Inside MachMaster: Excellence in Every Part

Explore how MachMaster blends precision, technology, and craftsmanship to achieve excellence in every project.

Industrial Zone Overview

Our facility is located in a modern industrial zone spanning over 20,000 square meters, with clearly defined production lines for CNC machining, injection molding, quality control, and warehousing.

The campus is equipped with dedicated logistics access, high ceilings, and stable infrastructure to support continuous manufacturing and global shipping demands.

CNC Milling Workshop

Our CNC milling area houses 40+ milling machines, including 3-axis, 4-axis, and 5-axis machining centers.

These machines handle aluminum, stainless steel, and engineering plastics with ±0.01mm precision.

All stations are integrated with centralized coolant systems and in-line measurement to ensure dimensional accuracy throughout the batch.

CNC Turning Workshop

Our turning workshop includes 10 CNC turning machines, covering vertical lathes, horizontal lathes, and multi-function turning centers.

Each machine is equipped with automated loading/unloading systems and robotic arms to maximize productivity and repeatability.

We also operate CNC grinding, drilling, and boring units for a full-process solution from raw stock to final finish.

Injection Molding Workshop

This workshop features fully-automated plastic injection molding machines ranging from 80 to 500 tons.

We specialize in high-precision ABS, PC, and nylon parts, with hot-runner molds and real-time temperature control.

Integrated QC and post-molding trimming help maintain part quality while reducing manual handling.

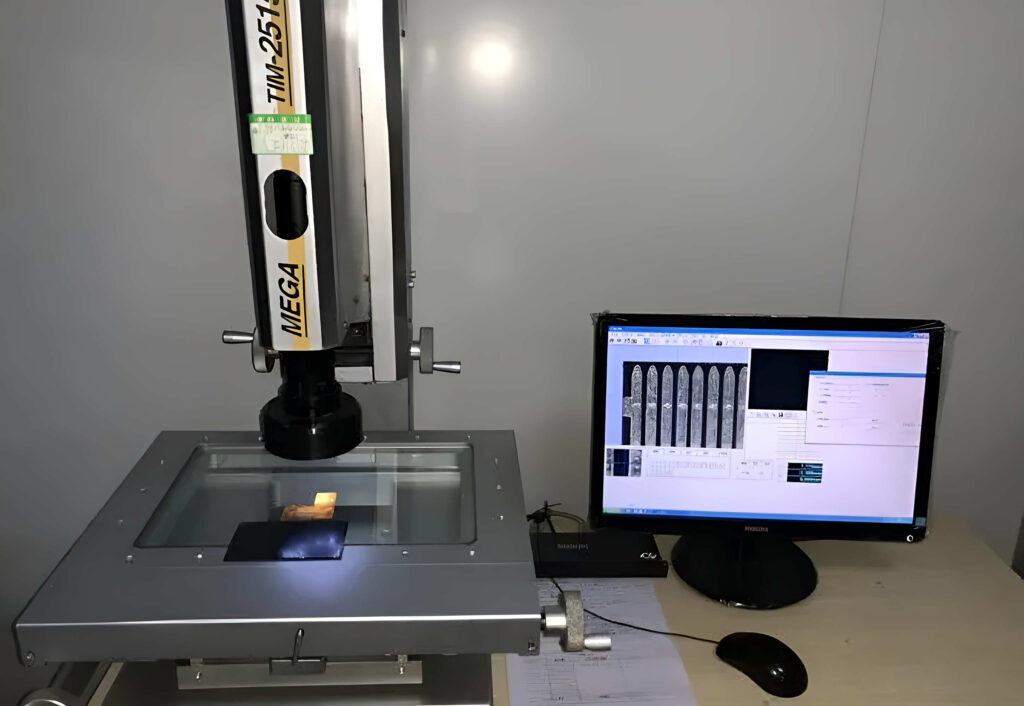

Inspection & QC Lab

Our inspection area is equipped with high-precision tools including height gauges, digital calipers, pin gauges, and optical measuring systems.

The lab ensures 100% dimensional check for first articles and batch inspection following ISO 9001 standards.

Humidity-controlled environments and traceable calibration further support long-term quality assurance.

Warehouse & Material Handling

Our warehouse supports over 100 active SKUs and includes areas for raw material intake, in-process staging, and finished goods.

All inventory is managed via barcode tracking, with FIFO flow and dedicated export packaging stations.

We maintain a 48-hour turnaround promise for most shipments, with flexible storage for both short-term and long-term projects.

