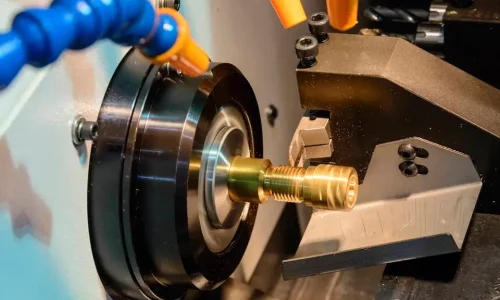

Precision Brass CNC Machining for Demanding Applications

Get durable, corro0.sion-resistant brass parts with excellent machinability. MachMaster delivers precision CNC machining services tailored to your specifications—ideal for decorative, electrical, and mechanical applications.

About Brass for CNC Machining

Brass is a copper-zinc alloy known for its excellent machinability, corrosion resistance, and attractive golden appearance. Its low friction properties and easy formability make it a preferred material for components that require both performance and aesthetics. Brass is also non-magnetic and spark-resistant, ideal for precision parts used in sensitive environments.

Advantages of Brass

- Excellent machinability for high-speed CNC machining

- Good corrosion and wear resistance

- Attractive surface finish, ideal for visible parts

- Low friction properties, suitable for fittings and gears

- Non-magnetic and spark-resistant

We work with various brass alloys including C360 brass for its superior machinability, lead-free brass for environmental compliance, and specialized alloys like 443 admiralty brass for marine applications. As a leading brass CNC machining supplier, we maintain strict quality control throughout our CNC machining brass parts production process.

Wide Application of Brass

Brass CNC parts are widely used in industries where both mechanical performance and appearance matter. Its excellent machinability and aesthetic finish make it ideal for:

Electrical connectors and terminals

Decorative hardware and plumbing fixtures

Precision gears, bushings, and bearings

Musical instruments and architectural components

Low-friction moving parts in industrial systems

Brass Alloy Classification

MachMaster supports a variety of brass grades tailored for different functional needs:

C360 (Free-Cutting Brass) – Known for outstanding machinability and chip control. Commonly used in high-volume production of precision-turned parts.

C260 (Cartridge Brass) – A ductile brass with good strength and corrosion resistance. Suitable for deep drawing, stamping, and bending applications.

C464 (Naval Brass) – Enhanced with tin for excellent corrosion resistance in marine and high-humidity environments. Ideal for outdoor and seawater-exposed parts.

Comprehensive Brass Machining Solutions

From prototype to production, we handle all aspects of brass CNC machining parts manufacturing

Manufacturing capacity

Precision brass components with tight tolerances

Custom brass parts for specialized applications

High-volume production for OEM partners

Complex geometries using multi-axis machining

Secondary operations including threading and finishing

Trusted Across Multiple Sectors

Aviation and aerospace components requiring reliability

Electronics and electrical connectors with excellent conductivity

Automotive and transportation parts demanding durability

Marine applications needing corrosion-resistant admiralty brass components

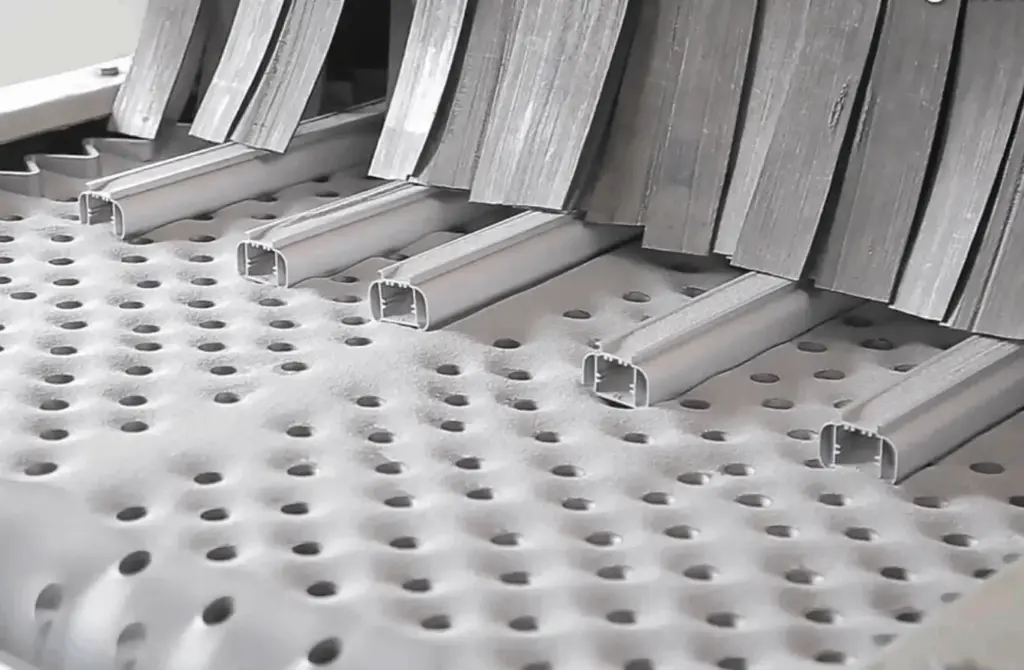

China Brass CNC Machining Factory

For over 15 years, we’ve been providing comprehensive brass CNC machining services to clients across multiple industries. Our China brass CNC machining factory combines advanced technology with skilled craftsmanship to deliver components that exceed expectations.

