Quality Assurance

Machining Excellence Starts with Uncompromising Quality Control.

Built on a Proven Quality Management System

Our operations are guided by standardized management principles, lean production methods, and a strong commitment to environmental responsibility—ensuring high-quality outcomes at every stage.

We follow a strict ISO 9001:2015 quality management system across all prototyping and machining processes. From initial design to final inspection, each step is governed by standardized procedures and advanced testing equipment to ensure consistent quality, continuous improvement, and customer satisfaction.

Inspection and Quality Control Procedures

Our quality control begins from the moment of enquiry and continues through production to final delivery. Each order undergoes two independent reviews to confirm all details—dimensions, materials, quantities, and delivery timelines. A production engineer then evaluates manufacturing feasibility based on the part’s design and requirements. Special quality notes are documented, and an IPQC inspection plan is created based on tolerance levels, batch size, and process complexity.

Our Inspection Equipment

We use a comprehensive range of precision measuring tools to ensure every part meets strict dimensional and quality standards. Our key inspection equipment includes:

CMM (Coordinate Measuring Machine): Measuring range 800×1220×600 mm, MPE ±3.0 μm

Granite Surface Plates: 1200×1000 mm / 1000×750 mm

Digital Height Gauge: Measuring range 0–600 mm

Full-Range Vernier Calipers: 0–100 / 150 / 200 / 300 / 600 / 1000 mm

Micrometers (Outside & Inside): 0–25 / 75 / 100 / 125 / 150 mm and 12–20 / 50 / 100 mm

Pin & Plug Gauges: 0.5–12 mm / 1.0–100 mm, pitch interval 0.01 mm

Surface Roughness Meter & Hardness Tester

Quality Control Implementation

MachMaster applies strict quality control throughout the production cycle, covering:

DFM Review – Ensure designs are optimized for manufacturing.

Order Confirmation – Double-check contracts and specs.

Production Planning – Align capacity with delivery timelines.

Material Inspection – Verify incoming raw materials.

In-Process Checks – Monitor parts during production (IPQC).

Non-Conformance Handling – Apply corrective and preventive actions.

Final QC & Reports – Deliver full inspection and certifications (OQC).

Customer Feedback – Conduct satisfaction surveys twice a year.

Lean, Scalable Production

Driven by customer needs, our lean production system focuses on process improvement, cost control, resource optimization, and cross-team collaboration—ensuring efficiency, scalability, and customer satisfaction at every stage.

Integrated Quality & Efficiency

Through total quality management, we maintain strict inspection and control at every production step. Each process is optimized for accuracy, while strong internal communication ensures consistent quality and rapid delivery.

Responsible Manufacturing Practices

As a responsible manufacturer, we align with global environmental standards to help our customers meet compliance requirements, enhance brand reputation, and support long-term sustainability goals.

Certified by ISO 9001:2015

MachMaster follows a certified ISO 9001:2015 quality management system, delivering dependable, standards-compliant manufacturing across all projects—from prototyping to final production.

Manage Your Machining Needs with MachMaster

Quality Built Into Every Step

Every stage of our workflow is engineered to uphold precision, repeatability, and quality you can trust.

01 Quotation &

Order Review

Drawings and specs are reviewed to align materials, tolerances, and lead times.

02 Production Planning

Schedules and resources are coordinated to ensure smooth and efficient production.

03 Material Procurement

Certified materials are sourced to meet specs, lead times, and part requirements.

