I used to think overmolding was too complex.

The first time I considered it, I was building a small batch of handheld devices. I needed soft grips molded over a hard plastic shell. But every supplier gave me different answers—and pricing that didn’t add up.

I didn’t want to waste time or money. So I did the research myself.

That’s why I wrote this guide. I’ve worked with product designers and manufacturers who’ve used overmolding on everything from medical tools to fitness gear. I’ve seen what works—and what doesn’t.

If you’re wondering whether overmolding is right for your product, this article will help.

I’ll show you the process, step by step. You’ll see what materials work best, how the tooling is made, and what to expect at each stage.

By the end, you’ll know exactly how overmolding works—and whether it’s the right fit for your design or project.

So let’s get started!

Step #1: Mold the Base Substrate (First Shot)

Before anything gets overmolded, you need a solid base. This is called the base substrate—and it’s the first step in the overmolding process.

It gives your part its shape, strength, and structure.

If you’re molding a power tool grip or a soft medical handle, the hard plastic inside is your base.

How the Base Is Made

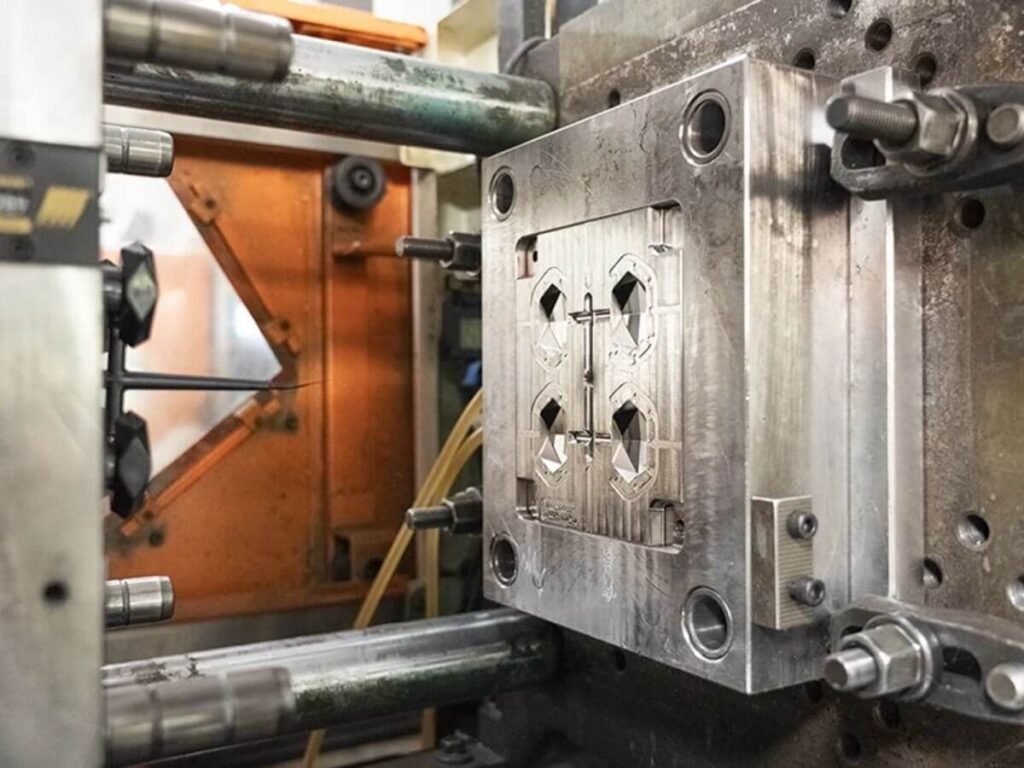

The base part is created using injection molding.

Injection molding is a process where melted plastic is pushed into a steel mold under high pressure. It cools and hardens into the shape of your design.

Common Materials

You’ll want a plastic that’s strong and bonds well with soft materials.

Some of the most common choices are:

- ABS: Tough and great for consumer goods

- PC (Polycarbonate): Clear and impact-resistant

- Nylon: Strong and resistant to wear

These work well with soft overmold materials like TPE or TPU.

