Stainless Steel CNC Machining Capabilities in China

Get high-strength, corrosion-resistant stainless steel parts tailored to your exact specifications. MachMaster factory offers precision CNC machining for various stainless grades, ideal for structural, medical, and industrial applications.

Precision Stainless Steel Parts Manufacturing for Global Industries

We provide high-quality, precision stainless steel CNC machining solutions serving clients across various industries worldwide. From rapid prototyping to high-volume production, we meet your manufacturing requirements with exceptional quality and reliability.

Stainless Steel Description

Stainless steel is a versatile and durable alloy known for its resistance to corrosion, heat, and wear. It’s ideal for CNC machining due to its mechanical strength, dimensional stability, and compatibility with finishing processes like polishing or passivation.

Advantages of Stainless Steel

- Excellent corrosion and rust resistance

- High strength and toughness

- Stable mechanical properties under heat

- Suitable for both milling and turning

- Wide range of surface treatment options

Wide Application of Stainless Steel

CNC-machined stainless parts are widely used in demanding environments where strength and hygiene matter. Common applications include:

Surgical instruments, medical implants, diagnostic equipment components, device housings, and specialized medical tools requiring biocompatible materials.

Aircraft structural components, engine parts, avionics housings, precision fasteners, and defense system components meeting stringent aerospace standards.

Food-grade valves and kitchen components

Engine components, transmission system parts, fuel system assemblies, exhaust system components, and specialized fasteners for automotive applications.

Semiconductor manufacturing equipment parts, connectors, enclosures, heat sinks, and precision components for electronic devices and testing equipment.

Stainless Steel Grade Classification

MachMaster works with various stainless steel grades depending on project needs:

SS 303 – Excellent machinability and corrosion resistance. Commonly used in fittings and general-purpose components.

SS 304 – Food-grade stainless steel with strong corrosion resistance. Ideal for kitchen, medical, and consumer hardware.

SS 316 – Marine-grade alloy offering superior corrosion resistance in chloride or high-humidity environments.

SS 416 – A free-machining stainless grade, ideal for high-precision turned parts.

Our Stainless Steel CNC Machining Services

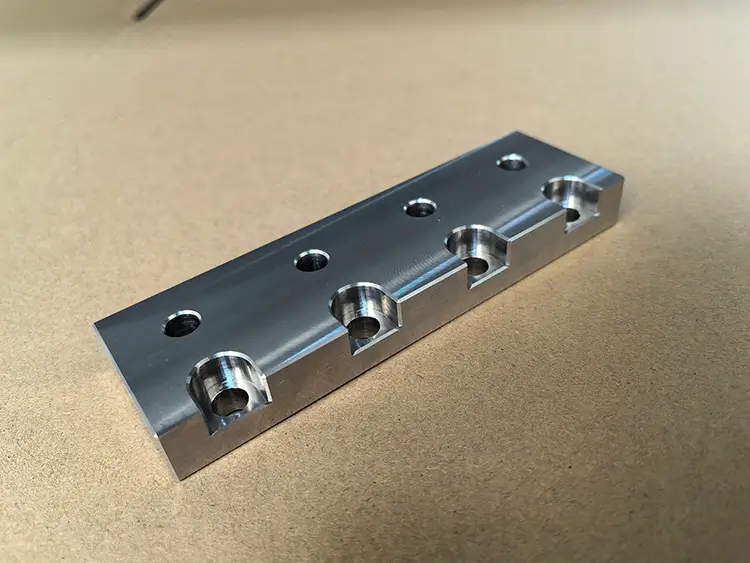

Precision Custom Stainless Steel Parts

Utilizing advanced multi-axis CNC machinery, we manufacture stainless steel components with complex geometries while maintaining tight tolerances and superior surface finishes. Our capabilities range from simple components to intricate parts requiring 5-axis machining.

Stainless Steel Prototyping

Quickly transform your designs into high-quality stainless steel prototypes for design validation and functional testing. Our rapid prototyping services significantly reduce product development cycles while maintaining production-level quality standards.

