I used to “guess” my way through plastic part production.

Sometimes it worked. Other times, I ended up with warped parts, long delays, or higher costs than planned.

One project almost didn’t launch because I misunderstood how the tooling process worked.

I approved the wrong design, the mold had to be redone, and the launch was pushed back by two months.

That’s why I wrote this article for people like you who are making real product decisions and don’t have time to figure it out the hard way.

You’ll learn:

- What plastic injection molding is

- How it works step-by-step

- What matters during design, sourcing, and production

By the end, you’ll have the tools to choose the right supplier, ask better questions, and avoid the mistakes I made.

Let’s begin!

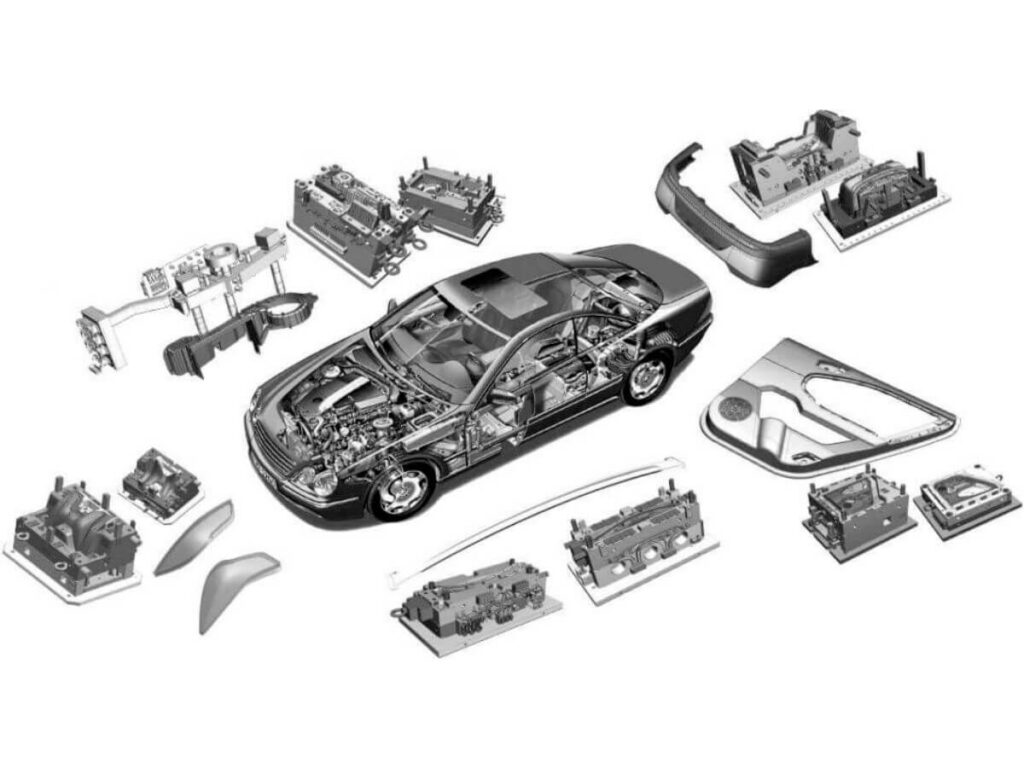

1. What Is Automotive Plastic Injection Molding?

Before I worked with molded parts, I used to think all plastic parts were just pressed or poured into shape. I had no idea how much went into making a dashboard clip or a seatbelt cover. But once I saw the process myself, it all made sense.

Let’s break it down together.

Plastic injection molding is a process that shapes plastic by injecting hot, melted material into a mold.

Think of it like baking, you pour batter into a cake mold, let it cool, and pop out a finished shape. This works the same way but with plastic.

Here’s how it works:

- Plastic pellets are melted inside a machine.

- The molten plastic is forced into a metal mold under high pressure.

- After cooling, the mold opens, and the part comes out.

It sounds simple. But this process can produce everything from small clips to large panels—fast and with repeatable accuracy.

You’ve probably seen injection molded parts in:

- Car dashboards

- Center console buttons

- Interior panels

- Under-the-hood components

Now that you know what it is, let’s talk about why automakers use it so much.

Automotive plastic injection molding is everywhere because it works well for large-scale production.

Here’s why:

- You get consistent parts, every single time.

- Plastic is lightweight, which helps improve fuel efficiency.

- The molds are expensive at first, but they save money over thousands or even millions of parts.

That’s why it’s a top choice for companies looking to scale. Once the mold is ready, the parts just keep coming.