At MachMaster, we handle both the base substrate and the overmolding in-house. That keeps tight control over tolerances—up to ±0.01mm—and helps prevent misalignment between layers.

Why Cooling Is Critical

After molding, the base part must cool completely.

If you try to overmold it too soon, it may still shrink or soft inside.

That can lead to:

- Poor bonding

- Warping

- Misaligned layers

I’ve made this mistake myself. On one project, I rushed to the next step to save time.

The result? Parts with bubbles, gaps, and wasted material.

Take the time to cool the base fully. Let it stabilize.

It’s not wasted time—it’s smart manufacturing.

Once your base is fully molded and cooled, you’re ready for Step #2: placing it into the overmold tool.

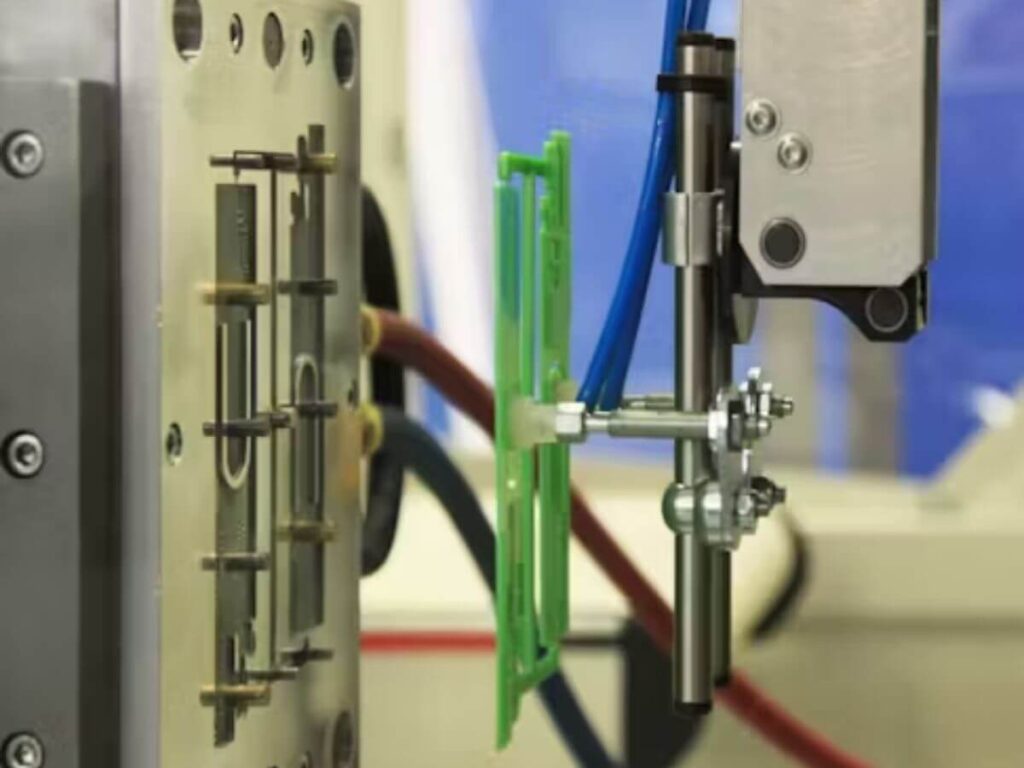

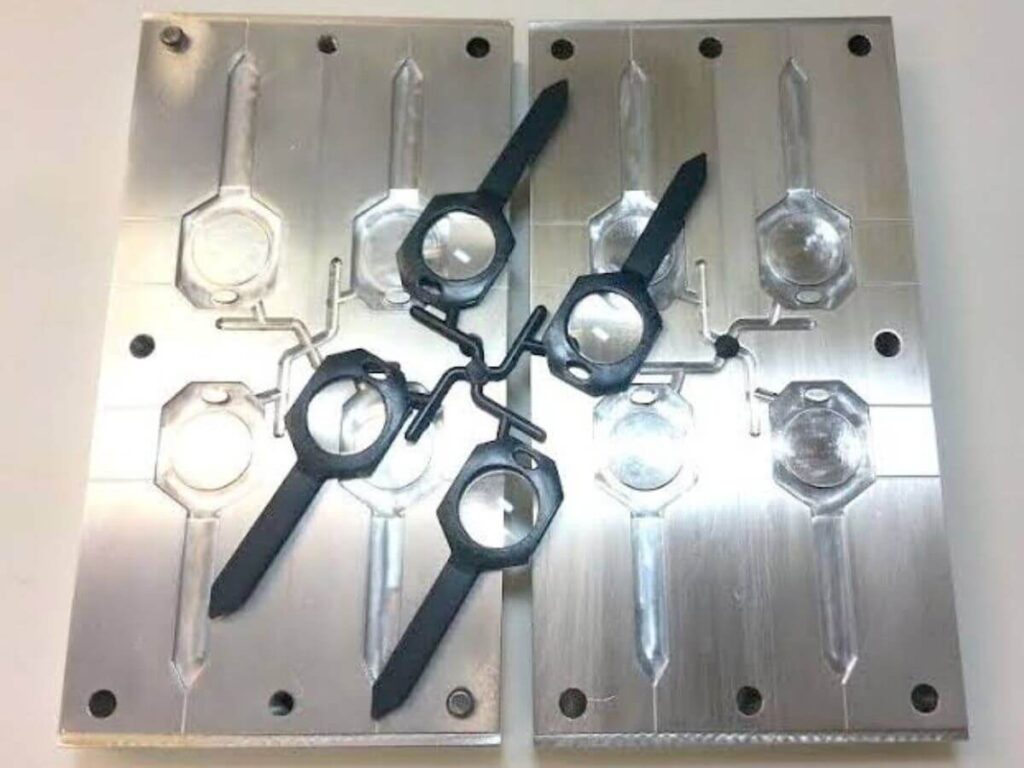

Step #2: Load the Substrate into the Overmold Tool

Now that the base part is fully molded and cooled, it’s time for the next step. You’ll place that base into a second mold. This is called the overmold tool.

The base part now acts like an insert. That insert needs to sit in just the right spot.

Manual vs. Automatic Loading

There are two common ways to load the base part into the new mold:

- Manual loading: An operator places the part by hand

- Automatic loading: A robot arm picks and places the part

Manual loading is fine for small batches or prototypes. For larger runs, robots save time and reduce placement errors. I’ve seen both methods work well. In a short production job I did for handheld fitness devices, we loaded parts manually. It took focus. One tilted insert threw off the entire overmold.

Why Alignment Is Critical

Overmolding is all about precision. If the base isn’t aligned, the soft layer won’t form cleanly. You could get:

- Gaps between the layers

- Overflow or “flashing” (extra material in unwanted spots)

- Weak bonding between materials

That’s why most molds use locator pins, alignment guides, or clamps to keep everything in place. Even a small shift—half a millimeter—can ruin a full batch.

You want the insert to be:

- Fully seated in the cavity

- Locked into position

- Centered, so the second shot flows evenly

If you’re using automation, great. Just double-check the robot’s accuracy during setup. If you’re loading by hand, go slow and pay attention to fit.

Treat the Base Like Part of the Tool

At this stage, the base isn’t just a part—it’s now part of the mold itself. The overmold tool is built around it. That’s why positioning matters so much. Once you’ve got it placed correctly, you’re ready for the next shot.

