Custom Plastic Injection Molding Services

Injection molding services in China

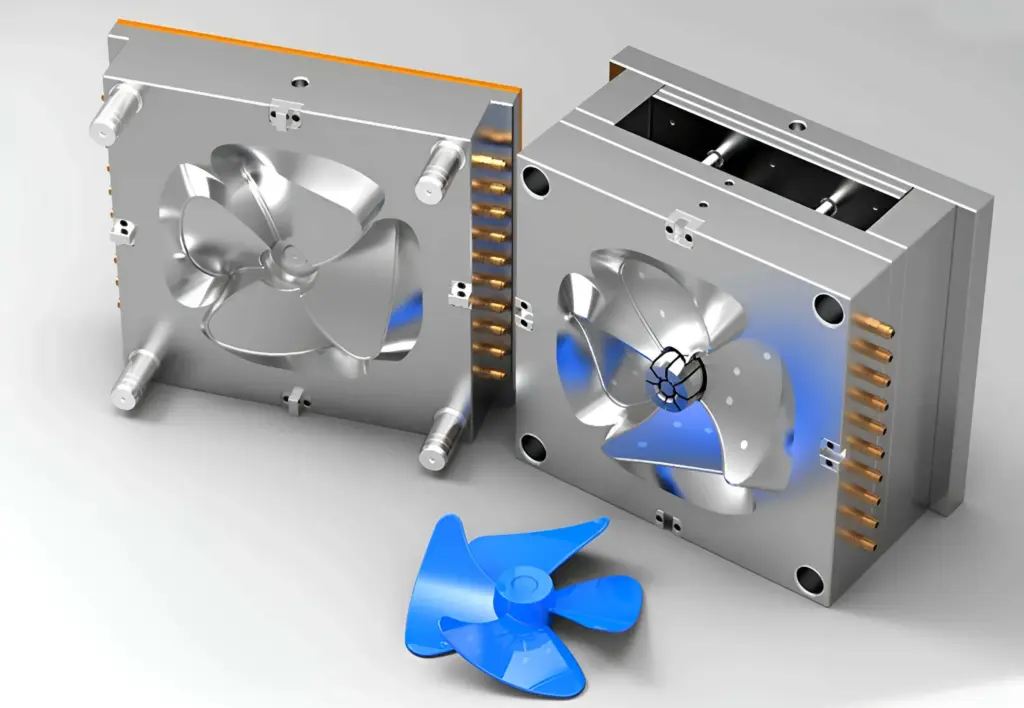

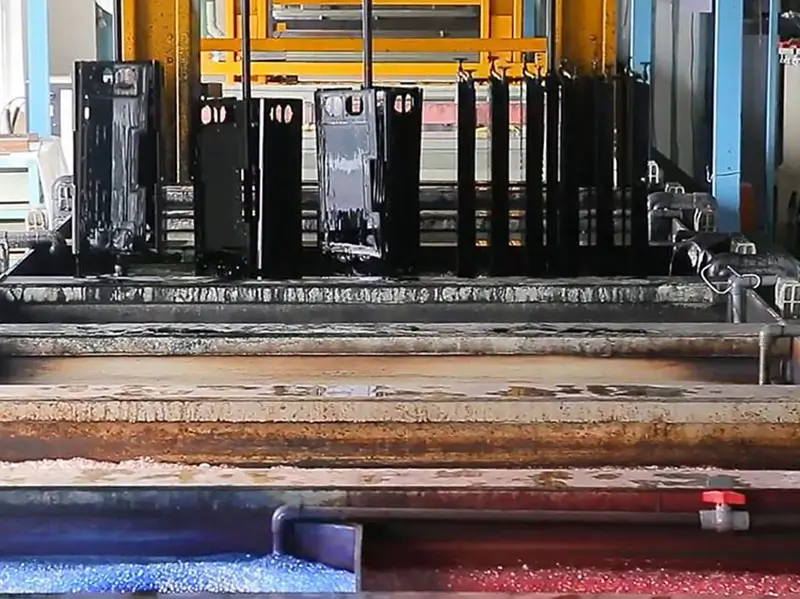

Injection Mold Tooling

Injection mold tooling is the precision-made core of the molding process. It enables consistent, high-volume production by shaping molten plastic into exact, repeatable part geometries.

