Die Casting Services

China Die Casting Manufacturer You Can Trust

MachMaster specializes in high-precision aluminum and zinc alloy die casting services, delivering complex and durable components for industries including automotive, electronics, lighting, and aerospace. With over 20 years of expertise, we provide end-to-end die casting solutions—from mold design and precision casting to CNC post-machining and surface finishing.

Utilizing advanced die casting machines and automated production lines, we ensure excellent dimensional stability, tight tolerances, and consistent product quality at scale. Whether for high-volume production or custom prototype orders, our engineering team tailors every process to your specifications.

Backed by ISO 9001:2015 certification and rigorous quality control, MachMaster guarantees reliable delivery, competitive pricing, and superior performance on every die cast part.

Manage Your Machining Needs with MachMaster

Alloys Used in Die Casting Production

Die casting relies on a range of metal alloys—each chosen for its unique balance of strength, weight, corrosion resistance, and cost-efficiency. Selecting the right alloy ensures optimal performance and value for your custom parts.

Aluminum 413

Offers good machinability and moderate strength. Commonly used for aluminum die casting parts that require precision machining after casting.

Aluminum 6061

Highly corrosion-resistant and weldable, making it ideal for automotive and aerospace die cast components.

Aluminum 7075

A high-strength aluminum alloy with excellent fatigue resistance—perfect for aerospace, defense, and high-stress structural applications.

Zinc 3

A high-strength die casting alloy with excellent ductility and impact resistance. Commonly used for automotive components, electrical housings, and hardware parts.

Zinc 5

Delivers a well-balanced combination of strength, ductility, and castability. Ideal for general-purpose zinc die casting across various industries.

Zinc 7

Known for its high mechanical strength and superior corrosion resistance. Often selected for precision parts requiring durability and performance.

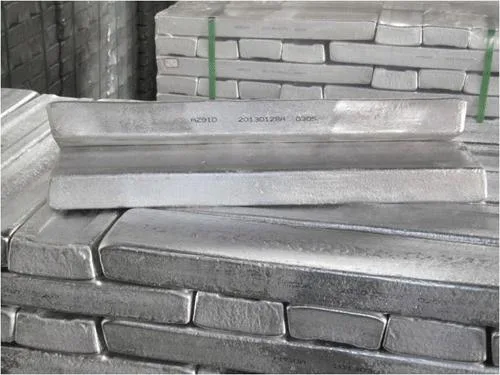

Magnesium AZ91D

Offers an excellent balance of strength, ductility, and corrosion resistance. Commonly used in automotive components, power tools, and lightweight structural parts.

Magnesium AM60B

A high-strength alloy with superior castability and machinability. Widely applied in automotive and aerospace industries for parts requiring weight reduction and mechanical performance.

