Surface Roughness: Everything You Need to Know

The first time I handled surface roughness specs on a drawing, I googled “Ra” in a panic. I wasn’t alone. Our supplier had done the

Explore Our Perspectives on Precision, Innovation, and Manufacturing.

The first time I handled surface roughness specs on a drawing, I googled “Ra” in a panic. I wasn’t alone. Our supplier had done the

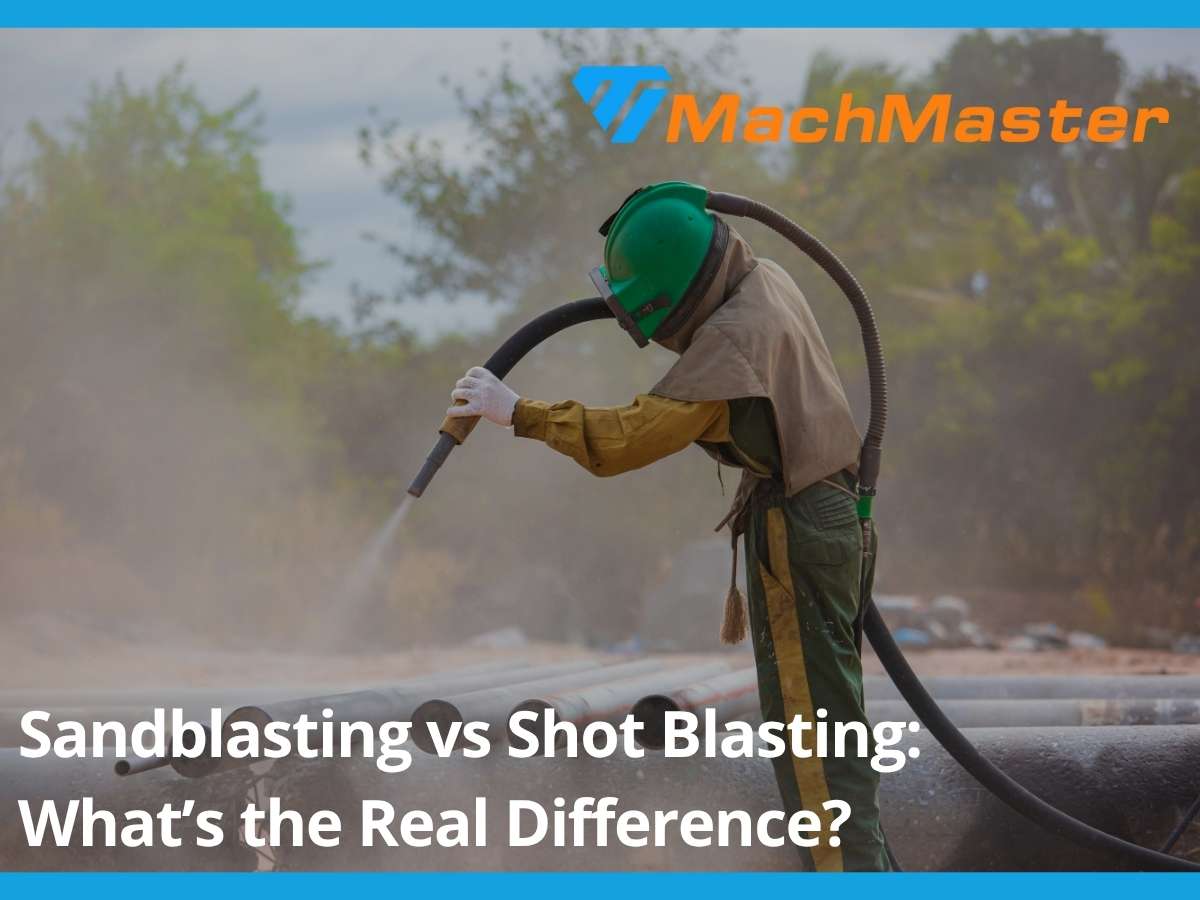

I remember the first time I saw a metal part go from rusty and rough to smooth and clean in minutes. But then someone asked,

I once took on a small rust-removal job using crushed glass. Thought it would be perfect. It wasn’t. The glass cut too deep. Left pits

Most people don’t notice surface finishing, until it goes wrong. Years ago, I managed a run of aluminum enclosures for an audio client. The machining

Black oxide makes metal look sharp. But good looks don’t always mean good performance. I learned that early in my work with engineered tools. We

I still remember the moment the parts arrived. I asked for a matte finish, something soft and clean. But when I opened the box, the

Years ago, I watched a shipment of beautifully machined parts fail inspection—only because the plating didn’t meet spec. It costs us time, money, and trust.