Ever wondered why some suppliers push injection molding for even small components? It’s because of that repeatability. The process gives you the same quality, over and over again.

Understanding this process gives you an edge. You can ask better questions, evaluate suppliers clearly, and avoid missteps that waste time or money.

2. How the Injection Molding Process Works (Step-by-Step)

The first time I visited an injection molding facility, I was surprised. I expected something slow and noisy. What I saw was smooth, fast, and precise.

Knowing how the process works can help you talk with suppliers, make better design decisions, and avoid costly surprises. Let’s walk through it step by step.

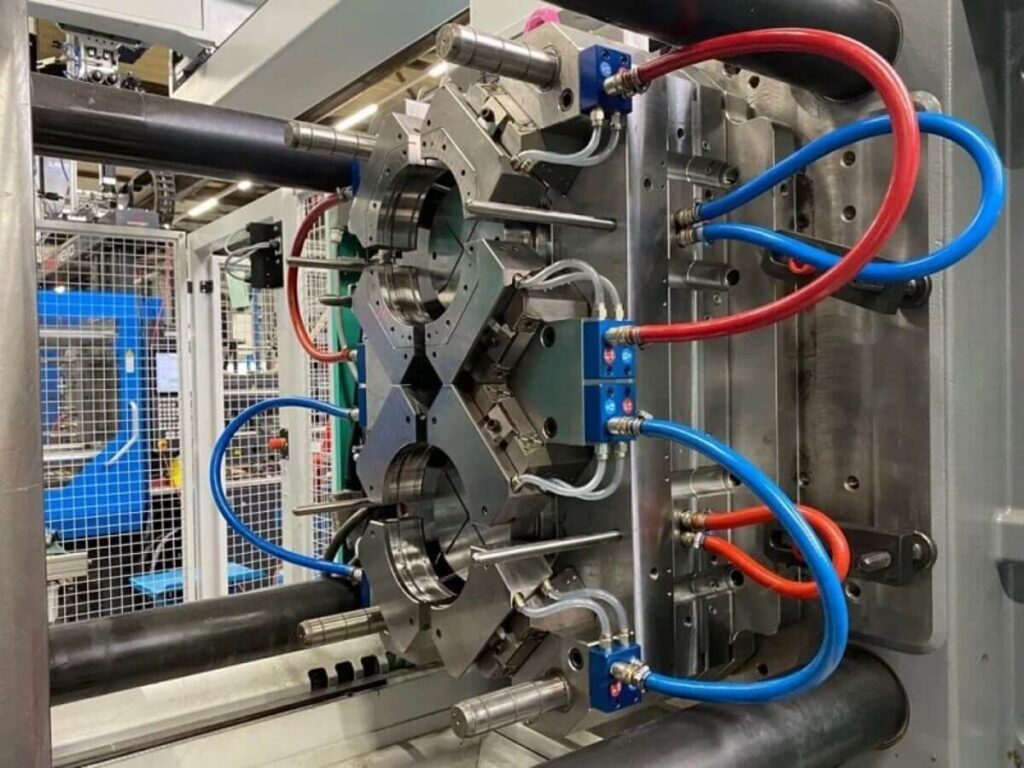

Mold Design

Before anything is molded, the design starts in CAD software. CAD stands for Computer-Aided Design. This is where your part begins to take shape.

But it’s not just about how the part looks. The mold also needs:

- Cooling channels: to help the plastic solidify evenly

- Ejection pins: to push the part out

- Gates: to control how the plastic enters the mold

Another key decision: the mold material. Steel lasts longer than aluminum, which makes it better for high-volume production.

Material Selection

The type of plastic you choose matters a lot. Here are some common choices:

- ABS: used for dashboards and trim

- Nylon: strong and heat-resistant, good for gears

- Polypropylene: flexible and used in bumpers

- PC (polycarbonate): clear and tough, often used in lighting

Think about what the part will face. UV rays? Engine heat? Chemicals? Your plastic needs to handle it.

Melting and Injection

Next, plastic pellets are melted into a liquid. Then, they’re injected into the mold under pressure.

This part is quick:

- Small parts might take seconds

- Larger parts can take a minute or more

It’s like filling a mold with hot syrup. It flows fast, and every second counts.