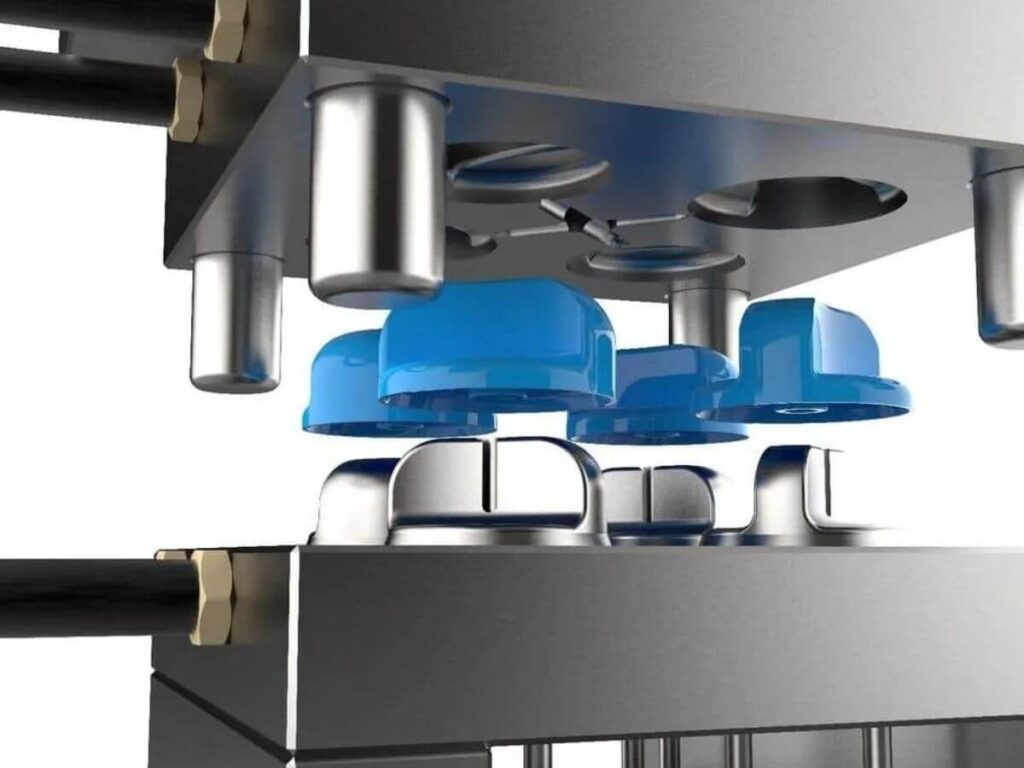

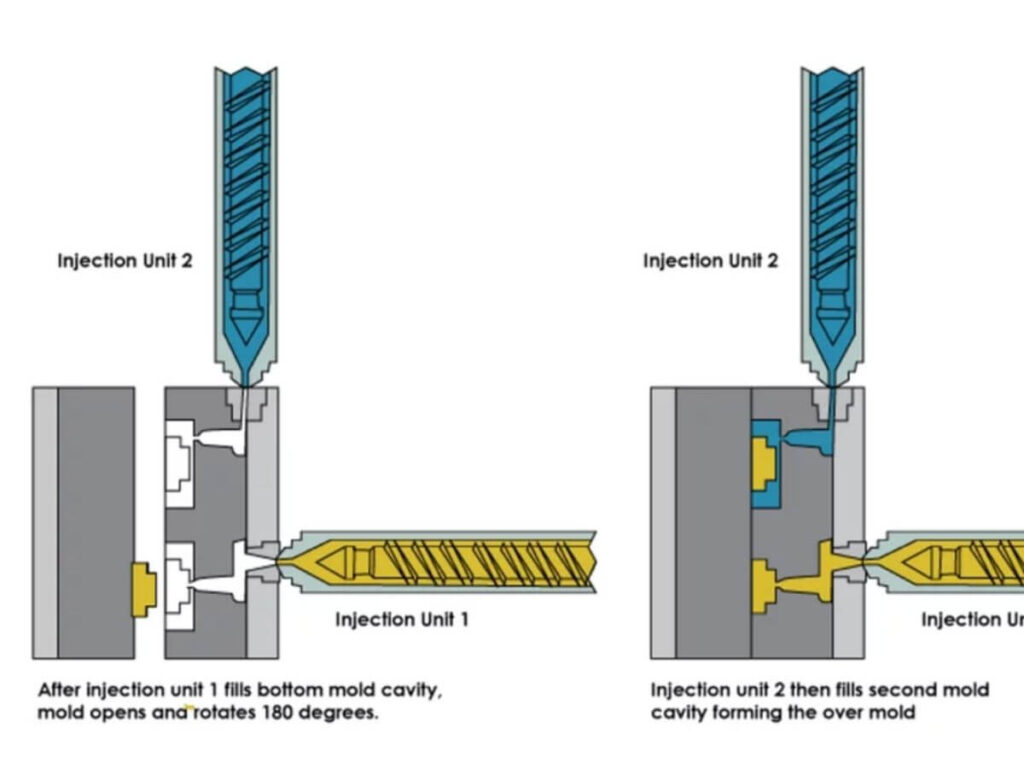

Step #3: Inject the Overmold Material (Second Shot)

Now it’s time for the second shot.