Manufacturing Advantages

- China brass CNC machining cost efficiency

- Large-scale production capacity

- Advanced CNC equipment park

- Experienced engineering team

- Competitive pricing structure

- Reliable supply chain management

Export & Logistics

- Worldwide shipping capabilities

- Export documentation handling

- Customs clearance support

- Just-in-time delivery options

- Inventory management services

- Global customer support

Manage Your Machining Needs with MachMaster

CNC Machined Brass Parts Gallery

As an experienced brass CNC machining manufacturer, we maintain ISO 9001 certification and implement rigorous quality control measures. Every CNC machined brass part undergoes thorough inspection to ensure it meets your specifications for dimensional accuracy, surface finish, and material properties.

Explore Our CNC Brass Materials

MachMaster offers high-performance brass alloys designed for smooth machinability, durability, and dimensional stability. Whether for decorative or functional use, our brass grades deliver reliable performance and excellent workability.

| Material | Description |

|---|---|

| Brass C360 (Free-Cutting Brass) | C360 brass is known for its exceptional machinability, making it ideal for high-speed turning and precision components. It offers solid strength, resists corrosion, and provides a smooth surface finish without requiring post-processing. Widely used in fittings, valves, and precision connectors. |

| Brass C260 (Cartridge Brass) | C260 combines good strength with superior ductility, allowing it to be drawn, stamped, or milled with ease. Its excellent cold workability and corrosion resistance make it a smart choice for industrial housings, electronic enclosures, and decorative components. |

Brass Alloy Properties Overview

| Material | CNC Process | Ultimate Tensile Strength | Elongation | Hardness (HRB) |

|---|---|---|---|---|

| Brass C260 | Milling | 62 ksi | 30% | 70 HRB |

| Brass C360 | Turning | 58 ksi | 25% | 78 HRB |

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Finishing Options for CNC Machining

From improved corrosion resistance to refined aesthetics, surface finishes are essential for CNC machined parts. We offer a variety of finishing options—such as anodizing, powder coating, polishing, and electrophoretic coating—each tailored to enhance durability, function, or appearance depending on your application needs.

Anodizing

Electrochemically forms a dense aluminum oxide layer on the surface to enhance corrosion and wear resistance. It can be dyed in various colors such as black, gold, red, and clear.

Electrophoretic Coating

Applies a uniform paint film through an electric field to improve surface corrosion resistance and visual appeal. The result is smooth, even, and protective.

Powder Coating

A dry powder is electrostatically sprayed onto the surface and then cured at high temperature, forming a durable, weather-resistant finish available in a variety of colors.

Polishing

Mechanical or chemical processes remove oxidation and micro-defects to produce a smooth, mirror-like surface—ideal for decorative and functional parts.

Sandblasting

High-speed abrasive particles are blasted onto the surface to remove oxide layers and residues, increase roughness, and enhance adhesion for subsequent coatings.

Brushing

Creates fine, directional textures using abrasive belts or brushes to achieve a matte, decorative finish with a consistent grain pattern.

Electroplating

Deposits a thin layer of metals like nickel, chrome, or copper on the aluminum surface to improve corrosion resistance, wear performance, or achieve a distinct appearance.

Laser Engraving

Uses precise laser technology to mark logos, text, or patterns on the aluminum surface—offering permanent, high-contrast, and aesthetic results.

FAQ: Brass CNC Machining

What Types Of Brass Do You Machine?

We commonly work with brass grades like C360 and C260. If you need other types, such as naval brass or European equivalents, we can evaluate them based on your project requirements.

Is Brass Easy To Machine Compared To Other Metals?

Yes. Brass, especially C360, is one of the most machinable metals, ideal for high-speed CNC turning and milling with minimal tool wear.

Do You Offer Surface Finishing For Brass Parts?

Yes. We provide polishing, sandblasting, plating (such as nickel or chrome), and custom finishes to enhance appearance and protect against corrosion.

What Industries Commonly Use CNC Brass Parts?

Brass parts are widely used in electronics, plumbing, automotive, decorative hardware, musical instruments, and precision engineering.

Can You Support Prototypes And Low-Volume Orders?

Absolutely. We offer flexible production, from single-piece prototyping to large-scale runs, all with consistent quality and tight tolerances.

How Fast Can I Get My Brass Parts?

Lead times vary by part complexity and quantity. Standard prototyping can be delivered in 5–7 working days. We also offer expedited services.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486