, easy to machine, and works well for many parts. You’ll find it useful for prototypes and structural components.

- Stainless Steel: This material is strong and resists corrosion, but it’s harder to cut. It can wear down tools fast.

- Brass: It machines smoothly and leaves a clean finish. It’s great for decorative parts or fittings. I once used it for a batch of knobs, and they came off the machine looking finished, with almost no extra work needed.

- Titanium: It’s light and extremely strong, which is why it’s used in aerospace and medical parts. But it’s expensive and difficult to machine.

Common Plastics Used

- ABS: This is a go-to option for your quick prototypes. It cuts easily, but it can melt if tool gets too hot.

- Nylon: It’s tough and slightly flexible. Just keep in mind—it absorbs moisture, and that can throw off your dimensions if you’re not careful.

- POM (Delrin): This plastic is strong, smooth, and has low friction. You’ll probably reach for it when you’re making gears or sliding parts.

Composites and Others

- Carbon Fiber Sheets: These offer high strength and low weight, but they’re rough on tools. You’ll need bits made for the job.

- G10/FR4: These are glass-filled materials often used in electronics. They’re durable, but they also wear out tools fast.

As you get more experience, picking the right material comes more naturally. You start to recognize which ones cut cleaner, last longer, or cost less.

Knowing all of these materials, you can suggest options to your manufacturer, or at least ask the right questions.

6. Applications of CNC Machining

When I started understanding how CNC worked, it was hard not to notice just how many parts in daily life were CNC-machined.

It’s used in so many industries—sometimes where it’s expected, and sometimes where it’s a surprise. Here are some of common industries that used CNC machining:

- Aerospace: In this field, every gram matters. Parts need to be light but also very strong. CNC is ideal because it can deliver tight tolerances and detailed geometries.

- Automotive: Engine blocks, brackets, and even small dashboard components often come off a CNC machine. With the ability to produce both prototypes and production parts, CNC is central to car design and repair.

- Medical Devices: Implants, surgical instruments, and housings for equipment must be both clean and precise. CNC machines can handle tight specs and fine finishes required for these parts.

- Consumer Electronics: From laptop housings to camera parts, CNC is behind many of the products people use daily. I’ve helped create phone case molds, stylus tips, and more. If you’re in this industry and looking for CNC maching services partner, choose MachMaster. We deliver fast, accurate machining and a clear focus on quality.

- Industrial Equipment: Large gears, brackets, clamps, and enclosures often start on a CNC bed. Many of these parts need to be strong, consistent, and easy to reproduce.

CNC machining shows up in more places than most people realize—making it a smart choice for businesses that need precision, speed, and repeatable results across different industries.

7. Challenges and Limitations of CNC Machining

Even though I’ve seen how CNC machining has changed the way things are made, I know it’s not perfect. Every method has trade-offs, and CNC has its own limits too.

The table below shows the challenges and limitations in CNC machining:

| Challenge | Why It Matters | Possible Solution |

| High Setup Cost for Small Orders | Setup involves programming, fixturing, and testing. For low volumes, unit cost increases. | Combine parts into a batch. Use CNC only when quality or speed justifies the cost. |

| Complex Geometry Issues | Features like deep pockets, undercuts, or internal threads can increase time or require special tools. | Work with your manufacturer early. Modify the design for machinability (Design for Manufacturing). |

| Tool Wear on Hard Materials | Cutting titanium or hardened steel wears tools faster, increasing time and cost. | Choose materials based on performance and machinability. Consider coatings or alternate metals. |

| Material Waste (Subtractive Process) | CNC removes material from a block. This leads to scrap—especially on large parts or expensive metals. | Optimize part layout. Use near-net-shape blanks or explore hybrid processes. |

| Surface Finish Limits | CNC can’t always meet super-smooth or mirror-finish specs without extra passes or polishing. | Add post-processing steps or adjust tolerances based on actual needs. |

| Soft or Flexible Material Problems | Some plastics or thin walls may deform during cutting, leading to bad tolerances or poor finish. | Choose better material grades or support structures. Consider fixturing options that reduce flex. |

| Operator Skill Dependency | Even with automation, setup and inspection need trained machinists. Inexperienced handling can cause errors. | Choose a manufacturer with strong QC processes and skilled operators. Ask for sample runs if needed. |

Seeing these limitations early has saved my projects from unexpected delays or extra costs. Each challenge can be managed with planning, design awareness, and regular communication with the machine shop.

8. Factors to Consider in Choosing CNC Machining Services

Finding the right CNC machining service can make or break your project. A good partner helps deliver parts on time and to spec. A poor fit causes delays, rework, and frustration.

Here are key factors that help assess whether a manufacturer is a solid match:

Capabilities

Not every manufacturer can make every part.

Ask:

- What machines do they use? (3-axis, 5-axis, turning centers?)

- Can they handle your material?

- Do they support both prototyping and production?

Tip: If your part has complex angles or tight tolerances, 5-axis milling might be required.

Tolerance and Precision

Ask about the tolerances they can hold. If manufacturer consistently hits ±0.005″ or better, they’ll usually mention it. It also helps to ask what kind of inspection tools they use. Calibrated gauges and documented checks show that they pay attention to accuracy.

Lead Time and Flexibility

Some suppliers can deliver parts in a few days. Others may take longer, especially on big runs or complex parts. You’ll want to ask what their typical lead times are.

If you’re working on a tight schedule, see if they offer faster options. A shop that can adjust quickly and handle last-minute changes makes your job a lot easier—especially when plans shift.

At MachMaster, fast turnaround isn’t a bonus—it’s a standard. Our team adapts quickly, communicates clearly, and gets things done without the back-and-forth.

Conclusion

CNC machining doesn’t feel so complicated anymore, right?

You’ve seen what it is, how it works, the key components involved, and how to choose a service that fits your needs.

At first, it was all technical jargon. Now, it’s a clear path forward.

We’ve supported countless businesses with their CNC projects—and we’re ready to help you too.

Got a project in mind? Let’s make it happen together.

Reach out to MachMaster today. We’ll talk through your needs and get your parts made right.

Explore More Helpful Resources

There’s more to explore! Check out our additional product selections to find exactly what you’re looking for:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.