Best Titanium CNC Machining Services

MachMaster offers high-precision CNC machining services for titanium alloy parts with tight tolerances and excellent surface finishes. Titanium is ideal for aerospace, medical, and high-performance applications requiring strength, corrosion resistance, and low weight.

Titanium Description

Titanium is a lightweight, high-strength metal known for its exceptional strength-to-weight ratio and outstanding corrosion resistance. Though challenging to machine due to its hardness and low thermal conductivity, it is an excellent choice for demanding and weight-sensitive components.

Advantages of Titanium

- High strength-to-weight ratio

- Excellent resistance to corrosion and chemicals

- Biocompatible – ideal for medical implants

- Withstands extreme temperatures and stress

- Good fatigue and fracture resistance

Wide Application of Titanium

Titanium CNC parts are widely used in industries that demand strength, lightweight design, and corrosion resistance. Typical applications include:

Aerospace brackets, turbine blades, and housings

Medical implants, surgical tools, and orthopedic components

Automotive performance parts and motorsports components

Chemical processing equipment and heat exchangers

Marine and offshore engineering parts

Titanium Grade Classification

MachMaster works with multiple titanium grades for various industries:

Grade 2 (Commercially Pure Titanium) – Offers excellent corrosion resistance, good ductility, and weldability. Used in chemical and marine applications.

Grade 5 (Ti-6Al-4V) – The most commonly machined titanium alloy, combining high strength and corrosion resistance. Widely used in aerospace and medical parts.

Grade 23 (Ti-6Al-4V ELI) – A low-oxygen version of Grade 5, ideal for medical implants due to improved biocompatibility and fracture toughness.

