I once ordered some aluminum parts that looked perfect at first. Smooth finish. Nice color. But a few weeks later, they started to corrode. Fast.

It caught me off guard.

That’s how I learned the type of anodizing really matters.

Since then, I’ve spent years learning which finish works best for different uses—through trial, error, and real-life experience.

If you’re wondering which anodizing type to use, this article will help.

You’ll learn what each type is, how they perform, and when to use them. I’ll break it down by durability, cost, and appearance—so you can make the right choice the first time.

So let’s begin!

Quick Comparison Chart

Before diving deeper into each anodizing method, here’s a quick side-by-side look. This gives you a snapshot of how they compare in performance, durability, cost, and color.

| Anodizing Type | Coating Thickness | Key Features | Best For | Color Options | Durability Level | Notes |

| Type I: Chromic Acid | 0.5–1.0 microns | High fatigue resistance, good corrosion protection | Aerospace, thin-walled parts | Limited (gray) | Low–Medium | Uses hexavalent chromium, regulated use only |

| Type II: Sulfuric Acid | 5–25 microns | Color variety, moderate protection, easy to scale | Consumer goods, decorative parts | Wide range | Medium | Colors may fade in sunlight |

| Type III: Hardcoat | 25–150 microns | Very durable, wear and corrosion resistant | Industrial, military, marine use | Dark tones (gray/black) | High | May affect part dimensions due to thickness |

| Decorative Anodizing | 5–25 microns (Type II) | Aesthetic finish, smooth feel, good for light use | Electronics, home goods, fashion items | Very wide range | Low–Medium | Less durable than hardcoat |

| Integral Anodizing | 5–25 microns | Built-in metallic color, long-lasting surface | Auto trim, architecture, premium components | Bronze, black | Medium–High | Requires specific alloys |

| PEO / MAO | Various (thick ceramic) | Ceramic-like finish, extremely hard, high insulation | Aerospace, racing, harsh environments | Dull/light gray | Very High | Needs special equipment, not widely available |

Now that you’ve seen how they stack up, let’s take a closer look at each type in more detail.

1. Type I Anodizing: Chromic Acid Anodizing

I still remember the first time I worked with chromic acid anodized parts. They weren’t colorful. No shine. Just a soft gray finish. But the strength? That surprised me. The parts were built for an aircraft—and they had to hold up under serious pressure.

That’s when I learned something important: the most useful finishes aren’t always the ones that stand out.

How It Works

Type I anodizing uses chromic acid as the electrolyte. An electrolyte is a liquid that carries electricity during the anodizing process.

This method forms a very thin oxide layer on aluminum. Usually around 0.5 to 1.0 microns thick. It’s much thinner than other anodizing types. That thin layer keeps your part’s size almost unchanged—perfect for parts that need high accuracy.

Key Benefits

- Fatigue resistance: Holds up under repeated stress

- Dimensional stability: Keeps tight tolerances intact

- Non-conductive surface: Blocks electrical flow

- Corrosion protection: Offers moderate resistance to wear and moisture

Best For

- Aerospace components: Frames, skins, and lightweight parts

- Military applications: Where performance matters most

- Thin-walled or detailed parts: Shapes that can’t handle thick coatings

Takeaway Note

It has a dull gray finish, involves toxic hexavalent chromium, and is mostly used in regulated industries due to strict safety and disposal rules.

2. Type II Anodizing: Sulfuric Acid Anodizing

If you’ve ever used an aluminum phone case or seen colored trim on a car, chances are it was sulfuric acid anodized. I still remember the first batch of parts I had anodized this way. The color options blew me away. Red, black, gold, blue—you name it. It made the parts stand out without adding much cost.

But good looks aren’t the only reason this type is so popular.

How It Works

Type II anodizing is the most common anodizing method used today.

It uses sulfuric acid as electrolyte. That’s the liquid that carries electric current during anodizing.

This process builds an oxide layer that’s thicker than Type I. Usually 5 to 25 microns. That gives the surface more protection without making it too thick.

Once anodized, the part can be dyed in many colors. The color sits inside the oxide layer, not just on the surface.

