You don’t want to overpay. You don’t want to miss your lead time.

And you definitely don’t want to hear that a part “can’t be made” after it’s already late.

I’ve been in that spot, watching costs rise and deadlines slip because we didn’t use the right machining method from the start. 5-axis machining would have solved it. But no one explained how or why.

That’s what this article is for.

I’ll help you understand what 5 axis CNC machining actually does, what types of parts benefit from it, and when it makes sense to use it. You’ll see the pros, the tradeoffs, and the questions you should be asking your supplier.

Let’s start!

1. What is 5-Axis CNC Machining?

Before I understood 5-axis machines, CNC felt like a black box. I’d send out a part drawing, and it came back done. But when production started slipping, I had to dig deeper.

Let’s start simple.

CNC machining stands for Computer Numerical Control machining. That just means a machine cuts or shapes parts using a computer program. No hand tools. No guessing. Just code, cutters, and control.

Most shops start with 3-axis machines. They move in three directions:

- Left to right (X)

- Front to back (Y)

- Up and down (Z)

This works fine—until your part has angles, curves, or features on multiple sides.

That’s where 5-axis CNC machining comes in.

It adds 2 more axes:

- Rotation around the X-axis (A)

- Rotation around the Y-axis (B) or Z-axis (C)

Now the machine can move the part or the cutting tool in 5 directions at once.

Why does this matter? Because now you can cut complex shapes in one setup:

- Angled holes

- Curved surfaces

- Tight spaces on multiple faces

With 3-axis, you need to stop and flip the part. That adds time. And mistakes.

4-axis helps by rotating the part, but it still has limits. It usually only turns the part in one direction.

5-axis removes most of those limits.

If you’ve ever looked at a part and thought, “How are we going to machine this?”, 5-axis might be the answer.

But is it always necessary? That’s what we’ll explore next.

2. Types of 5-Axis Machines

Now that you know what 5-axis CNC machining does, the next question is: how do these machines actually move?

There are three main types of 5-axis machines. Each one moves the cutting tool or the part in different ways. And that affects what kind of jobs the machine is best for.

Let’s break them down.

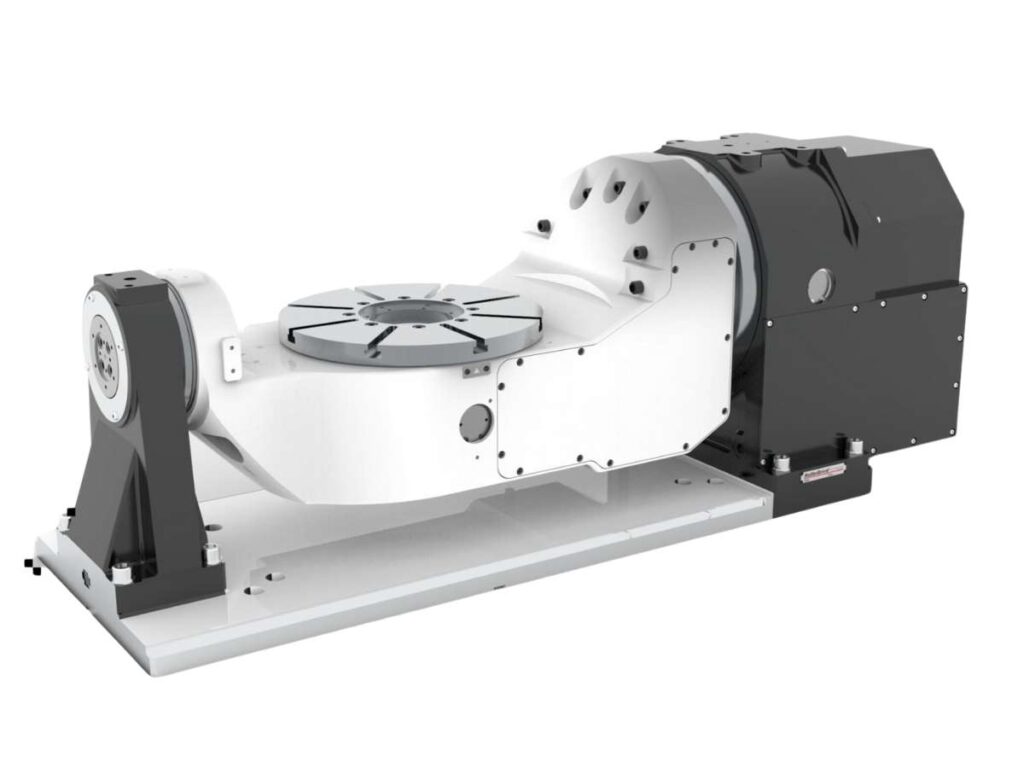

Table-Table

In this setup, the cutting tool stays still. The table holding the part moves:

- One rotary axis tilts the table (A)

- One rotary axis spins the table (C)

This type works well for small parts. It’s common in medical and aerospace jobs, where precision and part handling really matter.

I’ve seen these machines shine when you need to cut from multiple angles without touching the part between steps. But the table can’t hold large or heavy workpieces—it just can’t handle the weight.