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

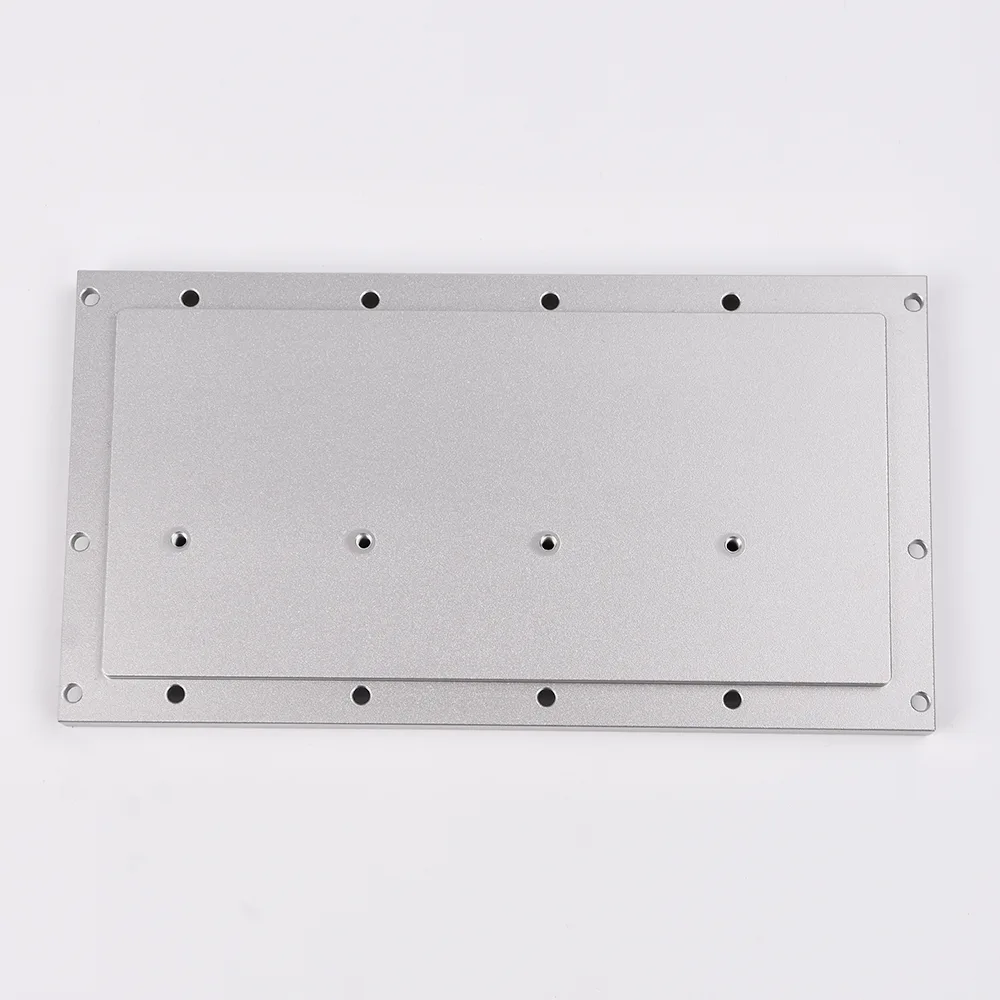

Real-World Die Casting Samples

Explore real die-cast parts we’ve manufactured for aerospace, medical, electronics, and other high-performance applications.