Key Benefits

- Corrosion resistance: Helps protect aluminum from moisture and wear

- Color variety: Easy to add dyes to black, red, gold, blue, and more

- Affordable: Great for large batches and budget-friendly projects

- Scalable: Works well for both small parts and mass production

Best For

- Consumer products: Electronics, furniture, and auto trim

- Decorative finishes: Where color and appearance matter

- Light-duty functional parts: Items that don’t face extreme wear or stress

Takeaway Note

It offers rich color options: may fade under UV light over time: and isn’t as strong or wear-resistant as Type III hard anodizing.

3. Type III Anodizing: Hardcoat Anodizing

I once worked on a project where the parts kept wearing out. Regular anodizing wasn’t enough. The surfaces got scratched. Edges wore down. After a few months, the parts had to be replaced.

That’s when I learned about hardcoat anodizing—and it made a huge difference.

How It Works

Type III anodizing is also called hardcoat anodizing. It’s a tougher, thicker version of sulfuric acid anodizing.

This process creates a much denser oxide layer, usually 25 to 150 microns thick. That’s several times thicker than Type II.

To get this result, it needs cooler temperatures and higher electrical current during the process. The setup is more controlled, and the outcome is built for durability.

Key Benefits

- Wear and abrasion resistance: Great for parts that move, rub, or scrape

- Corrosion protection: Strong defense against water, salt, and chemicals

- PTFE options: The coating can be soaked in PTFE (like Teflon) to reduce friction

- Electrical insulation: Blocks electricity, which helps in high-voltage setups

Best For

- Industrial equipment: Heavy-use parts that face repeated wear

- High-friction parts: Shafts, pistons, or sliding tools

- Outdoor or marine use: Where saltwater or rain is a problem

- Military-grade gear: Built for long-term use in tough conditions

Takeaway Note

It creates a naturally dark finish: usually grey or black: may slightly affect dimensions due to the thicker layer: and is more expensive than Type II anodizing. At MachMaster, we often recommend hardcoat anodizing for parts that face repeated wear or harsh environments—it’s a reliable choice when strength matters most.

4. Decorative Anodizing

Some anodized parts don’t just perform—they catch your eye. A deep blue laptop body. A smooth silver phone case. A gold faucet handle that shines just right. That clean, colorful surface? That’s decorative anodizing.

It turns plain aluminum into something that looks polished and feels expensive—even when it’s not.

How It Works

Decorative anodizing is usually done using the Type II sulfuric acid anodizing process. But this version focuses on aesthetics, not heavy-duty protection.

After the oxide layer is formed, the part is dyed in your chosen color. The color soaks into the porous layer before it’s sealed. This keeps the finish smooth and gives it a permanent, vivid look.

The layer is thin—enough to add color without changing the part’s shape or size.

Key Benefits

This type of anodizing is made to look good and feel smooth. It offers:

- Color variety: Red, black, gold, blue, silver, and more

- Smooth surface feel: Clean and consistent to the touch

- Visual upgrade: Makes products look high-end, even if they’re simple

Decorative anodizing is used when appearance plays a big role in how people experience your product.

Best For

This finish is great for parts that need to stand out, especially where people see or touch them often:

- Consumer electronics: Phones, tablets, laptops

- Home goods and hardware: Fixtures, knobs, handles

- Jewelry and accessories: Watch frames, belt buckles, metal charms

If your part is visible, this finish makes it more attractive.

Takeaway Note

It focuses on appearance: offers less durability than hardcoat anodizing: color results can vary depending on the aluminum alloy and process control: and at MachMaster, we often use decorative anodizing when a part needs to stand out visually while staying lightweight and clean to the touch.

5. Integral Anodizing

Some finishes look nice at first—but fade fast. I’ve seen parts lose their color after just a few months outside. Sunlight, scratches, and wear take their toll. That’s where integral anodizing stands out. It gives you a metallic look that lasts—because the color is part of the metal itself.