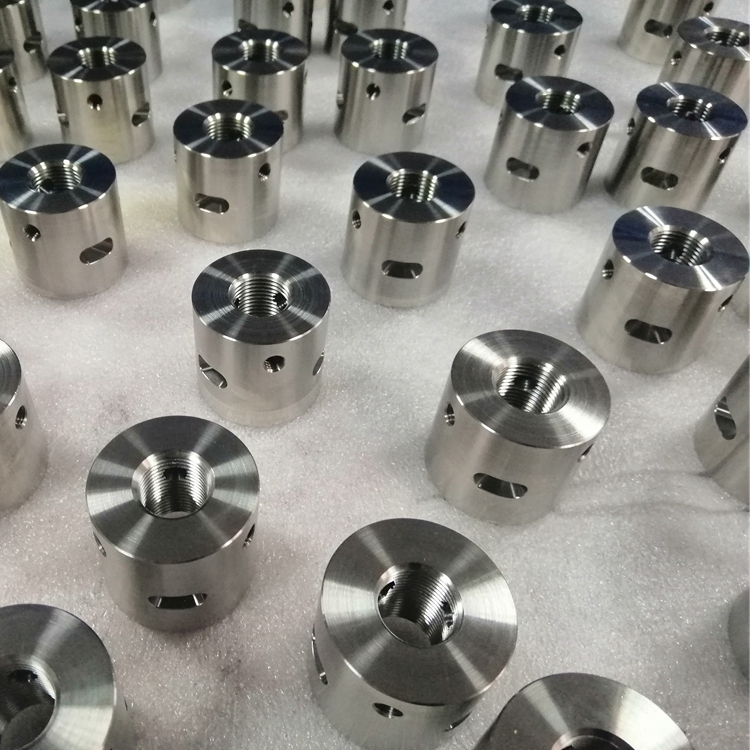

High-Volume Production

Equipped for large-scale manufacturing with consistent quality control processes. We ensure batch-to-batch consistency and reliable delivery schedules to meet your production timelines and volume requirements.

Manage Your Machining Needs with MachMaster

Explore Our CNC Stainless Steel Materials

We offer a variety of stainless steel grades suitable for different industries and applications. Each grade is selected based on mechanical strength, corrosion resistance, and machinability.

| Material | Description |

|---|---|

| Stainless Steel 303 | Excellent machinability with good corrosion resistance. Used in fasteners, shafts, and fittings. |

| Stainless Steel 304 | Versatile and food-safe. Great for medical, consumer, and kitchen-grade components. |

| Stainless Steel 316 | Superior corrosion resistance, especially in saltwater or chemical environments. |

| Stainless Steel 416 | Best for CNC turning. Offers good strength, machinability, and dimensional stability. |

| Stainless Steel 17-4PH | Precipitation-hardened stainless steel with excellent corrosion and oxidation resistance. Can be hardened up to 44 HRC. Ideal for turbines and chemical equipment. |

| Stainless Steel 15-5 | Tough precipitation-hardened alloy with improved transverse strength. Heat-treated to enhance mechanical properties. Common in aerospace and structural components. |

