A while ago, I took on a project that needed precision curves and deep pockets.

I thought 3-axis would do the trick. It didn’t. The finish was rough. Angles were off. The customer wasn’t happy.

So we switched to 5-axis. One setup. Clean surface. Perfect fit.

I’ve made mistakes, but we’ve also helped factories avoid them. Now, clients ask us first, because they know we’ve been there.

This article will help you avoid that same learning curve.

You’ll learn what 5-axis CNC machining really is, how it works, and when it makes sense. We’ll compare it to 3-axis and talk about costs, lead times, and setup differences.

I’ll give you the tools to make the right call, for your part, your timeline, and your business.

So let’s get started!

1. What is 5 Axis CNC Machining

5 Axis CNC Machining is a way to cut and shape parts using a machine that moves in five directions.

Most basic machines move in 3:

- Side to side

- Front to back

- Up and down

A 5-axis machine adds 2 more:

- It can tilt

- It can rotate

This gives you more control and lets the tool reach more angles in one go.

It’s often used to make complex parts, things with curves, sharp angles, or details on multiple sides.

You don’t need to stop the machine to flip the part. You don’t need lots of setups.

It saves time. It improves accuracy. And it can reduce costs.

We’ve used 5-axis for years in our own work. When a part is tricky or needs to be just right, it’s the method we trust.

If you’re looking for a shop that offers this kind of precision, MachMaster does 5-axis CNC machining and knows how to get it right.

2. How 5 Axis CNC Machining Works

At first, 5-axis machining might sound complex. But when you break it down, it follows a clear, logical process.

There are 3 key parts to how it works: how the machine moves, how the software tells it what to do, and how each job gets set up and run.

Let’s walk through each one.

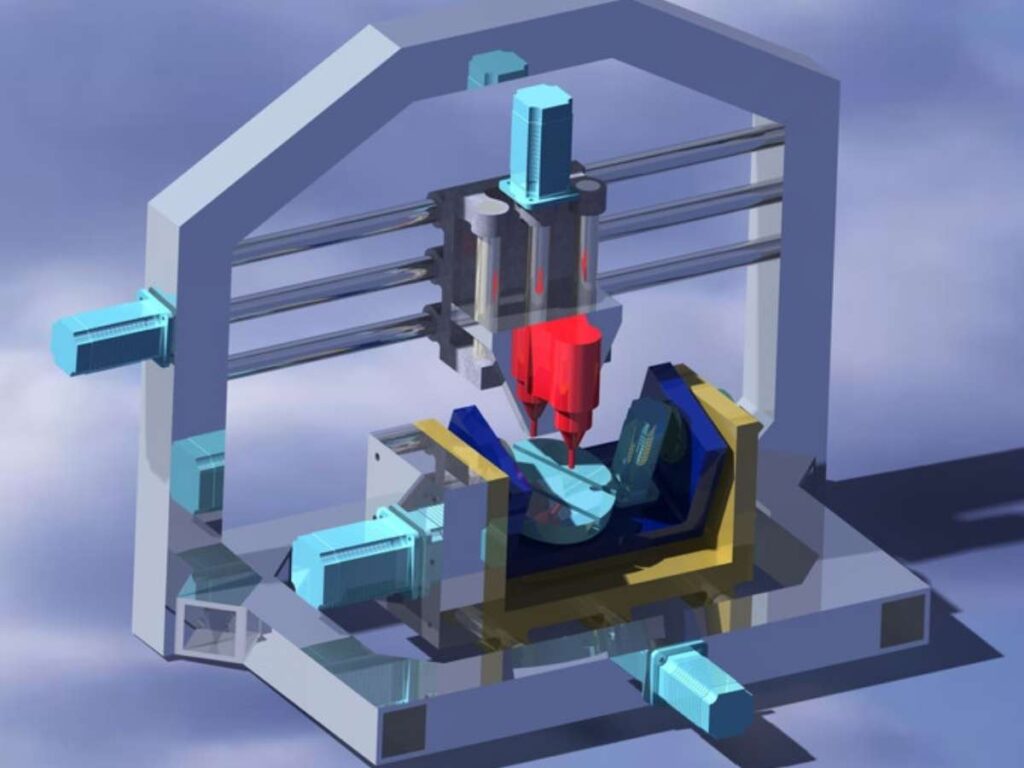

The Movement System

A 5-axis machine moves the tool or part in five directions:

