Best PC CNC Machining Services

MachMaster offers precision CNC machining services for polycarbonate (PC) parts, providing high impact resistance, excellent transparency, and great machinability. PC is ideal for demanding applications in electronics, automotive, and safety equipment, where durability and clarity are essential.

Material Description

Polycarbonate (PC) is a durable and transparent thermoplastic known for its impact resistance, high strength, and ease of machining. With excellent dimensional stability and optical clarity, PC is widely used for both structural and aesthetic components in industries that require transparency and durability.

Advantages of PC

- Exceptional impact resistance, even at low temperatures

- High optical clarity, ideal for transparent applications

- Good dimensional stability and low moisture absorption

- Excellent machinability, making it easy to process into complex parts

- Flame-resistant (UL 94 V-0 rating)

Wide Application of Polycarbonate

PC parts are commonly used in applications that require transparency, high strength, and resistance to impact. Common uses include:

Optical lenses, light covers, and window panels

Electrical enclosures and housings

Automotive headlamp lenses and interior components

Safety equipment such as helmets, shields, and eyewear

Medical devices and machinery covers

Polycarbonate Grades We Machine

We work with various grades of polycarbonate to meet your specific application needs:

General Purpose Polycarbonate – Standard grade for general applications where impact resistance and clarity are required.

Flame-Retardant Polycarbonate – PC with added flame-retardant properties, often used in electrical and aerospace applications.

Optical Grade Polycarbonate – Ultra-high clarity and surface smoothness, ideal for lenses, covers, and lighting components.