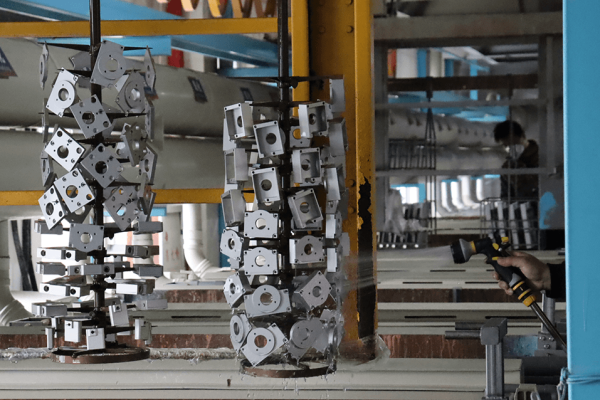

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

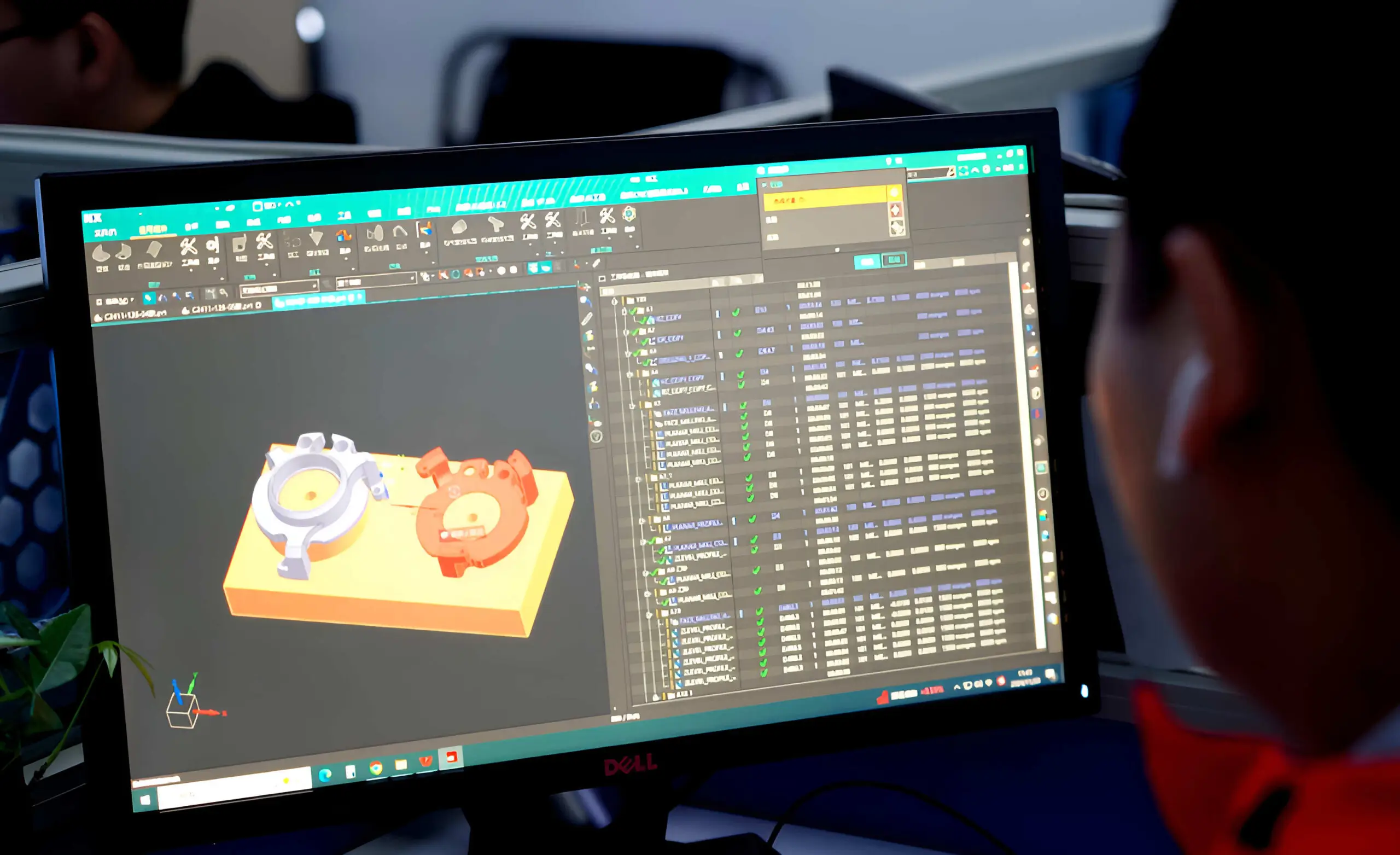

Engineering Team

Provides DFM analysis and technical solutions from design review to production readiness.

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

Understanding Metal Casting & Die Casting

What Is Die Casting?

Die casting is a manufacturing process that uses high pressure to inject molten metal into a precisely machined mold. The metal cools and solidifies quickly to form parts with tight tolerances and smooth surface finishes. It’s ideal for producing large volumes of identical components, such as automotive and electronic parts.

What Is the Die Casting Process?

The die casting process typically involves:

Melting the metal in a furnace

Transferring the molten metal into the casting machine

Injecting it into a mold under high pressure

Cooling and solidifying the metal

Opening the mold and ejecting the finished part

This process offers high dimensional accuracy, speed, and efficiency.

What Is Metal Casting?

Metal casting is a broad manufacturing technique where molten metal is poured or injected into a mold to create parts. Die casting is one type, known for its precision and speed.

What Are the Main Types of Metal Casting?

The three main types are:

Sand Casting – flexible, low-cost, suitable for small batches

Investment Casting – high detail and accuracy, ideal for complex parts

Die Casting – best for high-volume production with consistent quality

What Are the Advantages of Die Casting?

Excellent dimensional accuracy

Smooth surface finish

High production speed

Good material utilization

Suitable for mass production of metal parts

How Is the Cost of Metal Casting Calculated?

Costs are based on material type, mold complexity, labor, energy use, and production volume. Die casting is cost-effective for high-volume projects, despite higher upfront tooling costs.

What Should Be Considered When Choosing a Casting Method?

Consider your part’s complexity, production volume, required tolerances, and budget.

Use investment casting for small-batch, high-precision parts

Choose die casting for high-volume production with faster cycle times and consistent output

What Are the Precautions for Metal Casting?

It’s essential to control metal temperature, pouring speed, and mold conditions. Proper safety procedures must be followed to avoid burns, defects, and operational risks.

Explore More of Our Resources

Casting Fundamentals:

Die Casting (Aluminum & Zinc):

- What Is Aluminum Die Casting?

- Top 9 Aluminum Die Casting Manufacturers in China

- What Is Die Cast Zinc?

- Top 7 Zinc Die Casting Manufacturers in China

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486