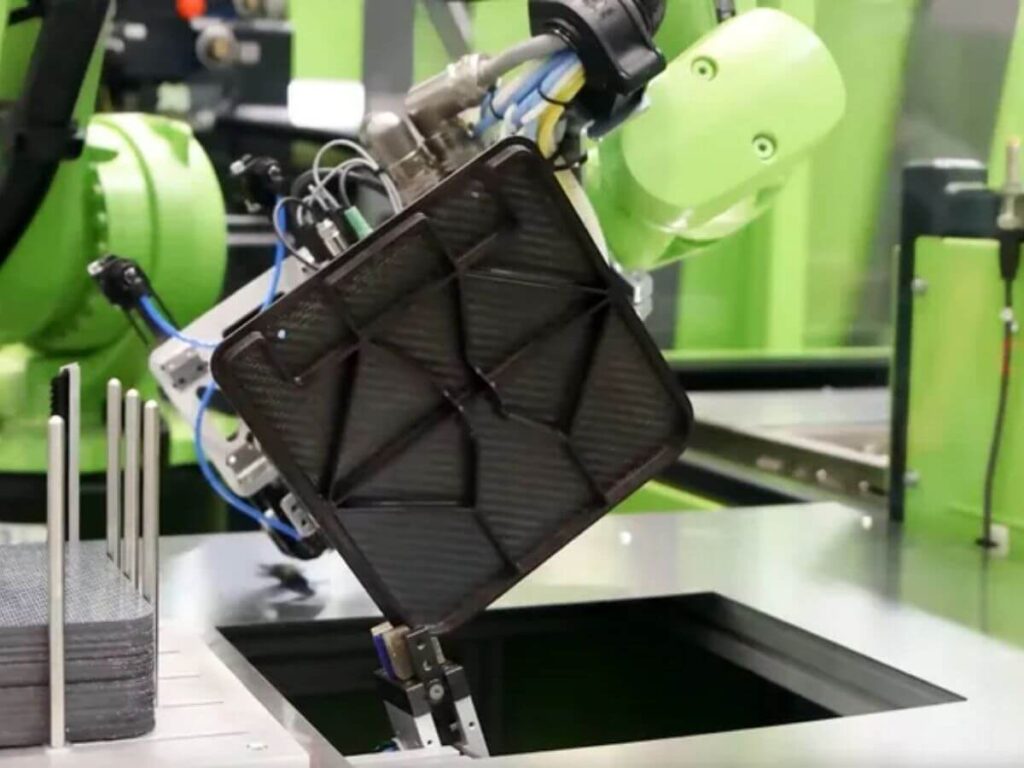

Cooling and Ejection

Once the plastic is inside, it needs to cool.

Cooling matters more than most people think. If the part cools too fast or unevenly, it can warp or shrink.

After it hardens, ejection pins push the part out of the mold.

Trimming and Quality Checks

Some parts come out with extra plastic around the edges. That’s called flash.

Workers trim the flash, check the part’s shape, and make sure it meets the specs.

Some companies use machines to check dimensions. Others still rely on skilled eyes and hands.

3. Is Injection Molding Right for Your Automotive Project?

Every project has trade-offs. I learned that while working on a custom part for an EV startup. We needed 10,000 interior clips. I thought 3D printing would be faster. It was—for the first 20. But then production slowed, quality dropped, and costs crept up. That’s when I realized we picked the wrong process.

So how do you know if injection molding fits your needs?

Let’s look at what it does well and where it doesn’t work.

Key Benefits for Automotive Applications

Injection molding shines in automotive for a few big reasons:

- High-volume repeatability: Every part comes out the same, even after 100,000 cycles.

- Tight tolerances: You can get precision up to ±0.01 mm.

- Design flexibility: Add clips, ribs, or complex shapes without needing multiple parts.

- Lightweight: Plastic can replace metal in many cases, reducing overall vehicle weight.

These benefits make it a favorite in large production runs.

Limitations You Should Know

But there are downsides.

- High upfront cost: The mold is expensive to build.

- Long lead time: It can take 4–12 weeks to make the mold.

- Not flexible: If you want to tweak the part later, you might need a whole new mold.

If your design is still changing, or your volume is low, this might not be the best fit.

Use Cases Where It Works Best

You’ll get the most value from injection molding in these situations:

- Mass production: Interior panels, buttons, housings, clips.

- Realistic prototypes: Need a production-grade sample for testing? This works.

- Structural components: Reinforced plastics can handle stress where metal isn’t needed.

Still wondering if it’s the right path? Just remember: if you need a lot of identical, high-quality parts, it probably is.

