Precision Copper CNC Machining

Get custom copper parts with tight tolerances and excellent conductivity. MachMaster delivers expert CNC machining with fast lead times and ISO-certified quality.

About Copper for CNC Machining

Copper is a widely used CNC machining material known for its excellent conductivity, corrosion resistance, and ductility. While pure copper is soft and difficult to machine, copper alloys improve workability without sacrificing performance—making them ideal for high-precision applications.

Key Advantages of Copper

- Outstanding electrical and thermal conductivity

- Excellent corrosion resistance

- Good ductility and formability

- Ideal for conductive and heat-dissipating parts

- Compatible with precision CNC turning and milling

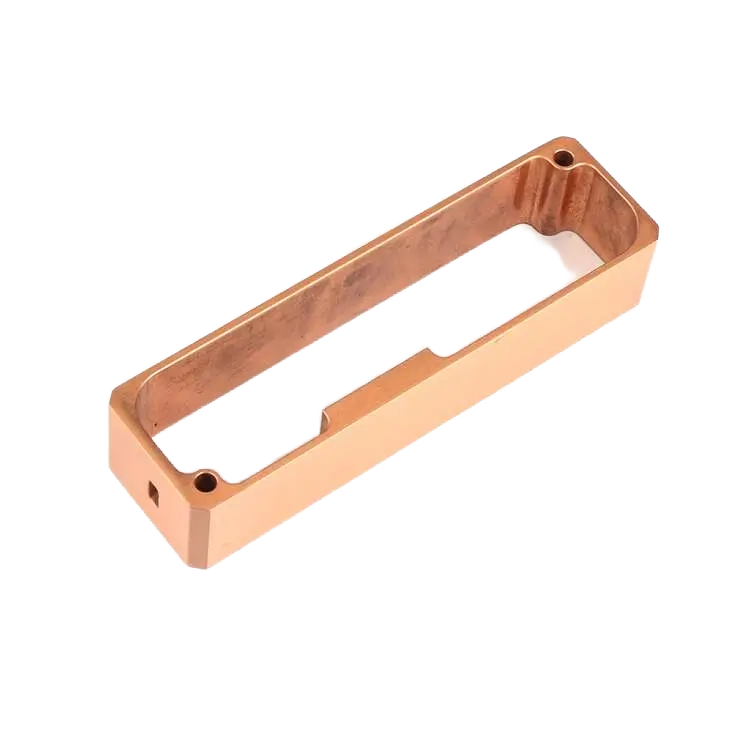

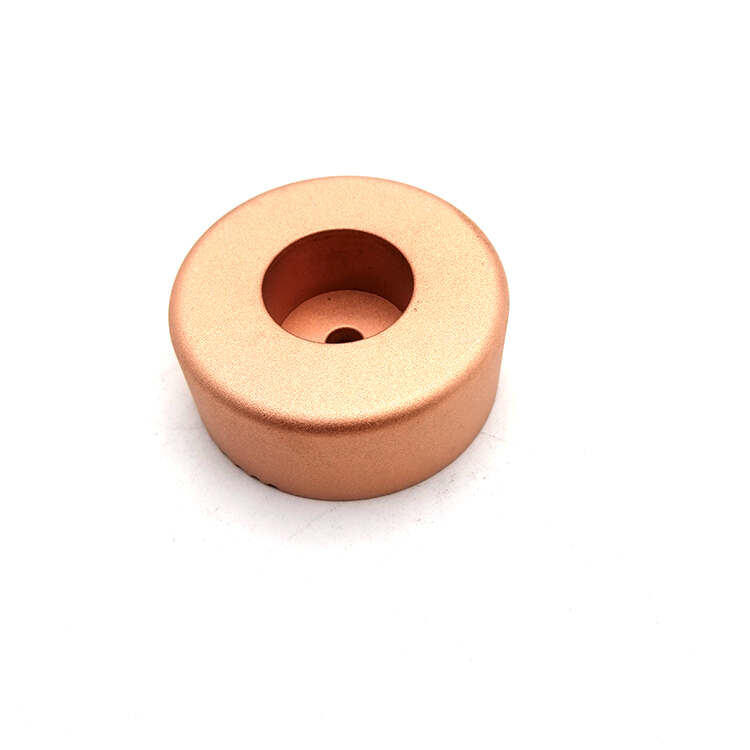

Our specialized copper CNC machining services deliver precision components that meet the exacting standards of industries requiring superior electrical conductivity and thermal management. With expertise in CNC copper machining of various alloys, we produce high-quality parts that perform reliably in critical applications.

Wide Application of Copper

Due to its exceptional conductivity and corrosion resistance, copper is widely used in industries where thermal and electrical performance are critical. Common applications include:

Electrical connectors, terminals, and bus bars

Heat exchangers, cooling systems, and radiators

RF shielding enclosures and EMI-sensitive components

Power distribution and grounding solutions

Precision components for automotive and medical devices

Our CNC machining copper

We understand that copper part CNC machining demands attention to detail and proper technique to prevent work hardening and ensure dimensional stability throughout production.

Precision milling and turning of pure copper and copper alloys

Complex geometries for electrical connectors and bus bars