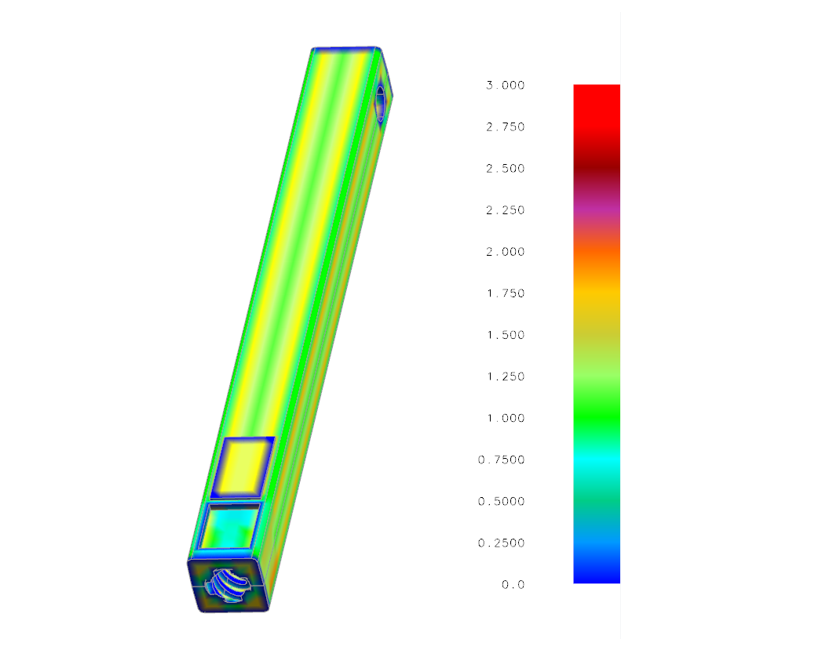

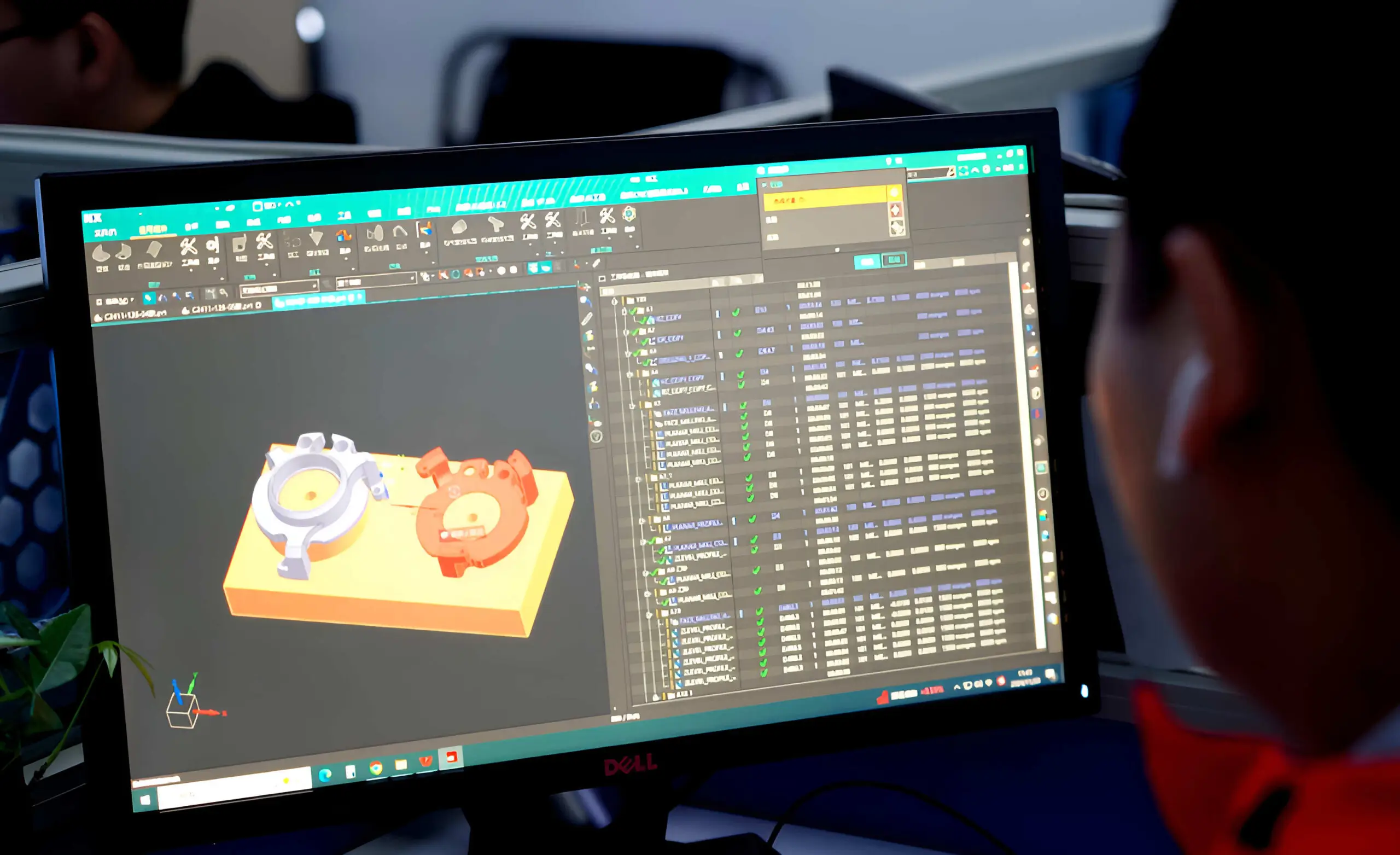

04 CNC Programming

Optimized tool paths and NC code are generated for accuracy and efficiency.