Plastic Injection Molding

This process melts thermoplastic resin and injects it into a mold cavity under pressure. The plastic cools and solidifies into a finished part—ideal for producing complex shapes with speed and accuracy.

Overmolding

Overmolding bonds two materials by molding one over another. It improves part function, grip, and aesthetics while reducing assembly steps and increasing design flexibility.

Insert Molding

Insert molding encapsulates metal or other components in plastic during molding. It merges materials in a single process, enhancing part strength, alignment, and manufacturing efficiency.

Manage Your Machining Needs with MachMaster

Plastic Injection Molding Materials

We offer a wide selection of industrial-grade materials for custom injection molding, suitable for both prototypes and full-scale production runs. From standard resins to engineering plastics, you’ll find options to match your part’s performance and appearance needs. If a specific material is not available locally, we also support customer-supplied materials for special requirements.

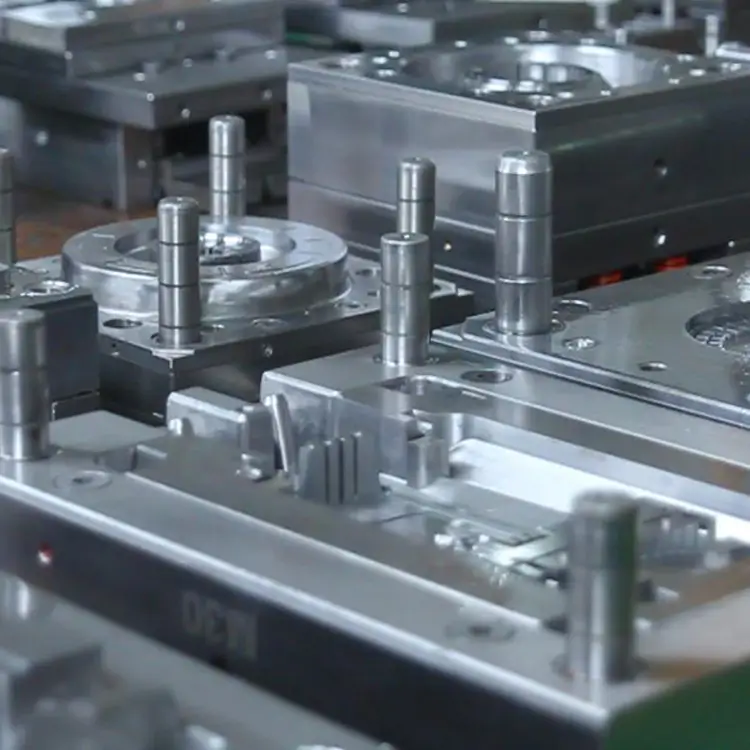

Tooling Materials for Injection Molding

Before starting low- or high-volume injection molding production, high-tolerance CNC-machined molds are required. We offer a range of durable tooling materials to meet different production needs and part specifications.

Common materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel: 420, NAK80, S136, 316L, 316, 301, 303, 304

Injection Molding Materials We Support

We offer a wide range of injection molding materials to match your part’s functional and performance requirements—whether you need high impact strength, thermal stability, rigidity, or chemical resistance.

Commonly used plastics include:

General-purpose plastics:

ABS, PP, PS, HDPE, LDPE, PMMA

Engineering plastics:

PC, POM, PA (Nylon), PET, PU

High-performance materials:

PEEK, PPA, PTFE (Teflon)

Thermoset Materials for Specialized Applications

Thermoset plastics are used in injection molding when high heat resistance, chemical stability, or structural rigidity is required. These materials form permanent molecular bonds during curing, making them ideal for high-performance and electrical applications.