4. Design for Manufacturability (DFM): Tips for Product Designers

I’ve made a few design mistakes that looked great on-screen… but failed in production. One part had walls so thin it warped during cooling. Another had sharp corners that cracked under pressure. It’s frustrating to watch your design fall apart literally.

That’s why understanding Design for Manufacturability (DFM) is so important. It helps you design parts that don’t just look good, but work well in injection molding.

Common Design Mistakes

Before you jump into production, it helps to know what usually goes wrong:

- Undercuts: These are shapes that block part removal from the mold. They often need extra tooling, which adds cost.

- Thin walls: These can warp or sink during cooling. Uniform wall thickness is key.

- Sharp corners: They create stress points. That’s where cracks start under pressure or impact.

Sound familiar? These issues are easy to miss until they show up in your molded part.

Tips to Optimize Your Part

Good design isn’t just about appearance. It’s about how easily and cleanly your part comes out of the mold. Try these tips:

- Add draft angles: A 1–2° angle on vertical walls helps the part release smoothly.

- Use consistent wall thickness: This reduces cooling time and keeps the shape stable.

- Add ribs: Ribs give your part strength without needing thick walls, which can cause defects.

These small changes can make a big difference in cost and quality.

What to Discuss with Your Manufacturer

Once your design is close, talk through the details with your supplier. Ask about:

- Gate placement: This affects how plastic flows into the mold.

- Parting line visibility: This line shows where the mold splits. It might impact your part’s appearance.

- Surface finishes: Matte, gloss, or texture? Pick what fits your function and look.

DFM isn’t just about avoiding mistakes. It’s about setting your part up for success—right from the start.

5. Prototyping vs. Production

Every project needs a test run. I’ve rushed into full production before, and it ended with changes I could’ve caught earlier if I had just prototyped properly.

Let’s look at the options that help you build smarter before going all in.

Prototyping Options

If your design still needs refining, start with quick-turn solutions:

| Option | Best For | Pros | Cons |

| 3D Printing | Early-stage prototypes | Fast, cheap, easy to change | Not always material-accurate |

| Aluminum Molds | Short runs (100–500 parts) | Closer to final product, real-world testing | Higher cost than printing |

These tools help you find problems early—before they get expensive.

Transitioning to Mass Production

Once your prototype works and you’ve tested it in real use, you can prepare for larger volumes:

- Use short runs to test fit, function, and even market reaction

- Finalize your mold only after those checks are complete

- Make adjustments while you still can

Need a step between prototyping and full production? That’s where bridge tooling fits in.

Bridge Tooling Strategy

Bridge tools are temporary molds, usually aluminum. They’re useful when:

- You want real parts fast

- You need production-quality testing

- You’re not ready to commit to a steel mold

This gives you flexibility and saves you from overcommitting too early.

A smart build process doesn’t skip steps, it learns from them. Starting small can lead to better, faster production later.

