Screws Tray Cases

MachMaster crafts an exquisite aluminum screw tray for customers to elevate their personalized desktop experience.

Project Overview & Solution

The customer is a DIY hobbyist who requires a custom screw tray to organize screws and small components for improved work efficiency.

Requirements and Challenges

Customer Requirements:

- Durability: The tray must be robust enough to withstand frequent use

- Aesthetics: A sleek and visually appealing design is essential

- Functionality: Optimized layout for easy access and efficient workspace organization

Key Challenges:

- Ensuring the compartments were accurately sized to hold different screw types and small parts.

- Making sure the tray was durable enough to withstand daily industrial use.

- Meeting tight deadlines while maintaining consistent quality across all produced units.

MachMaster’s Solution

Our Manufacturing Approach:

- CNC Process: MachMaster is manufactured using a CNC turning process using high strength aluminum alloy to ensure precise dimensions and a consistent surface finish.

- Surface Finish: Sandblasting 180#, matte anodizing.

- Quality Control: We implemented in-process inspections and testing to ensure that each tray met the client’s high standards for durability, accuracy, and functionality.

Manufacturing Details

For the screws tray project, MachMaster’s team applied expert CNC turning techniques to create a precise, functional tray with exactly the right compartments for screws and small parts. The tray is designed to be tough and durable for DIY hobbyist use, with a smooth finish that resists wear and makes it easy to clean.

| Item | Details |

|---|---|

| Material | 6063 Aluminum |

| CNC Process | CNC Turning |

| Surface Finish | Sandblasting 180#, matte anodizing. |

| Tolerance | ±0.02mm |

| Quantity | 50 pcs (Batch Production) |

| Lead Time | 10 Working Days |

| Application | DIY Screws Tray |

Manage Your Machining Needs with MachMaster

CNC-machined screws tray with precisely sized compartments, designed to keep screws and small parts organized and easily accessible in an industrial environment.

Finished Product Showcase

Our Process from File to Finished Part

01 Upload CAD File

Submit CAD drawings and RFQs with part specs and application details to get fast engineering support.

02 Review & Quote

Receive pricing and DFM feedback to ensure your design is ready for manufacturing.

03 Start Production

We begin machining or molding with selected materials and strict quality standards.

04 Parts Delivered

Parts are carefully inspected, securely packed, and shipped on time—ready for your next stage.