Stainless Steel Alloy Properties Overview

| Material | CNC Process | Tensile Strength | Elongation | Hardness (HRB) |

|---|---|---|---|---|

| Stainless Steel 304 | Milling | 73 ksi | 40% | 70 |

| Stainless Steel 316 | Turning | 79 ksi | 50% | 79 |

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

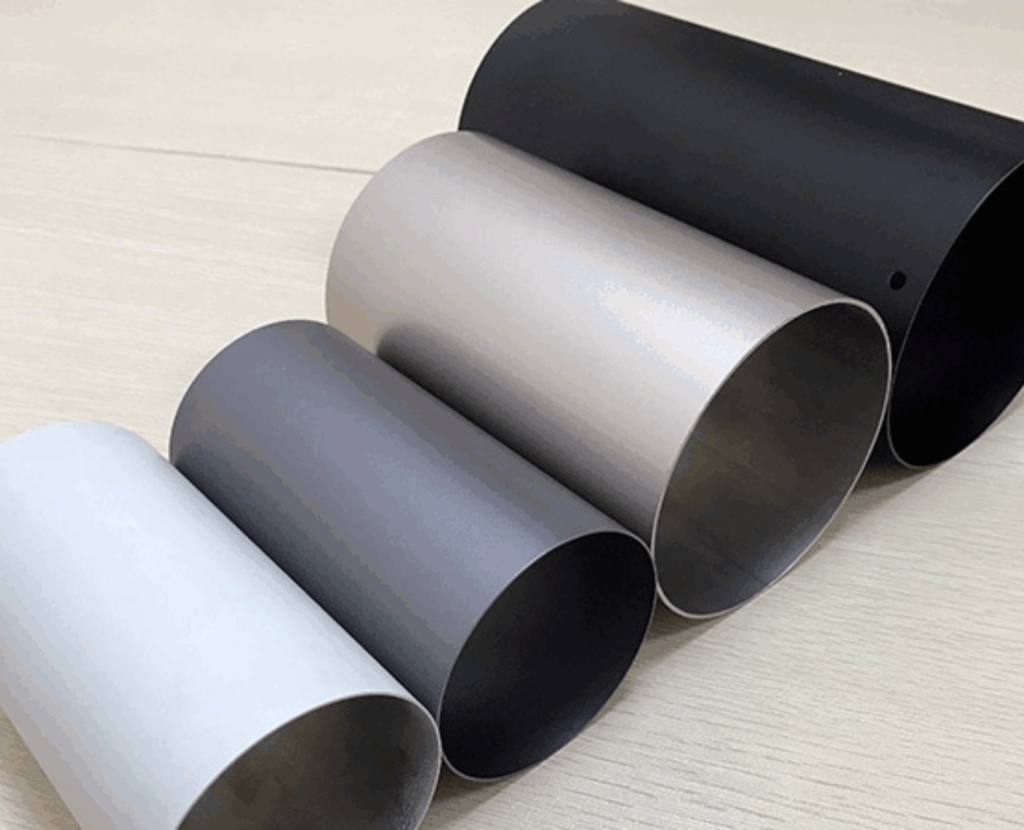

Stainless Steel Surface Finishing Options

Explore a wide range of stainless steel surface finishes tailored for both functional performance and visual enhancement. From bead blasting to black oxide coating, each process enhances corrosion resistance, aesthetics, and part durability—choose the right finish for your application.

Brushing

Creates fine, directional textures using abrasive belts or brushes to achieve a matte, decorative finish with a consistent grain pattern.

Sandblasting

High-speed abrasive particles are blasted onto the surface to remove oxide layers and residues, increase roughness, and enhance adhesion for subsequent coatings.

Powder Coating

A dry powder is electrostatically sprayed onto the surface and then cured at high temperature, forming a durable, weather-resistant finish available in a variety of colors.

Passivation

Chemical treatment to enhance the corrosion resistance of metals by removing free iron from the surface.

Polishing

Polishing removes surface flaws and creates a reflective, smooth finish. It’s used to improve aesthetics, reduce friction, and prepare parts for secondary coatings.

Plating

Black Oxide

FAQs About CNC Stainless Steel Machining

What Stainless Grades Do You Offer?

We commonly machine SS 303, 304, 316, and 416. If you need custom grades, we can evaluate them based on your design.

Is Stainless Steel Hard To Machine?

Some grades like 304 or 316 are tougher to cut, but with proper tools and speeds, we achieve excellent results. For better machinability, SS 303 and SS 416 are ideal.

Can You Polish Or Passivate Stainless Steel?

Yes. We offer polishing, passivation, bead blasting, and custom surface treatments depending on your application.

Do You Offer Food-Grade Or Medical-Grade Stainless Parts?

Absolutely. SS 304 and SS 316 are both widely used in food, beverage, and medical industries, and we follow relevant standards.

What Is Your Typical Lead Time For Stainless Parts?

Rapid prototypes can be delivered in 5–7 business days. Mass production timing depends on quantity and complexity.

Do You Support Tight Tolerances On Stainless Steel?

Yes. We can hold tolerances as tight as ±0.01mm, with full QA documentation upon request.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486