Insert Molding Services

High-Precision Insert Molding Solutions

Insert molding combines thermoplastic materials with preformed components such as metal inserts, threaded parts, or bushings. This process improves part strength, reduces assembly time, and creates a more integrated design. MachMaster’s insert molding capabilities support both prototyping and high-volume production with consistent dimensional accuracy and strong material bonds.

Manage Your Machining Needs with MachMaster

Insert Molding Capabilities

We support a variety of insert types and molding configurations to meet the needs of both functional and aesthetic parts.

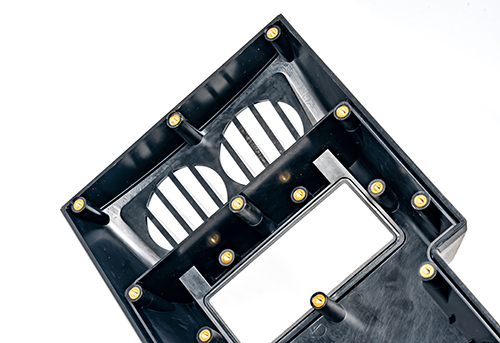

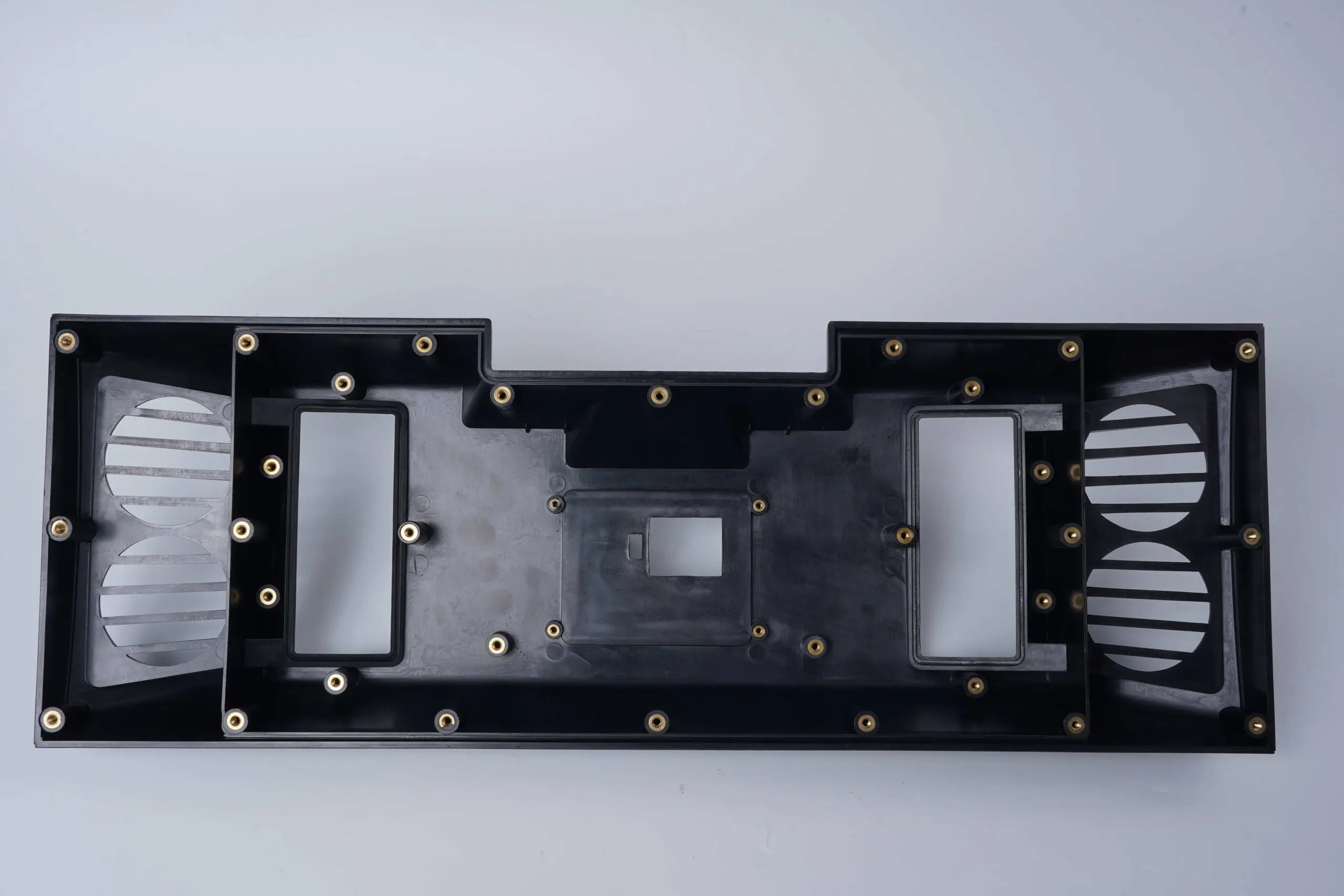

Threaded Inserts

Brass or stainless steel inserts molded into plastic parts to provide strong, reusable threads for fastening and assembly.

Metal Pins & Bushings

Metal components embedded during molding to improve wear resistance, mechanical support, or precise part alignment.