How It Works

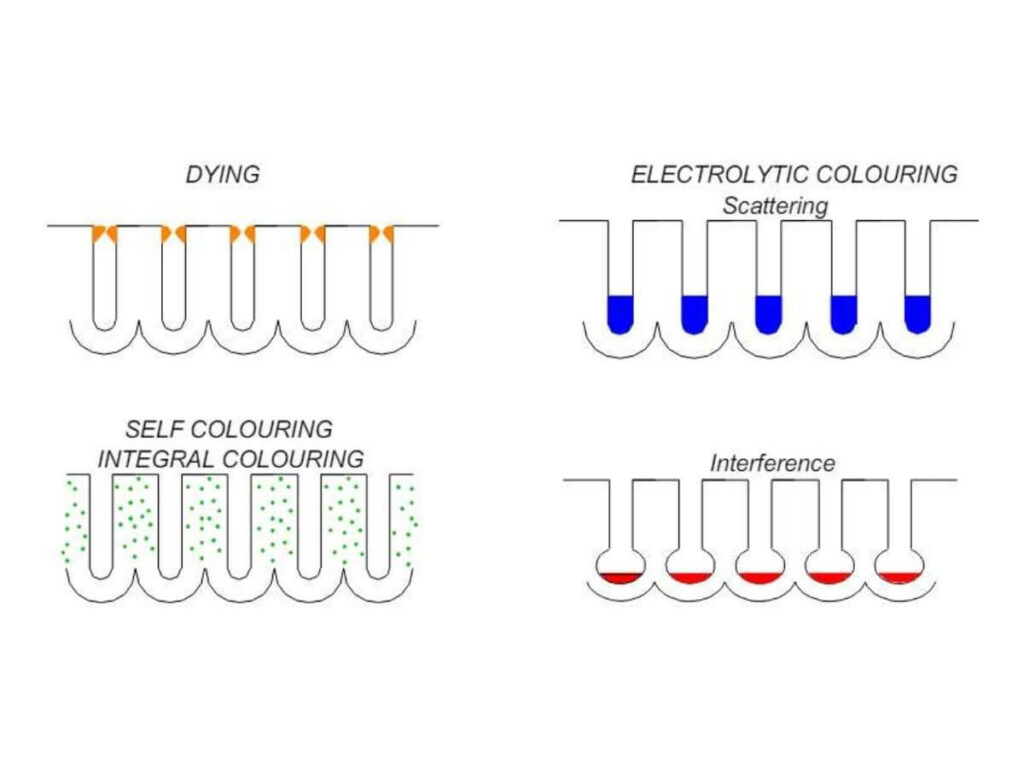

Integral anodizing combines anodizing and coloring in one step.

As the oxide layer forms on the surface, color develops inside the layer—not on top of it. That’s what makes it different from other dyed finishes.

The process uses higher current and specific aluminum alloys. And instead of applying dye afterward, the color builds along with the coating. It creates a rich, metallic tone that feels deeper and more natural.

Key Benefits

- Fade-resistant color: Built into the metal, not applied on top

- High durability: Strong coating that stands up to time and weather

- Scratch and wear resistance: Great for surfaces that get touched or rubbed often

Best For

- Automotive trim: Door handles, nameplates, interior details

- Architectural parts: Window frames, railings, panels

- High-end decorative components: Items that need both beauty and toughness

Takeaway Note

It delivers deep, built-in color: typically limited to bronze and black tones: costs more than regular decorative anodizing, and requires specific aluminum alloys to work properly.

6. Plasma Electrolytic Oxidation (PEO / MAO)

“Is this even aluminum?”

That’s what I thought the first time I held a part treated with Plasma Electrolytic Oxidation, also called PEO or Micro-Arc Oxidation (MAO). The surface felt more like stone than metal. Hard. Solid. Like it was built to survive just about anything.

This process is different from regular anodizing. It’s on a whole other level.