Manage Your Machining Needs with MachMaster

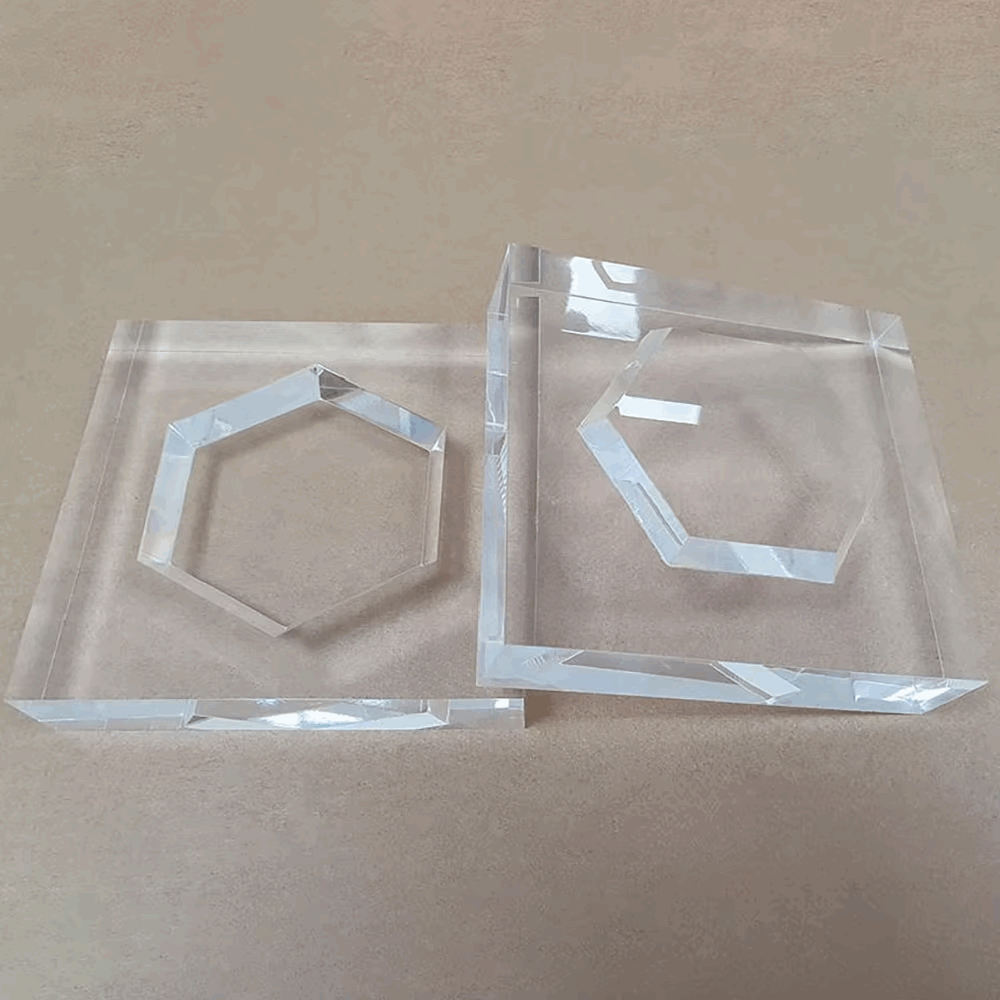

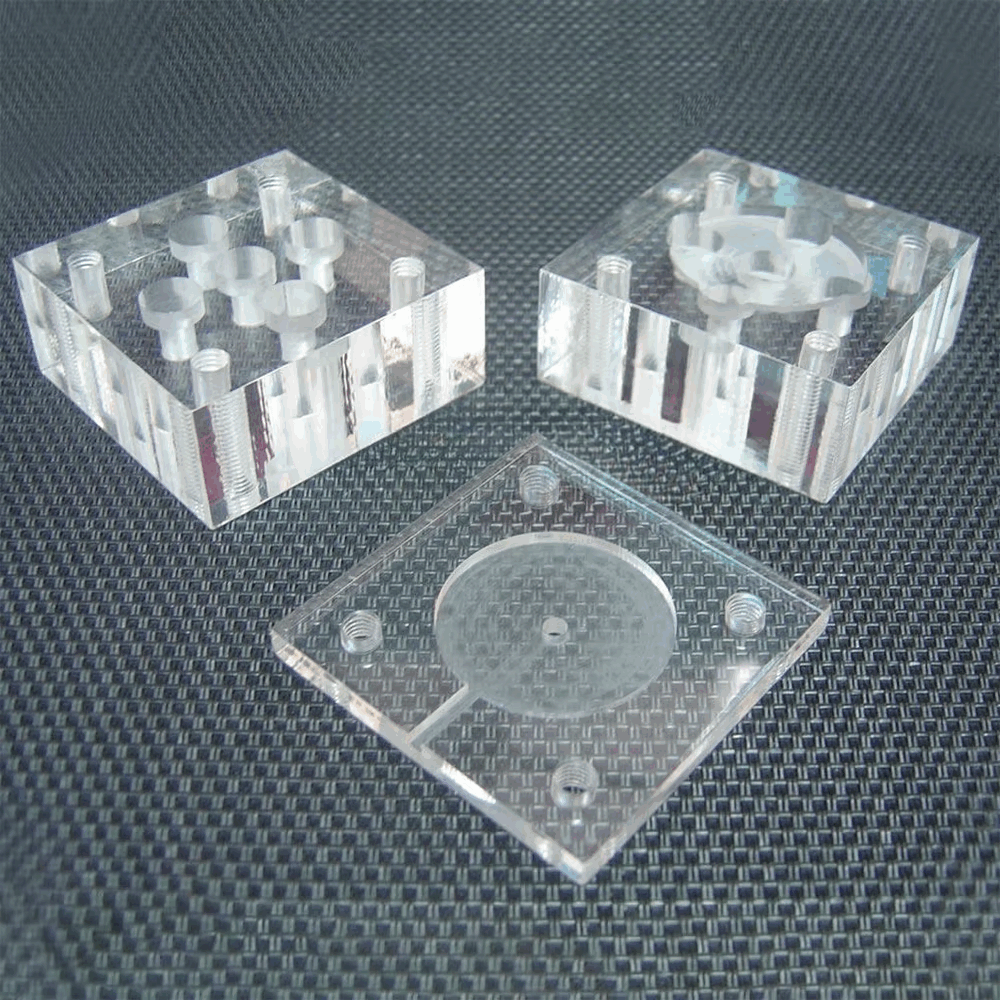

CNC Machined PC Parts Gallery

Polycarbonate Grades We Machine

Polycarbonate is a versatile, high-performance material used in a wide range of industries. Different grades of polycarbonate offer distinct advantages, depending on the application. Below are the common polycarbonate grades we machine:

| Material | Description | Heat Deflection Temperature Range |

|---|---|---|

| General Purpose Polycarbonate | Standard grade with good impact resistance and clarity, ideal for general applications like housings and enclosures. | 135°C - 145°C |

| Flame-Retardant Polycarbonate | Flame-resistant grade, suitable for electrical components and applications requiring compliance with safety standards. | 140°C - 150°C |

| Optical Grade Polycarbonate | High transparency and smooth surface finish, perfect for lenses, light covers, and optical components. | 150°C - 160°C |