Available options include:

Liquid Silicone Rubber (LSR) – Flexible, biocompatible, and ideal for medical and sealing parts

Epoxy – High strength and excellent chemical resistance

Polyurethane – Durable with good impact and abrasion resistance

Phenolic – Excellent dimensional stability and heat resistance, widely used in electrical components

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Injection Mold Surface Finishes

We provide a range of SPI finishes and VDI textures tailored for plastic injection molds. Please indicate your preferred surface finish when submitting your quote to ensure accurate production.

| SPI Finish Standards | Surface Roughness RA (mm) | Finishing Method | Texture | Steels Recommended |

|---|---|---|---|---|

| A1 | 0.012 to 0.025 | 6000 Grit Diamond | Super High Glossy Finish | S136 (54 HRC) or 8407(52 HRC) |

| A2 | 0.012 to 0.025 | 3000 Grit Diamond | S136 (54 HRC) or 8407(52 HRC) | Super High Glossy Finish |

| A3 | 0.05 to 0.10 | 1200 Grit Diamond | Normal Glossy Finish | S136 (300 HB) or 718 H |

| B1 | 0.05 to 0.10 | 600 Grit Paper | Fine Semi-glossy Finish | 718 H |

| B2 | 0.10 to 0.15 | 400 Grit Paper | Medium Semi-glossy finish | 718 H |

| B3 | 0.28 to 0.32 | 400 Grit Paper | Normal Semi-glossy finish | 718 H |

| C1 | 0.35 to 0.40 | 600 Grit Stone | Fine Matte Finish | 718 H |

| C2 | 0.45 to 0.55 | 400 Grit Stone | Medium Matte Finish | 718 H |

| C3 | 0.63 to 0.70 | 320 Grit Stone | Normal Matte Finish | 718 H |

| D1 | 0.80 to 1.00 | Dry Blast Glass Bead | Satin Textured Finish | 718 H |

| D2 | 1.00 to 2.80 | Dry Blast | Dull Textured finish | 718 H |

| D3 | 3.20 to 18.0 | Dry Blast | Rough Textured Finish | 718 H |

Real-World Uses of Injection Molding

Injection molding is used to produce high-precision parts across industries such as electronics, automotive, medical, and home appliances. It supports plastics, rubber, and elastomers—enabling complex geometries, tight tolerances, and consistent performance.

Why Our Injection Molding Stands Out

Our injection molding service combines precision tooling, flexible material options, and consistent quality—making it ideal for both prototyping and large-scale production.

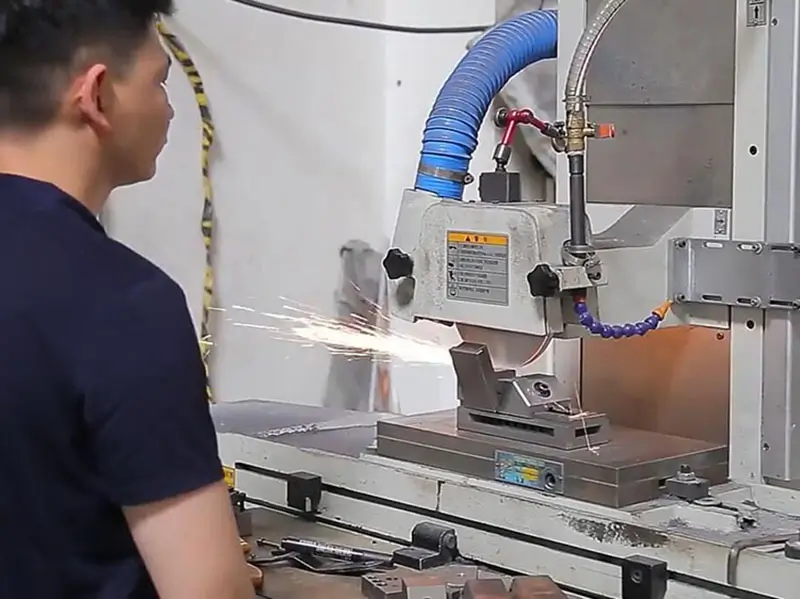

Precision Mold Manufacturing

We use CAD/CAM/CAE technologies and high-quality mold steel to produce durable, high-precision molds. This ensures dimensional accuracy, long mold life, and reduced defect rates in production.

Diverse Material Capabilities

We support a wide range of thermoplastics including ABS, PC, PA, POM, PP, TPU, and more. Our team recommends the most suitable materials based on your part’s functionality and performance needs.