Head-Table

This one is a mix. The table rotates in one axis, and the tool head tilts in the other.

It’s more flexible than table-table and can take on slightly bigger parts. Some shops choose this style to get more range without giving up too much strength.

Head-Head

Both rotary axes are in the tool head. The part stays still on the table.

This setup is great for large or heavy parts. Since the table doesn’t move, it can support more weight. The tool does all the work, moving and tilting as needed.

Each machine type has tradeoffs. What works best for you depends on your part size, geometry, and how much movement you need.

3. Key Benefits of 5-Axis

Once you understand how a 5-axis machine moves, the next big question is: what do you actually gain from it?

From my experience, the real value shows up in production. In the day-to-day. On the shop floor.

Here’s where 5-axis machining can really make a difference for your business.

Faster Lead Times

With 3-axis machines, the operator has to stop, flip the part, reset it, and then start cutting again. Every flip adds time and risk.

With 5-axis, most parts are machined in one setup. That means:

- Fewer pauses

- Less repositioning

- Faster turnaround

If you’re trying to meet tight deadlines, this alone can change the game.

Reduced Labor and Handling

Less repositioning means fewer hands on the part.

And that matters. Every time someone moves a part, there’s a chance something shifts or goes wrong. Over time, it adds up in labor hours and scrap.

Higher Precision for Complex Parts

Some parts have tough features:

- Angled holes

- Curved surfaces

- Tight tolerances on multiple faces

5-axis handles these with smoother transitions and cleaner finishes.

Better Fit for Difficult Geometries

You can cut features that are hard—or impossible—with 3-axis or 4-axis setups. That opens the door to more advanced designs.

Stronger Position in Advanced Industries

Industries like:

- Aerospace

- Medical

- Robotics

…often demand parts that 5-axis can handle better than anything else.

If you’re looking for fewer errors, faster delivery, and more flexibility, these benefits are hard to ignore.

4. Industries that Rely on 5-Axis CNC

Not every industry needs 5-axis CNC machining. But in certain fields, it’s more than a benefit—it’s a must.

I’ve worked with suppliers across several sectors, and in some jobs, you can’t get the part made without this level of precision and movement. Here’s where 5-axis really earns its place on the floor.

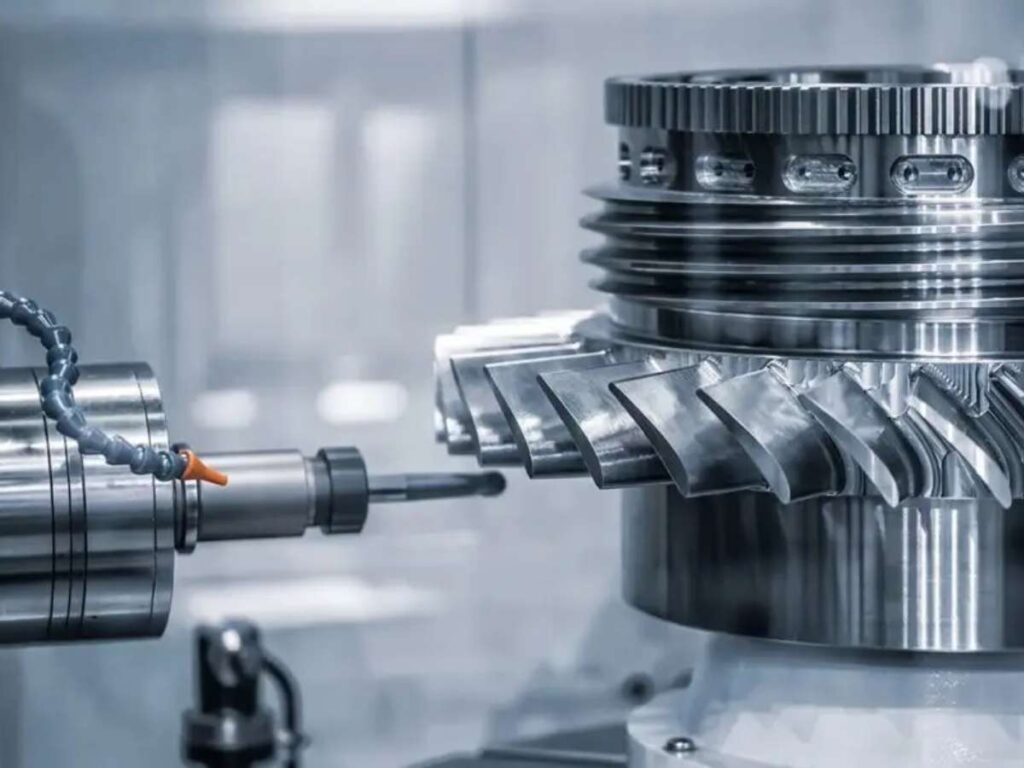

Aerospace

Turbine blades, structural components, and housings all require:

- Tight tolerances

- Smooth contours

- Features on multiple faces

These parts often need to be machined from hard metals like titanium or Inconel. That means fewer setups, better rigidity, and accurate toolpaths matter. A 3-axis machine just can’t keep up.