Manage Your Machining Needs with MachMaster

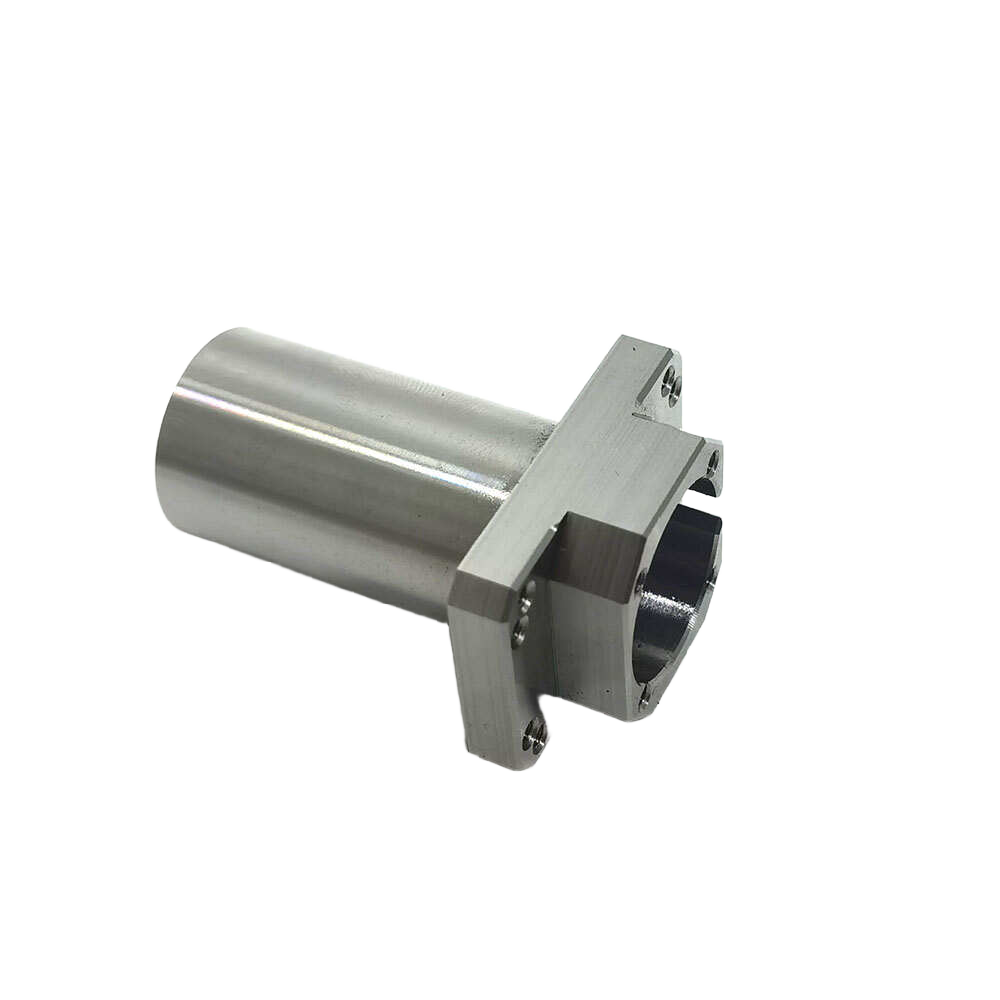

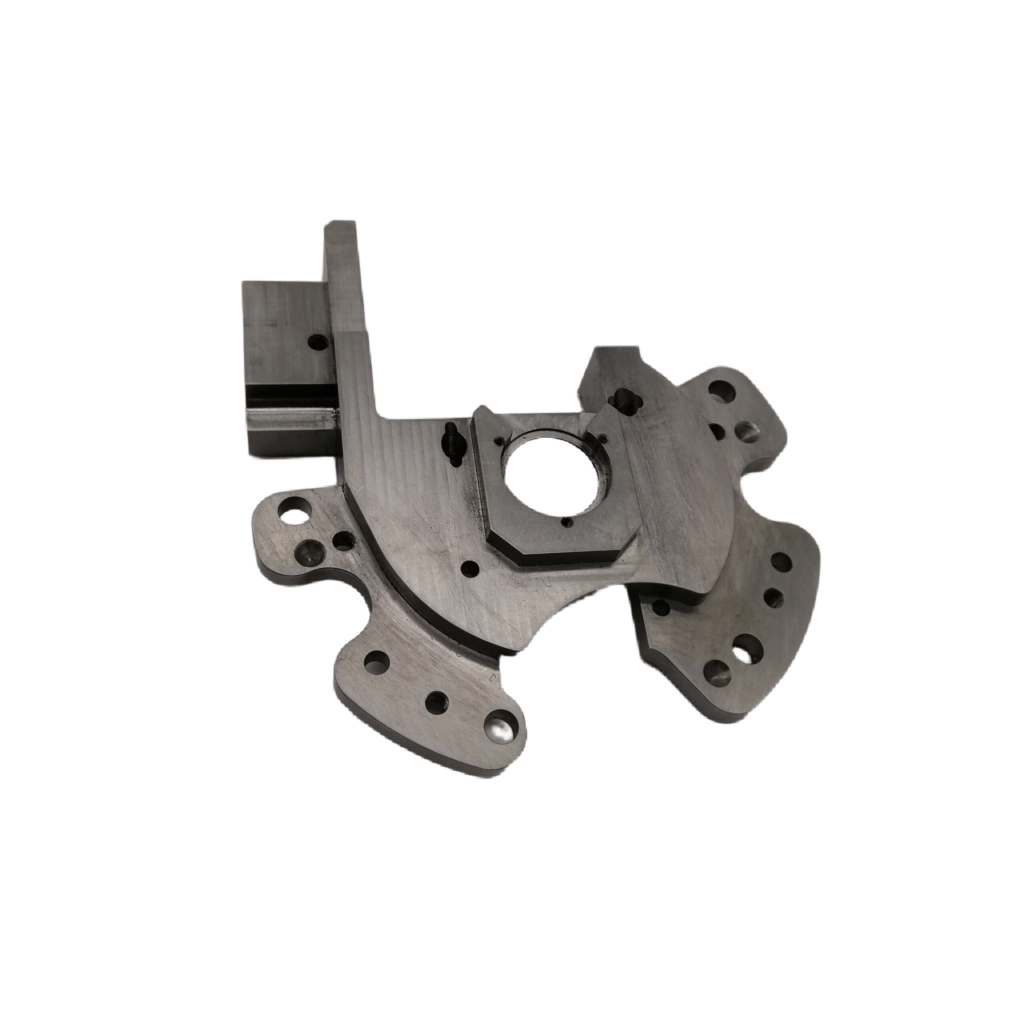

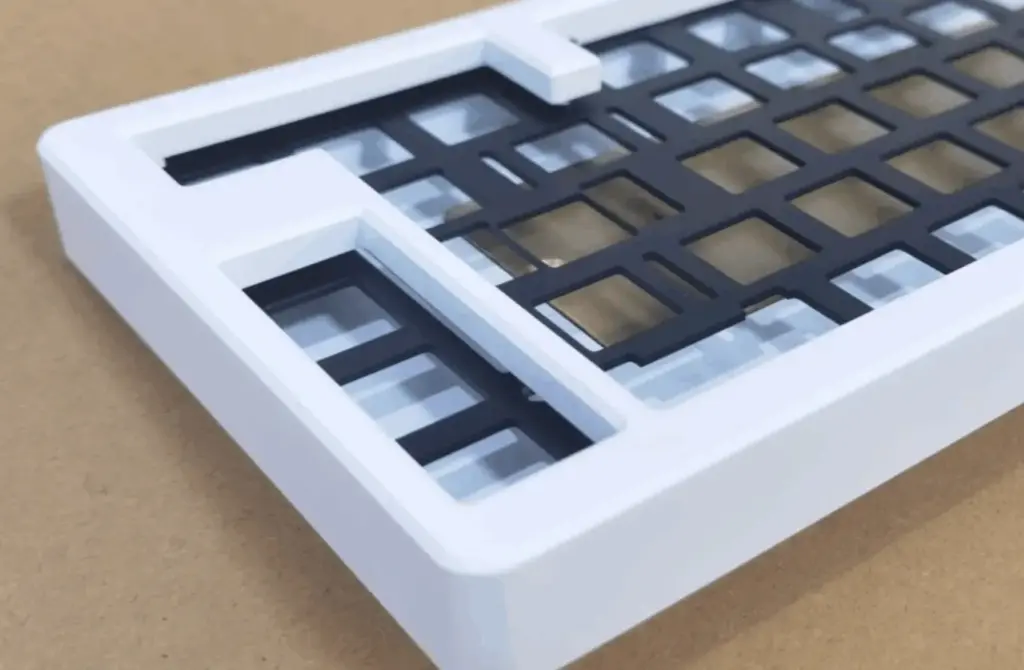

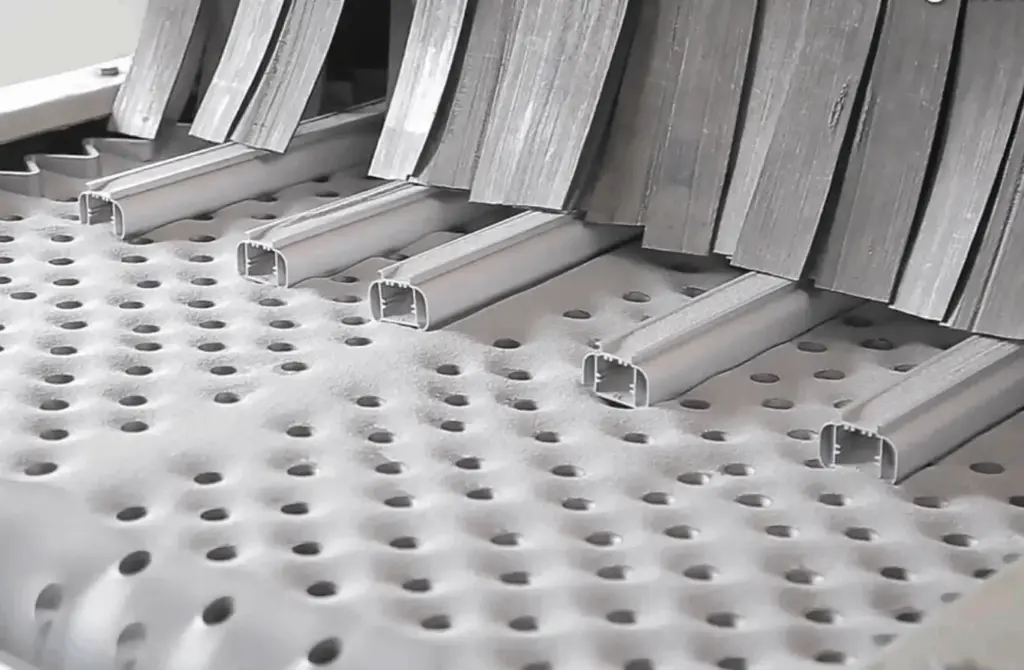

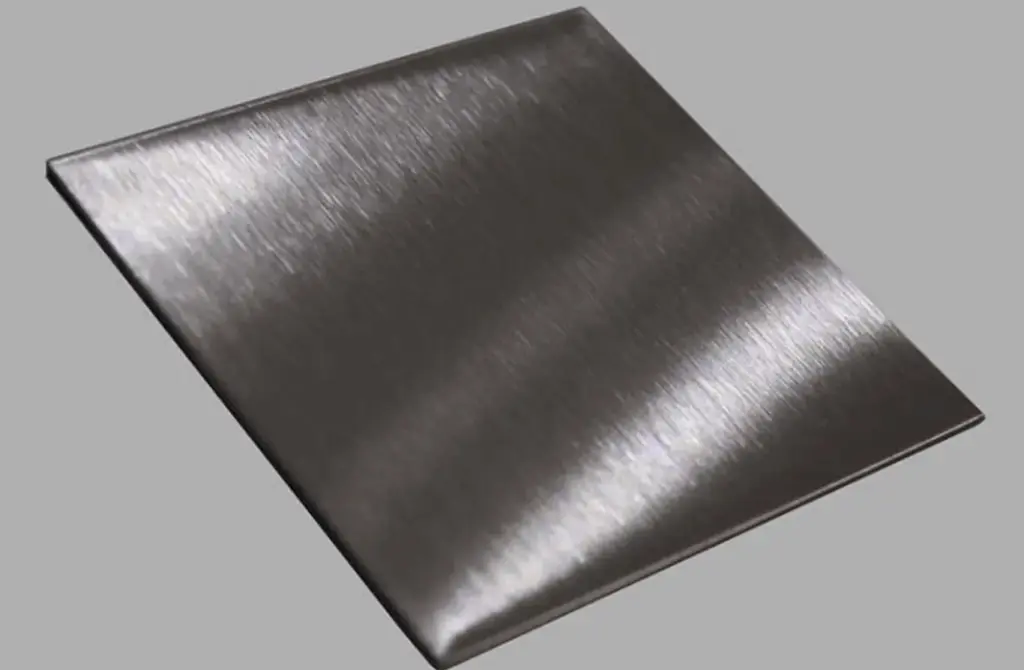

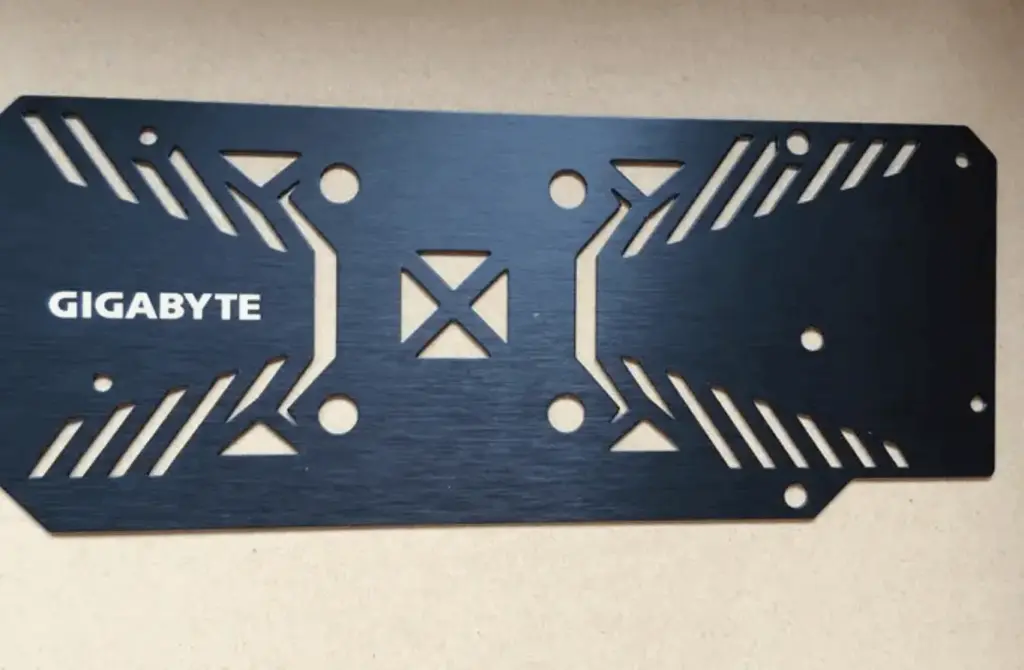

CNC Machined Titanium Parts Gallery

Titanium Grades We Machine

Titanium alloys offer superior mechanical properties and biocompatibility, making them ideal for high-end engineering applications. Below are the most commonly used grades:

| Material | Description |

|---|---|

| Grade 2 | Commercially pure titanium with excellent corrosion resistance and formability. Used in chemical, marine, and medical components. |

| Grade 5 (Ti-6Al-4V) | Aerospace-grade alloy combining high strength, corrosion resistance, and good machinability. |

| Grade 23 (Ti-6Al-4V ELI) | Medical-grade titanium with enhanced toughness and biocompatibility. Preferred for implants and surgical tools. |

Titanium Alloy Properties Overview