Thin-walled components requiring careful handling

High-volume production of copper CNC machined parts

Custom fabrication of specialized copper CNC machining parts

Copper Alloy Classification

MachMaster offers a selection of commonly used copper grades to meet different manufacturing and performance needs:

Copper C110 – Offers excellent electrical and thermal conductivity with good corrosion resistance. Commonly used in general-purpose electrical applications.

Copper C101 – Oxygen-free copper with ultra-high purity. Ideal for high-frequency, vacuum, and critical electronic systems.

Copper C145 – Tellurium copper with improved machinability. Suitable for complex parts requiring threads or high-precision turning.

Quality & Precision

Ensuring Excellence in Every Copper Component

Quality is paramount in copper CNC machining because even minor imperfections can affect electrical performance and reliability. Our quality assurance process includes:

- Material verification and traceability

- Precision machining with tight tolerances

- Surface finish optimization for electrical contact

- Dimensional verification using CMM

- Conductivity testing when required

- Visual inspection for burrs and defects

Why Our Copper Machining Stands Out

Machining copper presents unique challenges that require specialized knowledge and equipment. Our advantages include:

- Specialized Tooling: We use cutting tools specifically designed for copper machining to minimize work hardening and achieve superior surface finishes.

- Process Optimization: Our experience allows us to optimize feed rates, spindle speeds, and coolant application for each copper alloy we machine.

- Secondary Operations: Complete in-house capabilities including deburring, cleaning, plating, and passivation services for copper CNC machining parts.

- Prototype to Production: Seamless transition from initial prototypes to full-scale production of CNC machined copper parts.