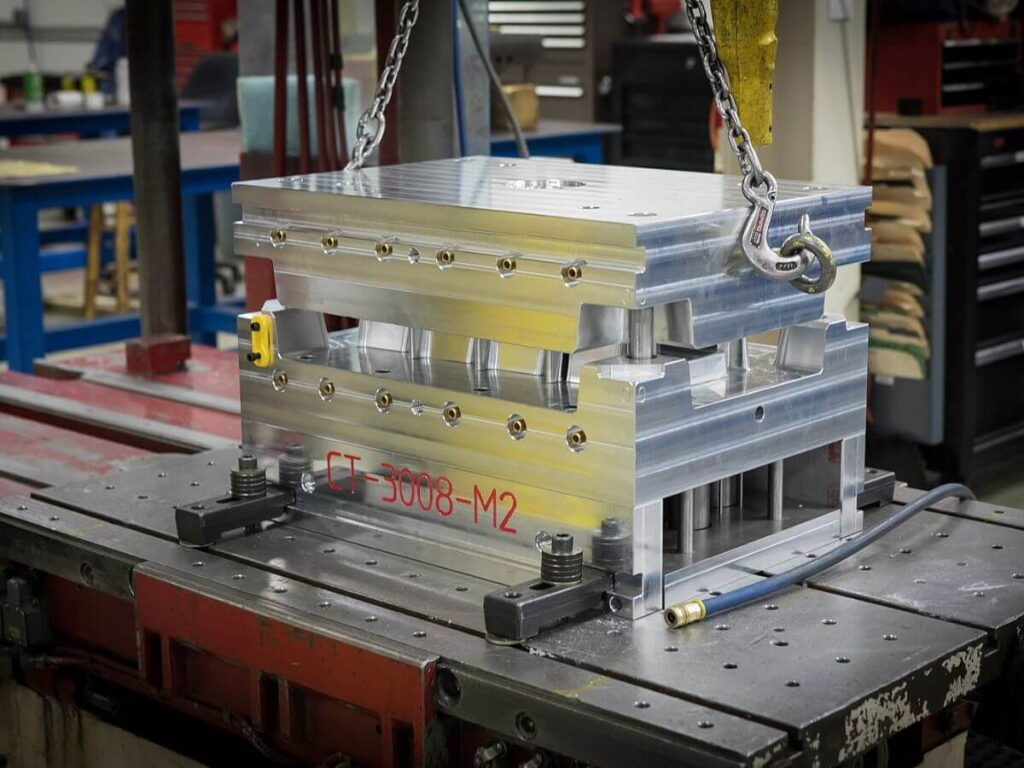

6. Mold Tooling: What Business Owners Need to Understand

Tooling decisions can make or break your production budget. I learned this the hard way on a project where the mold cost more than the first 10,000 parts combined. The quote made sense later but in the moment, I wasn’t ready for it.

If you’re planning a new part, understanding mold tooling is one of the most important steps you can take.

Types of Molds

There are two main types of molds used in plastic injection:

- Steel molds: Long-lasting and made for high-volume production. They’re more expensive upfront but can handle hundreds of thousands of cycles.

- Aluminum molds: Cheaper and faster to produce. Great for short runs, prototyping, or testing before full-scale production.

So, what’s your production volume? If you’re unsure, you might want to start with aluminum and switch later.

Tooling Lead Times

Time matters too. Here’s what to expect:

- Prototype molds: Usually take 2–4 weeks to build

- Production molds: Often take 6–12 weeks depending on complexity

Ask early. Long lead times can delay your launch if you don’t plan ahead.

Tool Ownership and Reuse

Here’s a question many forget to ask: Do you own the mold once it’s made?

Ownership impacts your ability to:

- Reuse the tool for future orders

- Move it to another supplier if needed

- Make minor changes without starting over

Some tools can also serve multiple part numbers or SKUs, which saves money long-term.

Think of the mold as an investment. The more you understand it, the more control you’ll have over your production.

7. What Procurement Professionals Should Look For

I once approved a supplier based on a clean quote and fast lead time. On paper, it looked great. But halfway through production, we hit delays. Turned out they didn’t have ISO certification, couldn’t trace materials, and didn’t follow automotive documentation standards.

That was a painful lesson. One I hope you can avoid.

If you’re sourcing injection-molded parts for automotive use, asking the right questions matters more than anything.

Key Questions to Ask a Molding Supplier

Start by getting clear answers to these:

- Do you have ISO 9001 or IATF 16949 certification? These show the supplier follows quality management systems.

- What’s your mold lead time and part turnaround? You’ll need this to plan your production timeline.

- Can you support PPAP or other automotive documentation? This is standard in many auto projects.

- Do you offer material traceability? It helps track issues back to their source if problems show up later.

If a supplier can’t answer these, that’s a red flag.

Want a supplier who understands precision, deadlines, and documentation? MachMaster offers ISO 9001-certified production with ±0.01 mm tolerances plus full traceability and responsive support every step of the way.

Price Factors

Next, break down the cost.

- Mold/tooling cost: This is a one-time setup cost. It’s usually the biggest line item.

- Per-part cost: Based on material, size, and how long it takes to mold.

- Volume discounts: Ask how pricing changes as your order size grows.

A cheap part might seem attractive—until hidden costs show up.

How to Evaluate a Quote

When comparing quotes, don’t stop at the total.

- Check for hidden costs: Like mold maintenance or file revisions.

- Ask about mold ownership: Will you own it, or are you locked in with that supplier?

Clarity now saves you problems later. Ask questions early, and don’t be afraid to push for specifics. Your supply chain depends on it.

Conclusion

I told you about the time I passed on a supplier because I didn’t understand injection molding.

That mistake cost me time and money.

Now you know what I didn’t.

- What injection molding is

- How the process works

- Where it fits best

- What to ask

- And how to move from prototype to production

So, what’s next?

Start now. Take your design. Ask the right questions. Avoid the guesswork I went through.

Your next step is simple, reach out to a manufacturer who speaks your language.

Need help reviewing a design or supplier quote? Contact us today.

Explore Related Resources

Want to see more? We’ve gathered additional product choices to give you even more variety:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.