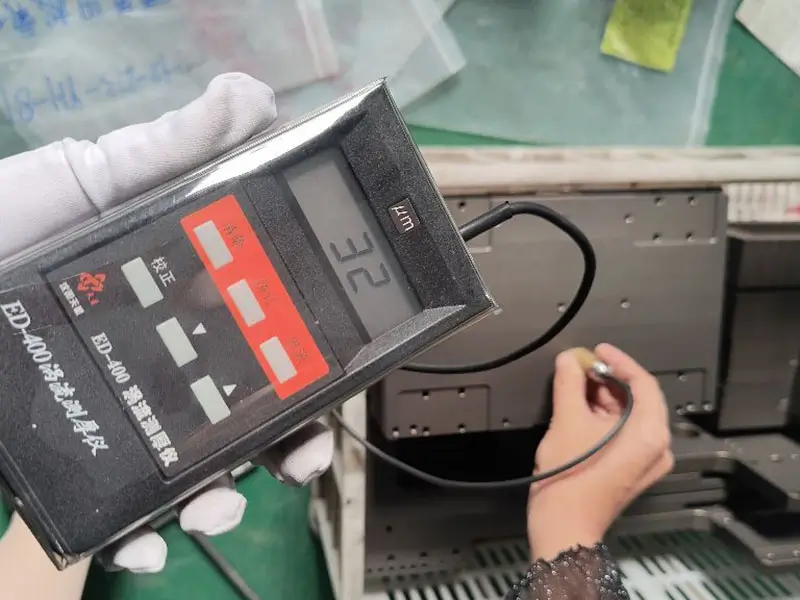

Strict Quality Control

Our ISO 9001-certified system covers every step—from raw material sourcing to molding and inspection—ensuring stable performance, surface quality, and dimensional accuracy.

Fast Response & On-Time Delivery

We handle urgent and short-lead-time orders with lean production management and backup resources, ensuring timely delivery even under unexpected demands.

Need-to-Know: Injection Molding

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing process in which molten thermoplastic is injected into a mold cavity under high pressure, then cooled and solidified into the desired shape. It is widely used for producing high-precision parts in industries such as electronics, automotive, consumer goods, and medical devices.

What Are the Advantages of Injection Molding?

Injection molding enables fast, automated production with high dimensional accuracy and repeatability. It supports complex part geometries, minimizes material waste, and works with a wide range of plastics. It’s ideal for medium to high-volume production with excellent cost efficiency and environmental recyclability.

What Are the Typical Applications of Injection Molding?

Injection molding is used in a wide range of industries:

– Automotive: dashboard panels, interior trims

– Consumer Electronics: device housings, buttons

– Medical Devices: syringes, enclosures

– Home Appliances: parts for washing machines, fans, and TVs

– Packaging & Consumer Goods: containers, toys, kitchenware

– Aerospace: seats, ducts, lightweight interior parts

What Are the 6 Main Stages of the Injection Molding Process?

Preparation: Machine and material setup

Melting: Plasticized into uniform melt

Injection: High-pressure filling of mold

Cooling: Curing inside the mold

Demolding: Part ejected from the mold

Post-processing: Trimming, cleaning, inspection, and packaging

What Are the 4 Basic Stages of an Injection Molding Cycle?

The four core steps include:

Clamping

Injection

Cooling

Ejection

Each cycle can last from a few seconds to a couple of minutes, depending on part size and complexity.

How Long Does Injection Molding Take?

Once the mold is built, injection molding is extremely fast. Cycle times can be as short as 10 seconds, making it ideal for medium and high-volume production of 10,000 to 100,000+ parts.

How Is the Cost of Injection Molding Calculated?

Pricing is based on material cost, tooling, machining time, finishing, and packaging, with a profit margin added. Part complexity, material type, tolerances, and order volume also influence the total cost.

How Much Does Injection Molding Cost in China?

In China, basic injection molding costs range from $5–$10/hour for simple plastic parts, and $10–$30/hour for high-precision or multi-axis machining. This is significantly more cost-effective compared to rates in Europe or the U.S.

What Are the Typical Tolerances for Injection Molded Parts?

At MachMaster, we follow ISO 20457 (previously ISO 2068-c) standards for injection molding tolerances. Depending on material and geometry, we can also meet tighter custom tolerance requirements.

Explore More of Our Resources

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486