05 Precision CNC Machining Process

Components are machined using 3- and 4-axis equipment to meet tight tolerances.

06 Finishing & Polishing

Parts are deburred, polished, or treated to meet both functional and visual needs.

07 Multi-Stage Quality Inspections

Multi-point inspections ensure dimensional accuracy and consistent part quality.

08 Packaging & Shipment

Finished parts are packed securely and shipped with traceable documentation.

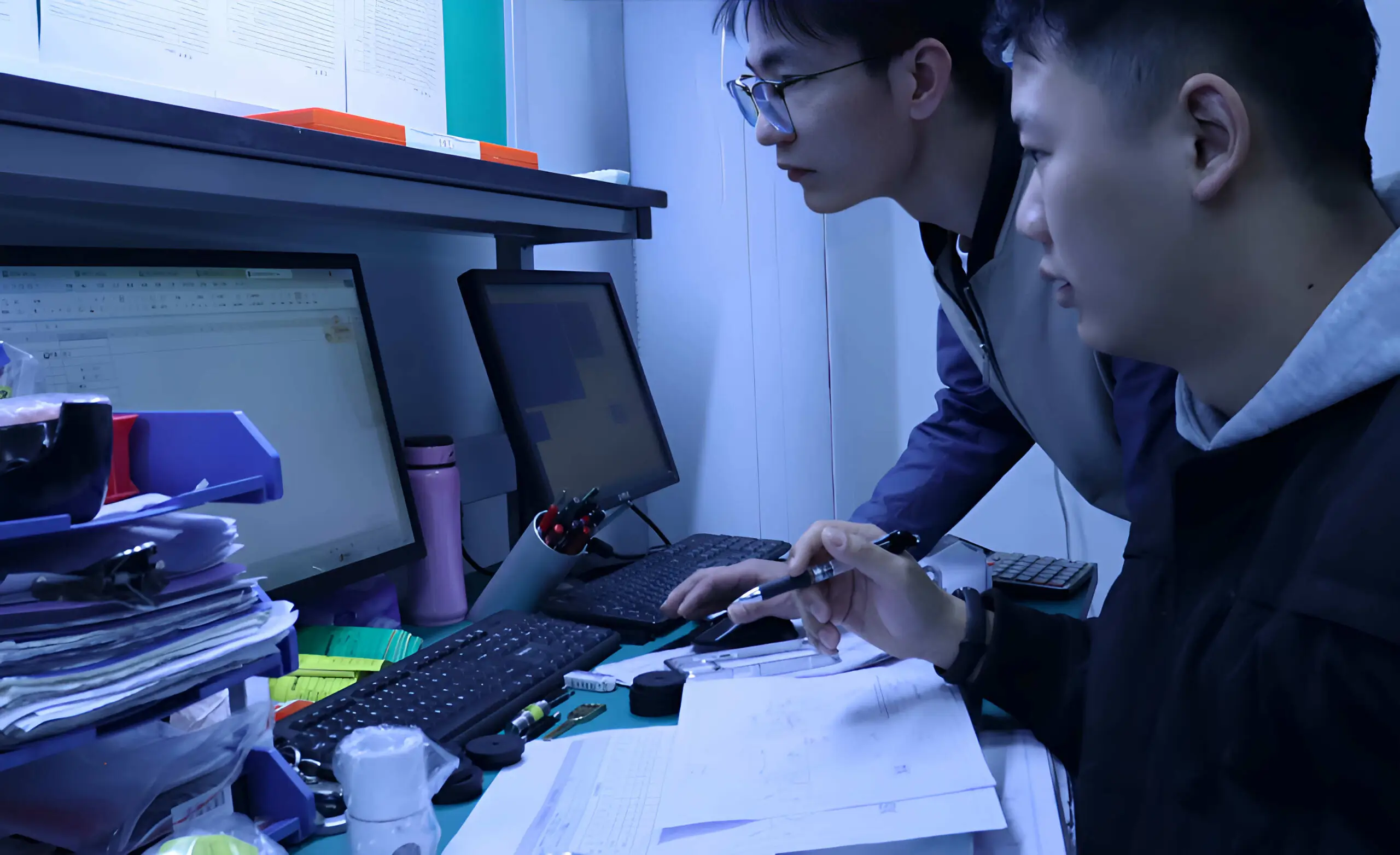

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

Engineering Team

Provides DFM analysis and technical solutions from design review to production readiness.

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486