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

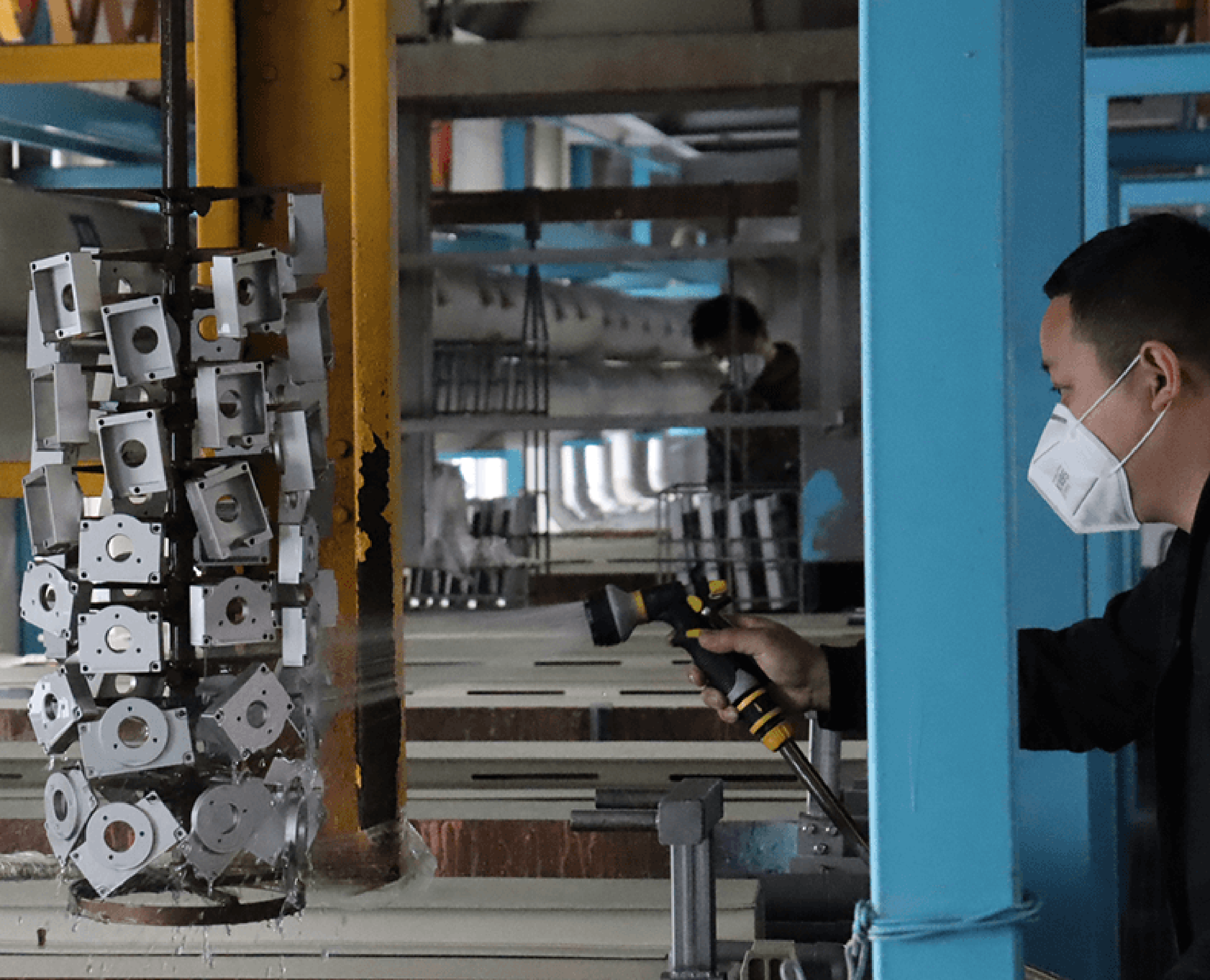

Our Screws Tray Production Shop

Screw Tray Types and Practical Advantages

Types of Screw Trays

Flat or Shallow Trays:

These trays are typically made of metal, plastic, or wood, and are designed to sort screws and fasteners by size or type. They feature a simple, no-frills design, often with a raised edge to prevent screws from rolling out.

Compartmentalized Trays:

Compartmentalized trays come with multiple small sections to help organize screws by type, size, or thread. These are especially useful for assembly workers, mechanics, or engineers who need quick access to a variety of fasteners.

Magnetic Screw Trays:

Magnetic screw trays are equipped with a magnetic surface or base to hold screws, bolts, and nuts in place. This makes them particularly helpful when working with metal parts, as the screws won’t roll off the tray easily.

Rotating Screw Trays:

Rotating screw trays, or carousel-style trays, allow the user to spin the tray to access different compartments quickly. This makes it convenient for picking different types of screws and organizing them efficiently.

Screw Organizers or Boxes:

Screw organizers, often enclosed with a lid, are similar to trays but offer portability. They are perfect for keeping screws organized while on the go, whether in the workshop or for assembly tasks.

Screw Dispensers:

More advanced than simple trays, screw dispensers can release screws one at a time, making them ideal for efficient handling during assembly or manufacturing processes.

Benefits of Using a Screw Tray

Using a screw tray offers several important benefits, especially in industrial and assembly settings.

Organization:

Screw trays help keep screws, bolts, and other fasteners neatly sorted, making it easier to find the right one when needed. This organization ensures faster workflow and reduces time spent searching for components.

Prevents Loss:

By containing all screws in one place, screw trays minimize the risk of losing parts during the assembly or repair process. This is particularly crucial in environments where losing small parts could cause delays.

Efficiency:

Using a screw tray significantly boosts efficiency by reducing the time spent looking for screws and fasteners. It helps streamline tasks that require a lot of assembly or repair work, increasing overall productivity.

Convenience:

Screw trays are particularly useful in environments such as assembly lines or construction sites, where screws need to be easily accessible at all times. Their organized design makes them convenient for workers to access and use screws quickly.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486