- X-Axis: Left and Right

- Y-Axis: Front and Back

- Z-Axis: Up and Down

- A-Axis: Tilt Around the X-Axis

- B-Axis: Rotate Around the Y-Axis

Imagine holding a part in your hand and turning your wrist to get the right angle, that’s basically what the machine does, but with cutting tools.

There are 2 common types of 5-axis machines:

- Rotary Table (Trunnion Style): The part sits on a table that rotates and tilts

- Tilting Head: The tool itself moves and changes angles during cutting

Both types help you reach more angles in one setup. We’ve used both in our shop, and the choice depends on the part’s size and geometry.

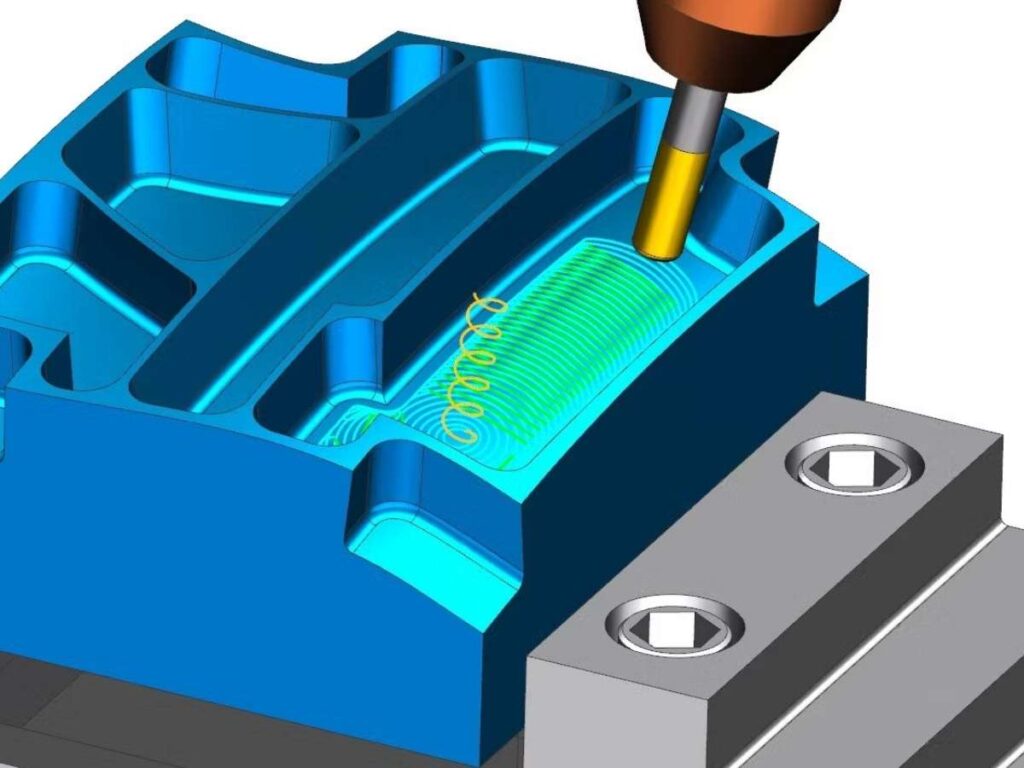

CAM Software & Programming

Before the machine can cut anything, it needs instructions.

That’s where CAM software comes in. (CAM stands for Computer-Aided Manufacturing.)

Here’s how it works:

- 3D Model: The Part Is Designed Using CAD Software

- Toolpath Creation: CAM Software Builds a Step-by-Step Cutting Plan

- Machine Control: The Software Sends Instructions to the CNC Machine

Common programs include Fusion360, MasterCAM, and HyperMill. These are powerful, but the user experience can stay simple if your model is clean and well-prepped.