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

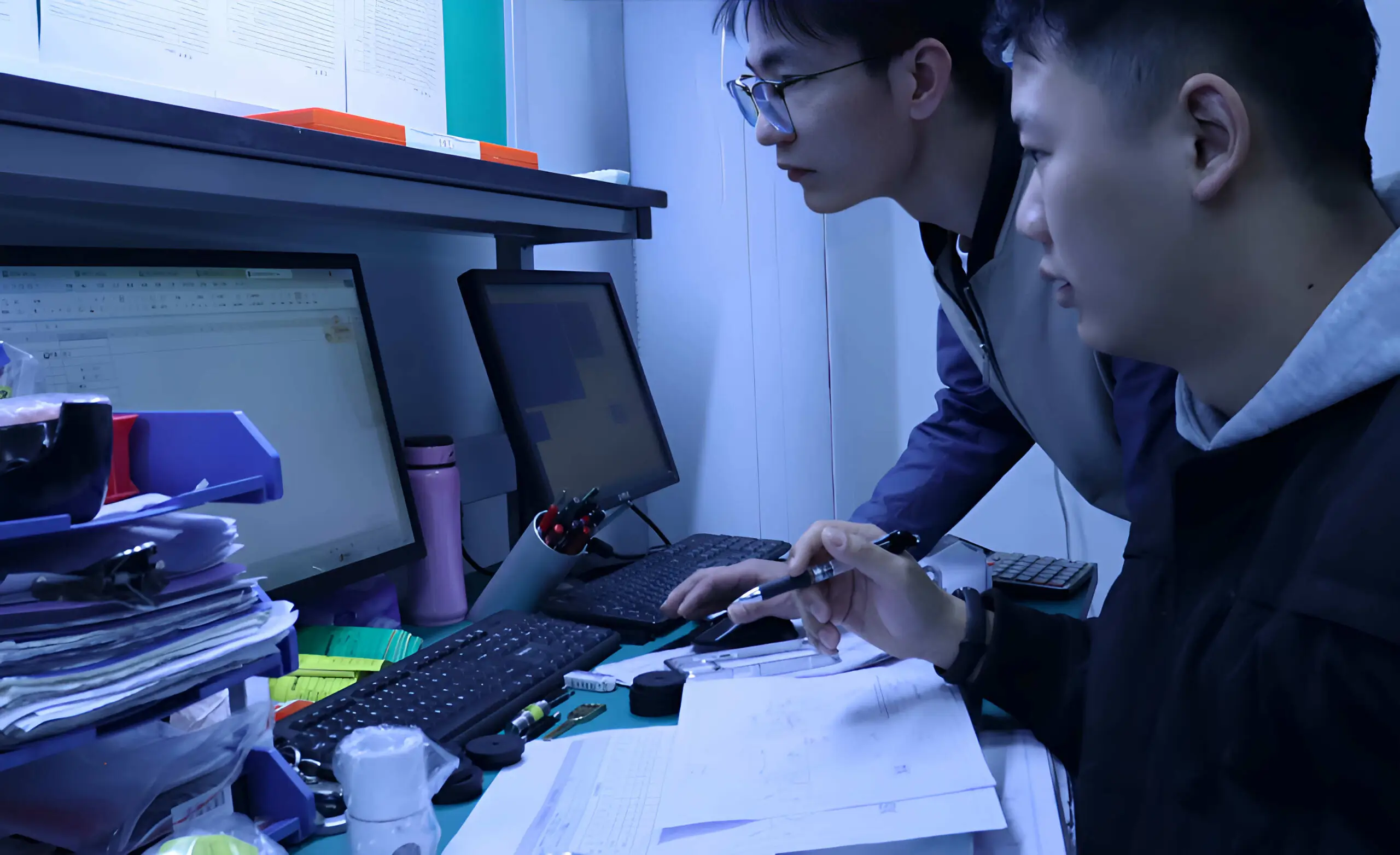

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

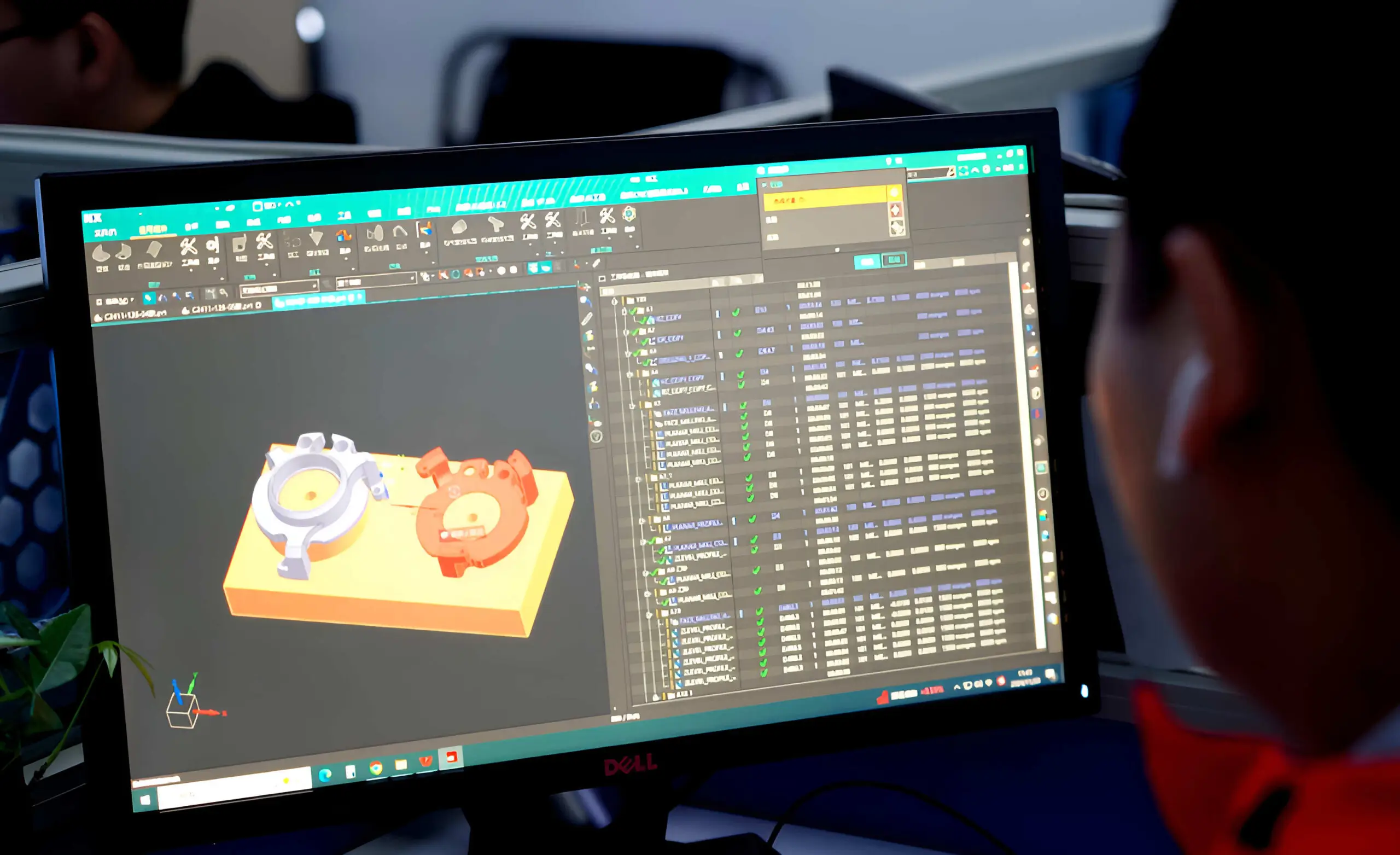

Engineering Team

Provides DFM analysis and technical solutions from design review to production readiness.