This is where the overmold material—usually soft and rubber-like—is injected over or around the base part.

This layer does more than just looks nice. It can improve grip, add comfort, or protect your product from impact or moisture.

I once worked on a wearable device that needed a soft-touch finish. The base shell looked fine, but it felt cold and slippery. After overmolding it with TPE, the whole product felt better—and users said so too.

What Is the Overmold Material?

Most second-shot materials are soft plastics, such as:

- TPE (Thermoplastic Elastomer): Feels like rubber, flexible and grippy

- TPU (Thermoplastic Polyurethane): Softer and more elastic, used for seals or padding

These materials are selected for their flexibility, durability, and bonding ability.

When injected, the soft plastic:

- Flows into detailed cavities of the overmold tool

- Bonds with the hard base (the substrate)

- Forms the soft outer layer of your part

This is how you get soft handles, protective covers, or flexible keypads.

Temperature and Pressure Matter

You can’t just run the same settings as you did in the first shot. The second shot uses lower temperatures because soft plastics melt more easily.

The pressure needs adjusting too. It has to:

- Be strong enough to fill the mold

- But gentle enough not to distort the base part

Getting this balance right helps the materials bond and form without warping or flashing.

Final Result

After the second shot cools and sets, the outer layer becomes part of the product. This is what gives it that soft grip or flexible edge.

Done right, it looks clean, feels great, and performs the way you intended.

You’re now just one step away from a finished overmolded part.

Step #4: Cool and Solidify the Overmold

Once the soft overmold material is injected, the next step is simple—but just as important.

You’ve got to let it cool and solidify inside the mold.

This might feel like a waiting game. But don’t skip it. I’ve seen parts get pulled out too early and lose their shape or develop weak spots. It’s frustrating—and totally avoidable.

Why Cooling Matters

Cooling gives the overmold its final shape and strength.

While it may look solid right after injection, it’s still soft underneath.

If you remove it too soon, you risk:

- Warping

- Surface dents

- Poor bonding between layers

The part needs time to chill, shrink slightly, and lock everything into place.

How Long Does Cooling Take?

It depends on a few things:

- Material type: Some plastics cool faster than others

- Wall thickness: Thicker parts take longer to cool

- Tool temperature: The mold itself can speed up or slow down cooling

In general, soft plastics like TPE or TPU cool faster than hard ones, but thicker layers always take longer.

Tip: Ask your material supplier for recommended cooling times. Many include this in technical data sheets

Keep It Even

The goal is uniform cooling. If one side cools faster than the other, you’ll get stress marks, warping, or air pockets. That’s why molds often use water channels or cooling lines built right into the tool.

A well-designed cooling system helps:

- Prevent uneven shrinkage

- Improve part strength

- Reduce defects and rework

On one job, we skipped proper cooling time to hit a tight deadline. The parts looked fine—at first. But after a few days, some started to bend and peel. That’s when I learned: cooling isn’t just extra time—it’s part of the process.

Let the part rest. Once the overmold is fully set, you’re ready to remove it from the mold and check the final result.

Step #5: Eject the Overmolded Part

After cooling, your part is ready to leave the mold.

This is the final step: ejection.

It sounds simple—just remove the part, right?

But this step takes care and precision. One wrong move, and you could damage all the work you’ve done so far.

How Ejection Works

Most molds use ejector pins to push the part out. These pins sit inside the mold and pop the part free once it’s cooled.

Other times, especially for small runs or delicate parts, manual removal is better. You—or the machine operator—might gently lift the part out by hand.

Either way, the key is not to force it.