You don’t need to understand the code behind it.

Just know that your part gets made by following a digital roadmap.

How a Job Is Set Up

Once the programming is done, the shop gets ready to run the job. The setup matters just as much as the design.

Here’s what happens:

- CAD Design: The 3D Part File Is Prepared

- CAM Setup: Toolpaths Are Programmed in the Software

- Toolpath Review: Speeds, Angles, and Cut Order Are Adjusted

- Fixturing: The Part Is Clamped Securely in Place

- Machining: The Job Is Running on the 5-Axis CNC Machine

You usually only need one setup. That means fewer handling steps, fewer chances for error, and tighter tolerances across the whole part.

3. Key Advantages of 5 Axis CNC Machining

So what does all that movement actually get you?

If you’ve ever dealt with long lead times, part misalignment, or multiple setups just to cut all sides of a part, 5-axis solves a lot of that. It’s not just about more motion. It’s about less waste, tighter tolerances, and faster results.

Let’s walk through the biggest benefits.

Fewer Setups, Fewer Mistakes

One of the biggest headaches in traditional machining is flipping the part. Every time you reposition it, you open the door to error. Even a small shift can throw off hole alignment or surface flatness.

With a 5-axis, the machine moves around the part. You don’t need to stop and re-fixture.

That alone saves time, and removes a major source of mistakes.

We’ve seen jobs that would normally need four setups get done in one. The result? Fewer inspection issues and cleaner results, even on tight-tolerance parts.

Reach Hard-to-Access Features

Some parts just aren’t made for 3-axis. They have curved surfaces, deep pockets, or angled holes that a straight tool can’t reach from the top.

5-axis machining solves this by letting the tool come in at an angle. It can cut from the side, the bottom, or even inside a tight space, without flipping the part around.

I remember a housing we worked on that had angled channels deep inside. No matter how we looked at it, 3-axis couldn’t do it cleanly. One pass with a 5-axis, and the issue was gone.

Better Surface Finish

With a 5-axis, the tool stays closer to the surface. It follows the shape of the part with smoother movements. That helps avoid sharp tool entries and exits.

You get fewer marks. Less cleanup. A better finish straight off the machine.

For many of our clients, this means skipping a second process like polishing or grinding, saving even more time and money.

Shorter Lead Times

Because you’re cutting more in one go, 5-axis often means faster jobs. No extra fixtures. No retooling. Just a better flow from start to finish.

That doesn’t mean every job is instant. But when you cut out 2 or 3 setups, the time adds up fast. Especially if you’re on a deadline.

4. Materials Compatible with 5 Axis CNC

One of the best things about 5-axis CNC machining is its flexibility.

It works with a wide range of materials, from soft plastics to tough metals.

That means you can choose the right material for your part, not just the one the machine can handle.

Metals That Work Well

If you’re working with metal, you’re in good hands. 5-axis machines are built to handle high-strength materials with precision.

Here are some of the most common:

- Aluminum: Lightweight, easy to machine, and cost-effective

- Stainless Steel: Durable, corrosion-resistant, great for functional parts

- Titanium: Strong and light, often used in aerospace and medical applications

- Brass: Soft, stable, and easy to cut, great for fittings and connectors

We’ve machined all of these in-house. Some materials take longer or need different tools, but the machine can handle them.

Plastic and Other Non-Metals

5-axis isn’t just for metals. It also works well with:

- ABS: A common plastic for enclosures

- Nylon: Strong, wear-resistant, and flexible

- PEEK: High-performance plastic for aerospace and medical use

- Acrylic: Clear and lightweight, good for covers and panels

These materials are often used for prototypes, housings, or lightweight parts.

5. Design Tips for 5 Axis CNC

Designing for 5-axis machining gives you more freedom, but it also needs a bit more thought.

The machine can do a lot, but clean results start with smart design.

Here are a few tips we always share with our clients.

Avoid Deep Narrow Pockets

Long, skinny pockets are tough, even for 5-axis. The deeper the pocket, the more likely you’ll run into chatter, tool deflection, or finish issues.