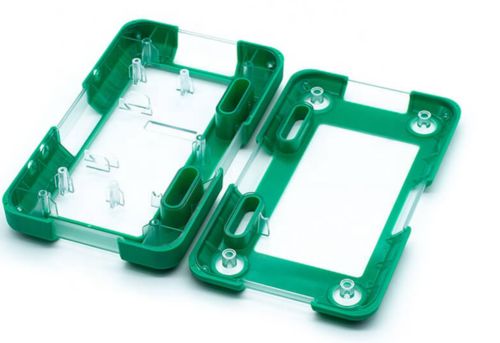

Complex Inserts

Supports molding multiple inserts in a single cycle—ideal for housings, connectors, or integrated hybrid parts.

Flexible Insert Loading

Accommodates both hand-loaded and robotic insert placement for various part geometries and production volumes.

Materials for Insert Molding

We work with a wide selection of thermoplastics and insert materials to meet performance, durability, and bonding requirements.

ABS, PC, PP, PA, POM, and other engineering plastics compatible with metal inserts and tight-tolerance molding.

Brass, stainless steel, and aluminum inserts including threads, pins, bushings, and terminals.

TPU, TPE, and soft-touch plastics for dual-material parts requiring grip, sealing, or flexible surfaces.

Materials like PEEK and PPS support demanding applications with elevated heat or chemical resistance.

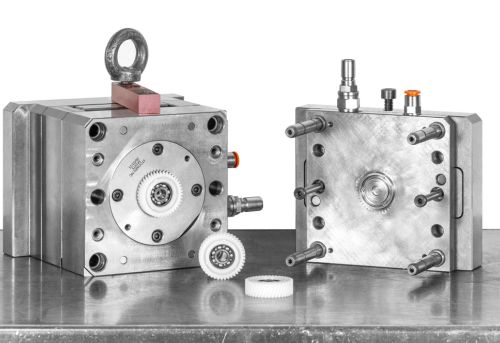

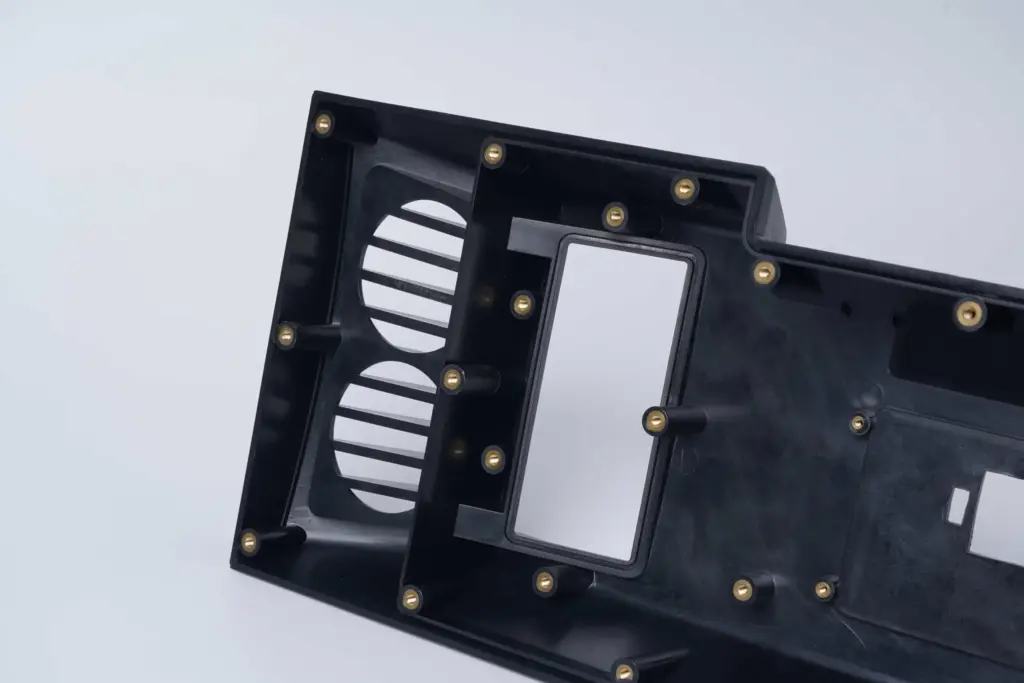

Real-World Insert Molding Samples

Explore actual insert molding parts used in automotive, electronics, and appliance projects. See how metal and plastic are combined for strength, precision, and production efficiency. Ideal for engineers and buyers evaluating insert molding capabilities.

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

FAQs About Insert Molding

What Is Insert Molding?

Insert molding is a process where metal or plastic components—such as threaded inserts or pins—are placed into a mold and then encapsulated in plastic during injection molding. This creates a single, integrated part.

What Are The Benefits Of Insert Molding?

Insert molding improves part strength, reduces secondary assembly, and allows for more compact, functional designs. It also increases reliability by reducing the number of separate components.

What Types Of Inserts Can Be Used?

Common inserts include brass or stainless steel threads, pins, bushings, and even electronic contacts. The insert must be able to withstand injection temperatures and pressures.

Is Insert Molding Suitable For Low Volumes?

Yes. Insert molding can be done for both prototypes and large production runs. Manual loading is suitable for smaller volumes, while automation supports high-throughput applications.

Explore More of Our Resources

- Insert Molding: What You Need to Know

- What Is Insert Molding?

- Insert Molding vs Overmolding: A Comparison Guide

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486