Manage Your Machining Needs with MachMaster

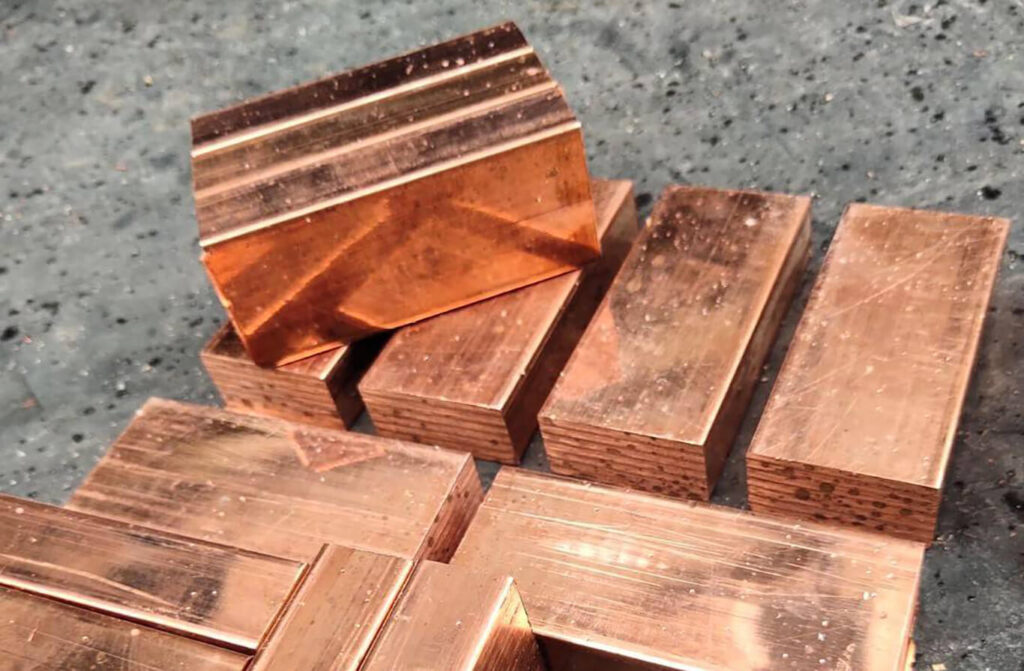

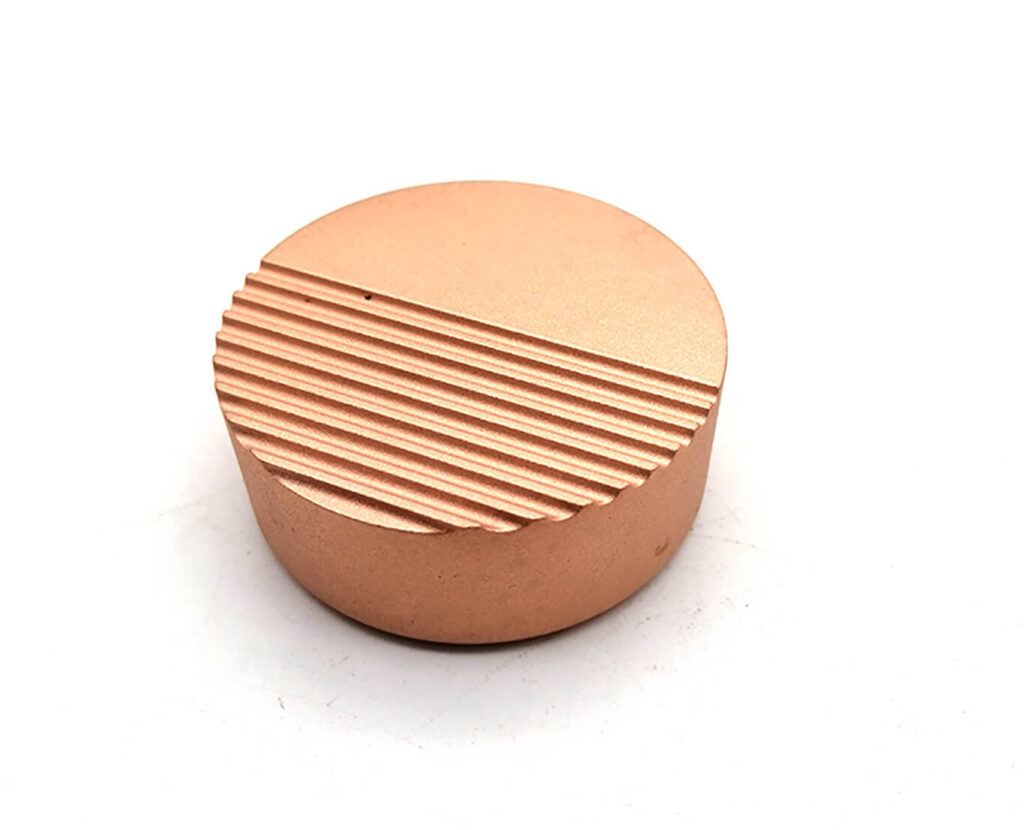

CNC Machined Copper Parts Gallery

As a china source for copper CNC machining, we maintain consistent quality standards across all production runs, ensuring that every CNC machining copper part meets or exceeds specifications.