Handle With Care

At this point, the base and overmold layers are bonded. But they’re still fresh. Rough handling can:

- Tear the soft overmold

- Create dents or stretch marks

- Separate the layers before they’ve fully cured

I once saw a batch of grips get ejected too fast by a worn-out pin system. The pins left circles on the soft layer, and some parts didn’t sit flat afterward. We had to scrap half the batch.

So, whether you’re using ejector pins or pulling by hand, go slow. Let the mold open fully. Give the part room to release without stress.

What You’re Left With

Now you’ve got it—your finished overmolded part.

It’s a combination of 2 materials, molded into one functional shape. The hard base gives it structure. The soft layer adds grip, protection, or flexibility.

You can now inspect it, trim any leftover flash (extra plastic at the edges), and move it to packaging or further assembly.

Tip: Some manufacturers add a post-cooling period outside the mold to help the overmold fully settle

This is the final step in the overmolding cycle.

From here, your part is ready for the real world. Whether it’s a power tool grip, a medical handle, or a protective case—it’s built to last.

Step #6: Inspect and Perform Basic Post-Processing

After molding and ejection, you’re not quite finished yet. Now it’s time to inspect the part and make sure everything looks—and works—the way it should.

Even if the mold ran perfectly, small defects could still appear. This step helps you catch them before they cause trouble later.

What to Check

Look closely at each part. You’re checking for:

- Flash: Thin layers of excess plastic along the edges

- Voids or bubbles: Air pockets inside the soft layer

- Poor adhesion: Gaps where the overmold didn’t bond to the base

These are common in overmolding. A little flash might be harmless, but too much can make the part hard to use. Bubbles can weaken the grip or ruin the look. Poor bonding? That’s a deal-breaker.

On one project, I noticed a thin gap where the soft layer peeled slightly from the hard base. It didn’t fail in testing, but the customer returned it weeks later. That’s when I started checking every part up close.

Light Post-Processing

If the part passes inspection but has minor flaws, a bit of post-processing helps clean it up.

You might:

- Trim flash using a blade or snips

- Smooth sharp edges with a fine tool

- Wipe down the surface if dust or residue is visible

For small batches, this is often done by hand. For larger runs, you might use a rotary trimmer or heated blade.

Tip: If you’re seeing the same defect on multiple parts, it could be a sign that the mold needs repair or the injection settings need tuning.

Why It Matters

This step helps you catch mistakes early.

You’ll save time, reduce scrap, and send out cleaner parts.

You don’t need high-end tools—just good lighting, a steady hand, and the patience to check each piece.

Once everything looks solid and clean, your overmolded part is ready. You’ve made it from raw plastic to a dual-material product—start to finish.

Step #7: Final Testing and Packaging

You’ve molded the part.

You’ve checked it for flash, bubbles, and bonding.

Now it’s time to get it ready for real use.

This step is all about final testing and packaging—making sure your part works the way it should before it ships out or goes into assembly.

What Does Final Testing Look Like?

Depending on your part, you might check:

- Grip or surface feel: Is the overmold comfortable to hold?

- Flexibility: Does it bend, twist, or move as expected?

- Sealing: For waterproof parts, does the overmold seal correctly?

Even basic testing can catch a lot. A twist, press, or pull by hand often tells you more than a report.

If something feels off, it usually is.

For highly regulated industries, testing goes a step further.

For medical or electronics applications, MachMaster also offers functional testing, cleanroom packaging, and surface treatment—making parts ready for end use or assembly.

These extra services help meet strict quality and compliance standards without needing third-party handling.

Next: Packaging or Assembly

Once your part passes inspection and testing, you’re ready to:

- Pack it for shipment

- Move it into the next production step

- Or store it for later use

I’ve worked on projects where every part was individually wrapped. Others were bulk-packed in trays. It depends on your product, your process, and your customer’s expectations.

Conclusion

I began this journey thinking overmolding was too complex—too many unknowns, too much conflicting advice.

But I worked through it step by step. Now, so have you.

You understand the process. You know what matters. You’re no longer guessing—you’re equipped.

If you’re ready to move forward with overmolding services, contact us today.

More Guides and Tips to Explore

We’ve got more for you! These articles provide more tips and guidance to keep you on track:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.