| Material | CNC Process | Tensile Strength | Elongation | Hardness (HRB) |

|---|---|---|---|---|

| Grade 2 | Milling | 50 ksi | 20% | 70 |

| Grade 5 (Ti-6Al-4V) | Turning | 130 ksi | 14% | 36 |

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Finishing Options for CNC Machining

From improved corrosion resistance to refined aesthetics, surface finishes are essential for CNC machined parts. We offer a variety of finishing options—such as anodizing, powder coating, polishing, and electrophoretic coating—each tailored to enhance durability, function, or appearance depending on your application needs.

Anodizing

Electrochemically forms a dense aluminum oxide layer on the surface to enhance corrosion and wear resistance. It can be dyed in various colors such as black, gold, red, and clear.

Electrophoretic Coating

Applies a uniform paint film through an electric field to improve surface corrosion resistance and visual appeal. The result is smooth, even, and protective.

Powder Coating

A dry powder is electrostatically sprayed onto the surface and then cured at high temperature, forming a durable, weather-resistant finish available in a variety of colors.

Polishing

Mechanical or chemical processes remove oxidation and micro-defects to produce a smooth, mirror-like surface—ideal for decorative and functional parts.

Sandblasting

High-speed abrasive particles are blasted onto the surface to remove oxide layers and residues, increase roughness, and enhance adhesion for subsequent coatings.

Brushing

Creates fine, directional textures using abrasive belts or brushes to achieve a matte, decorative finish with a consistent grain pattern.

Electroplating

Deposits a thin layer of metals like nickel, chrome, or copper on the aluminum surface to improve corrosion resistance, wear performance, or achieve a distinct appearance.

Laser Engraving

Uses precise laser technology to mark logos, text, or patterns on the aluminum surface—offering permanent, high-contrast, and aesthetic results.

FAQ: Titanium CNC Machining

What Titanium Grades Do You Work With?

We commonly machine Grade 2, Grade 5 (Ti-6Al-4V), and Grade 23 (Ti-6Al-4V ELI). Other grades can be considered upon request.

Is Titanium Difficult To Machine?

Yes, titanium is harder to machine than aluminum or brass. However, with specialized tools, speeds, and cooling strategies, we ensure stable results and tight tolerances.

What Are The Advantages Of Using Titanium?

Titanium offers high strength, low weight, corrosion resistance, and biocompatibility. It’s ideal for aerospace, marine, and medical-grade parts.

Can You Provide Medical-Grade Titanium Parts?

Yes. We offer precision machining for medical components using Grade 23 titanium, following strict quality standards.

Do You Offer Surface Finishing For Titanium?

We offer polishing, passivation, bead blasting, and can support anodizing or PVD coating if required.

What Is Your Typical Lead Time For Titanium Parts?

Prototypes can be delivered in 7–10 business days. Lead times for mass production vary by part complexity and order volume.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486