You know that feeling when everything looks right on your screen, but when the parts arrive, something’s just, wrong? The color’s off. The shine feels

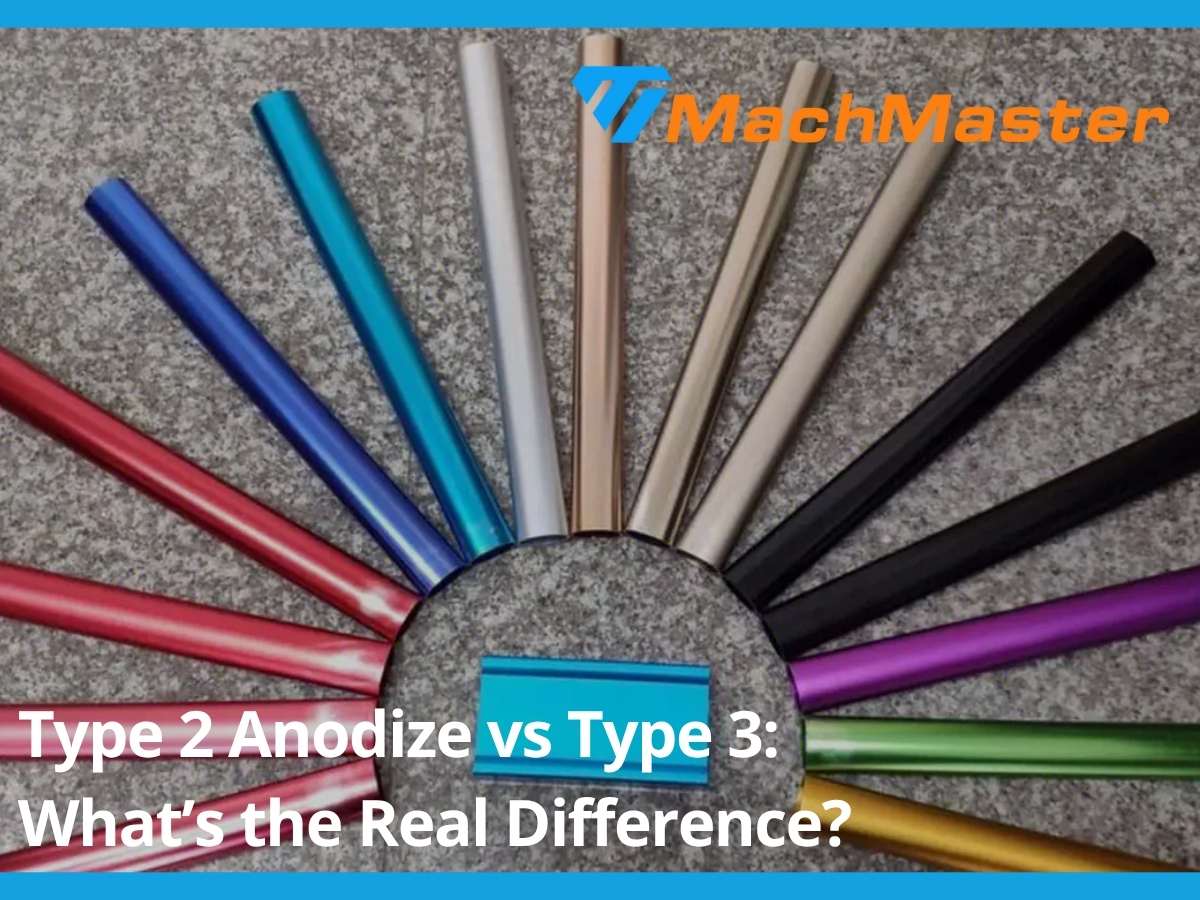

I used to think Type 2 and Type 3 anodizing were just about how the surface looked. Type 2 meant color. Type 3 meant gray.

Service

About MachMaster

2026. All Rights Reserved.

WhatsApp us