Our Surface Treatment Options

Surface treatment technologies are used to improve part appearance, durability, or performance. Each process has its own requirements for material compatibility, color, texture, and cost. Below are the finishing options we offer for both functional and aesthetic applications.

As-Machined

Sand Blasting

Anodizing

Laser Logo

Brushing

Polishing

Electroplating

Chroming

Black Oxide

Powder Coating

Passivation

Electrophoretic Coating

Manage Your Machining Needs with MachMaster

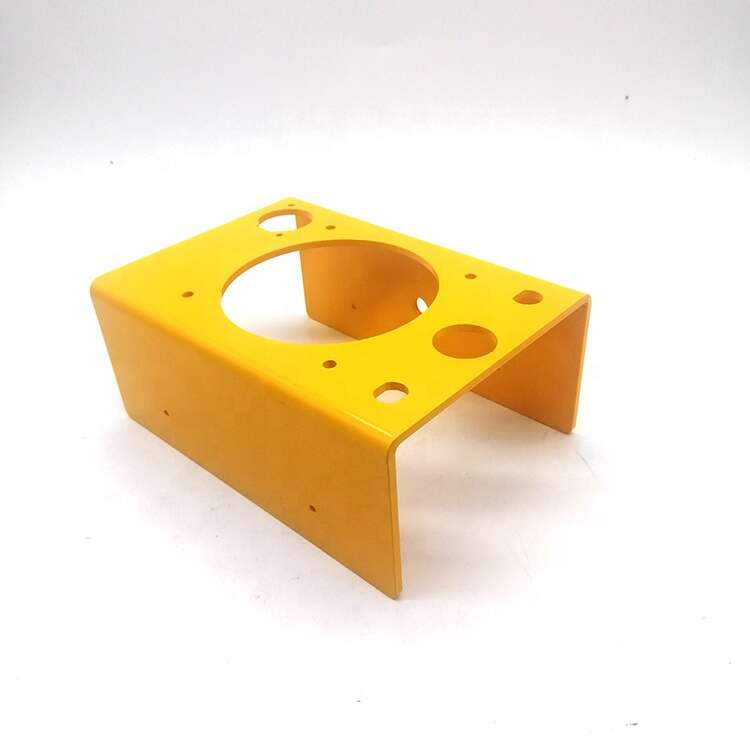

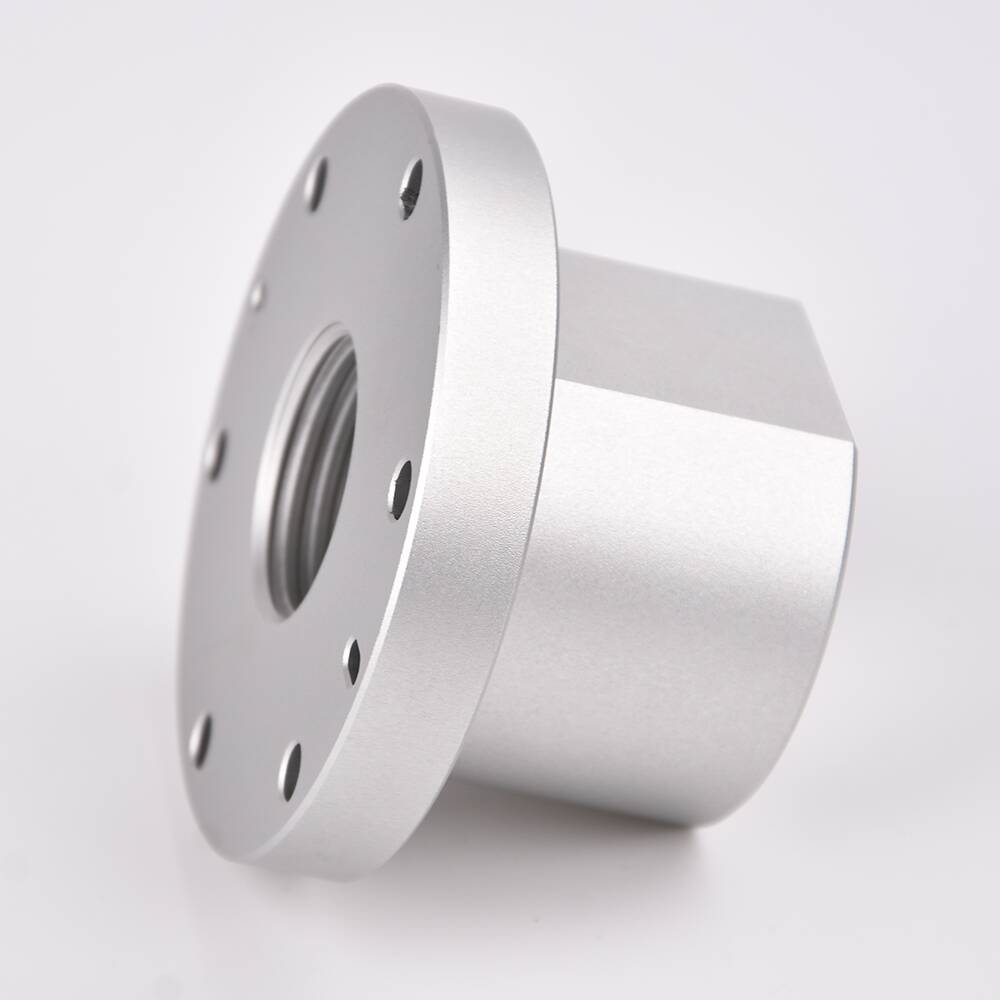

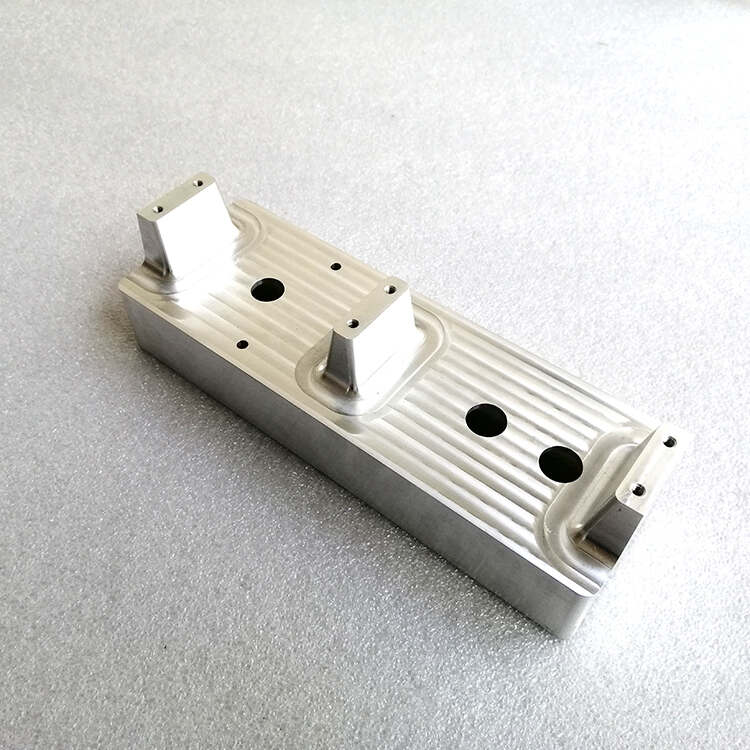

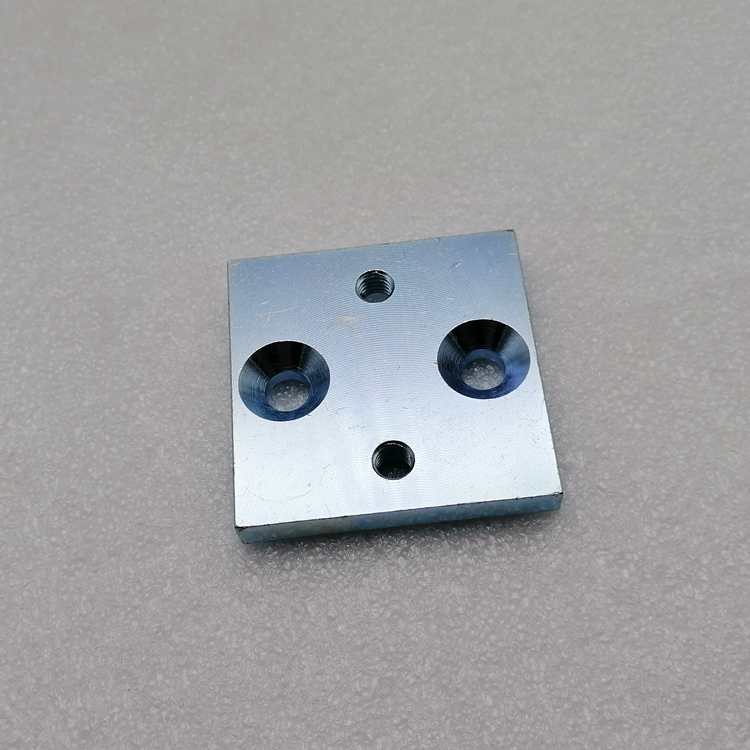

Real-World Surface Finishing Examples

Explore how MachMaster applies a wide range of surface finishes to improve the function and aesthetics of CNC-machined parts across aerospace, medical, electronics, and more.

FAQ About Surface Finishing for CNC Parts

Will Surface Finishing Affect Part Tolerances?

Yes, but we take it into account. Each surface treatment process—such as anodizing, plating, or bead blasting—can slightly alter dimensions. We pre-adjust for this based on your specified tolerances to ensure all parts remain within ISO 2768 limits.

What Materials Support Surface Finishing? Can Plastics Be Finished Too?

Most metals like aluminum, stainless steel, brass, and copper support various finishes. Some engineering plastics such as ABS or PC can undergo painting or light coating, but results vary and require evaluation based on the end use.

Which Surface Finishes Are Available, and How Do I Choose?

We offer anodizing, powder coating, plating, bead blasting, brushing, polishing, and more. The right choice depends on your requirements—whether you prioritize wear resistance, corrosion protection, or cosmetic appeal. Our engineers are happy to assist with recommendations.

Does Surface Finishing Increase Lead Time?

Some finishes (e.g., hard anodizing or multi-step coatings) may add 1–3 days to production. However, our in-house coordination and trusted vendor network minimize delays and streamline delivery even for complex requirements.

How Do You Ensure Surface Consistency Across Batches?

All finished parts go through visual inspection for consistency in color, texture, gloss, and coverage. We follow AQL 2.5 standards and can provide samples or color swatches upon request for your approval.

Is Surface Finishing Included in the Quote?

Yes. All quotes are comprehensive and tailored to your drawing and spec—including surface finishing, QC, packaging, and delivery. No need to manage multiple suppliers—we handle everything in one place.

Explore More of Our Resources

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486