If your part needs a deep pocket, add a bit of tape if you can. Even 1 or 2 degrees helps the tool stay stable and cut clean.

Use Draft Angles Where It Makes Sense

If your part has vertical walls, think about adding a slight angle. This helps the tool move in and out more smoothly, especially on internal features.

It’s not required, but it can improve finish and make toolpaths more efficient.

Send Clean 3D Models

The better your model, the better your part.

Use proper file types like STEP (.step) or IGES (.igs). Avoid messy or overly detailed files that slow down CAM programming.

We’ve had jobs delayed just because the model had extra bodies or broken edges. A clean file saves time on both ends.

Know Your Tolerances

Tighter tolerances mean more time, and more cost. If a feature doesn’t need ±0.01 mm, don’t call for it.

Be honest about what really matters, and where there’s room to loosen up.

We’ve seen parts come in with tight tolerances on cosmetic surfaces. That just adds cost without any benefit.

6. Limitations and Challenges to Consider

5-axis CNC machining is powerful. But like any tool, it has its limits.

Before you commit, it’s important to understand what could slow things down, or drive up cost. We’ve seen clients get surprised by these. You don’t have to be one of them.

Higher Machine and Setup Cost

5-axis machines are more advanced. They cost more to buy, and they take longer to program and set up.

That doesn’t mean every 5-axis job is expensive. But if your part is simple, the 3-axis might be faster and cheaper.

Sometimes we tell clients, “You don’t need 5-axis for this.” That honesty builds trust, and saves them money.

Not Every Part Needs It

Just because you can cut it on a 5-axis machine doesn’t mean you should. Flat parts, single-sided features, or basic holes might be better handled with simpler tools.

We’ve seen parts over-engineered to fit 5-axis, when a basic setup would’ve done the job faster.

Always ask: Is this part truly complex? Or just familiar?

Long Lead Times on First Runs

For brand-new parts, expect more time upfront.

The CAM work, tool selection, and test runs all take longer, especially if the design is complex or unproven.

Once it’s dialed in, things move quickly. But the first one always takes the most effort.

7. How to Choose a 5 Axis CNC Machining Partner

Choosing the right shop makes all the difference.

Even with a great design and material, your part depends on who’s running the machine.

We’ve worked with customers who came to us after getting burned elsewhere, poor tolerances, late deliveries, or just bad communication.

Here’s what to look for in a good 5-axis CNC machining partner:

Look for Real Experience

Not every shop with a 5-axis machine knows how to use it well.

Ask for examples of similar parts they’ve made.

Better yet, ask them how they handled tricky features, tight tolerances, or unusual materials.

Companies like MachMaster offers 5-axis CNC machining and has experience with everything from aerospace housings to custom medical parts, so they know how to handle complex jobs.

If they’ve done it before, they’ll tell you how, and what they’d do differently next time.

Ask About CAM and Setup

A good shop will:

- Use high-quality CAM software like MasterCAM, Fusion360, or HyperMill

- Do full simulations to avoid tool collisions

- Explain their fixturing and inspection process clearly

If they can’t walk you through their workflow, that’s a red flag.

Check Their Communication

You want a shop that talks to you like a partner, not just a vendor.

They should:

- Give honest feedback on your design

- Suggest ways to cut costs or improve function

- Flag risks early (instead of when it’s too late)

We’ve had customers send over parts with small design flaws. A quick heads-up saved them days, and their budget.

Understand Lead Times and Capacity

Good shops are often busy. Ask when they can realistically run your part, not just when they can quote it.

Also, check if they can handle your full volume or future runs.

Some shops are great for prototypes, but not ready for production.

Conclusion

That mold job I mentioned?

It taught me that the right tool isn’t just faster, it protects your reputation.

You now know what 5-axis CNC machining is, how it works, and when to use it.

You’ve seen the pros, the limits, and how to design smarter.

If you’re looking for a reliable partner to machine complex parts, MachMaster offers 5-axis CNC machining with real experience and care.

Don’t wait for a mistake to learn. Start the right way. Contact us today.