Explore Our CNC Copper Materials

MachMaster offers a range of copper alloys ideal for high-precision CNC machining. Each material is selected for its outstanding conductivity, durability, and stability—ensuring your parts meet both performance and production standards.

| Material | Description |

|---|---|

| Copper C110 (Electrolytic Tough Pitch) | C110 is a highly conductive, commercially pure copper alloy. Known for its excellent electrical and thermal conductivity, it also offers strong corrosion resistance. Commonly used in electrical conductors, terminals, and thermal transfer components. |

| Copper C101 (Oxygen-Free High-Conductivity Copper) | C101 offers ultra-high purity (99.99%) and excellent conductivity. With minimal oxygen content, it is ideal for vacuum environments, high-frequency transmission, and precision electronic components where material integrity is critical. |

Copper Alloy Properties Overview

| Property | Copper C101 | Copper C110 |

|---|---|---|

| Ultimate Tensile Strength | 41 ksi (283 MPa) | 32–41 ksi (220–280 MPa) |

| Yield Strength | 8.7–34.8 ksi (60–240 MPa) | 8.7–34.8 ksi (60–240 MPa) |

| Hardness (Rockwell) | 40 | 95 |

| Electrical Conductivity | 96.5% IACS | 101.5% IACS |

| Thermal Conductivity | 390–398 W/(m·°C) | 380–388 W/(m·°C) |

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Finishing Options for CNC Machining Copper

From improved corrosion resistance to refined aesthetics, surface finishes are essential for CNC machined copper parts. We offer a variety of finishing options—such as powder coating, polishing, and electrophoretic coating—each tailored to enhance durability, function, or appearance depending on your application needs.

Electrophoretic Coating

Applies a uniform paint film through an electric field to improve surface corrosion resistance and visual appeal. The result is smooth, even, and protective.