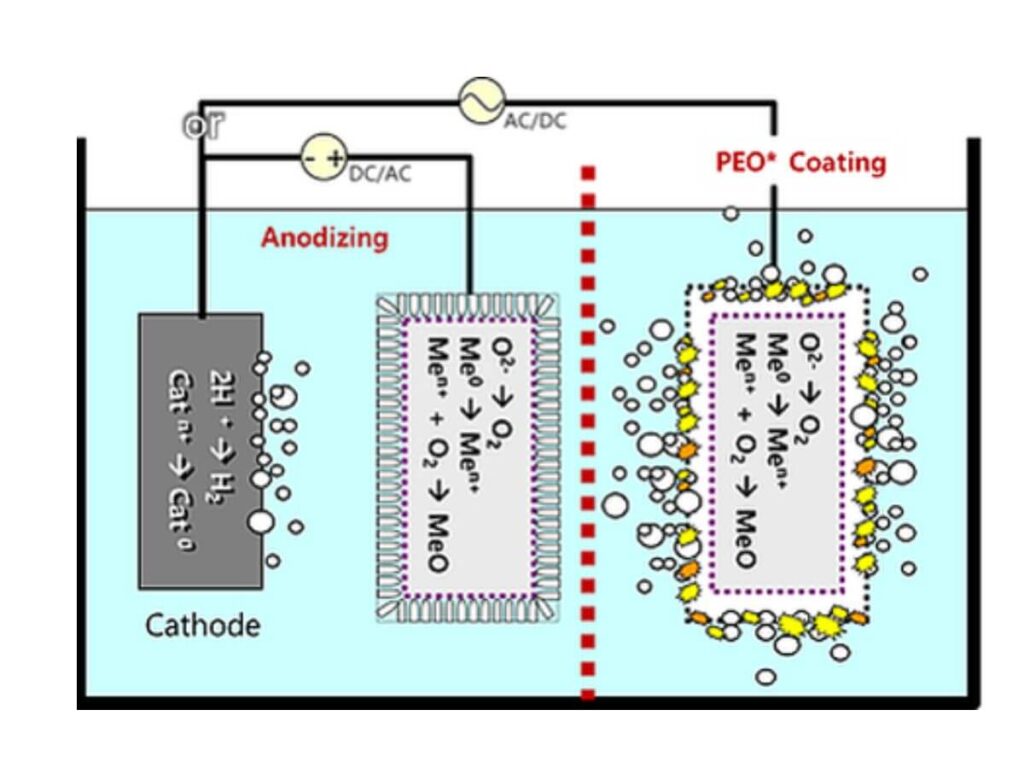

How It Works

PEO uses high-voltage electricity to transform the metal surface into a ceramic-like coating.

As the current runs through the electrolyte bath, tiny sparks—or micro-arcs—form on the surface. These sparks create heat and pressure, which build a strong, thick oxide layer.

The result? A surface that’s harder and more resistant than standard anodizing. And it works on more than just aluminum—you can also apply it to magnesium and titanium.

Key Benefits

PEO is made for extreme conditions. If you’re working on parts that face heat, friction, or stress, this finish delivers:

- Extreme hardness: More resistant to wear than other anodizing types

- High dielectric strength: Works well for electrical insulation

- Thermal resistance: Stays strong even under high temperatures

- Multi-metal use: Works on aluminum, magnesium, and titanium

Best For

- Aerospace and defense: Parts exposed to pressure, heat, and vibration

- Motorsports: High-friction, high-speed components

- Harsh environments: Anywhere regular coatings wear out too fast

Takeaway Note

It creates a ceramic-like finish: costs more than standard anodizing: needs special equipment: and isn’t available from every shop.

Conclusion

You’ve now seen what each type offers. You know which finish fits tight spaces, harsh weather, or stylish products.

The right surface isn’t just a detail—it’s part of your product’s success.

What’s holding you back?

Start now. You don’t need to guess.

Contact us today to get expert guidance for your next project.

Recommended Reads for You

If you need more options, take a look at our full range of products. You might find just what you need:

Interested in more? Here are some additional articles with insights and tips to keep you informed:

- Anodizing Type II: What You Must Know

- Type 2 vs Type 3 Anodizing: What’s the Real Difference?

- Type 2 Anodize vs Type 3: What’s the Real Difference?

- Anodized vs Non Anodized: A Comparison Guide

- Anodized Aluminum vs Non Anodized: What’s the Difference?

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.