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

Supporting Equipment in Production

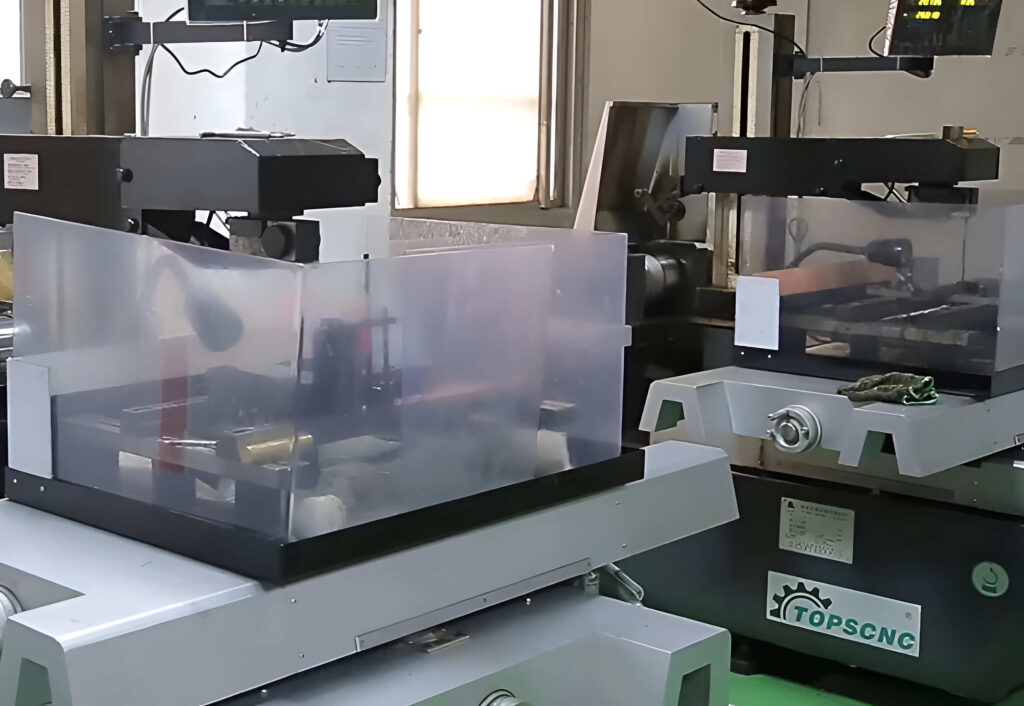

SW-EDM

2D CMM

EDM

Grinding

WEDM

Manage Your Machining Needs with MachMaster

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486