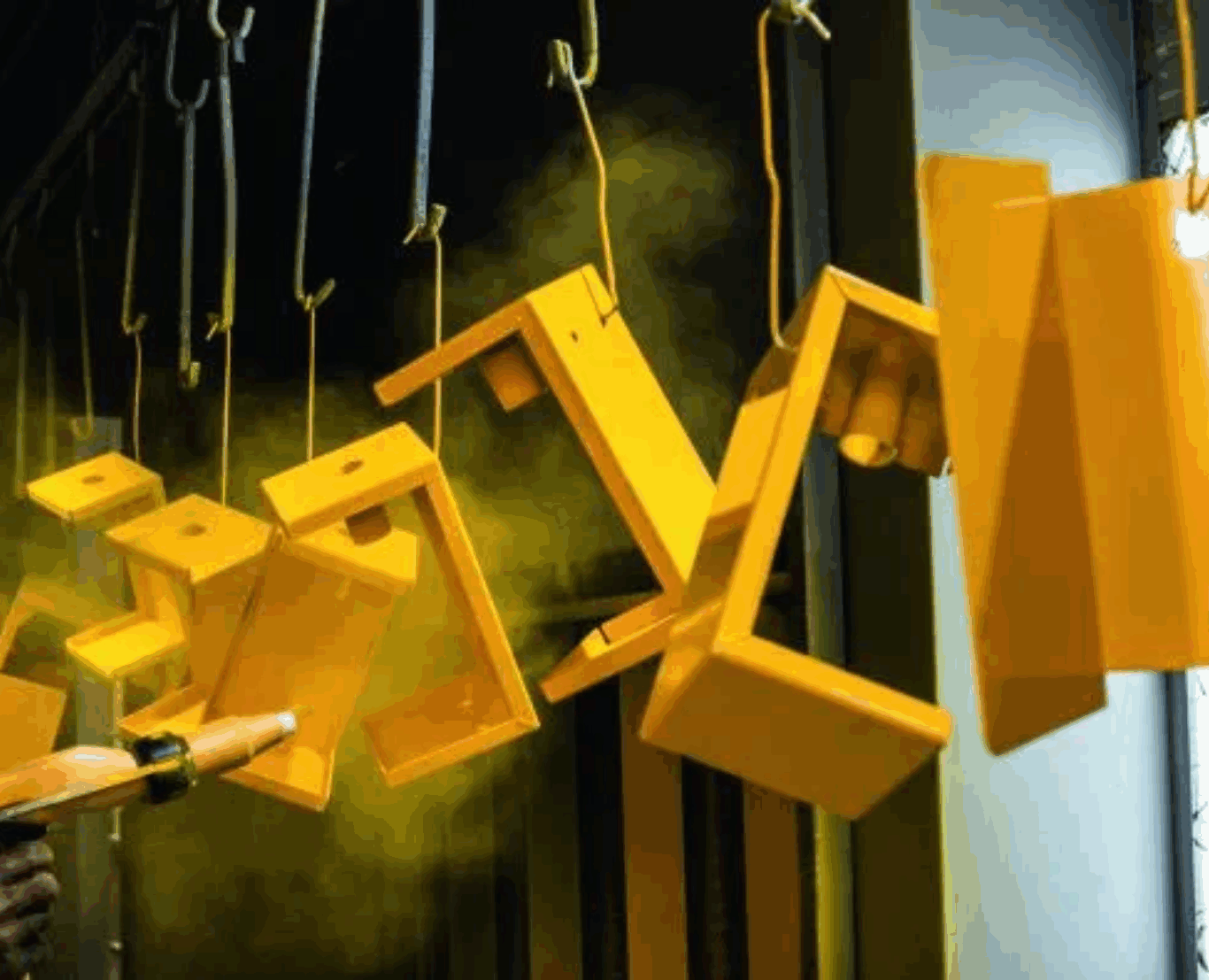

Powder Coating

A dry powder is electrostatically sprayed onto the surface and then cured at high temperature, forming a durable, weather-resistant finish available in a variety of colors.

Polishing

Mechanical or chemical processes remove oxidation and micro-defects to produce a smooth, mirror-like surface—ideal for decorative and functional parts.

Sandblasting

High-speed abrasive particles are blasted onto the surface to remove oxide layers and residues, increase roughness, and enhance adhesion for subsequent coatings.

Brushing

Creates fine, directional textures using abrasive belts or brushes to achieve a matte, decorative finish with a consistent grain pattern.

Electroplating

Deposits a thin layer of metals like nickel, chrome, or copper on the aluminum surface to improve corrosion resistance, wear performance, or achieve a distinct appearance.

FAQs About CNC Copper Machining

What Types Of Copper Can You Machine?

We commonly work with C110, C101, and C145 grades. If you require other copper alloys, we can evaluate them based on your design and application needs.

How Accurate Is Your Copper CNC Machining?

We support low-volume prototyping from just 1 piece, as well as high-volume production runs.

Can You Provide Surface Finishing For Copper Parts?

Yes. We offer nickel plating, tin plating, polishing, passivation, and custom finishes upon request.

What Is Your Minimum Order Quantity For Copper Parts?

With in-house CNC machines, fast DFM feedback, and streamlined quoting, we reduce lead times from days to hours—ideal for rapid prototyping or low-volume production.

How Fast Can I Get My Copper Parts?

Lead time depends on the part complexity and order quantity. Rapid prototyping can be delivered within 5–7 working days.

Do You Offer Quality Inspection Reports For Copper Parts?

Yes. We provide material certificates, dimensional inspection reports, and can support third-party testing upon request. Our processes are ISO 9001 certified to ensure consistent quality.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486