Polycarbonate Properties Overview

| Material | CNC Process | Tensile Strength | Elongation | Hardness (Rockwell) |

|---|---|---|---|---|

| General Purpose Polycarbonate | Milling | 9,500 psi | 120% | R120 |

| Flame-Retardant Polycarbonate | Turning | 10,000 psi | 80% | R130 |

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

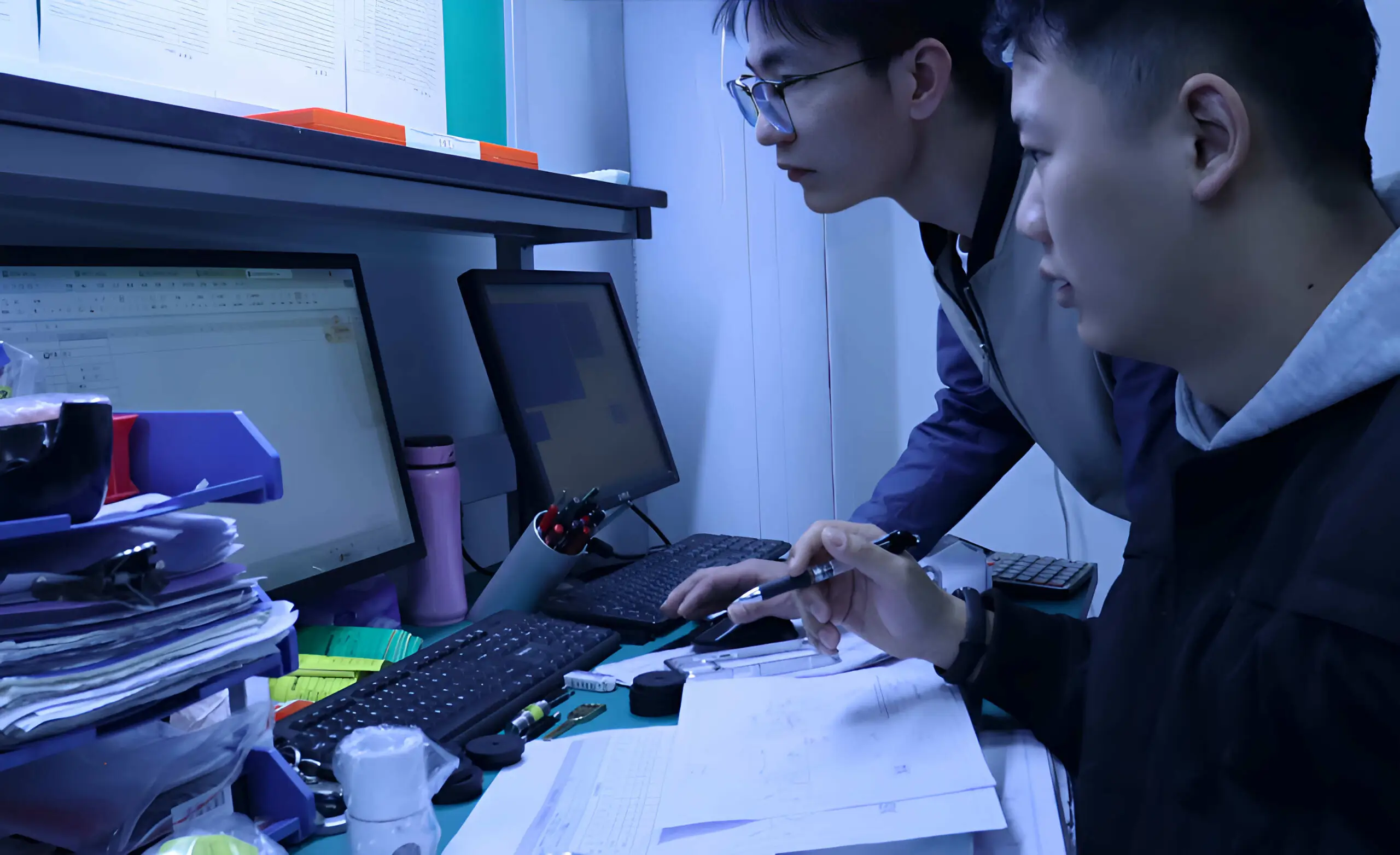

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

Engineering Team

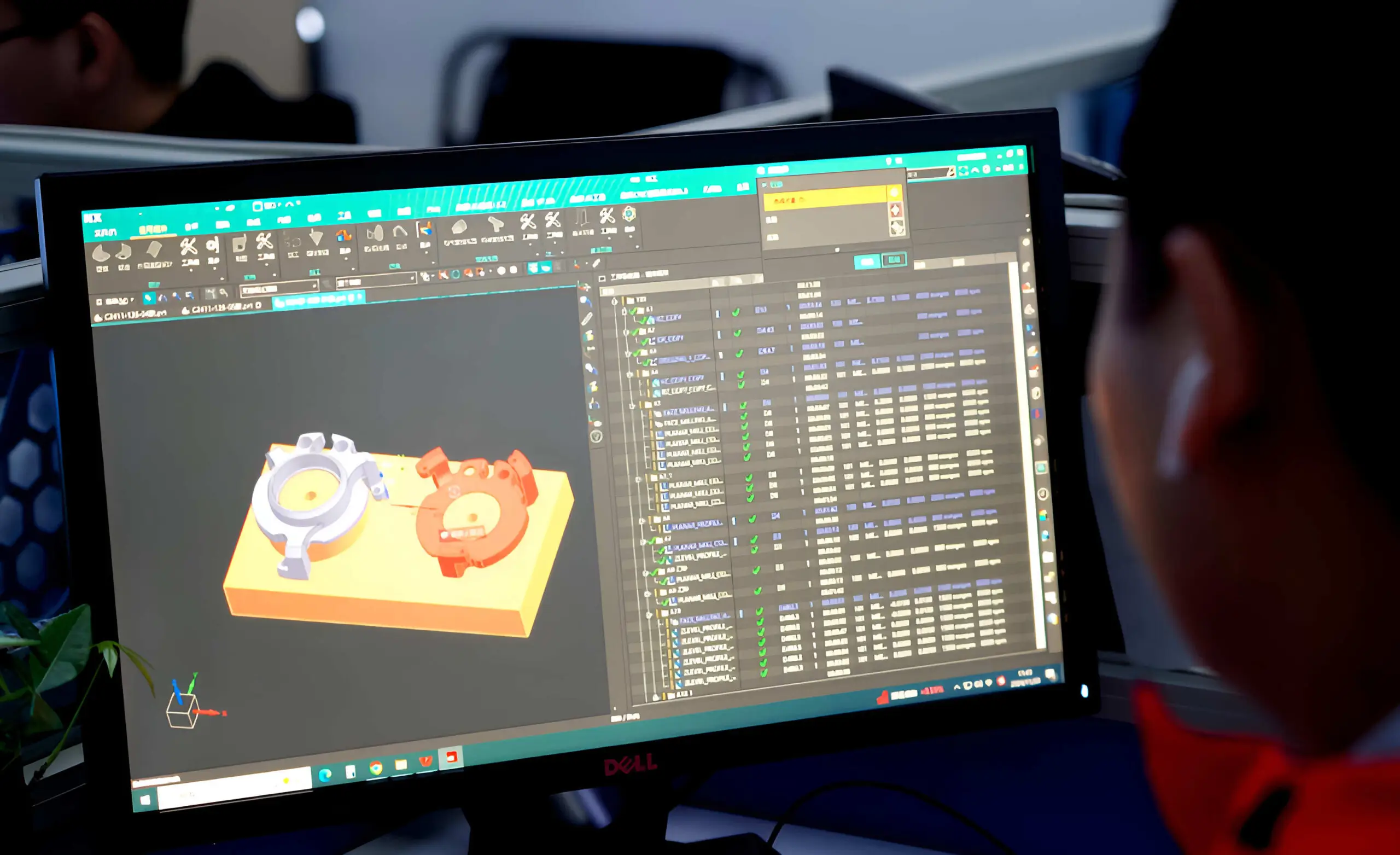

Provides DFM analysis and technical solutions from design review to production readiness.

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

FAQ – Polycarbonate CNC Machining

What Types Of Polycarbonate Do You Machine?

We work with general-purpose polycarbonate, flame-retardant polycarbonate, and optical-grade polycarbonate, based on your application needs.

Is Polycarbonate Easy To Machine?

Yes, polycarbonate is a machinable thermoplastic. It can be milled, turned, and CNC machined with excellent results, offering low wear on tooling.

Can You Provide Transparent Polycarbonate Parts?

Absolutely. We can provide high-clarity optical-grade polycarbonate parts for applications such as lenses, light covers, and displays.

What Are The Common Applications Of Polycarbonate Parts?

Polycarbonate parts are used in a wide range of industries, including automotive, electronics, medical, and safety. Common applications include lenses, enclosures, panels, and more.

Can You Handle Low-Volume Polycarbonate Orders?

Yes, we offer flexible manufacturing options for both prototypes and low-volume production runs, ensuring high-quality results and timely delivery.

How Fast Can I Receive My Polycarbonate Parts?

For prototypes, we typically deliver within 5–7 business days. Larger production runs will depend on part complexity and order quantity.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486