Medical

Surgical instruments and orthopedic implants are small—but complex. You might be dealing with:

- Internal channels

- Smooth, curved surfaces

- Unusual angles

In the medical field, precision isn’t a luxury. It’s critical to patient safety.

Automotive

From mold cavities to gear housings, automotive suppliers use 5-axis for:

- Rapid prototyping

- Short-run tooling

- Multi-face features in one operation

It helps speed up delivery without sacrificing quality—especially on high-mix jobs.

Robotics

Compact parts with multiple faces, screw holes, or mount points all benefit from 5-axis. It allows you to cut every side of a component in one go. That means tighter assemblies and fewer errors.

If you work in any of these fields—or support companies that do—5-axis capability isn’t a maybe. It’s a need.

5. Cost vs Value: Is 5-Axis Worth It?

You’ve seen the benefits. But now you might be wondering: what’s the catch?

Let’s be honest. 5-axis CNC machines cost more. And so do the people who run them. But that’s only part of the story.

Let’s talk numbers

Yes, the upfront price is higher.

The machine itself is more advanced. And a skilled operator doesn’t come cheap.

But here’s what you gain in return:

- Fewer setups mean less labor time per part.

- Higher accuracy means fewer mistakes and less scrap.

- One machine can take the place of several steps in your process.

I’ve worked on jobs where we were juggling three machines just to finish one part. With 5-axis, we cut that down to one machine and one operator. The time savings were immediate. And the final part? Better all around.

But, when the ROI makes sense?

Not every job needs 5-axis. But in some cases, the value adds up fast:

- Prototypes with complex features

- Small to mid-size production runs with frequent changes

- Long-term projects where you repeat the same setup hundreds of times

In those cases, setup time is money. And reducing that setup means real savings.

So before you decide it’s too expensive, take a step back. Think about your time, your waste, and your labor. Sometimes, what looks expensive up front saves you more in the long run.

6. How 5-Axis Compares to 3-Axis and 4-Axis

You’ve seen the benefits and the cost breakdown. But how do the different machine types actually stack up?

Here’s a quick comparison to help you see the difference at a glance:

| Machine Type | Movement Capabilities | Limitations | Best For |

| 3-Axis | Tool moves along X, Y, and Z | Needs manual repositioning for multiple sides | Simple parts with features on one face |

| 4-Axis | Adds one rotary axis (usually A) to rotate the part | Still needs repositioning for angled cuts or undercuts | Cylindrical parts or parts with features around one axis |

| 5-Axis | Moves in X, Y, Z + 2 rotational axes (A and B or C) | Higher cost, steeper learning curve | Complex parts with curves, angles, and features on multiple faces |

What does this mean for you?

If you’re machining flat plates or simple blocks, 3-axis might still do the job. If you’re working with tubes or round parts, 4-axis can help.

But if you want to cut everything in one go with better finish, fewer setups, and tighter tolerances, 5-axis gives you that flexibility.

7. How to Choose a 5-Axis CNC Machining Supplier

Finding a supplier with 5-axis equipment isn’t hard.

Finding one who actually knows how to run it well? That’s where things get tricky.

I’ve seen shops buy a 5-axis machine just to check a box but barely use it. Or they run parts with no DFM feedback, hoping the CAM software does all the work. If you’re trusting them with your parts, that’s a risk.

Here’s what to look for before you send over a drawing.

Specialization in 5-Axis Work

Ask if 5-axis is part of their core business or just a side capability.

- A real 5-axis shop will show examples.

- They’ll have operators trained for multi-axis jobs.

- You’ll hear them talk about fixtures, simulations, and tool paths—not just “we can try.”

Tight Tolerance Experience

It’s not enough to say “we can hold it.”

Ask what tolerances they’ve consistently hit on past parts. Ask for material types too—titanium and aluminum cut very differently.

Support Across Prototyping and Production

Some shops do one-off prototyping. Others only handle long runs. Look for a partner who can support both. That way, you don’t need to switch suppliers mid-project.

Clear DFM (Design for Manufacturability) Feedback

A good shop won’t just quote your file. They’ll review your model, flag risky features, and suggest better options. This early feedback prevents delays, saves money, and avoids rework later.

Looking for a supplier who’s already delivered complex 5-axis jobs across medical, electronics, and industrial parts? MachMaster is ISO 9001 certified, and we’ve supported over 500 global customers with tolerances down to ±0.01mm. From trial runs to full-scale production, we know what it takes to get your job done right.

Conclusion

If your parts are complex, your deadlines tight, or your quality bar high, 5-axis might be what you’ve been missing.

You’ve learned:

- What makes 5-axis different

- When the ROI is worth it

- How to spot a capable supplier

I started this journey unsure. I thought 3-axis was enough. I was wrong.

You don’t have to make the same mistake.

Are you ready to cut smarter, faster, and cleaner?

Let’s talk about what 5-axis can do for you. Contact us today.

Check Out These Additional Resources

For more in-depth knowledge, take a look at these recommended reads. We think you’ll find them useful:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.